OpenMMS Hardware¶

OpenMMS Open-Source Hardware License

This documentation describes Open Hardware and is licensed under the CERN-OHL-S v2 license.

View the OpenMMS Open-Source Licenses for more details.

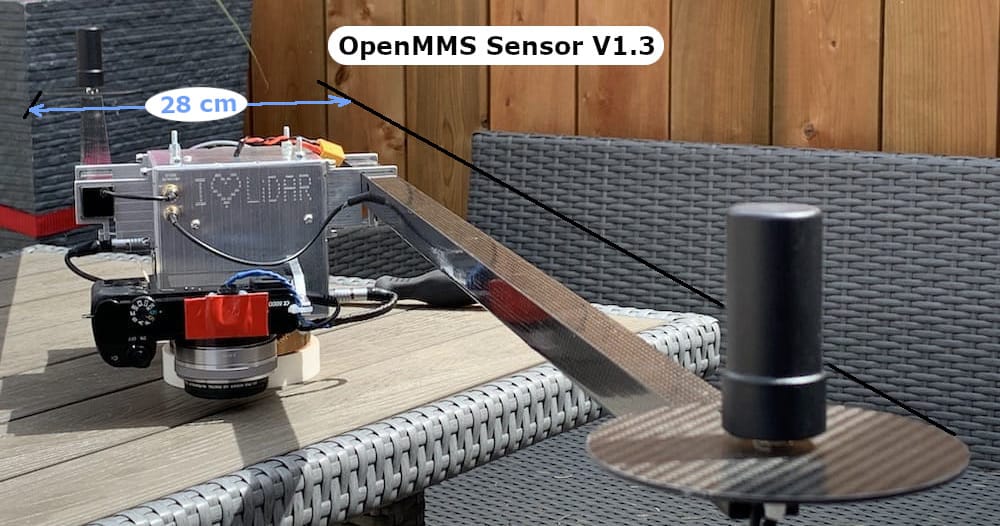

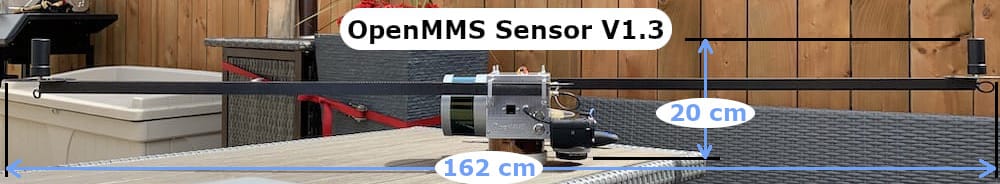

CURRENT SENSOR VERSION: 1.3

1. Project Goals¶

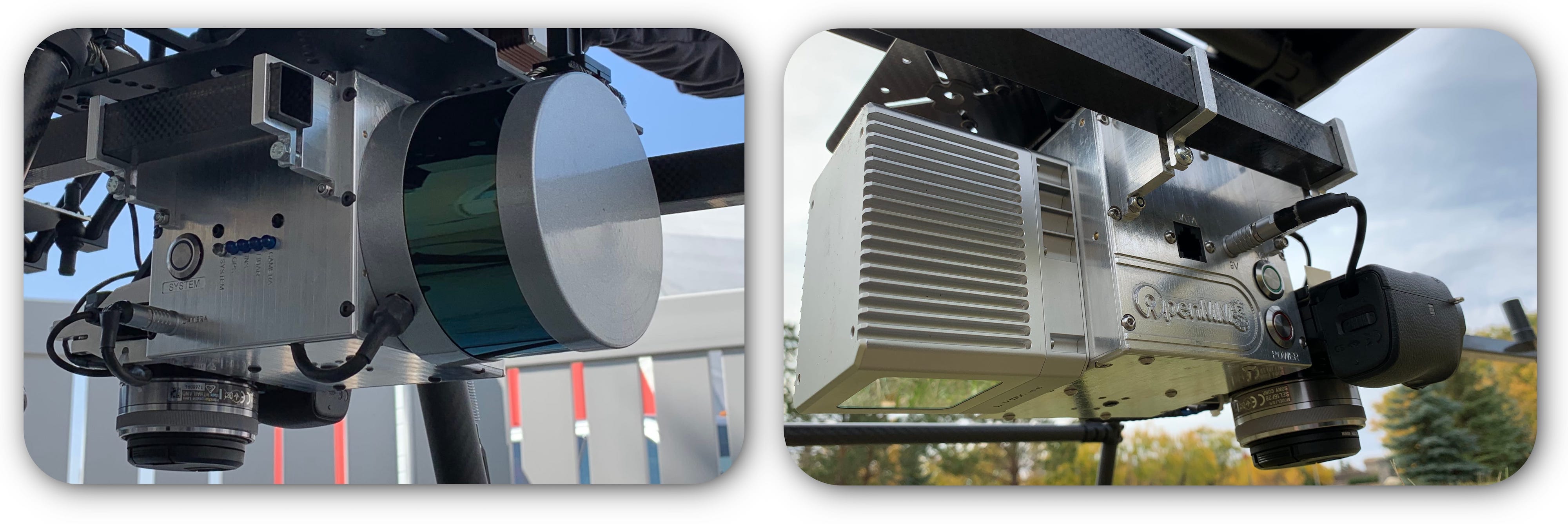

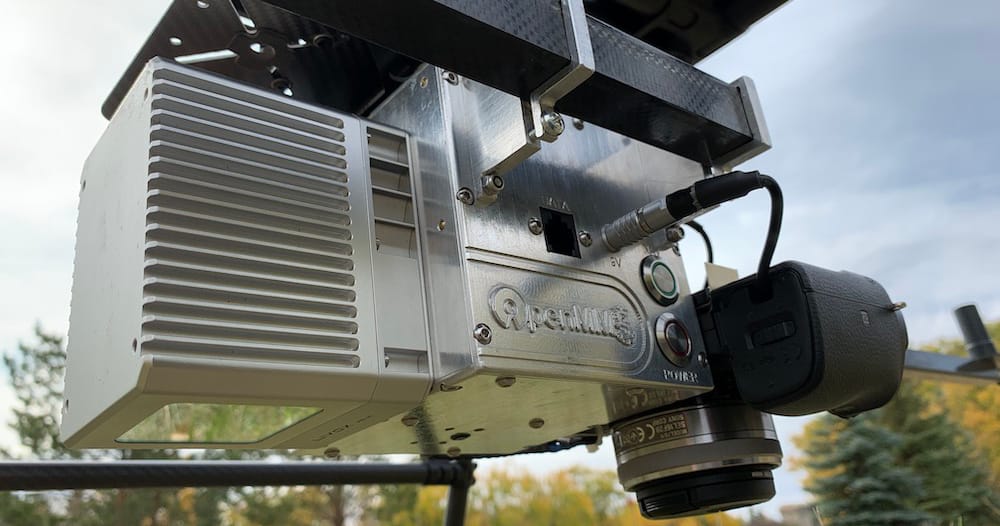

For the OpenMMS Version 1.3 sensor, the primary development goal was to start from a clean slate and completely redesign the sensor. The OpenMMS Version 1.3 sensor project officially began on May the 4th (be with you), 2020. The major goals include:

1. Install and integrate the following components into the system.

2. Design a new aluminum case and new printed circuit boards (PCBs) for:

Minimizing the electrical interference experienced by the onboard IMU sensor on the APX-18 board.

Installing the APX-18 board, so the IMU frame was in a traditional orientation with respect to the vehicle body frame.

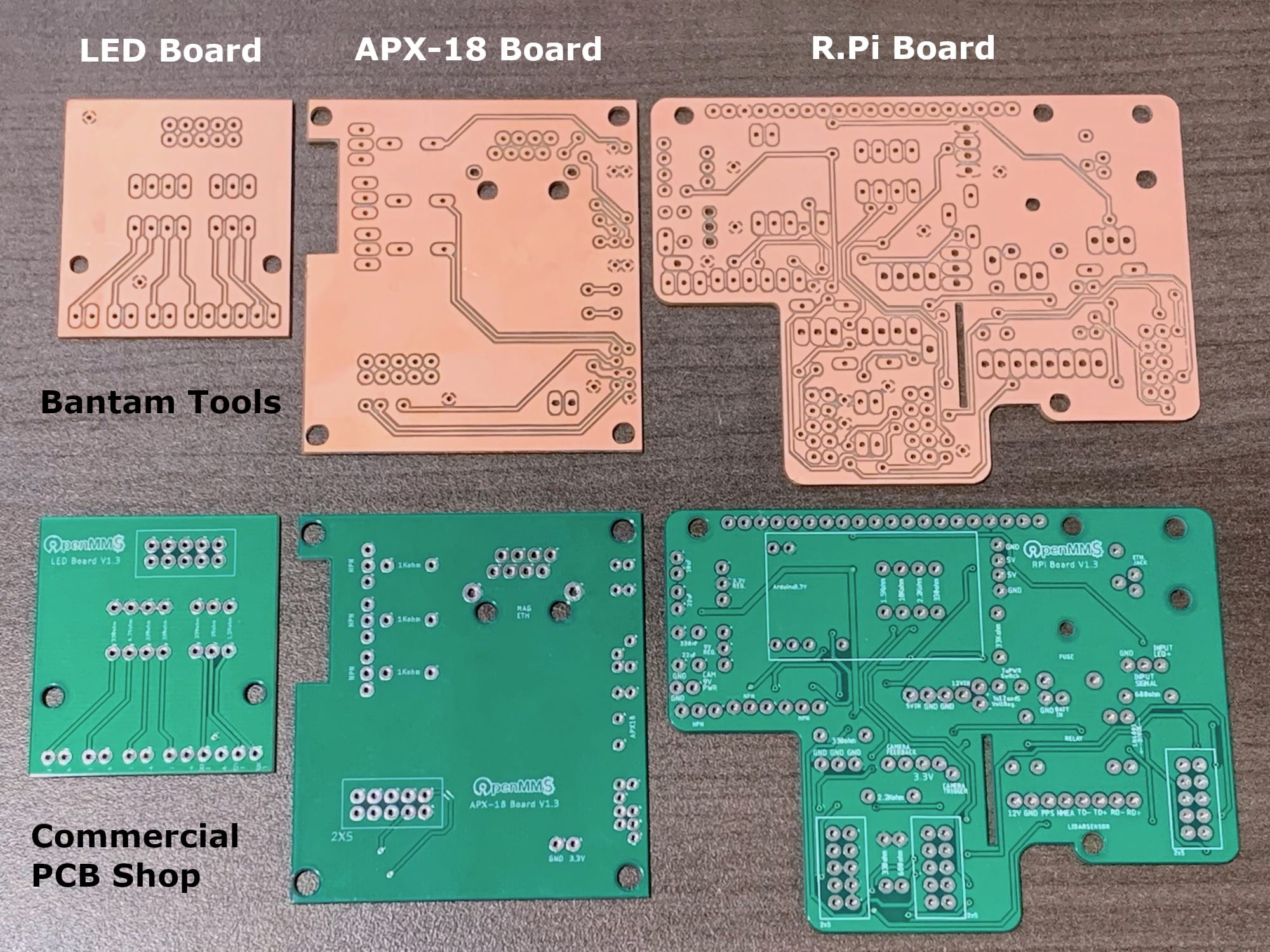

Printed circuit board designs that can be created using the Bantam Tools Desktop PCB Milling Machine and are also ready for commercial PCB manufacturing.

Incorporate Lemo power and data ports for connecting to the Sony A6000 camera outside the case.

3. Create simplified software and procedures for calibrating the lever-arm offsets and lidar and camera boresight angles.

4. Create an easy and streamlined data processing and quality assurance post-processing workflow.

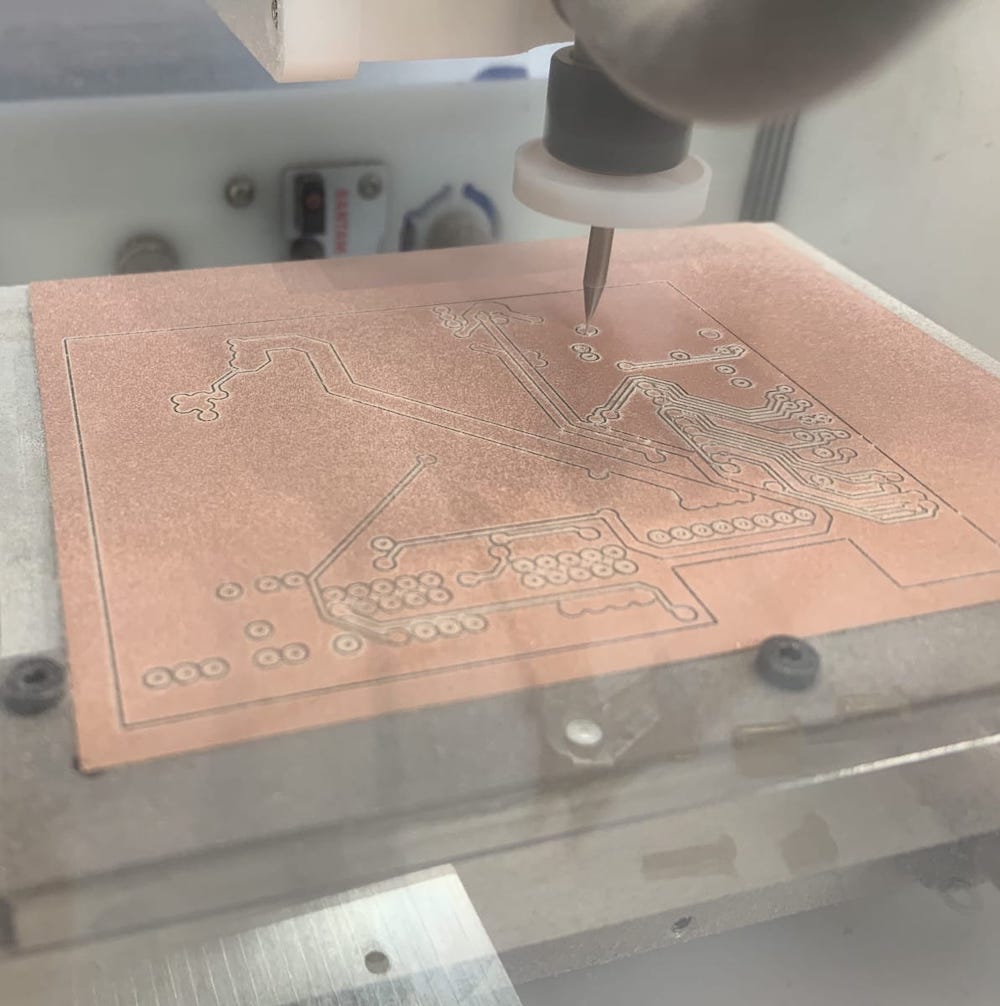

2. Specialized Tools¶

Etching and milling approaches for creating PCBs using desktop manufacturing techniques were investigated. Each method had advantages and disadvantages over the other. Both manufacturing techniques required that the layout (design) of the PCB be completed first. After manufacturing, both methods still needed the vias to be manually connected by soldering. PCB etching was fast and less expensive but required chemical processes and a lot of manual work to complete the circuit board. PCB milling required practically no manual work and produced circuit boards with precise traces. It needed an expensive Computer Numerical Control (CNC) machine, specialized tools, and the knowledge base to convert PCB designs into CNC programs (i.e., manufacturing instructions). In the end, PCB milling was selected because of its ability to produce precise and repeatable results, required little manual work, and allowed open-source hardware files and documentation to be more easily created.

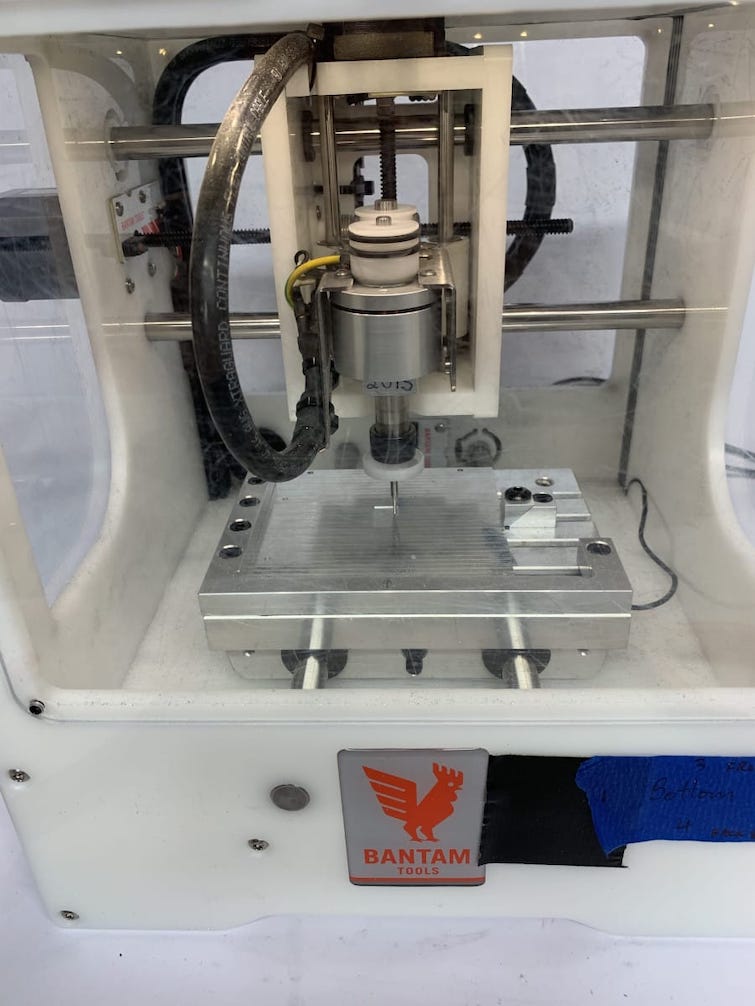

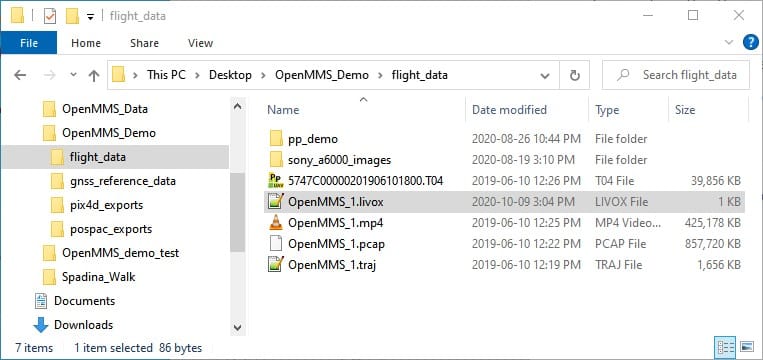

2.1. Bantam Tools Machine¶

Upon researching the commercially available options for desktop PCB milling machines, the Bantam Tools Desktop PCB Milling Machine was discovered. This machine was capable of milling PCBs, but it was also capable of precisely machining aluminum, dense plastics, and many other materials. Additional benefits of using the Bantam Tools Machine included:

Excellent online documentation, tutorials, and example projects to help get started.

Worked well with Autodesk’s Eagle PCB design and Fusion 360 3D design software.

Easy to learn, machine control software (Bantam Tools Machine Software).

Support for a wide selection of end mills and bits

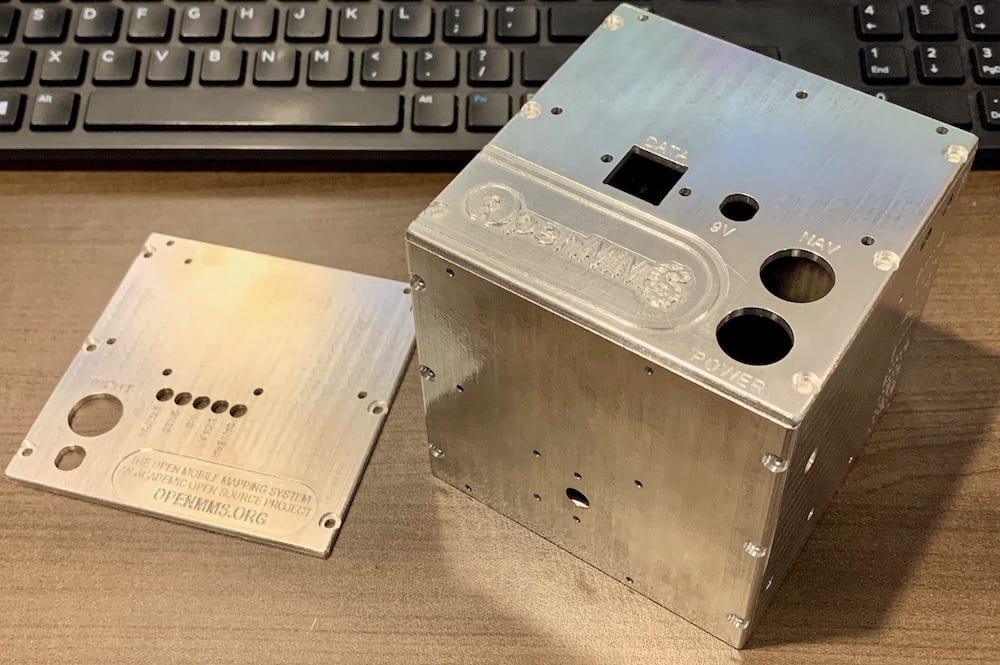

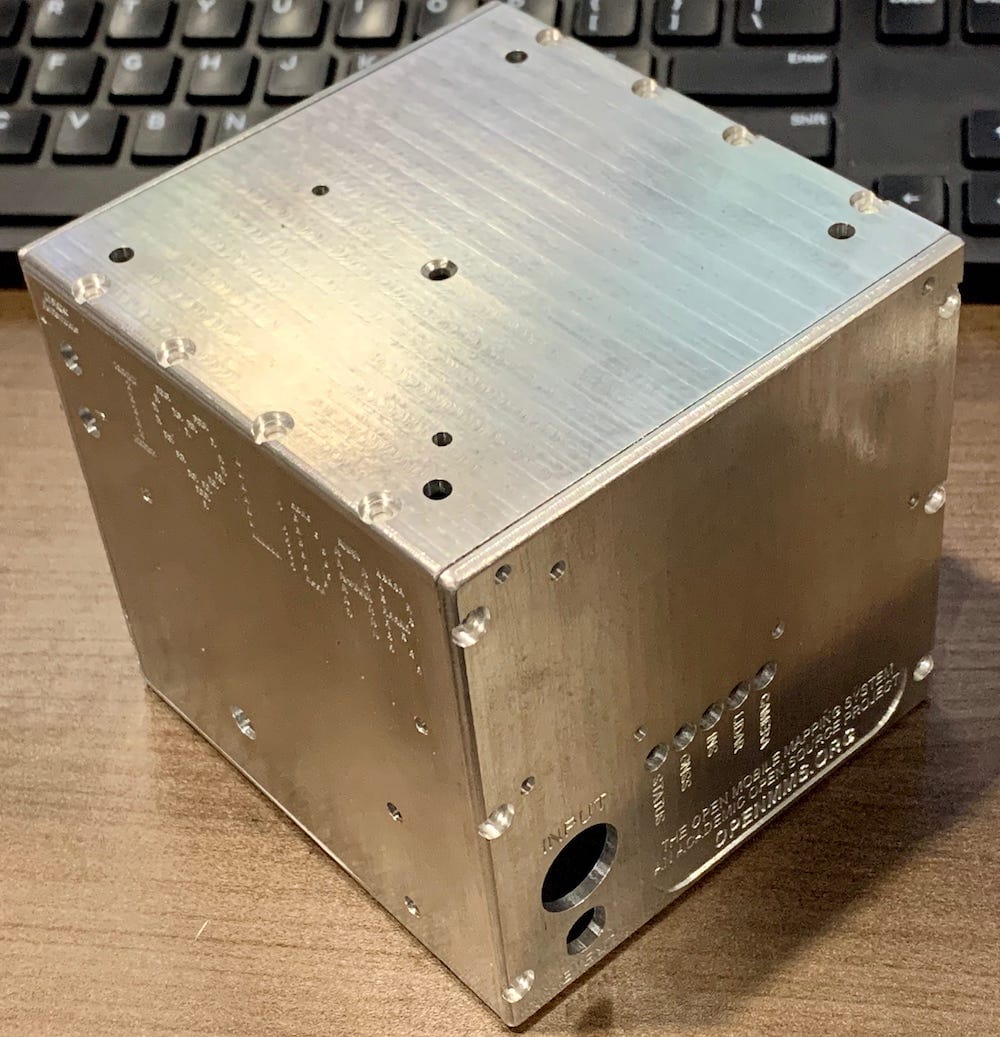

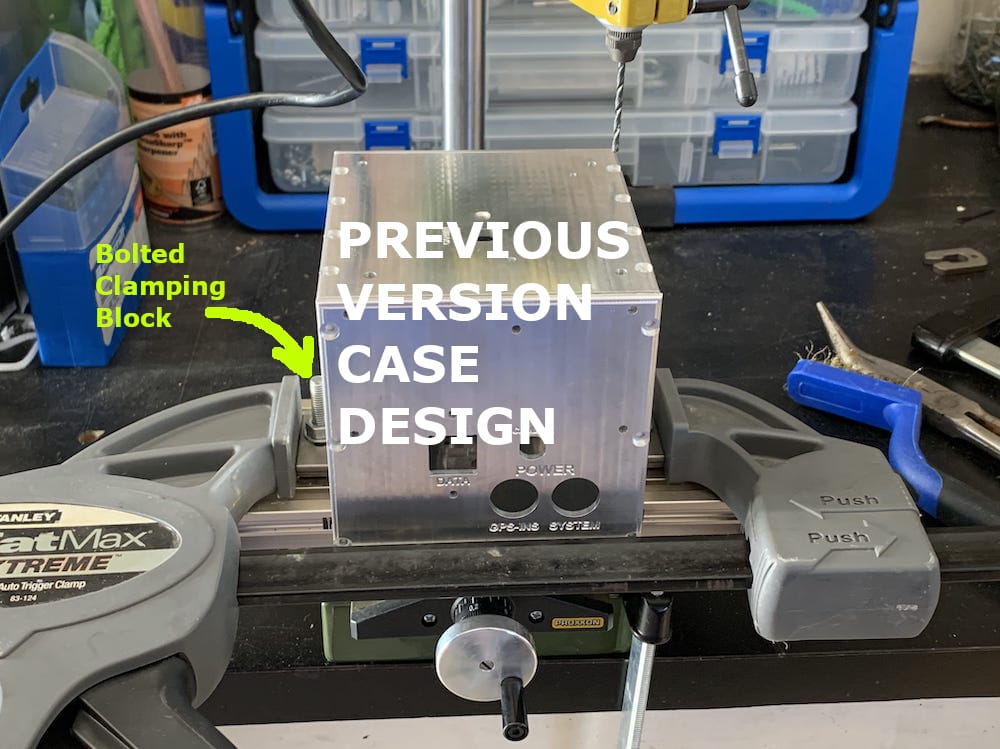

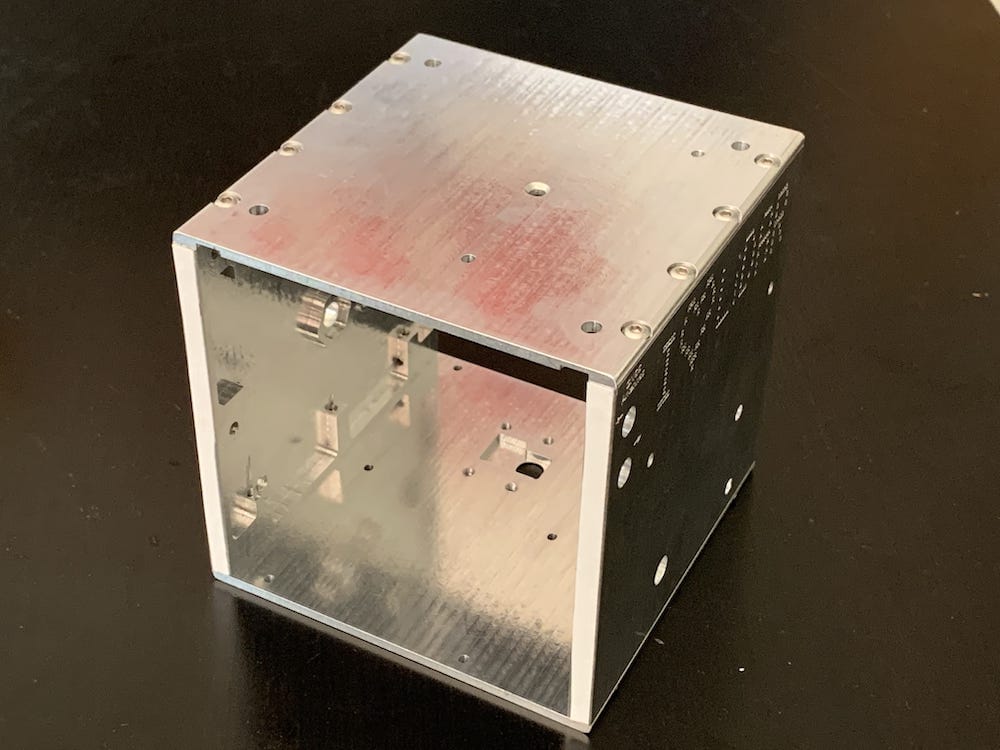

The Bantam Tools Machine did pose a limitation on the size of the machined parts that could be produced. As a result, the aluminum case design utilized six machined main parts, one for each face of the cubed case. The case could then be assembled using metric bolts and Loctite.

2.2. Bantam Tools Machine Setups (BTMS)¶

There are four different machine setups used during the OpenMMS milling operations using the Bantam Tools Machine.

2.2.1. 1st setup¶

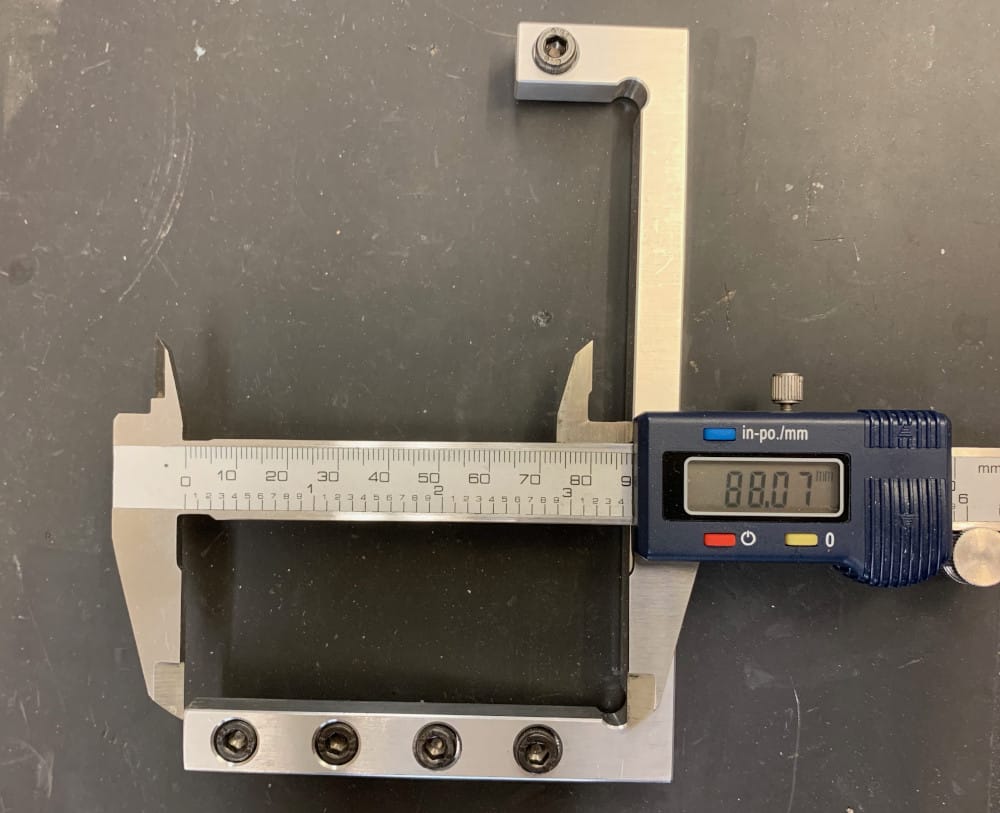

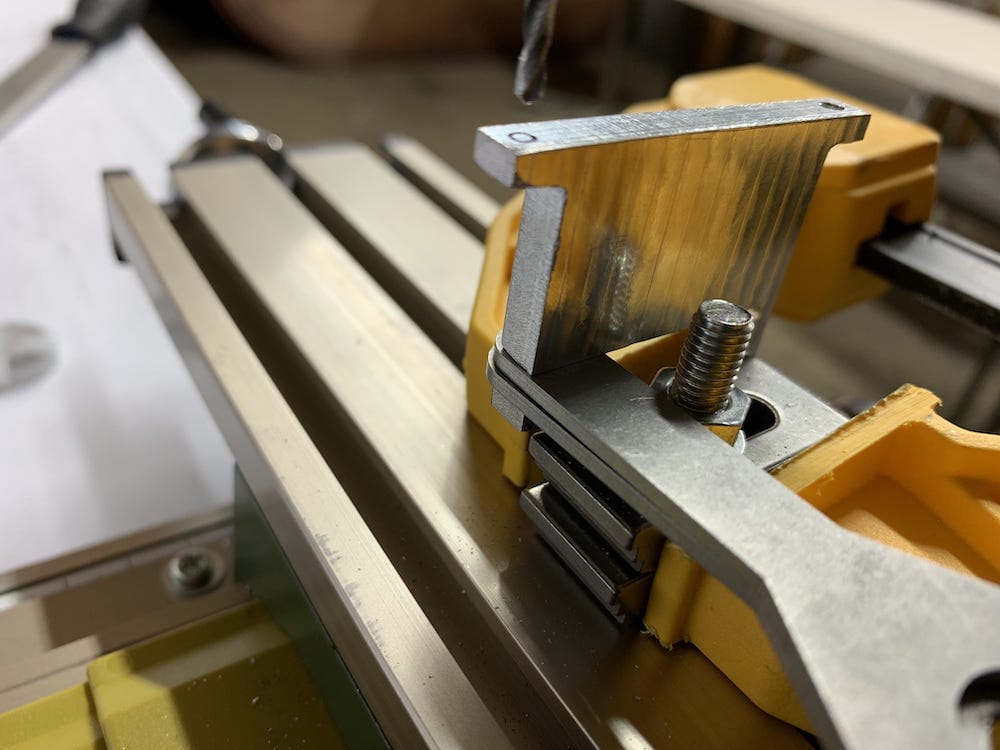

This setup requires the installation of the Precision Fixturing and Toe Clamp Set onto the machine. These instructions explain the installation procedure. However, the left side of the Precision Fixture needs to be shortened, for the aluminum milling operations not to collide with the fixturing. The inside dimension (ID) of the left side of the Precision Fixturing needs to be ~ 88mm. It can easily be shortened using a hacksaw. The images below show the shortened Precision Fixturing installed on the machine.

2.2.2. 2nd setup¶

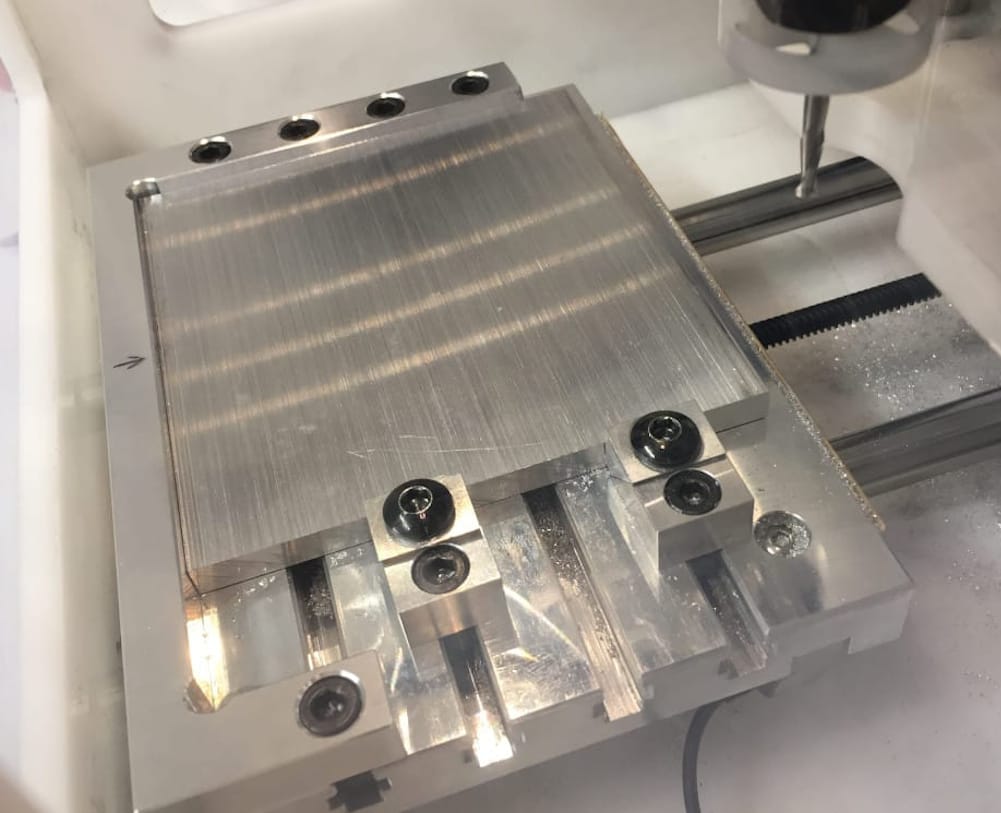

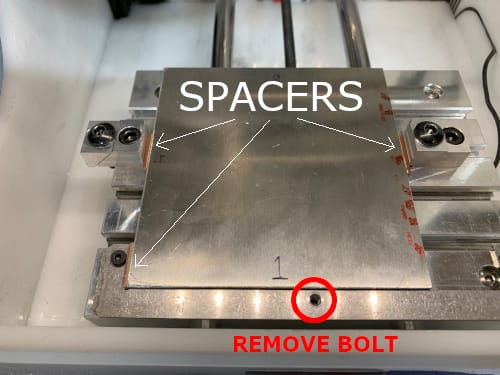

This setup requires the installation of the Alignment Bracket that comes included with the Bantam Tools Machine. However, before the Alignment Bracket is installed, the spoilboard must be removed, which differs from the instructions provided by the manufacturer. Once the Alignment Bracket is installed, the Toe Clamps, from the Precision Fixturing and Toe Clamp Set, are installed on each side of the bracket. To complicate the setup even further, small spacers (of equal dimensions) need to be placed in-between the aluminum material being milled and the clamps on both sides and the left edge of the Alignment Bracket. Using small pieces of PCB blanks works well for this. These spacers allow the End Mill to reach the very edges of the material without colliding with the fixturing. The clamp on the right side is used to secure the material and can be moved around depending on the milled material’s width. The left side clamp is installed backward, and the clamp is positioned rigidly and inline with the small inside left edge of the Alignment Bracket. The final steps are to insert and clamp the aluminum material to be milled, and then remove the middle bolt that secures the Alignment Bracket. Again, this needs to be done to ensure that the End Mill does not collide with this middle bolt. The images below illustrate the small spacers and the installation of the Alignment Bracket for this 2nd setup. A final very important step is to change the Material Placement’s X coordinate setting to the spacer thickness within the Bantam Tools Software. This setting accounts for the installed aluminum material being offset from the Alignment Bracket (i.e., where X = 0.0mm).

2.2.3. 3rd setup¶

The 3rd setup also requires installing the Alignment Bracket, but now the bracket is installed on top of the spoilboard. The spoilboard needs first to be installed on the machine’s fixed bed, and then the Alignment Bracket is installed. This setup follows the instructions provided by the manufacturer. High-strength, double-sided tape must be used to hold the material to the spoilboard. To easily remove the finished aluminum brackets from the spoilboard, use a small prying tool (e.g., a putty knife) to create a small gap in-between the milled aluminum and the spoilboard. Apply a small amount of 91% isopropyl alcohol into the gap. Gently tilt the entire Bantam Tools Machine to the left and right, as well as forward and backward (being careful not to damage the power cord or USB cord connected to the back of the machine). Tipping the machine allows the alcohol to flow into the double-sided tape and release the part.

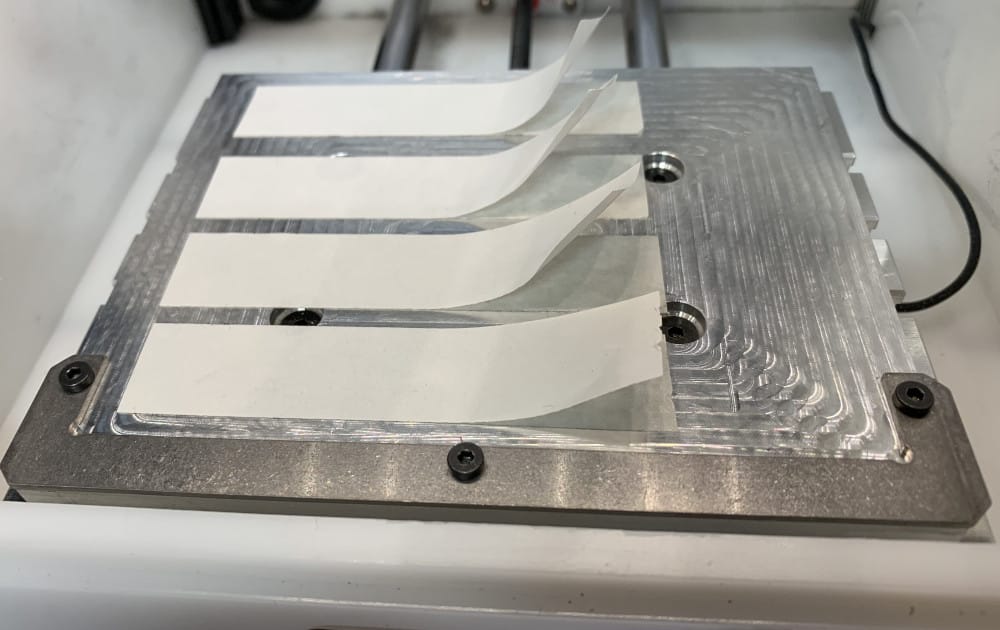

Fig 2.2-6. Alignment Bracket on spoilboard with double-sided tape (3rd setup)¶

2.2.4. 4th setup¶

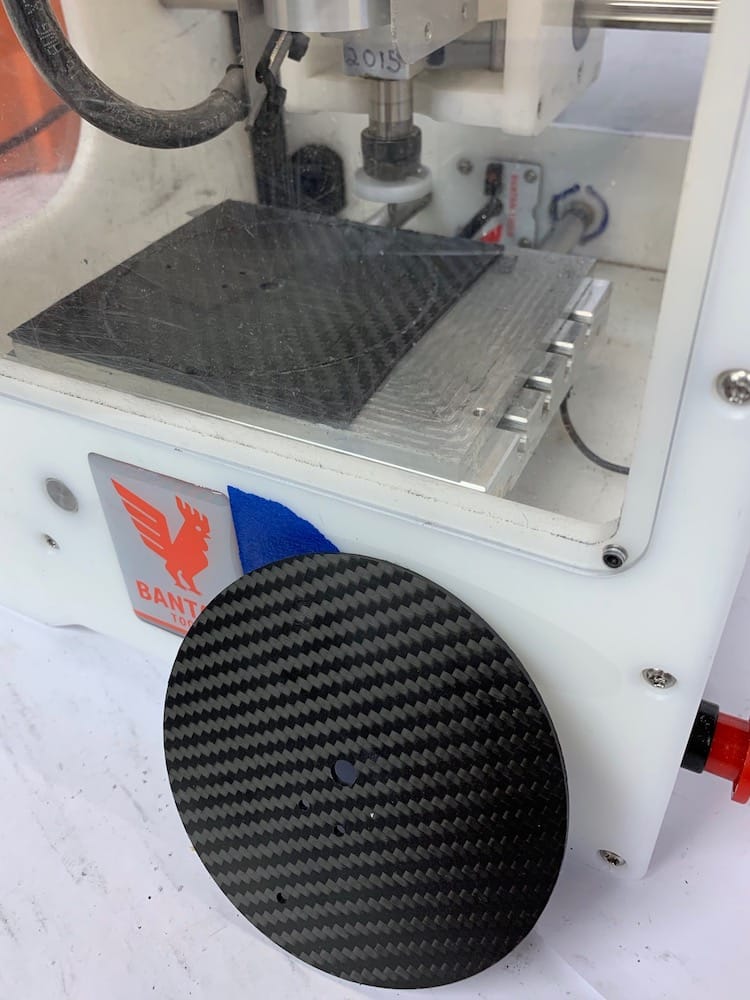

This setup is essentially the same as the 3rd setup, with the only difference being that the Alignment Bracket is not used. High-strength double-sided tape is still required to secure the material to the spoilboard of the machine. The front-left corner of the spoilboard is used as the alignment point for the material. Thus, the precision at which the material is installed on the spoilboard is not very important. Aligning the material on the spoilboard by eye is sufficient. Once again, isopropyl alcohol should be used to release the machined part after the milling operation(s) is complete.

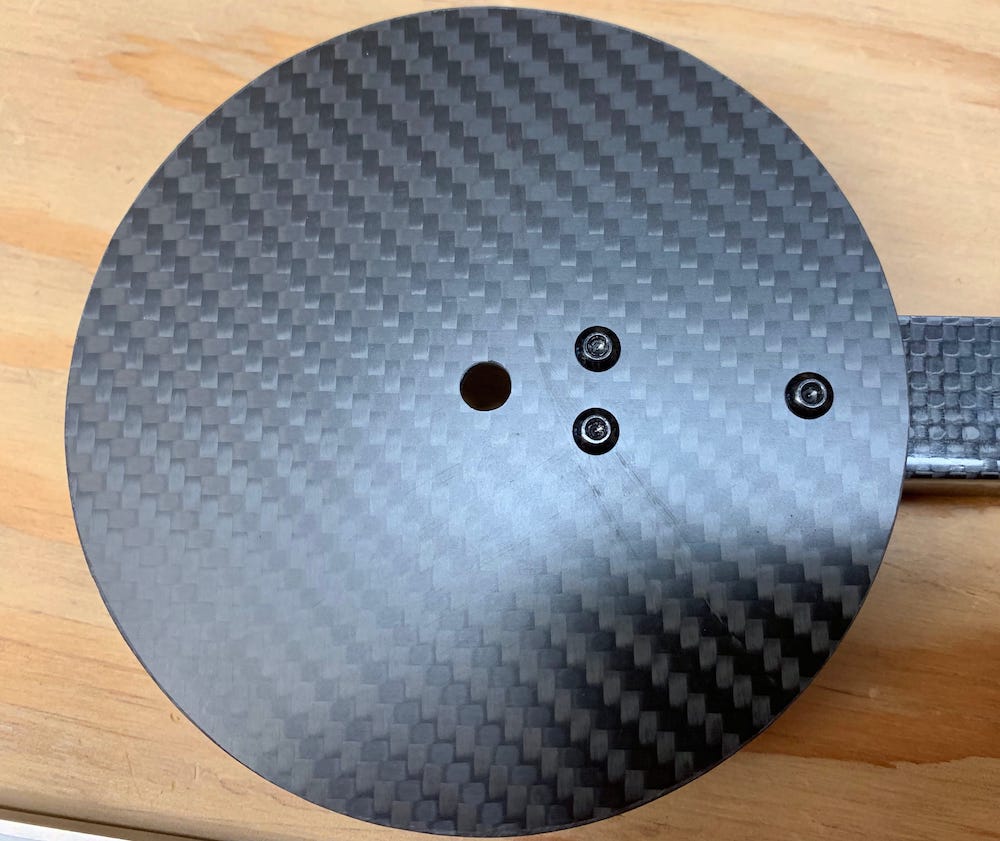

Fig 2.2-7. Carbon fiber plate aligned to the front-left corner of the spoilboard (4th setup)¶

2.3. Proxxon MICROMOT Tools¶

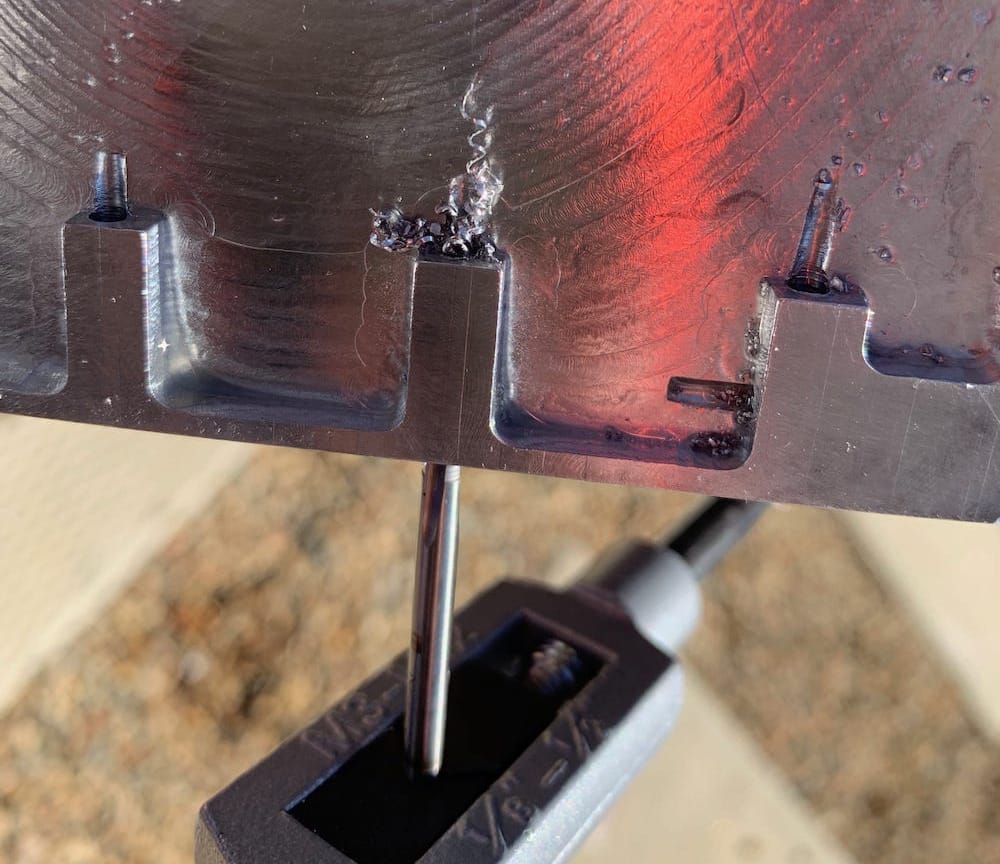

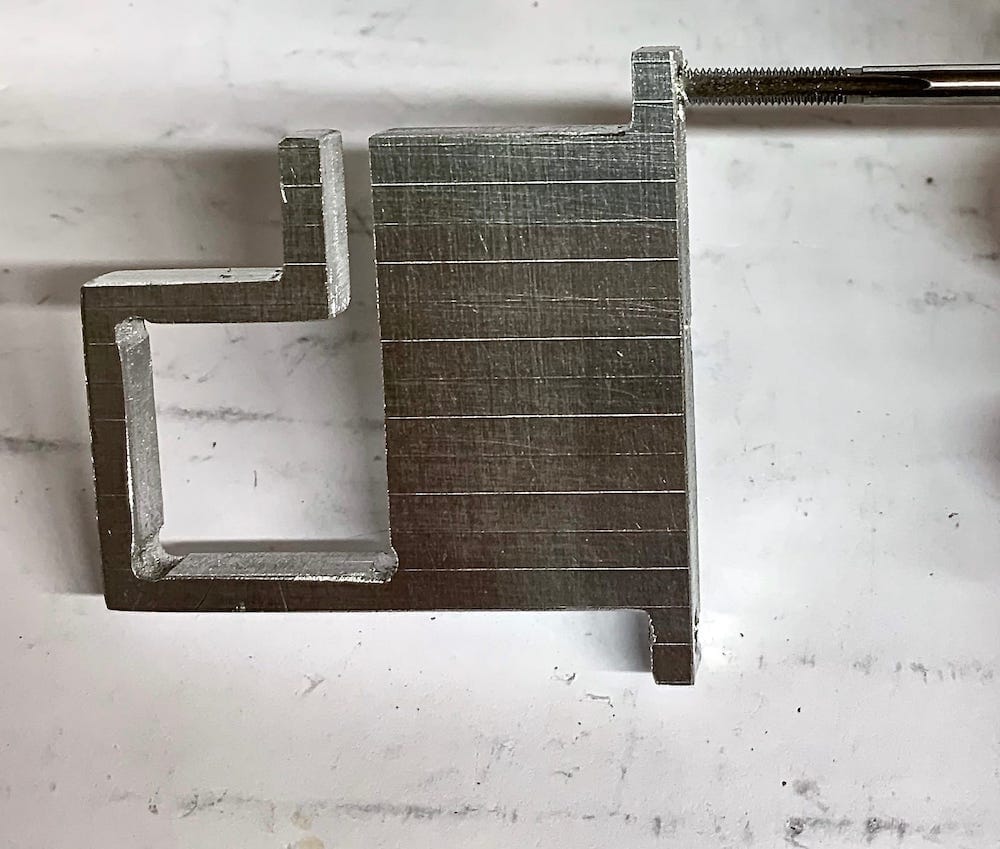

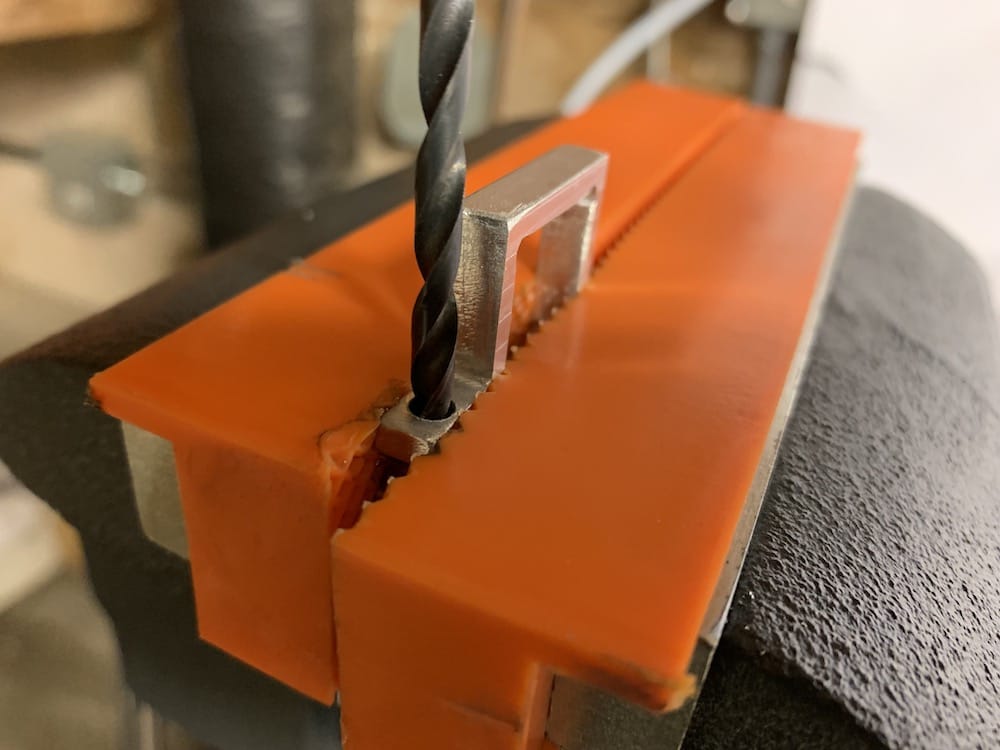

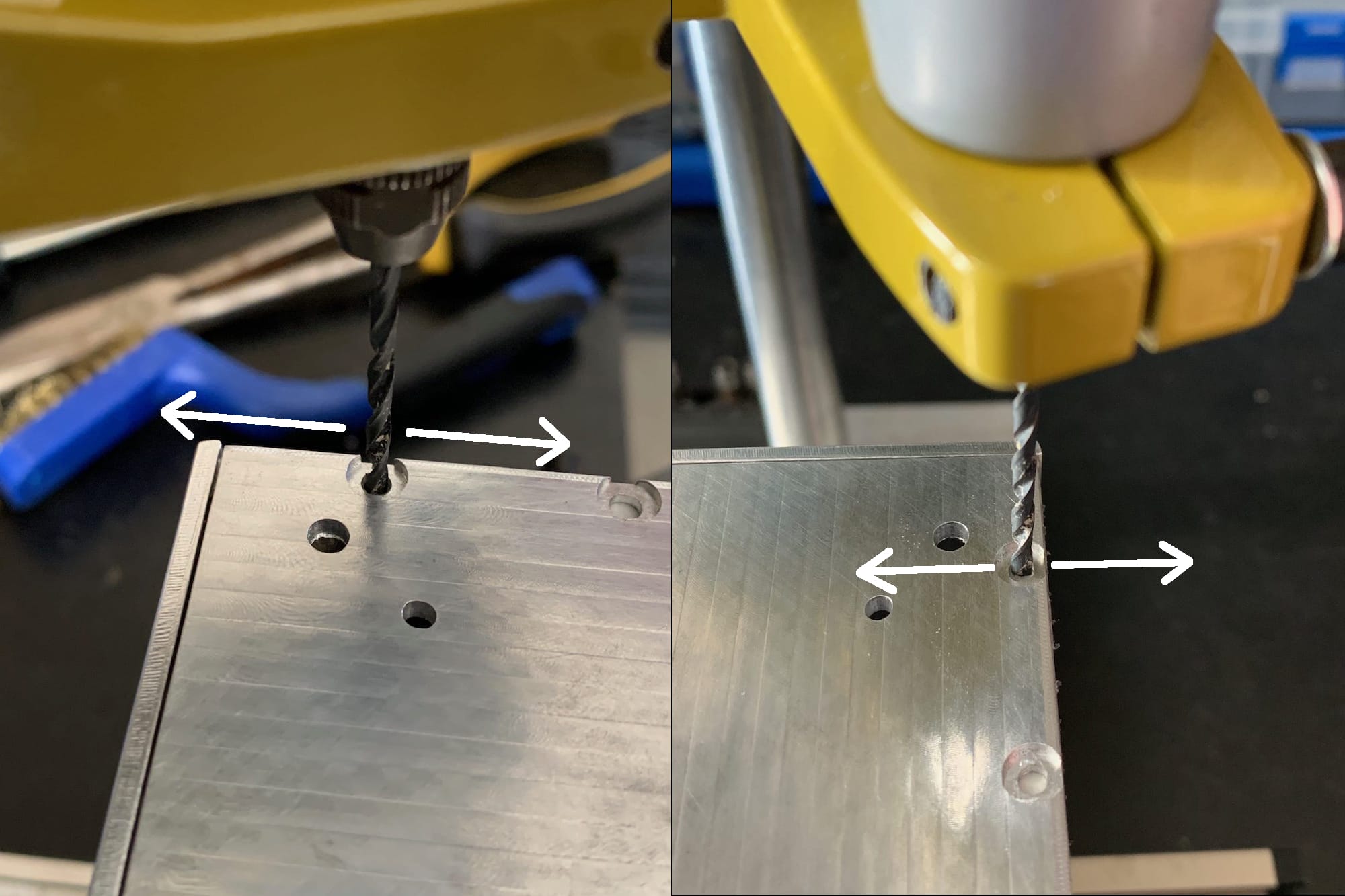

Because the case is constructed out of individual aluminum sides, threaded bolt holes need to be machined into the ends (i.e., into the thickness) of the front and back aluminum parts. The Bantam Tools Machine is not capable of performing these end milling tasks. A manual process using a drill press and a hand tap is needed to create these threaded bolt holes. In a continued effort to minimize project costs and only utilize desktop manufacturing techniques, the Proxxon MICROMOT System of Tools was used to complete these machining tasks. The following Proxxon tools were used:

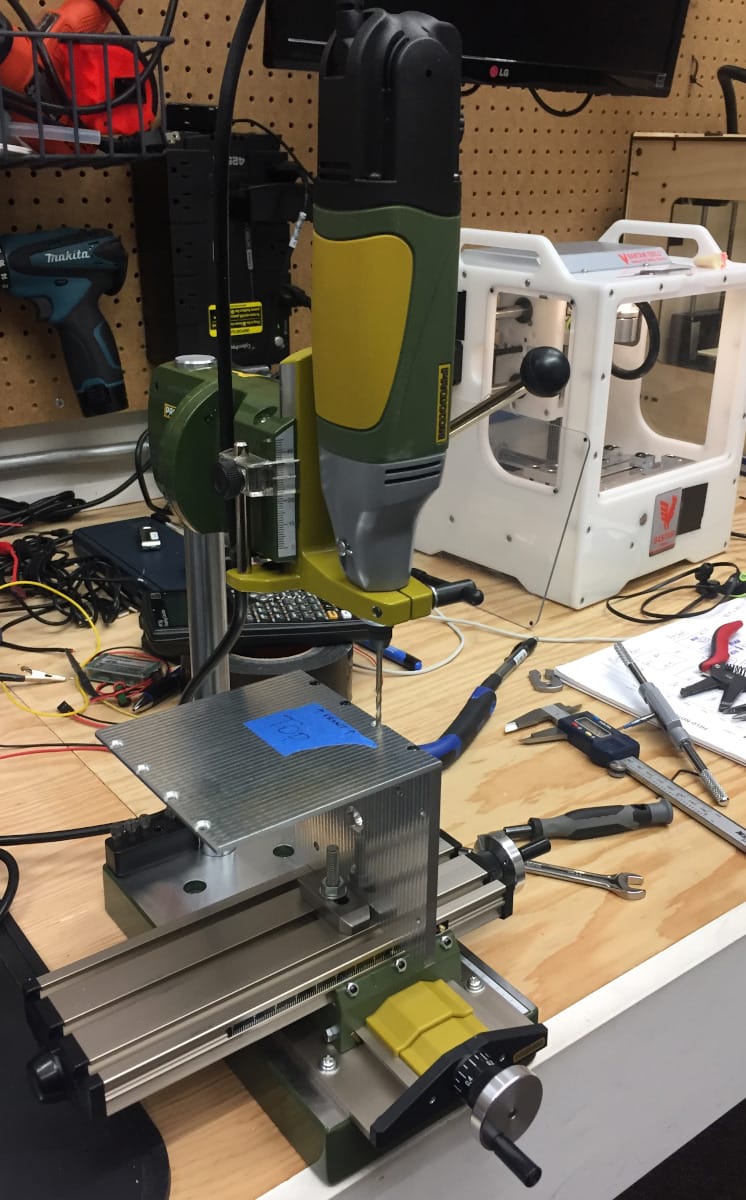

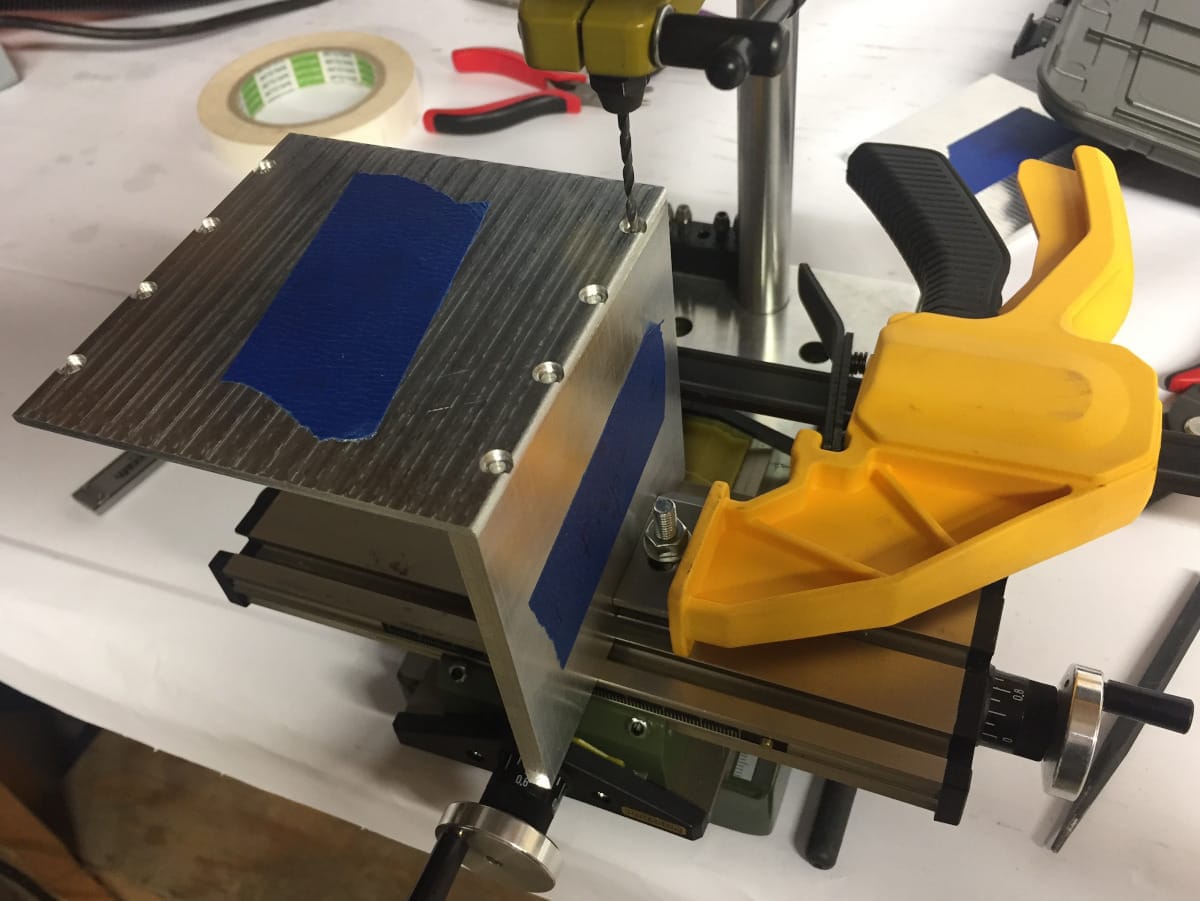

Fig 2.3-1. Proxxon MICROMOT Drill Press¶

Fig 2.3-2. End milling holes in the front face (top face used as a guide)¶

Note

The Proxxon Professional Rotary Tool was a little underpowered for the task of drilling the deeper holes in ends of the front and back aluminum pieces. To improve drilling performance, ensure the drill bits being used are sharp, drill small amounts at a time, and try to remove the swarf continuously from the drill hole and the drill bit, using a vacuum and a coarse brush.

3. Getting Started¶

DISCLAIMER

This documentation provides specific instructions on how the author manufactures and assembles an OpenMMS Version 1.3 sensor. No warranties, of any kind, and no guarantees, of any kind, are included with the following instructions being able to produce an OpenMMS Version 1.3 mobile mapping system.

It is the complete responsibility of the reader of this documentation, to ensure that no personal harm or injuries occur, and no physical damage occurs to any of the individual tools, materials, sensors, components, and electronics, during manufacturing and assembling an OpenMMS Version 1.3 sensor. By continuing to read and execute the following steps; the reader agrees to be responsible for the risks associated with all aspects of the OpenMMS project.

3.1. List of Safety Equipment¶

|

|

3.2. List of Tools¶

|

|

3.3. List of Build Materials¶

|

|

3.4. List of Sensors and Electronics¶

|

|

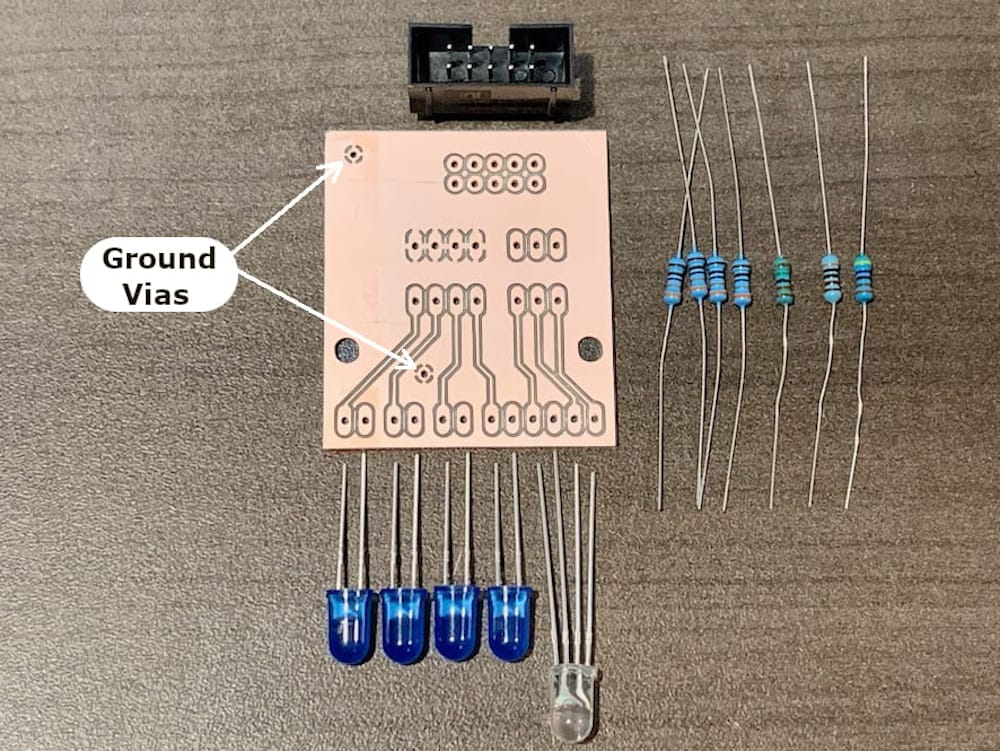

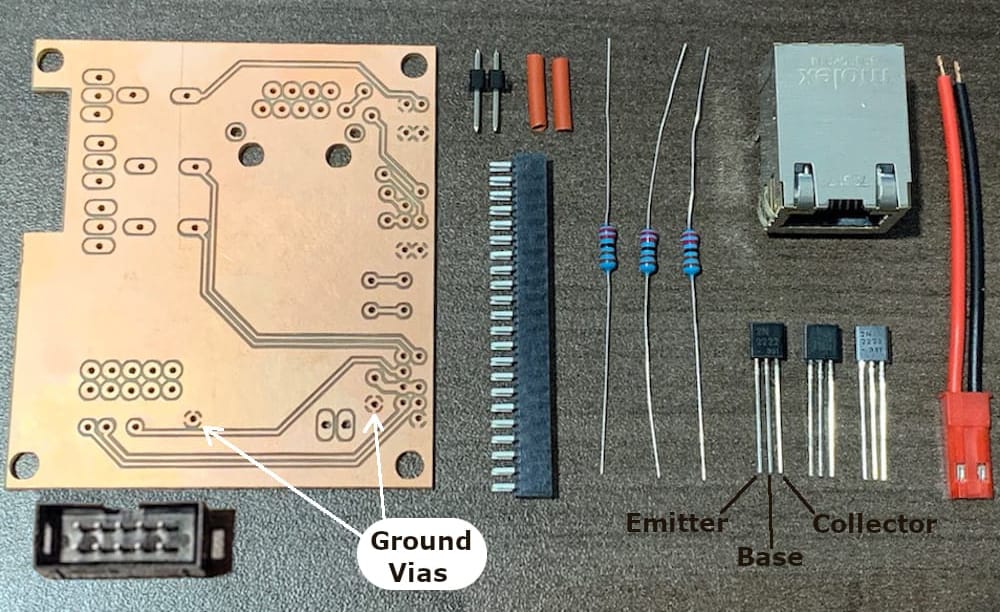

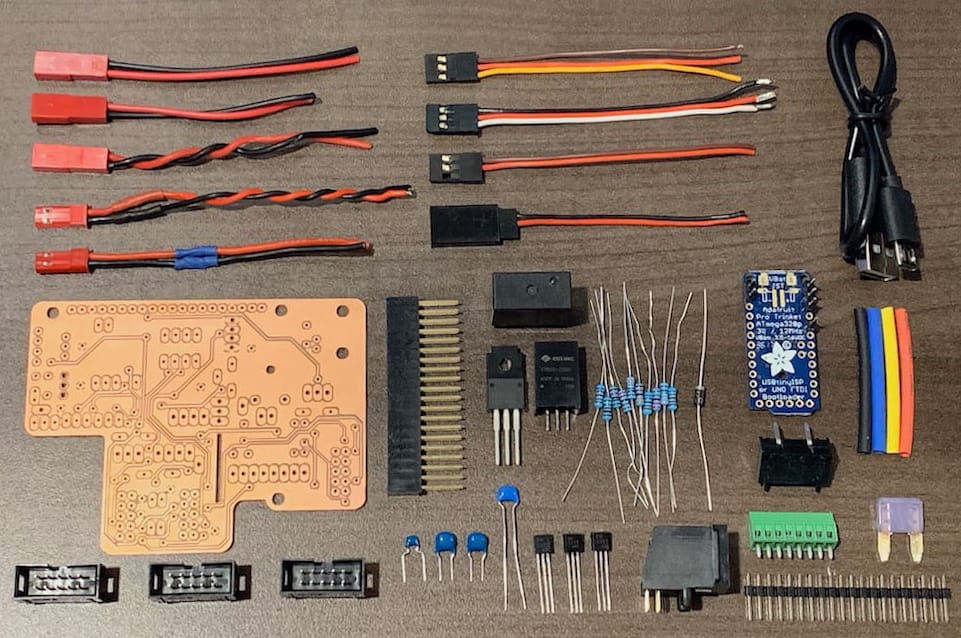

3.5. List of Printed Circuit Board Components¶

NOTE: All components are through-hole (TH)

|

3.6. List of Software¶

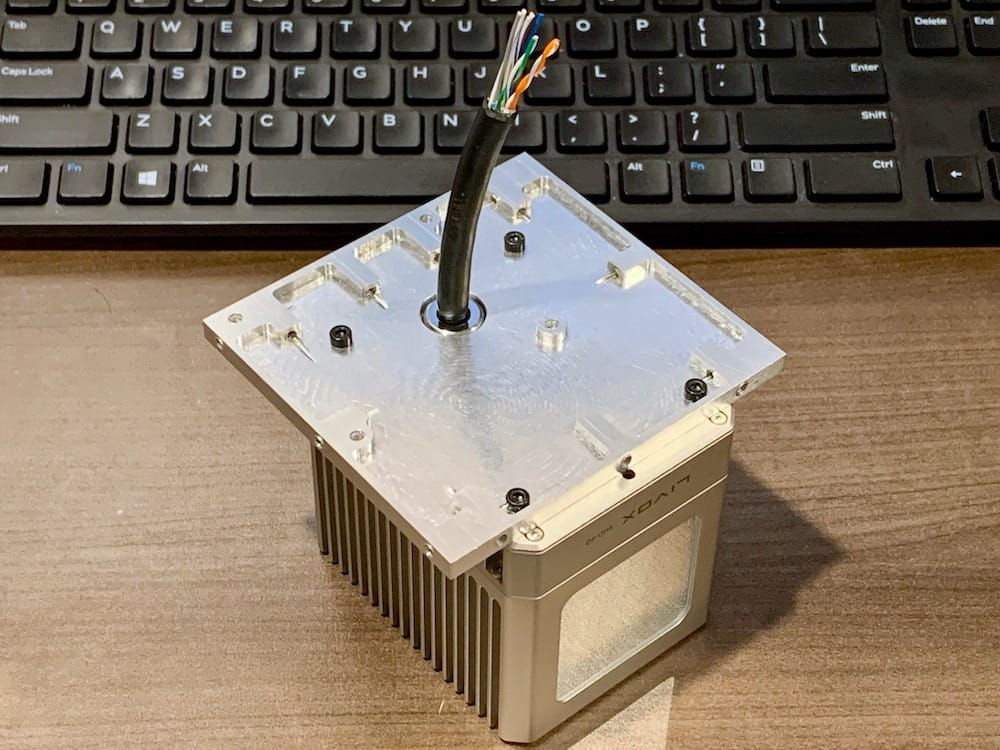

4. Aluminum Parts Manufacturing¶

4.1. Overview¶

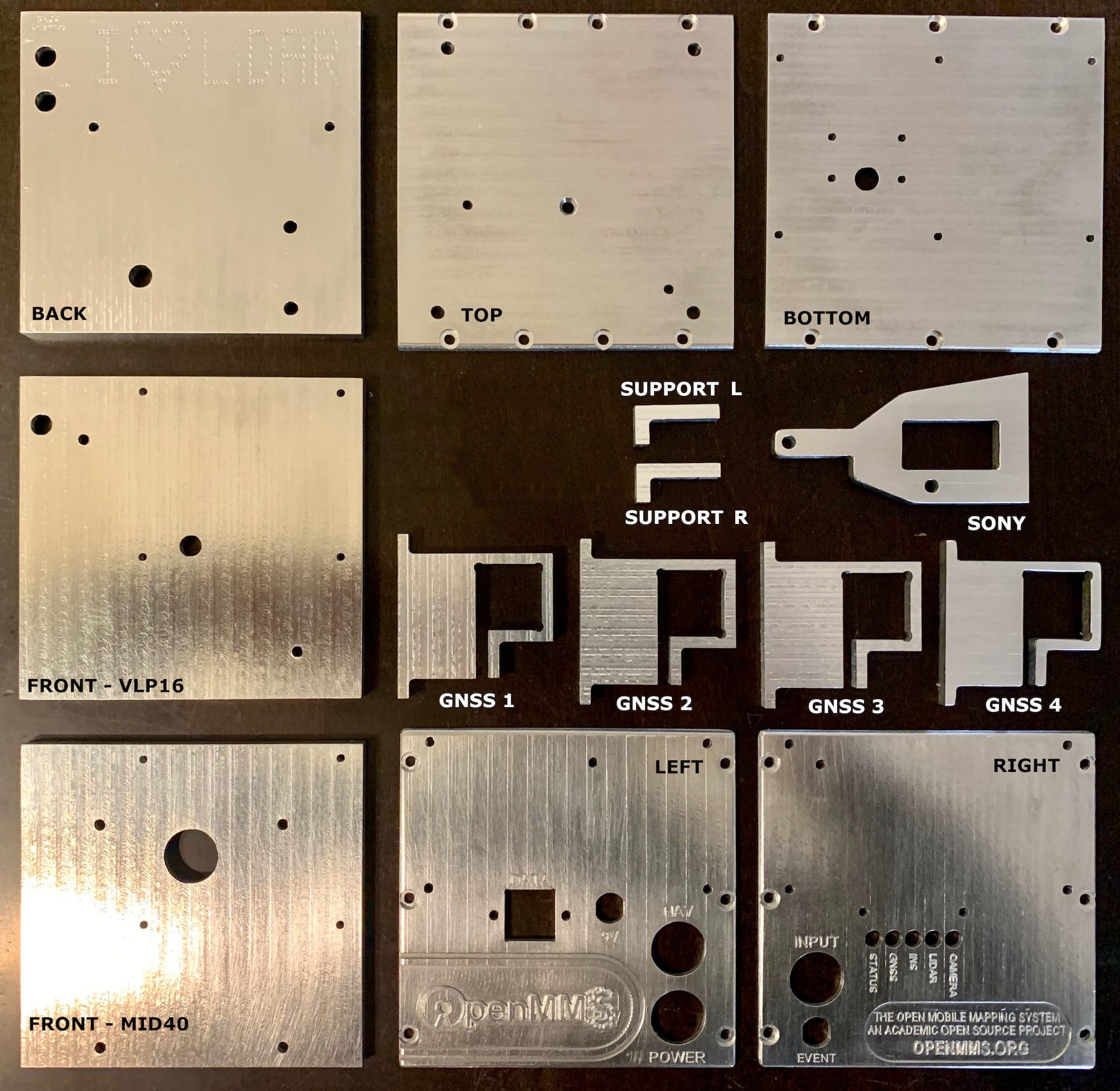

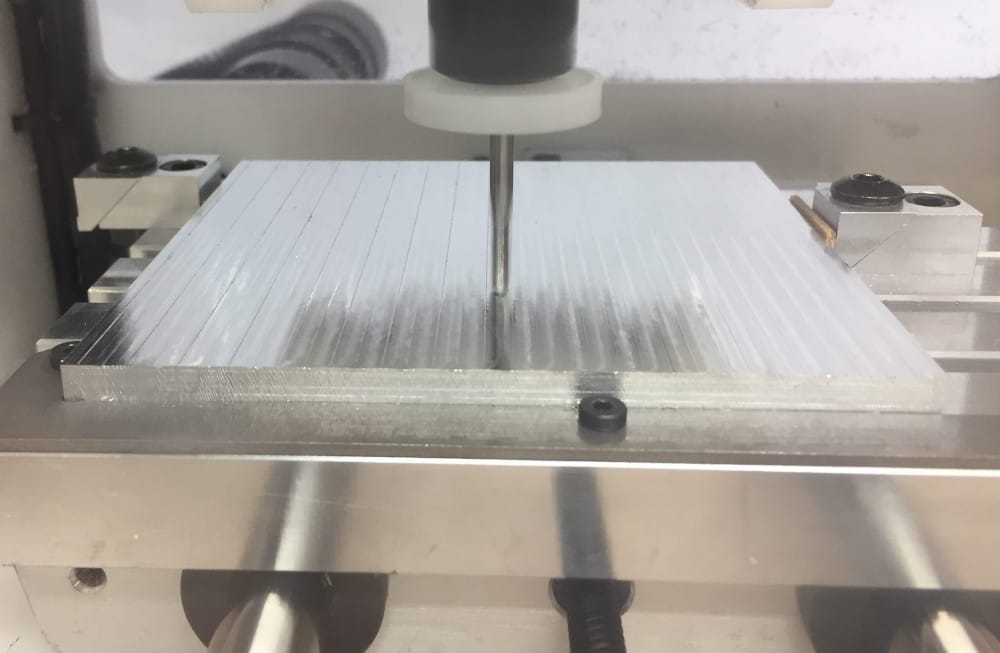

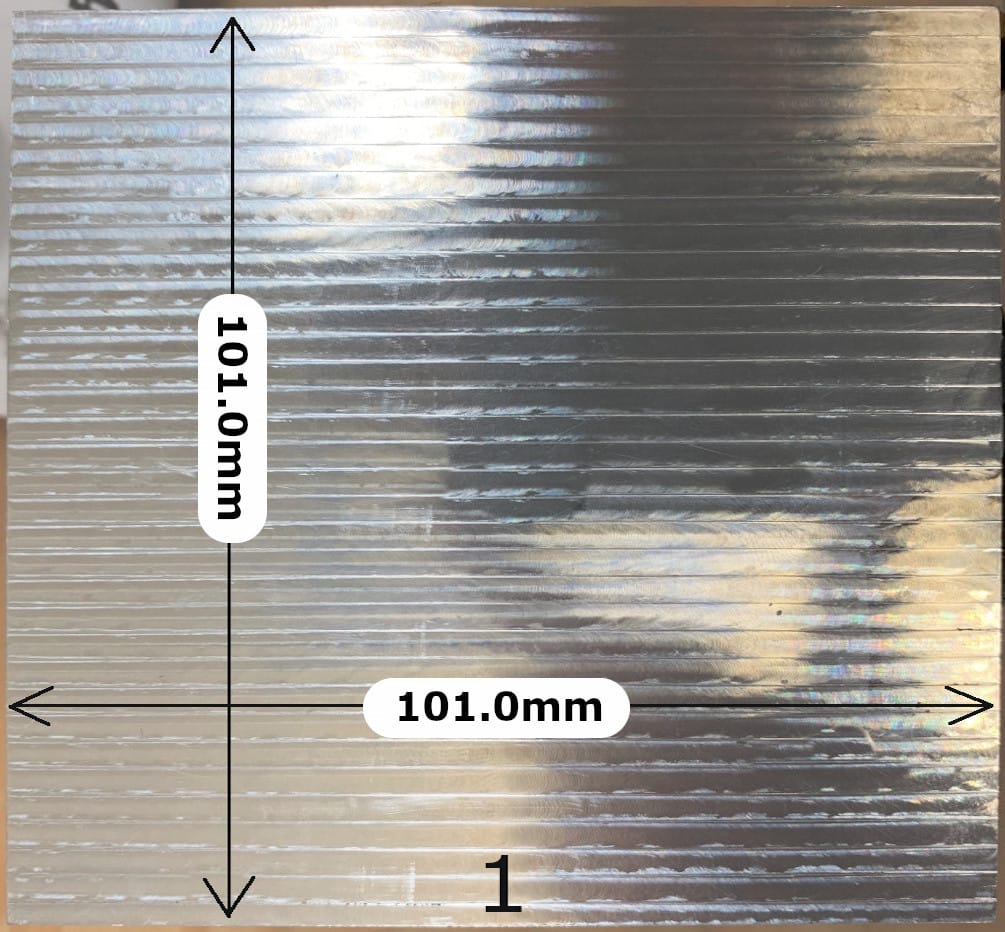

There are a total of thirteen aluminum parts that need to be manufactured using the Bantam Tools Machine. The Top, Bottom, Left, and Right Faces are machined out of 1/8” thick 6061 aluminum material. All other parts are machined out of 1/4” thick 6061 aluminum material. Pay close attention to the required End Mill for each milling operation and ensure that the Bit Fan is always installed on each End Mill. The Bantam Tools Machine should be cleaned, and swarf removed whenever safely possible. The Fine Dust Collection System or Vacuum Port performance upgrades are highly recommended.

The reader is strongly encouraged to work through the Bantam Tools Fusion 360 Aluminum Rings Getting Started Project before proceeding with manufacturing the OpenMMS aluminum parts. The Getting Started Project provides excellent explanations, does and don’ts, and other valuable information on aluminum milling using the Bantam Tools Machine.

3D Model¶

Model A: OpenMMS v1.3 Aluminum Case

4.2. Instructions¶

Each of the thirteen aluminum parts that need to be manufactured is listed below. Notice that the required quantity of each part is listed in the top right corner of each table. The Autodesk Fusion 360 3D design files have been included for each part. If the reader is interested in making edits to these files, the Bantam Tools tool library needs to be set up within their Fusion 360 software. Bantam Tools provides an excellent introduction to setting up and using Fusion 360, an interested reader should view this page. The Bantam Tools Machine instruction files (a.k.a., GCODE files) for all milling operations are included in the correct order of execution. Each GCODE file represents milling operations that use the same tool (i.e., a single End Mill). The order the milling operations are executed is critical!

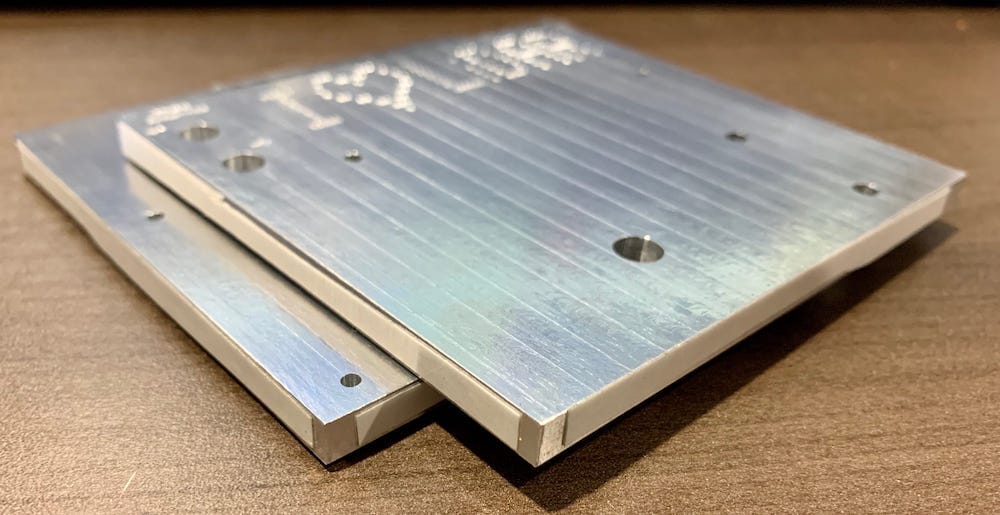

Fig 4.2-1. All thirteen aluminum parts (two front faces are shown, one for each current lidar sensor option)¶

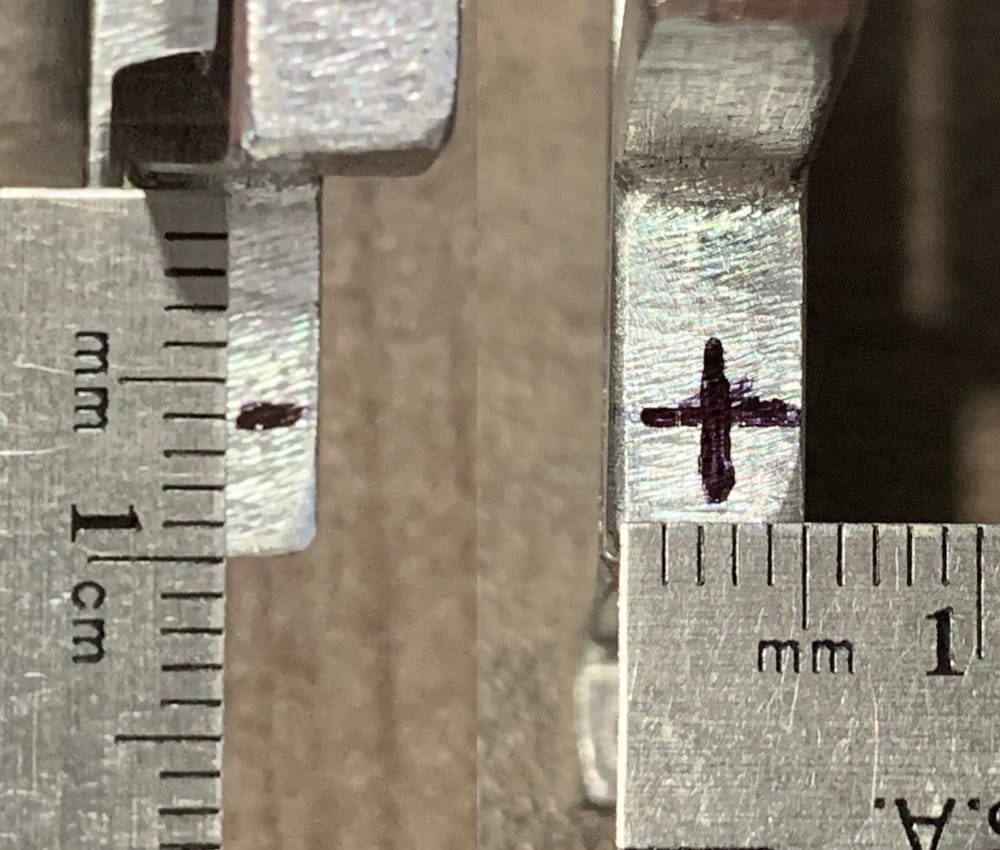

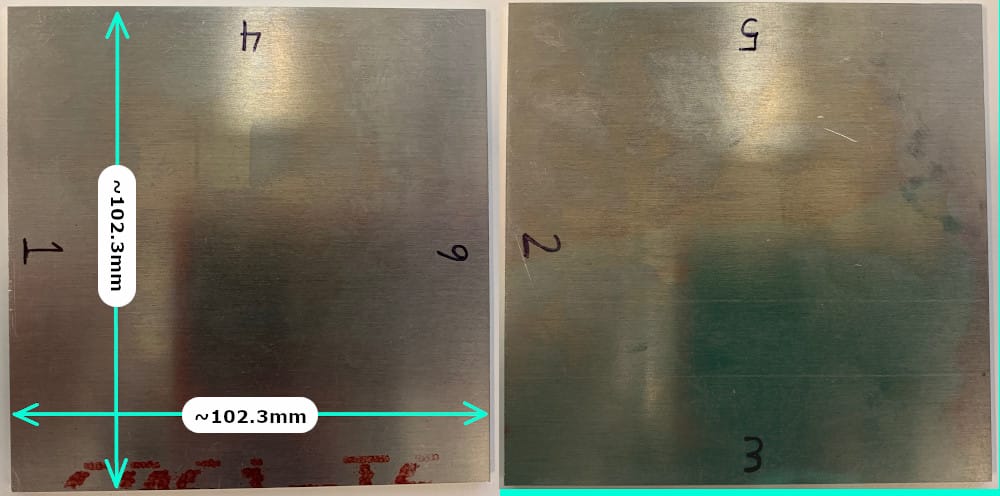

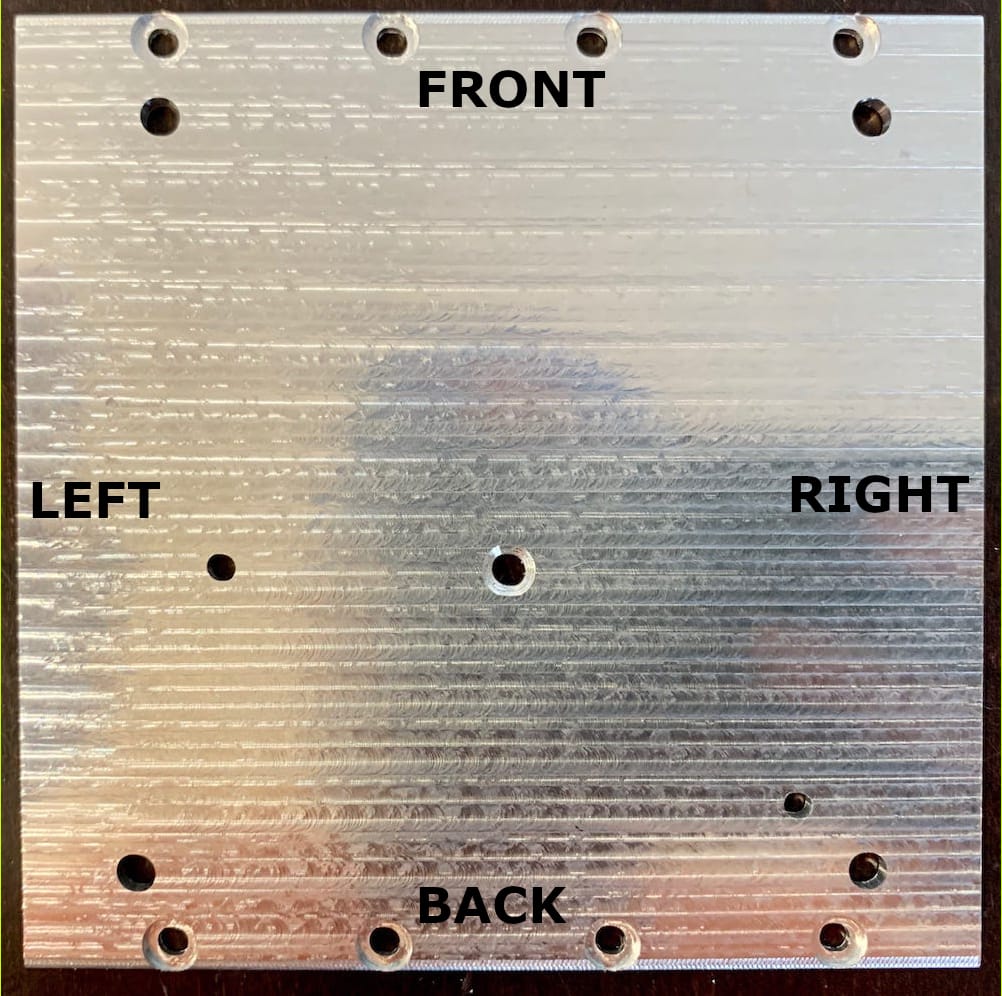

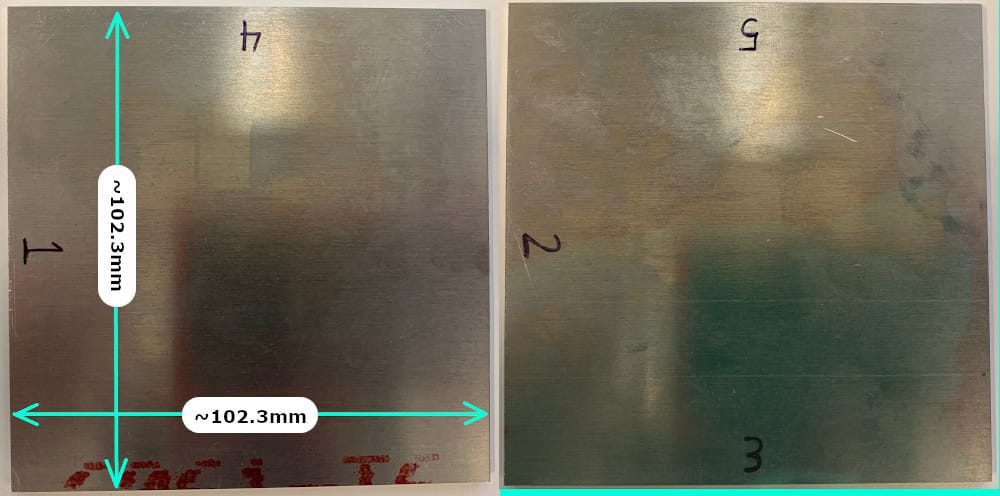

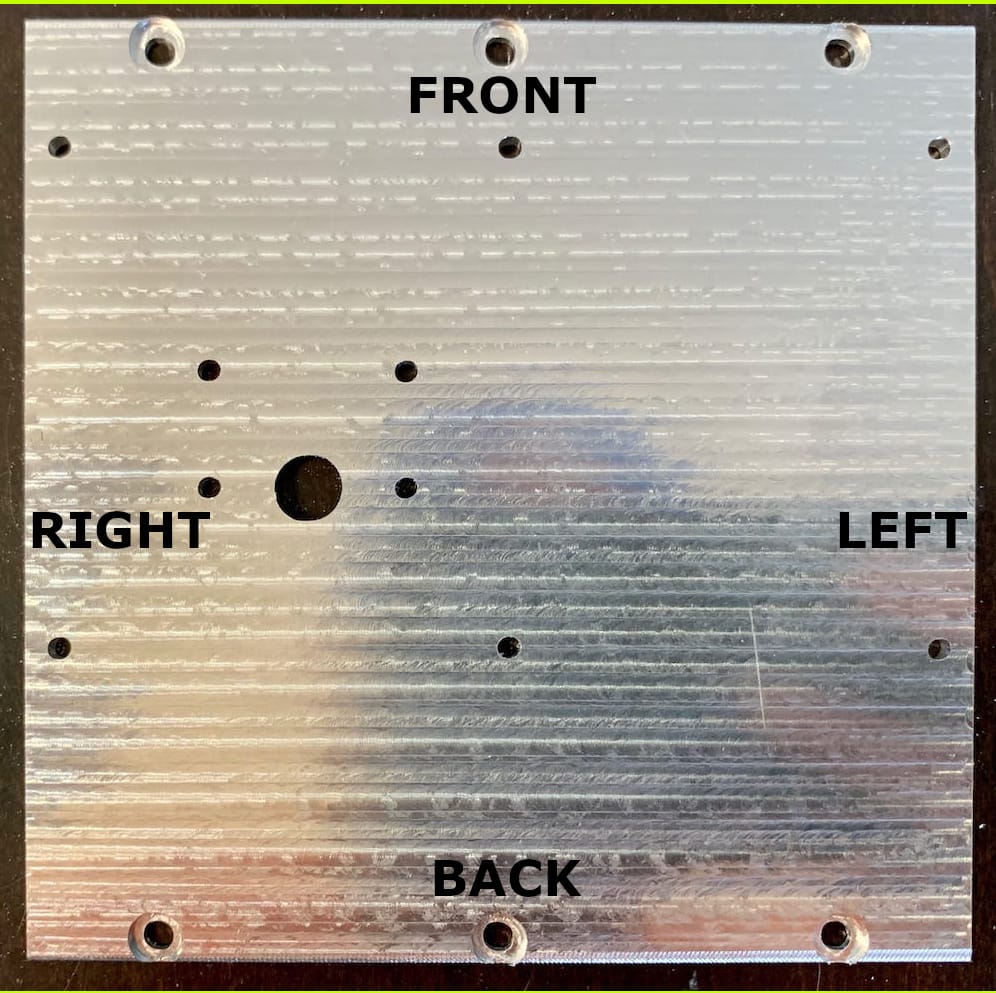

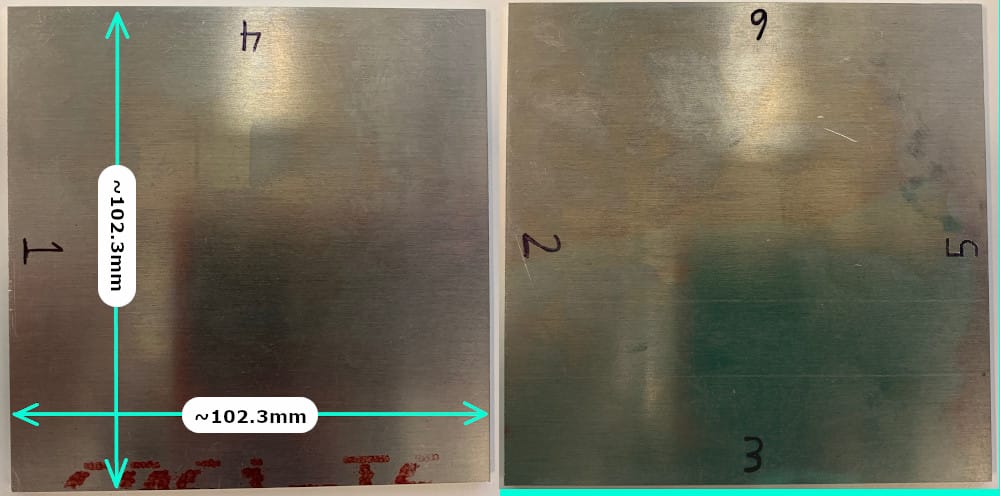

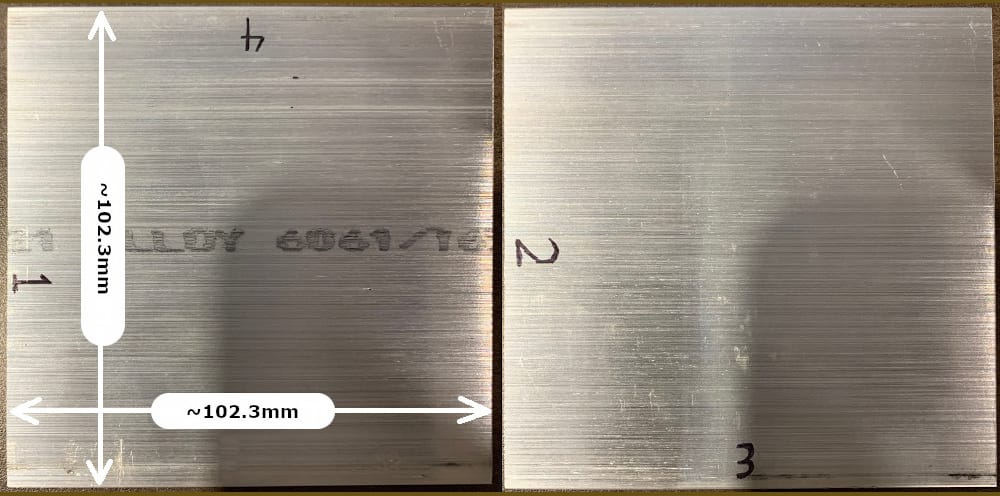

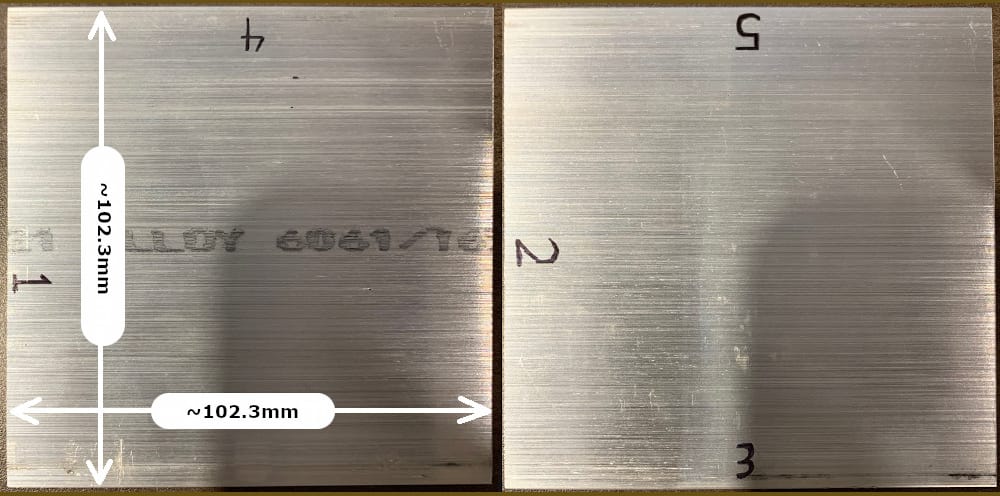

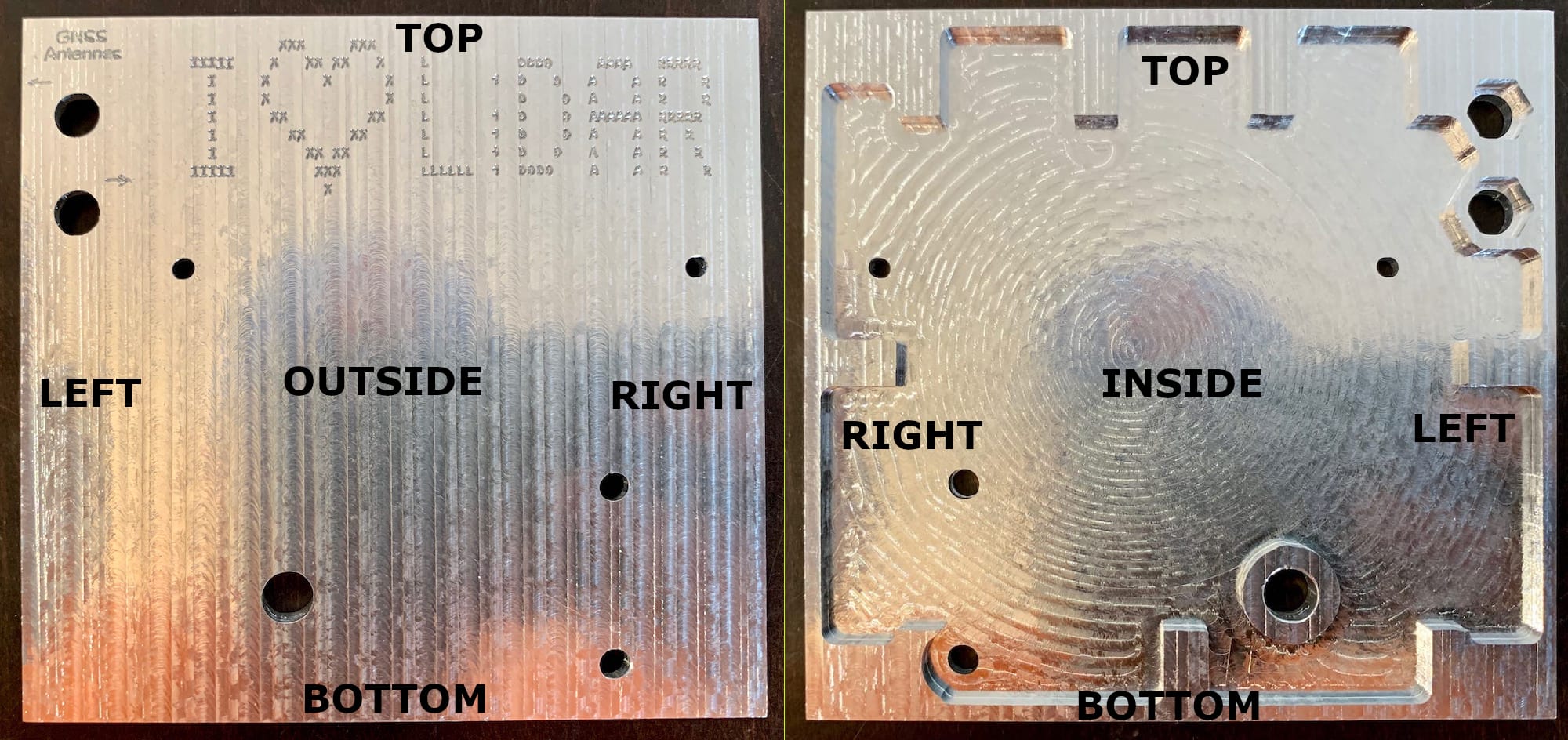

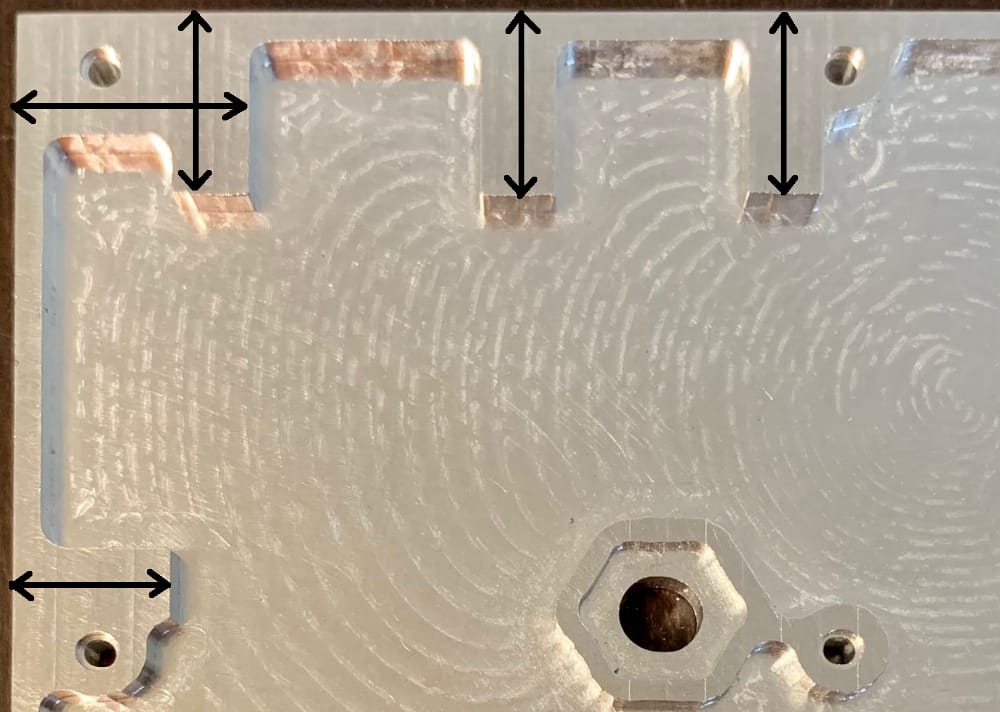

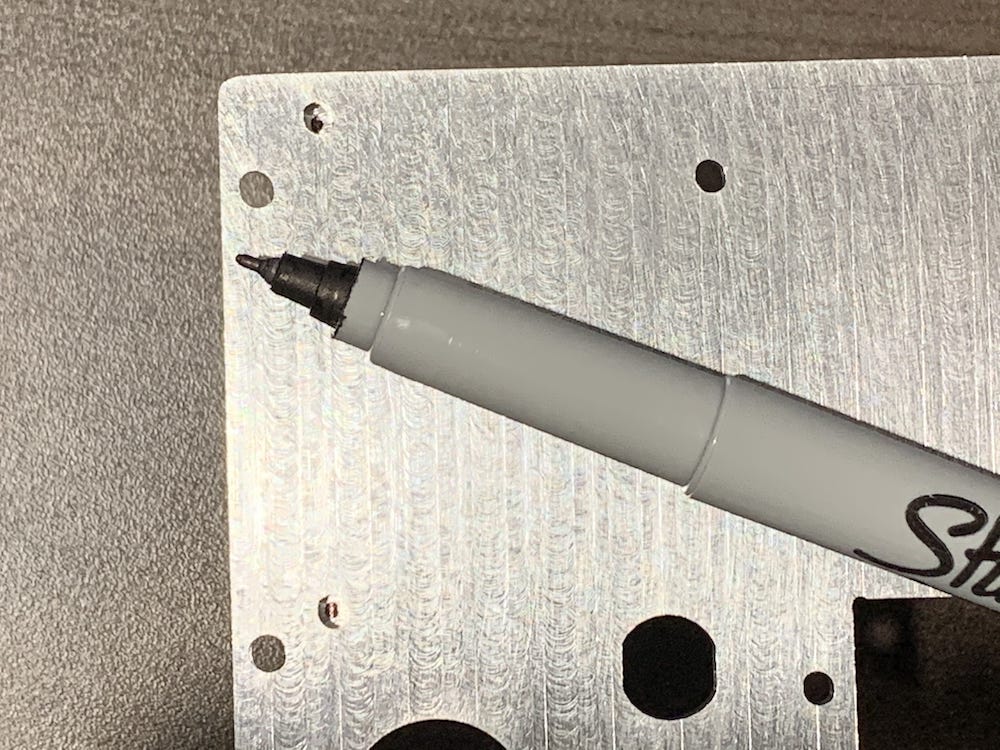

Begin by viewing the edge descriptions image for the part being manufactured and write the number of each listed edge directly on the blank piece of aluminum. The width and height dimensions of the blank are assumed to be the same. Therefore, the orientation of the blanks does not matter. The left and right images show the opposite sides of the same piece of aluminum. The images share the common edge between them, with the piece of aluminum being flipped over like turning the page of a book. For example, the Top Face edge descriptions image illustrates that edge #6 (on side A) and edge #2 (on side B) are the same edges. As the respective milling operations are performed, the written edge numbers will be removed. It is important to keep track of which edge is which throughout the milling operations. It is recommended to either rewrite the edge numbers back onto the aluminum after the milling operation is complete or use pieces of tape with the edge numbers written on them. The tape must be removed before a milling operation is started and replaced after the operation is complete.

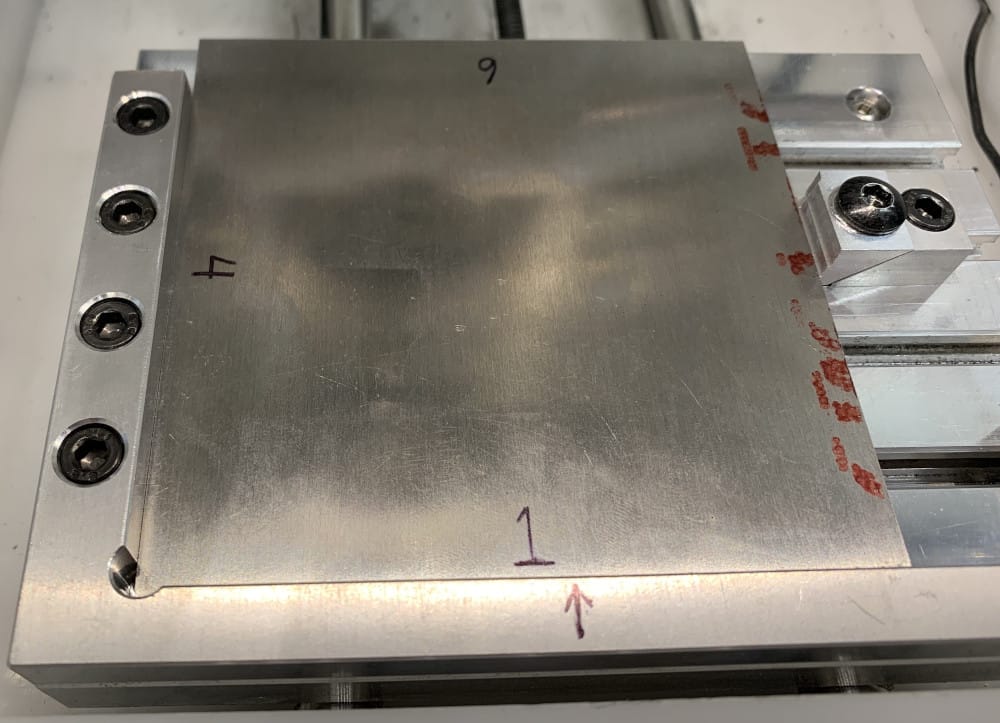

Each milling operation requires the aluminum blank to be installed into the Bantam Tools Machine in a particular way. All aluminum milling operations require the aluminum blanks to be installed tight against the left corner of the fixturing bracket. The part tables below, indicate how the aluminum blank must be installed via the Install @ column under the milling operations section. The number listed indicates which edge of the aluminum blank needs to be positioned against the fixturing bracket’s long side (left/right direction). The edge number needs to be facing upwards and, therefore, readable after the aluminum blank is installed in the machine. Figure 4.2-2 illustrates an aluminum blank installed at edge #1.

Attention

If using the efficient approach discussed below, the reader must pay close attention to ensuring the edge numbers for each aluminum blank are maintained throughout the milling operations.

The most efficient approach to milling the aluminum parts is to configure the Bantam Tools Machine using the 1st setup and execute milling operations 1-4 for the respective Face parts and Bracket Blanks, as listed below (totaling eight separate pieces). The milling operations 1-4 will cut the aluminum pieces into the correct X and Y dimensions. Next, configure the Bantam Tools Machine using the 2nd setup and execute milling operations 5-6 on the previous eight respective aluminum pieces. Milling operations 5-6 will plane the aluminum pieces into the correct Z dimensions (i.e., thicknesses). Then, reset the Bantam Tools machine using the 1st setup and execute the remaining milling operations for the six respective Face parts. Lastly, configure the Bantam Tools Machine using the 3rd setup and complete the milling operations for all the Bracket parts, as listed below. An additional benefit to this approach is that after completion of the aluminum parts milling, the Bantam Tools Machine will already be configured into the 3rd setup and therefore, ready to begin with the PCB milling steps.

Danger

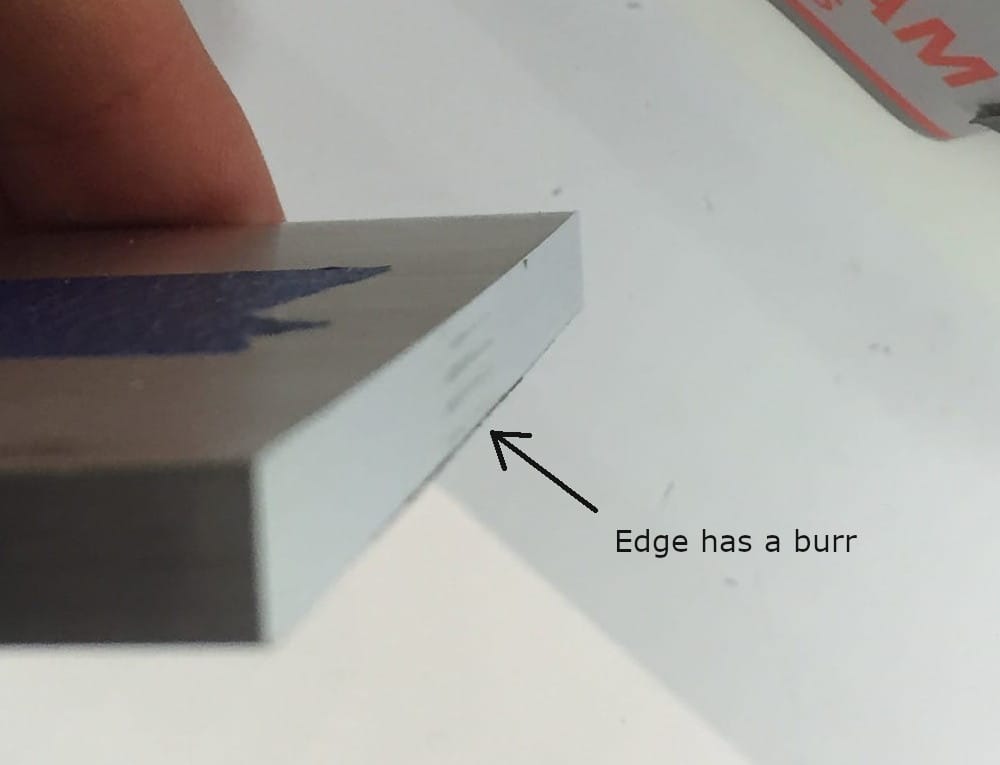

After each milling operation has finished, it is recommended to examine the area(s) on the aluminum that was milled to see if any unwanted material remains (e.g., burr or wire edge). BE CAREFUL WHEN EXAMINING THE PIECE OF ALUMINUM AS A BURR OR WIRE EDGE CAN BE VERY SHARP AND EASILY CUT SKIN. WEARING PROTECTIVE WORK GLOVES WHEN MILLING ALUMINUM IS RECOMMENDED! If a burr or wire edge exists, it can be easily removed using a metal file or possibly even a coarse plastic or brass brush. Figure 4.2-3 illustrates a milled aluminum edge that contains small, but very sharp, burrs.

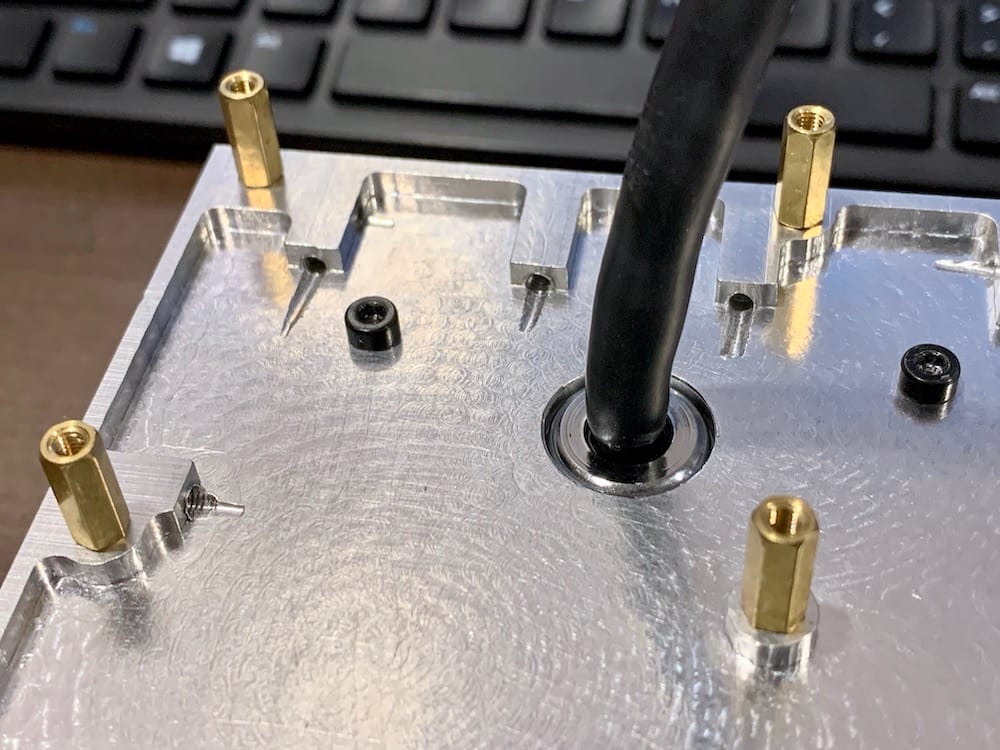

4.3. Top Face¶

Table H1: Top Face Design and Manufacturing Files

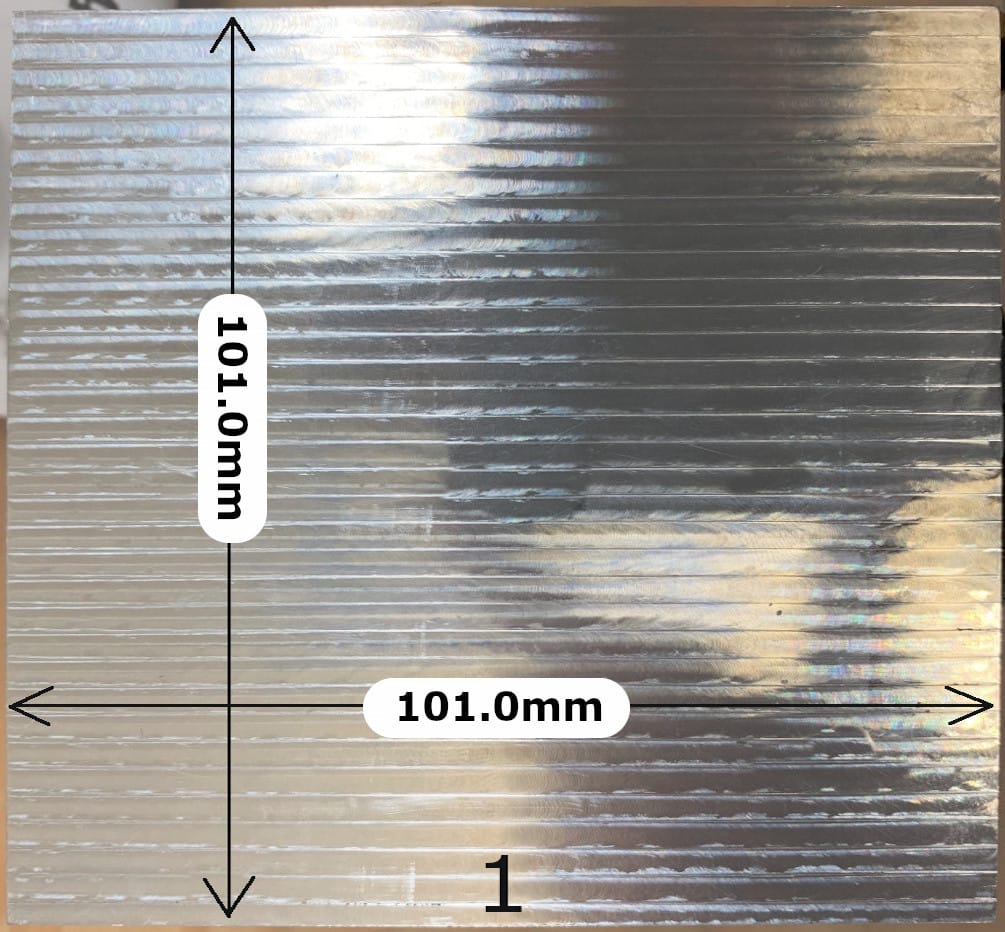

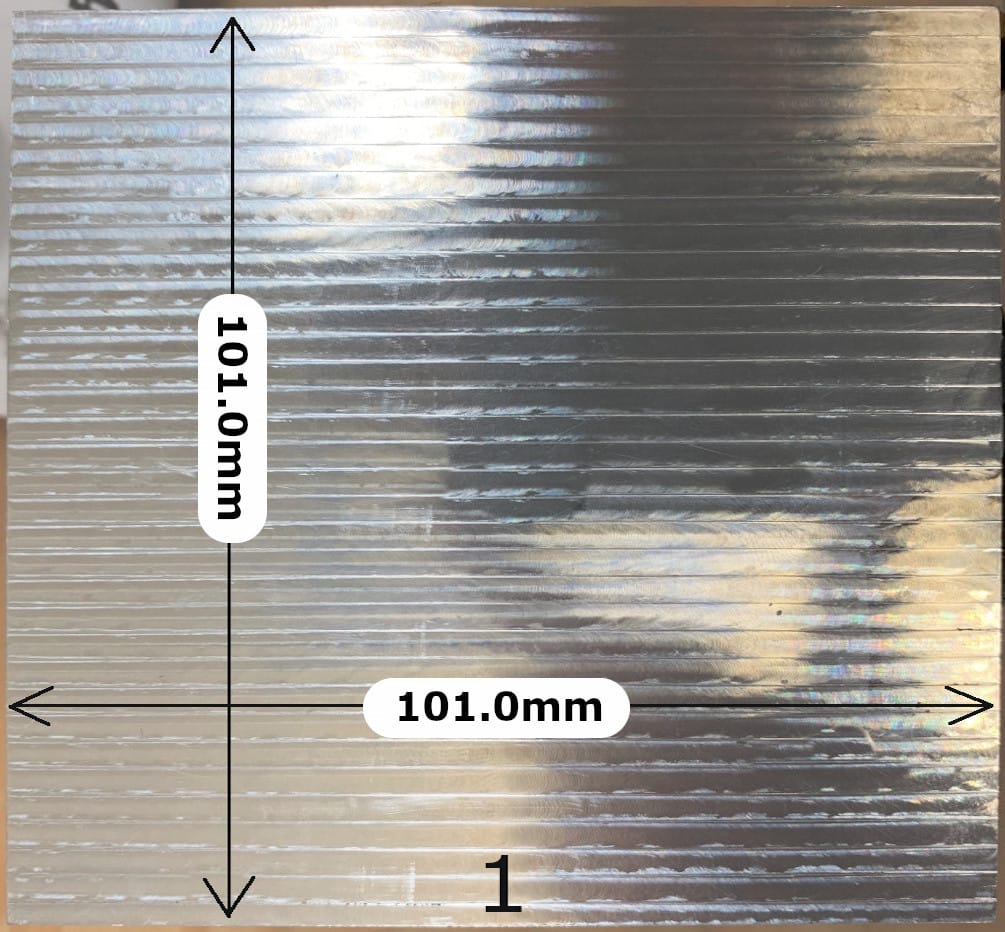

Fig 4.3-1. Top Face - Edge Descriptions¶

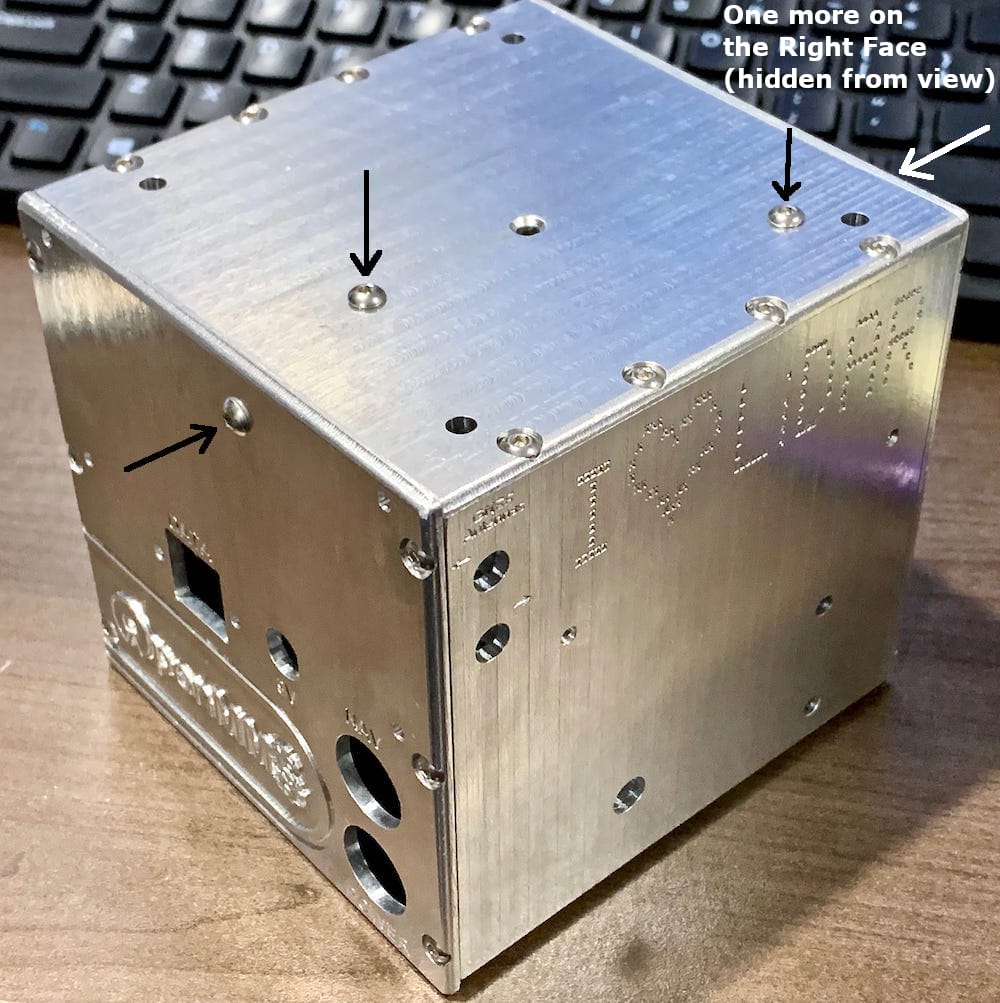

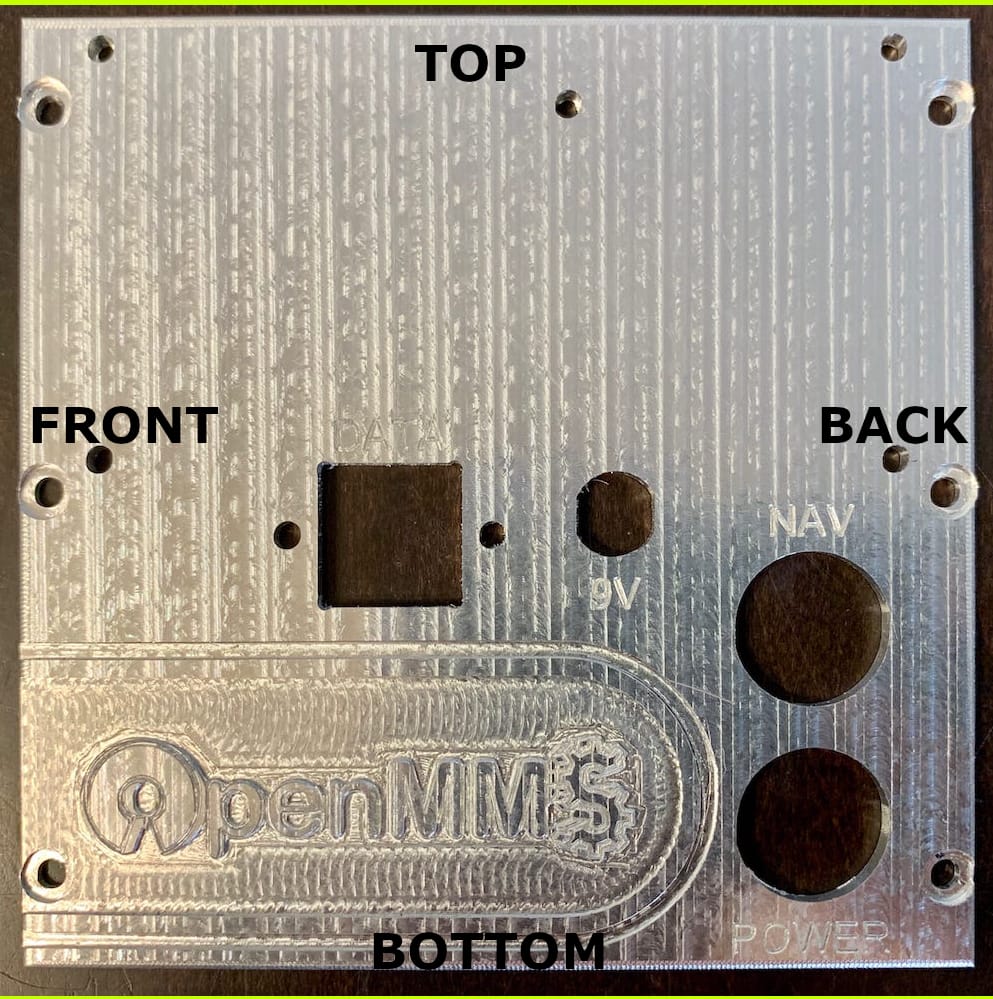

Fig 4.3-2. Completed Top Face¶

Version: 1.3

Quantity: 1

Material:

1/8” thick 6061 Aluminum

End Mills Required:

Raw Dimensions:

102.3mm x 102.3mm x 3.1mm (approx.)

1/8” Flat End Mill (8F)

1/8” Round End Mill (8R)

1/16” Flat End Mill (16F)

1/16” Round End Mill (16R)

Final Dimensions:

101.0mm x 101.0mm x 2.7mm

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE File:

Bantam Tools Software Configuration

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Cut

Cut

Cut

Cut

Plane

Plane

Smooth

Smooth

Holes

Holes

Smooth

Holes

Holes

Notches

Notches

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

2

3

4

1

2

3

5

5

3

5

5

5

1

6

8F

8F

8F

8F

8F

8F

8R

8R

16F

16F

16R

16F

8F

8F

8F

SAME AS PREVIOUS

SAME AS PREVIOUS

4.4. Bottom Face¶

Table H2: Bottom Face Design and Manufacturing Files

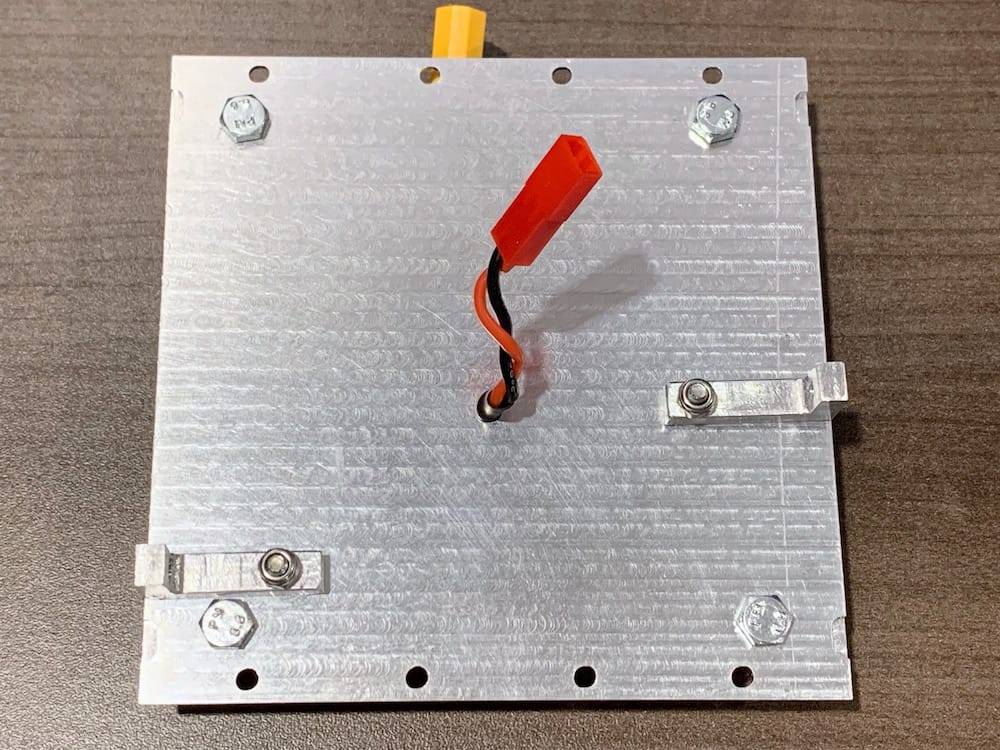

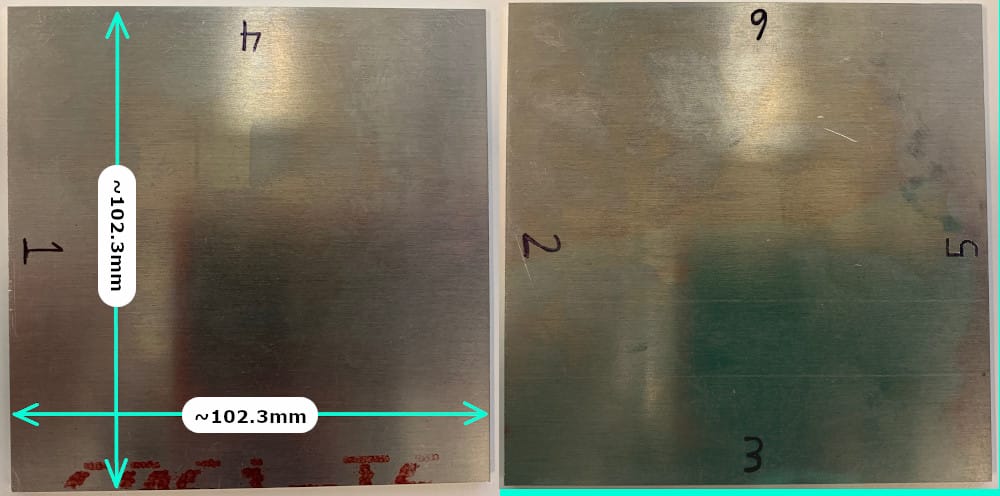

Fig 4.4-1. Bottom Face - Edge Descriptions¶

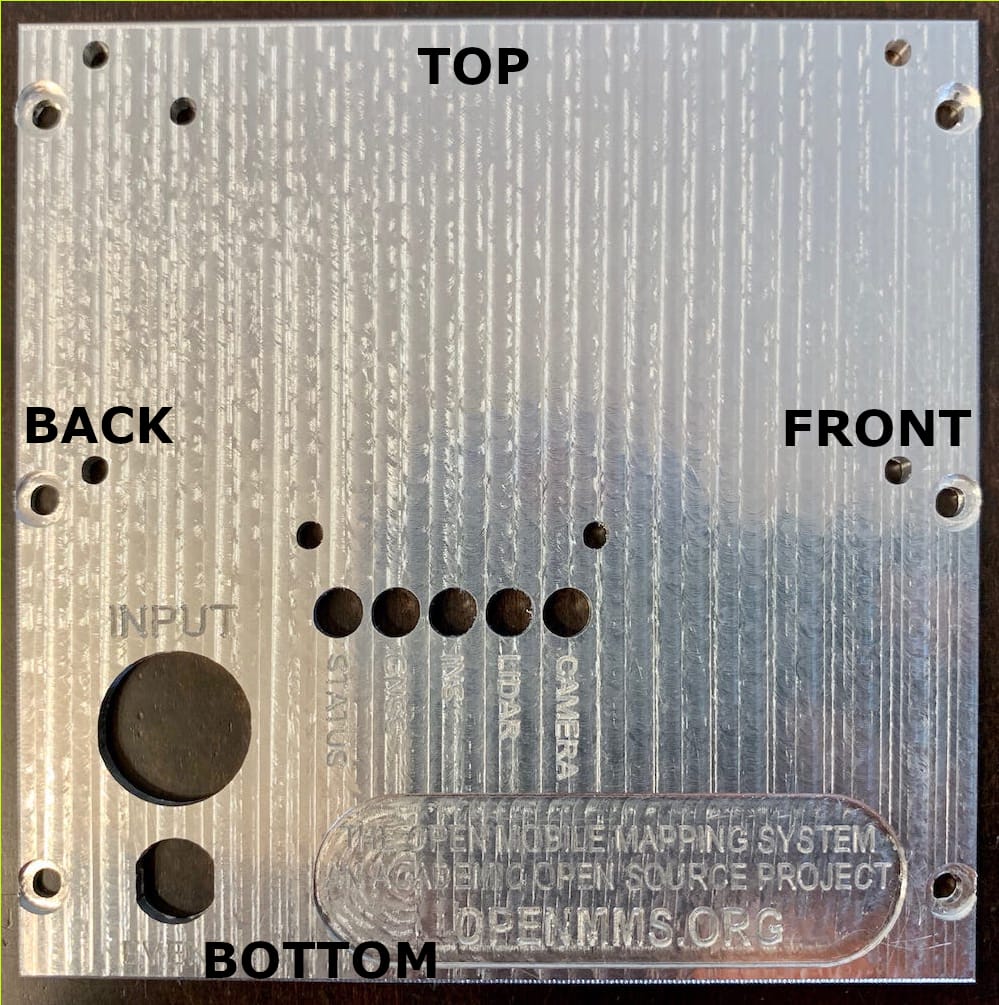

Fig 4.4-2. Completed Bottom Face¶

Version: 1.3

Quantity: 1

Material:

1/8” thick 6061 Aluminum

End Mills Required:

Raw Dimensions:

102.3mm x 102.3mm x 3.1mm (approx.)

1/8” Flat End Mill (8F)

1/8” Round End Mill (8R)

1/16” Flat End Mill (16F)

Final Dimensions:

101.0mm x 101.0mm x 2.7mm

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE File:

Bantam Tools Software Configuration

1

2

3

4

5

6

7

8

9

10

11

12

Cut

Cut

Cut

Cut

Plane

Plane

Smooth

Smooth

Holes

Holes

Holes

Holes

1

1

1

1

2

2

1

1

1

1

1

1

1

2

3

4

1

2

3

5

5

3

4

4

8F

8F

8F

8F

8F

8F

8R

8R

16F

16F

8F

16F

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

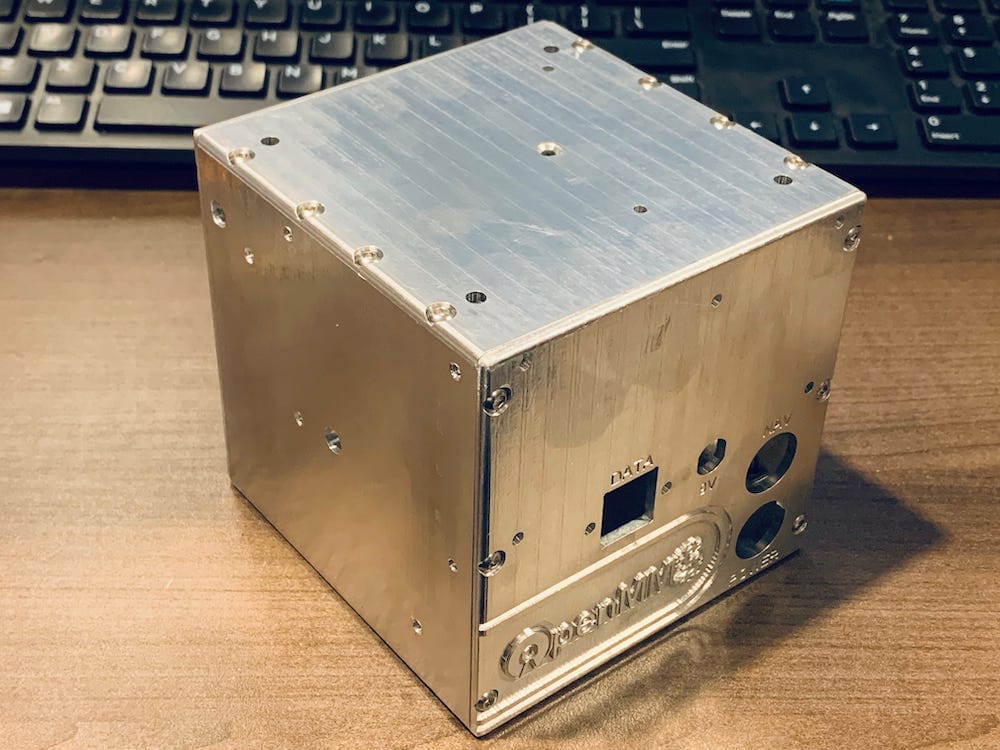

4.5. Left Face¶

Table H3: Left Face Design and Manufacturing Files

Fig 4.5-1. Left Face - Edge Descriptions¶

Fig 4.5-2. Completed Left Face¶

Version: 1.3

Quantity: 1

Material:

1/8” thick 6061 Aluminum

End Mills Required:

Raw Dimensions:

102.3mm x 102.3mm x 3.1mm (approx.)

1/8” Flat End Mill (8F)

1/8” Round End Mill (8R)

1/16” Flat End Mill (16F)

1/32” Flat End Mill (32F)

Metal Engraving Bit (ME)

Final Dimensions:

101.0mm x 101.0mm x 2.7mm

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE File:

Bantam Tools Software Configuration

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Cut

Cut

Cut

Cut

Plane

Plane

Smooth

Smooth

Smooth

Smooth

Holes

Holes

Holes

Holes

Logo

Engrave

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

2

3

4

1

2

2

3

5

6

6

3

3

3

3

3

8F

8F

8F

8F

8F

8F

8R

8R

8R

8R

16F

16F

8F

16F

32F

ME

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

4.6. Right Face¶

Table H4: Right Face Design and Manufacturing Files

Fig 4.6-1. Right Face - Edge Descriptions¶

Fig 4.6-2. Completed Right Face¶

Version: 1.3

Quantity: 1

Material:

1/8” thick 6061 Aluminum

End Mills Required:

Raw Dimensions:

102.3mm x 102.3mm x 3.1mm (approx.)

1/8” Flat End Mill (8F)

1/8” Round End Mill (8R)

1/16” Flat End Mill (16F)

Metal Engraving Bit (ME)

Final Dimensions:

101.0mm x 101.0mm x 2.7mm

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE File:

Bantam Tools Software Configuration

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Cut

Cut

Cut

Cut

Plane

Plane

Smooth

Smooth

Smooth

Smooth

Holes

Holes

Holes

Holes

Engrave

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

2

3

4

1

2

2

3

5

6

6

3

3

3

3

8F

8F

8F

8F

8F

8F

8R

8R

8R

8R

16F

16F

16F

8F

ME

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

SAME AS PREVIOUS

4.7. Front Face¶

Table H5: Front Face Design and Manufacturing Files

Fig 4.7-1. Front Face - Edge Descriptions¶

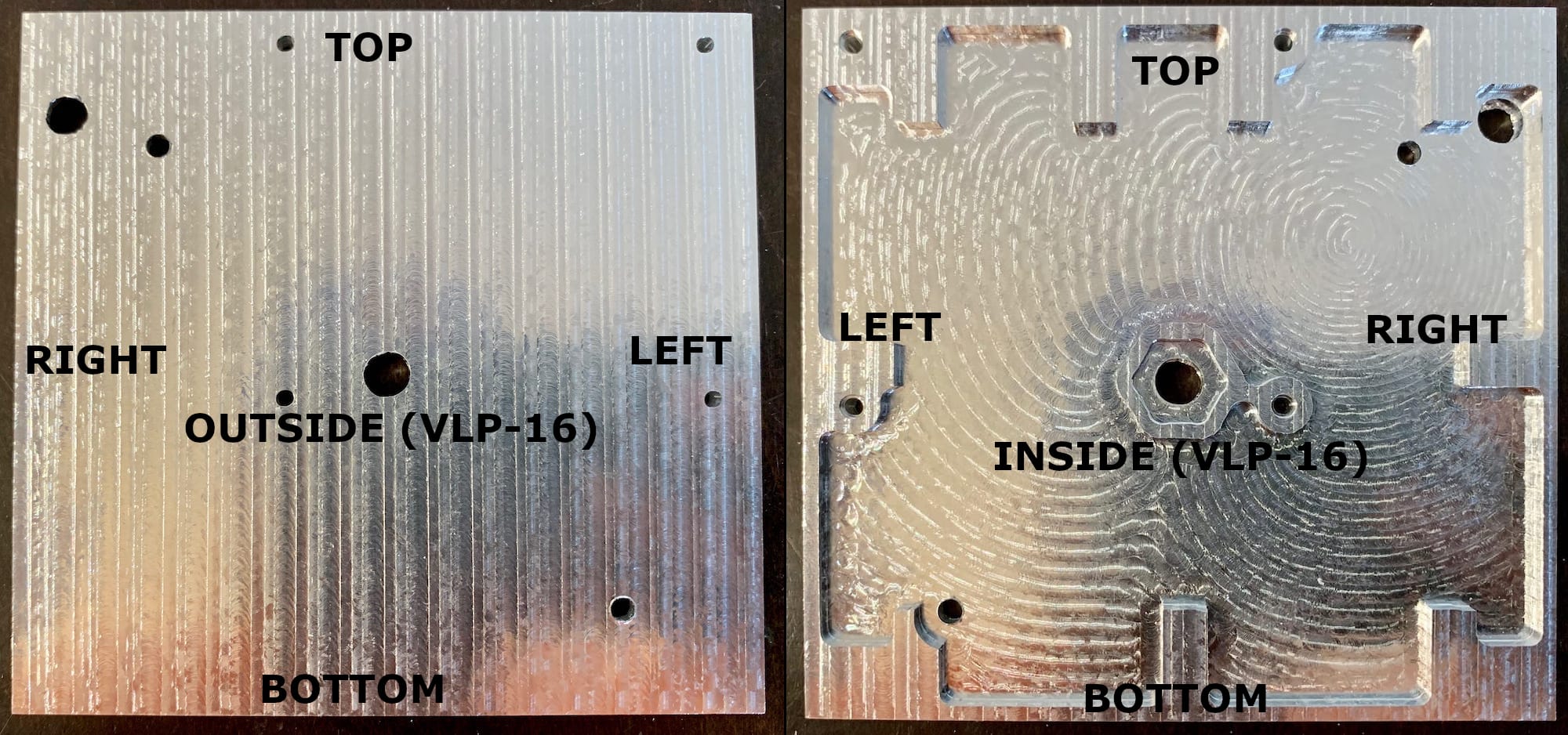

Fig 4.7-2. Completed Front Face (VLP-16) *¶

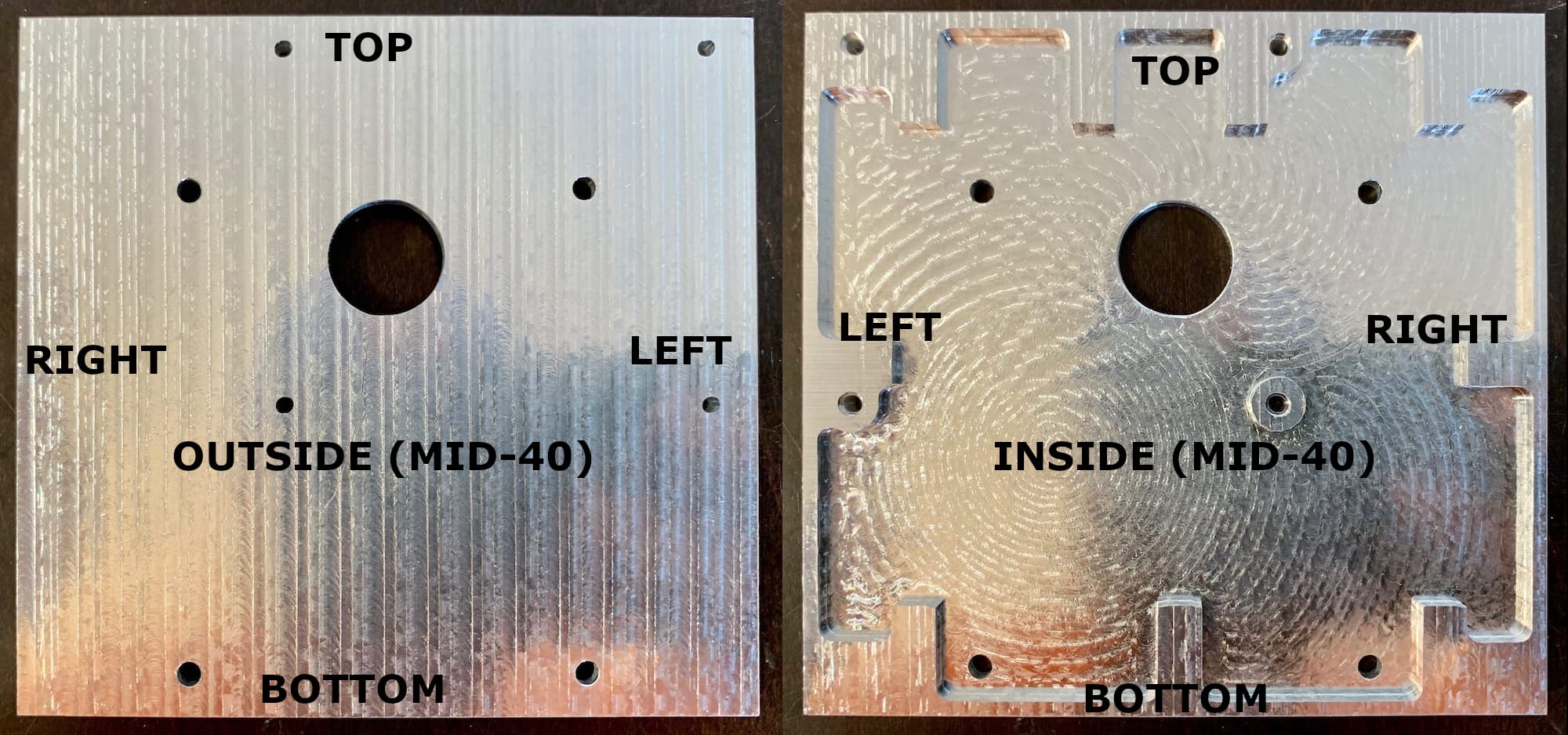

Fig 4.7-3. Completed Front Face (MID-40) **¶

Version: 1.3

Quantity: 1

Material:

1/4” thick 6061 Aluminum

End Mills Required:

Raw Dimensions:

102.3mm x 102.3mm x 6.4mm (approx.)

1/8” Flat End Mill (8F)

1/16” Flat End Mill (16F)

Final Dimensions:

101.0mm x 95.6mm x 5.8mm

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE File:

Bantam Tools Software Configuration

1

2

3

4

5

6

7*

8*

7**

8**

9

Cut

Cut

Cut

Cut

Plane

Plane

Holes

Holes

Holes

Holes

Holes

1

1

1

1

2

2

1

1

1

1

1

1

2

3

4

4

3

4

4

4

4

4

8F

8F

8F

8F

8F

8F

8F

8F

8F

8F

16F

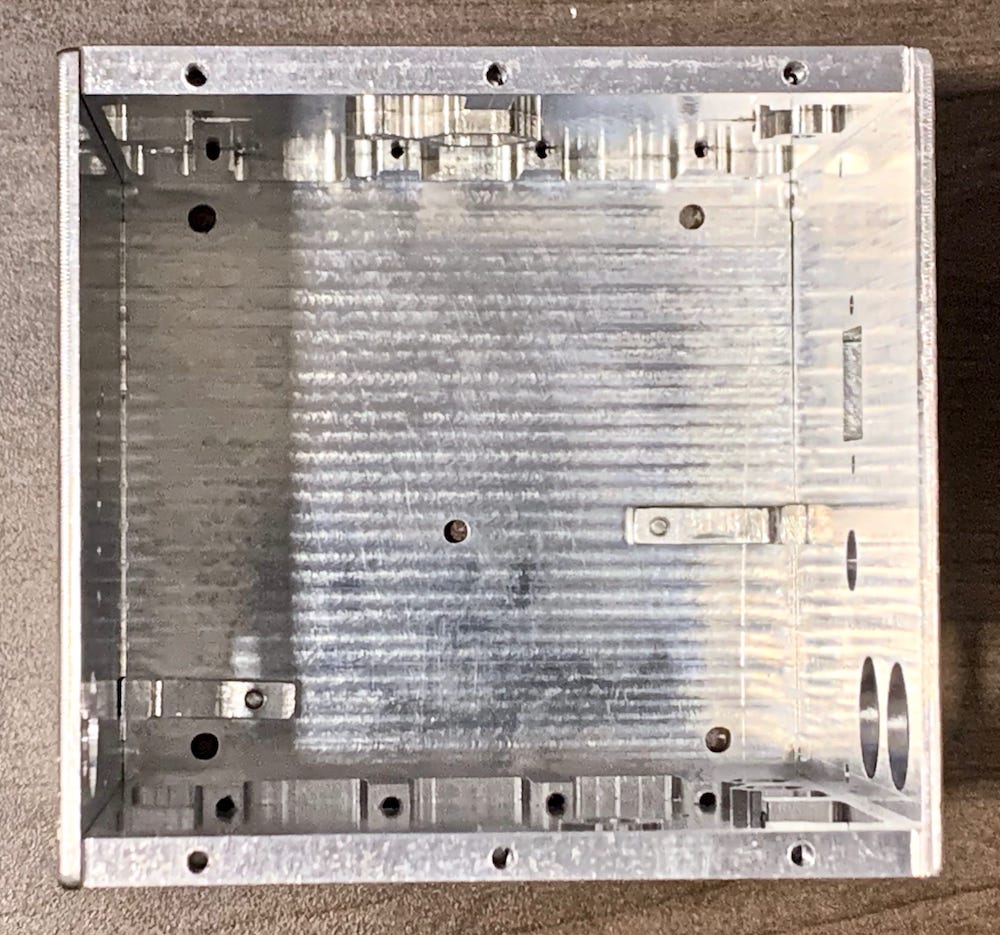

4.8. Back Face¶

Table H6: Back Face Design and Manufacturing Files

Fig 4.8-1. Back Face - Edge Descriptions¶

Fig 4.8-2. Completed Back Face¶

Version: 1.3

Quantity: 1

Material:

1/4” thick 6061 Aluminum

End Mills Required:

Raw Dimensions:

102.3mm x 102.3mm x 6.4mm (approx.)

1/8” Flat End Mill (8F)

1/16” Flat End Mill (16F)

Metal Engraving Bit (ME)

Final Dimensions:

101.0mm x 95.6mm x 5.8mm

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE File:

Bantam Tools Software Configuration

1

2

3

4

5

6

7

8

9

10

Cut

Cut

Cut

Cut

Plane

Plane

Holes

Holes

Holes

Engrave

1

1

1

1

2

2

1

1

1

1

1

2

3

4

4

3

4

4

4

5

8F

8F

8F

8F

8F

8F

8F

8F

16F

ME

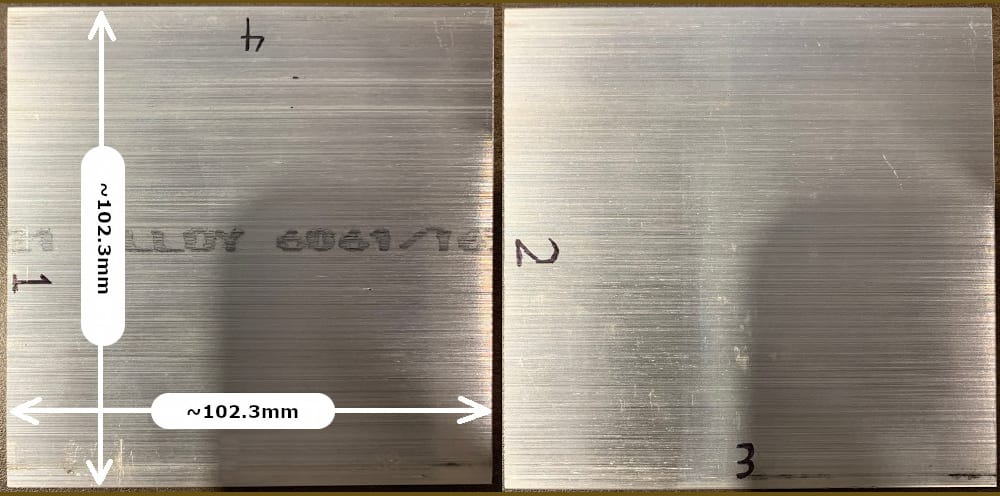

4.9. Bracket Blanks¶

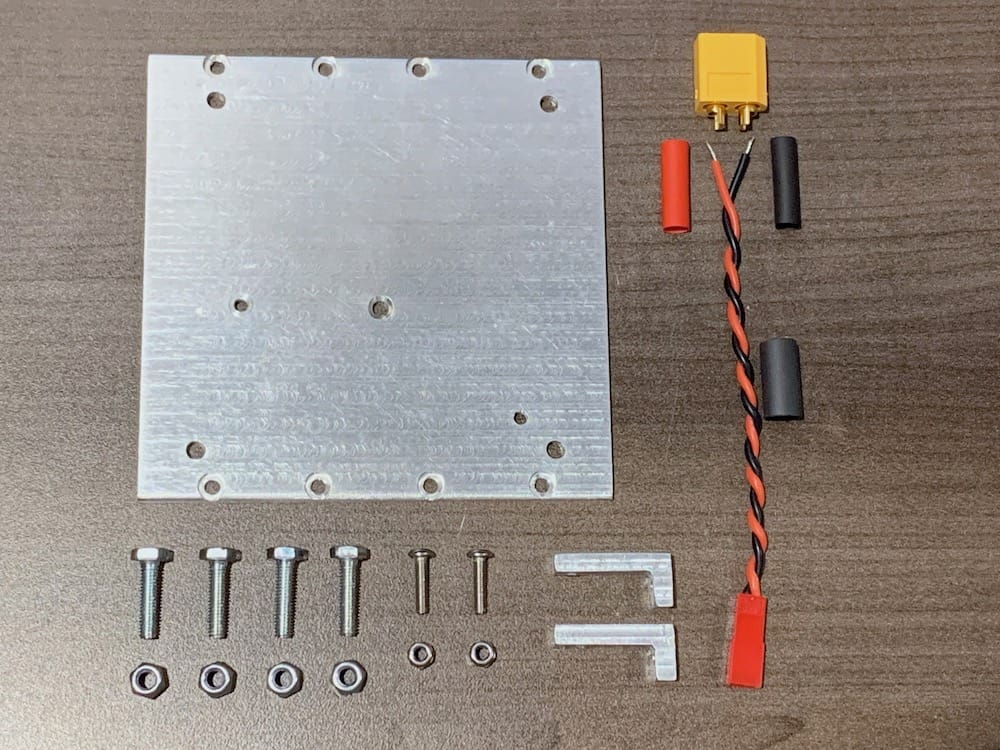

The remaining seven aluminum parts (all a type of support bracket) are manufactured out of 1/4” thick 6061 aluminum. An additional TWO aluminum blanks milled so they have the same final dimensions as the front and back parts, are needed to have enough aluminum material to mill the support brackets.

On the 1st bracket blank, the Sony bracket, both reinforcement brackets, and the first of the four GNSS brackets can be milled. Here is the brackets layout for the 1st blank. On the 2nd bracket blank, the remaining three GNSS brackets can be milled; here is the brackets layout for the 2nd blank.

Table H7: Bracket Blank Design and Manufacturing Files

Fig 4.9-1. Bracket Blank - Edge Descriptions¶

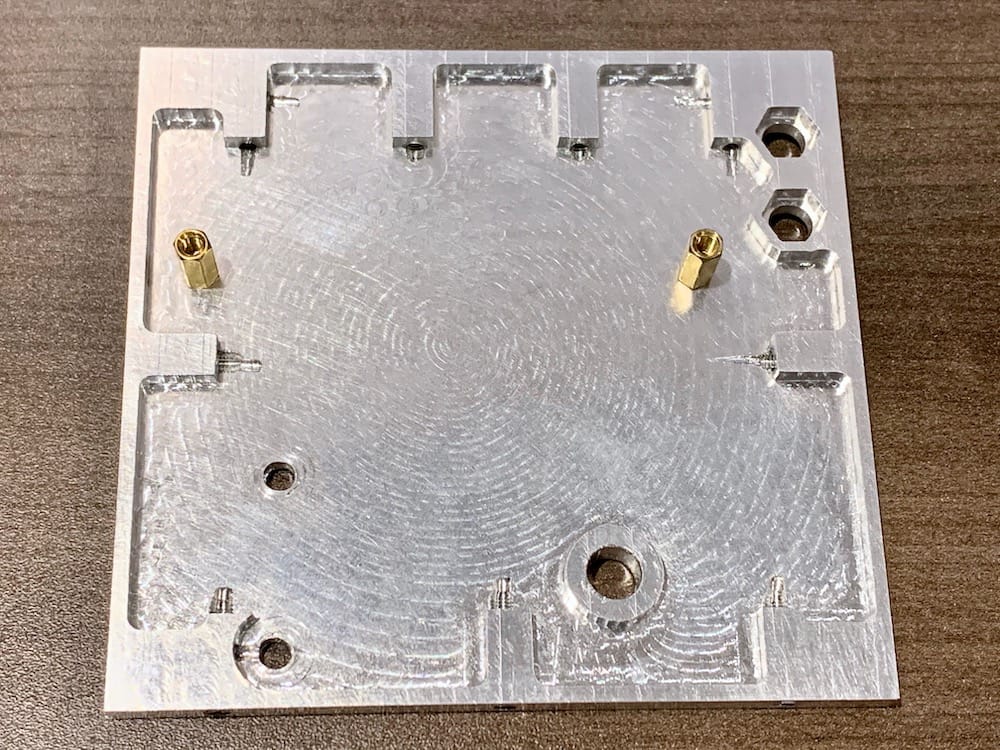

Fig 4.9-2. Completed Bracket Blank¶

Version: 1.3

Quantity: 2

Material:

1/4” thick 6061 Aluminum

End Mills Required:

Raw Dimensions:

102.3mm x 102.3mm x 6.4mm (approx.)

1/8” Flat End Mill (8F)

Final Dimensions:

101.0mm x 101.0mm x 5.8mm

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE Files:

Bantam Tools Software Configurations

1

2

3

4

5

6

Cut

Cut

Cut

Cut

Plane

Plane

1

1

1

1

2

2

1

2

3

4

4

3

8F

8F

8F

8F

8F

8F

4.10. Sony Bracket¶

Table H8: Sony Bracket Design and Manufacturing Files

Fig 4.10-1. 1/4” Blank - Edge Descriptions¶

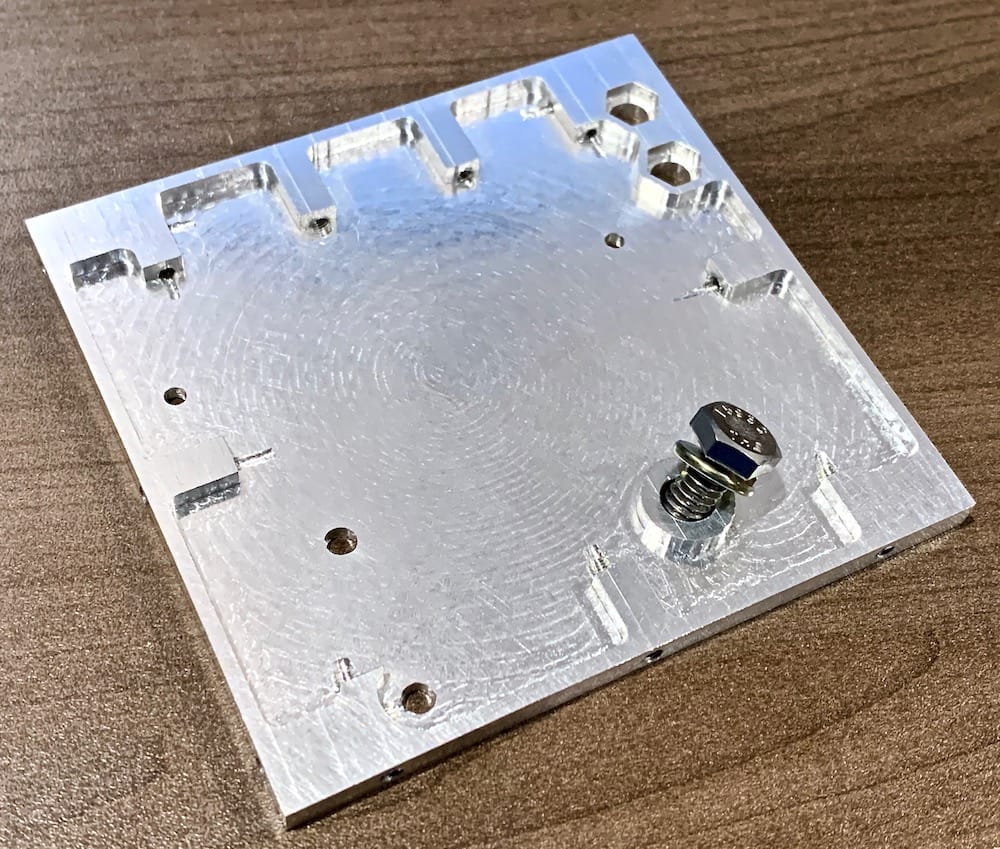

Fig 4.10-2. Completed Sony Bracket¶

Version: 1.3

Quantity: 1

Material:

1/4” thick 6061 Aluminum

End Mills Required:

Blank Dimensions:

101.0mm x 101.0mm x 5.8mm

1/8” Flat End Mill (8F)

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE Files:

Bantam Tools Software Configurations

1

Cut

3

1 on Blank 1

8F

4.11. Reinforcing Bracket¶

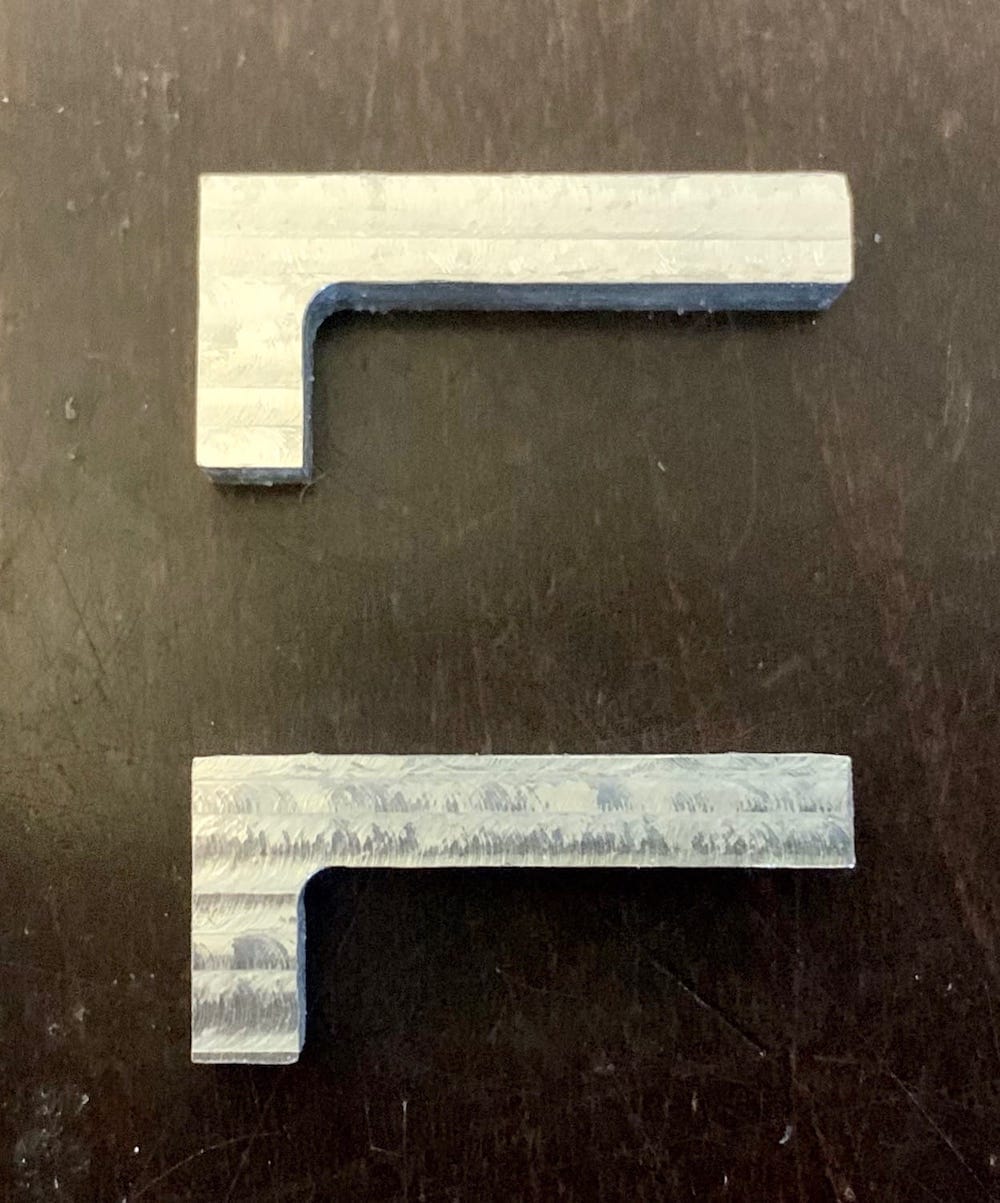

Table H9: Reinforcing Bracket Design and Manufacturing Files

Fig 4.11-1. 1/4” Blank - Edge Descriptions¶

Fig 4-11.2. Completed Reinforcing Brackets¶

Version: 1.3

Quantity: 2

Material:

1/4” thick 6061 Aluminum

End Mills Required:

Blank Dimensions:

101.0mm x 101.0mm x 5.8mm

1/8” Flat End Mill (8F)

Fusion 360 File(s):

See Sony_Bracket_Design.zip

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE Files:

Bantam Tools Software Configurations

1

2

Cut

Cut

3

3

1 on Blank 1

1 on Blank 1

8F

8F

4.12. GNSS Antenna Bracket¶

Attention

Pay close attention to the information displayed in the Bantam Tools Software Configurations image for each of the GNSS brackets. Each bracket is positioned on the respective 1/4” aluminum bracket blank to optimize the usable aluminum. The position of each GNSS bracket on the aluminum blanks is defined by the Placement settings for each GCODE file in the Bantam Tools Machine Software (not to be confused with the Material Placement settings).

Table H10: GNSS Antenna Bracket Design and Manufacturing Files

Fig 4.12-1. 1/4” Blank - Edge Descriptions¶

Fig 4-12.2. Completed GNSS Bracket¶

Version: 1.3

Quantity: 4

Material:

1/4” thick 6061 Aluminum

End Mills Required:

Blank Dimensions:

101.0mm x 101.0mm x 5.8mm (x2)

1/8” Flat End Mill (8F)

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE Files:

Bantam Tools Software Configurations

1

2

3

4

Cut

Cut

Cut

Cut

3

3

3

3

1 on Blank 1

1 on Blank 2

1 on Blank 2

1 on Blank 2

8F

8F

8F

8F

SAME AS PREVIOUS

SAME AS PREVIOUS

4.13. After Milling¶

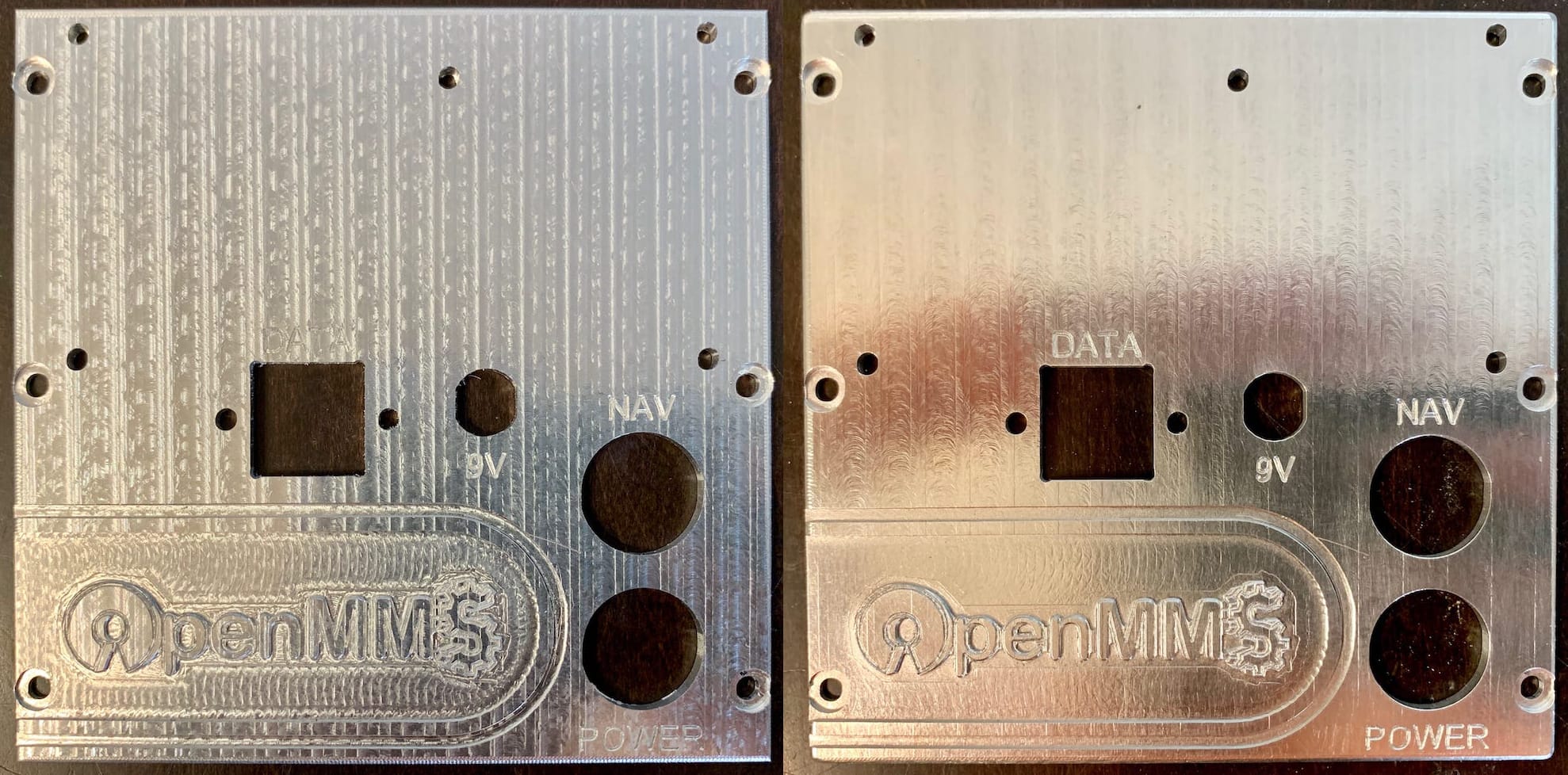

It is recommended to use a metal file to gently round/break the sharp 90 degree edges of the manufactured parts after being milled by the Bantam Tools Machine. During assembly, many tight-fitting connections need to be made within the case. By having ‘softer’ aluminum edges, your hands will thank you. It is also recommended to scour all surfaces of the manufactured parts thoroughly. Scotch-Brite abrasive pads or a softer metal brush (e.g., brass) work well for this task. The goal is to remove any tiny aluminum debris/swarf from the manufactured parts. These small pieces of aluminum could cause electrical damage (i.e., create short-circuits) on the sensitive (and costly) sensors and components inside the case. Additional cleaning and finishing steps will be performed at a later stage in the manufacturing process. One last (subjective) benefit to scouring the aluminum parts is, the machining marks on the aluminum surfaces, created by the end mills, can largely be removed. As a result, the aluminum parts will have a ‘nicer’ appearance.

Fig 4.13-1. Left face before (left image) and after (right image) scouring¶

4.14. Test Fit the Case¶

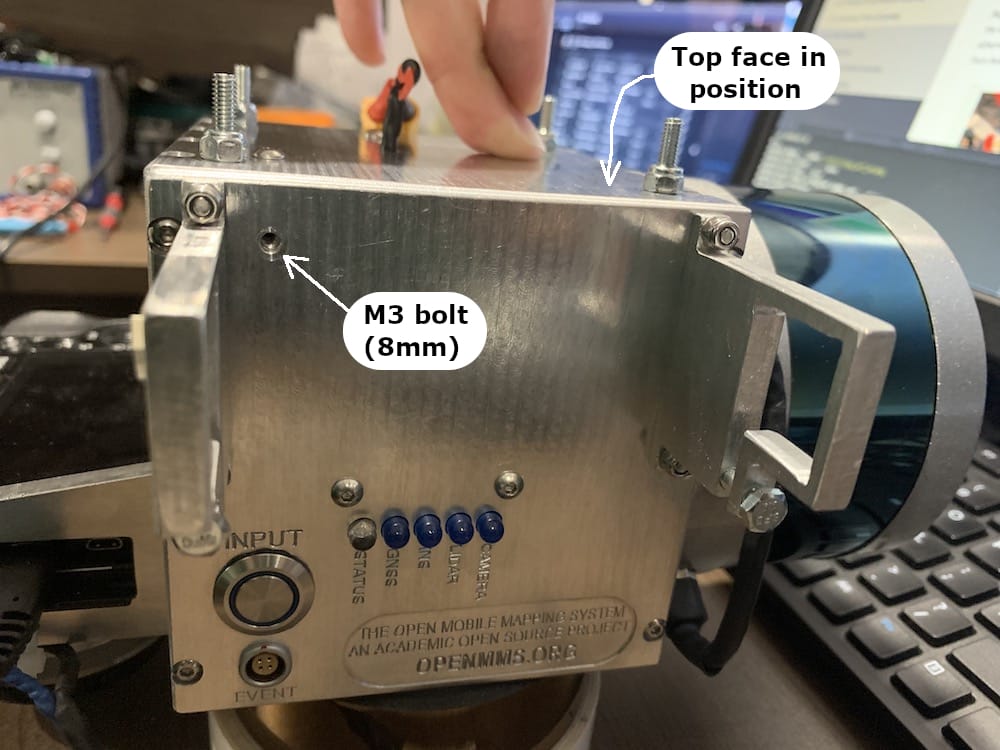

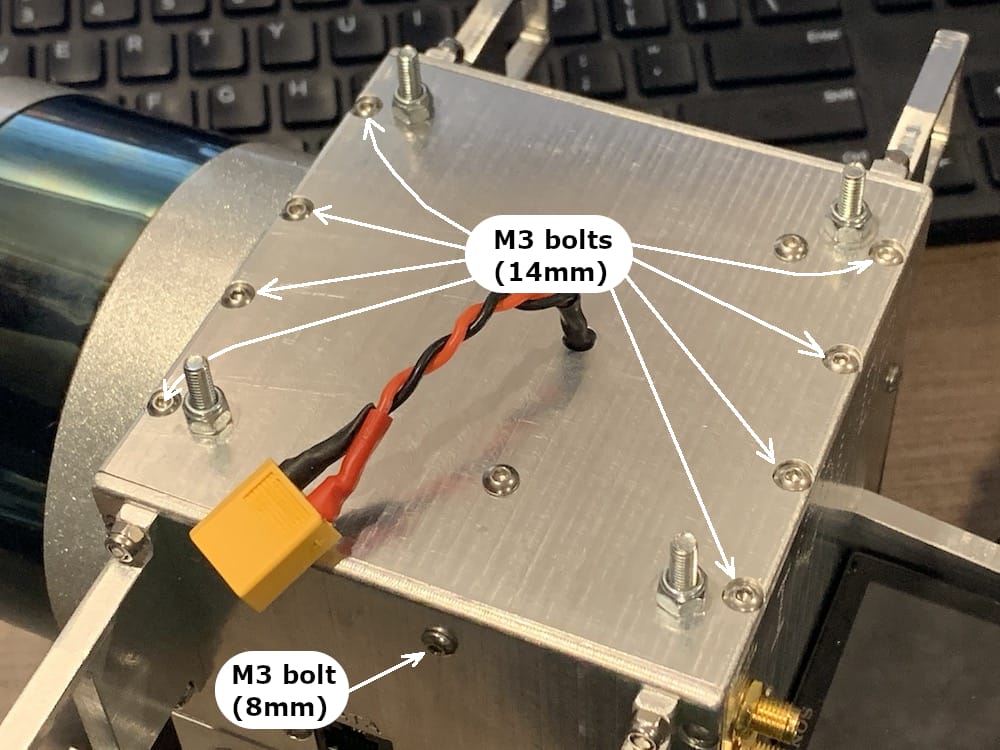

With all the aluminum parts now manufactured, the next step is to test fit the six faces of the case together. Cut thin strips of the high-strength double-sided Nitto tape and apply them to all four edge surfaces of the front and back aluminum parts. Next, align and stick the top face to the front and back faces, followed by attaching the bottom face to the front and back faces. Use the labels in the previous parts’ images to figure out how the six faces correctly go together.

Fig 4.14-1. Nitto tape on front and back faces’ edge surfaces¶

Fig 4.14-2. Top and bottom stuck to front and back¶

Lastly, stick the left and right faces to the front and back faces. You should see some small gaps between the faces due to the thickness of the Nitto tape. The left and right faces may seem slightly short from top to bottom (again, this is due to the thickness of the tape). Check for any apparent errors in each of the six faces. If needed, fix/re-manufacture any of the faces now, before proceeding.

4.15. Drilling and Tapping Holes¶

“SLOW AND STEADY IS THE NAME OF THE GAME!!!”

4.15.1. Case Holes¶

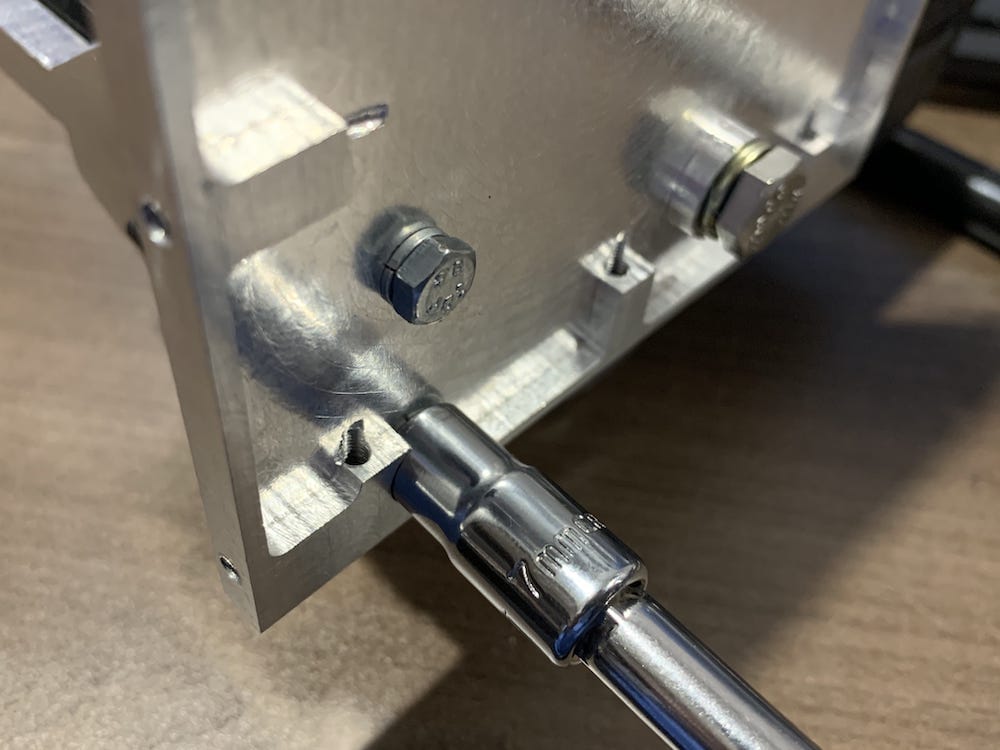

This step is the most labor-intensive part of the entire OpenMMS project! While the case is securely held together by the Nitto tape (double-check that the six case faces are exactly aligned), install the entire case on the Proxxon Compound Table underneath the Proxxon Rotary Tool (i.e., drill press). A quick clamp with the rubber pads removed works well to secure the case to the compound table. Be careful when the clamp ends are compressing the front and back faces as only the Nitto tape is securing these faces to the top, bottom, and sides. Install a 3/32” drill bit into the Rotary Tool. Adjust the drill stand, so the end of the drill bit is a few millimeters above the case. Using the adjustment dials on the compound table, precisely align the drill bit (front to back and left to right) with the first hole to be drilled. As previously mentioned, it helps to use a new, sharp drill bit when machining these holes and remove the aluminum swarf from the drill bit and from inside the hole as often as possible. It is recommended to drill entirely through the thicker aluminum sections on the front and back faces, creating a drilled ‘tunnel’ from the outside edges to the inside of the front and back faces. By doing this, the tapping process (i.e., creating threads inside the holes) is easier, as the aluminum swarf created by the tap has a means of leaving the tunnel.

Fig 4.15-1. Case under the Proxxon ‘drill press’¶

Fig 4.15-2. Quick clamp installing case on the compound table¶

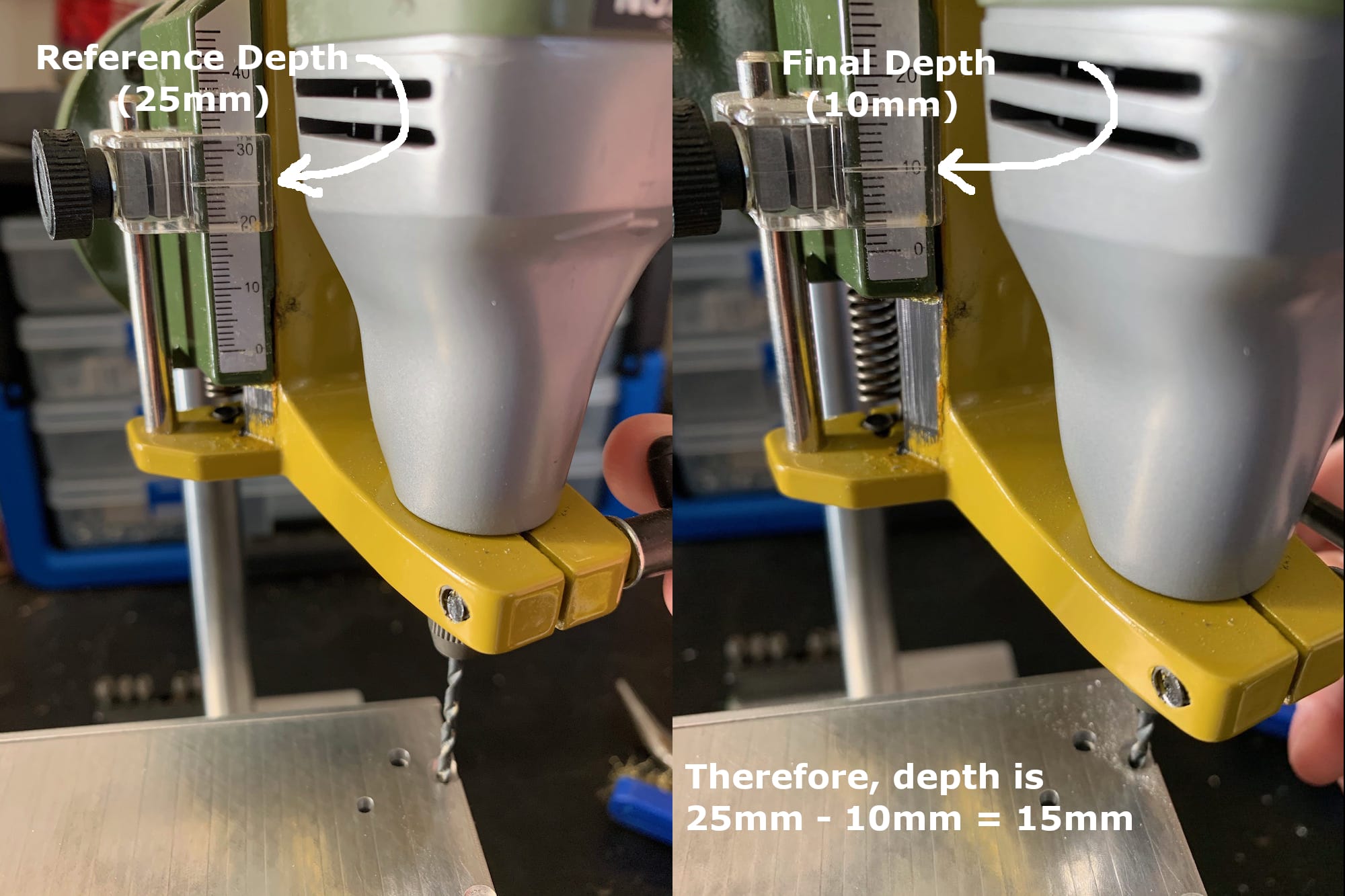

Start the drilling process by drilling the eight holes for the top face of the case. The holes need to be ~ 15mm in depth to go all the way through the thicker sections of the front and back faces. The Proxxon drill stand has a depth gauge that can be used to quickly and easily see the current drilled hole’s depth. With the Rotary tool off, plunge the drill bit until it touches the aluminum (where drilling would begin). Manually observe the depth gauge’s number. Subtracting the desired depth from this number will indicate the gauge number when the currently drilled hole’s depth has been achieved. Be careful when approaching the desired depth, as the drill bit may become jammed and potentially break.

Fig 4.15-3. Align front to back and left to right¶

Fig 4.15-4. Hole depth measurement using the gauge¶

Fig 4.15-5. Thicker sections on the front face¶

Next, drill the six holes for the bottom face of the case. The three holes in the front face need to be ~ 15mm deep, and the three holes in the back face need to be ~ 12mm deep. After drilling the six bottom holes, carefully disassemble the case and remove the Nitto tape from the four edges of the front and back faces.

It is recommended for an inexperienced person to clamp the respective aluminum face piece within a bench vise before starting the tapping process. Install a 3mm (M3) x 0.5mm pitch tap into a tap handle/wrench. In a well-ventilated area, spray a small amount of WD-40 (or similar) liquid into one of the drilled holes in the front face. Slowly and carefully align the tap with the hole’s opening, ensuring that the tap is perpendicular (in both directions) to the surface containing the drilled hole. While applying moderate pressure on the tap in the direction of the hole, begin rotating the tap handle/wrench clockwise. The most challenging part of hand tapping these holes is getting the tap started within the drilled hole. Within a few turns from the start, it should become evident if the tap is beginning to make threads within the drilled hole.

Caution

Manually tapping 3mm holes is time-consuming because the tap is very sensitive to breaking if too much rotational force is applied. It doesn’t take much force to break a 3mm tap. Once the tap feels ‘snug’ within the drilled hole, remove it and clean the swarf from its threads and from inside the drilled hole. Re-apply a small amount of WD-40 liquid in the drilled hole before beginning to deepen the tap from where you previously stopped. REMEMBER … SLOW AND STEADY!

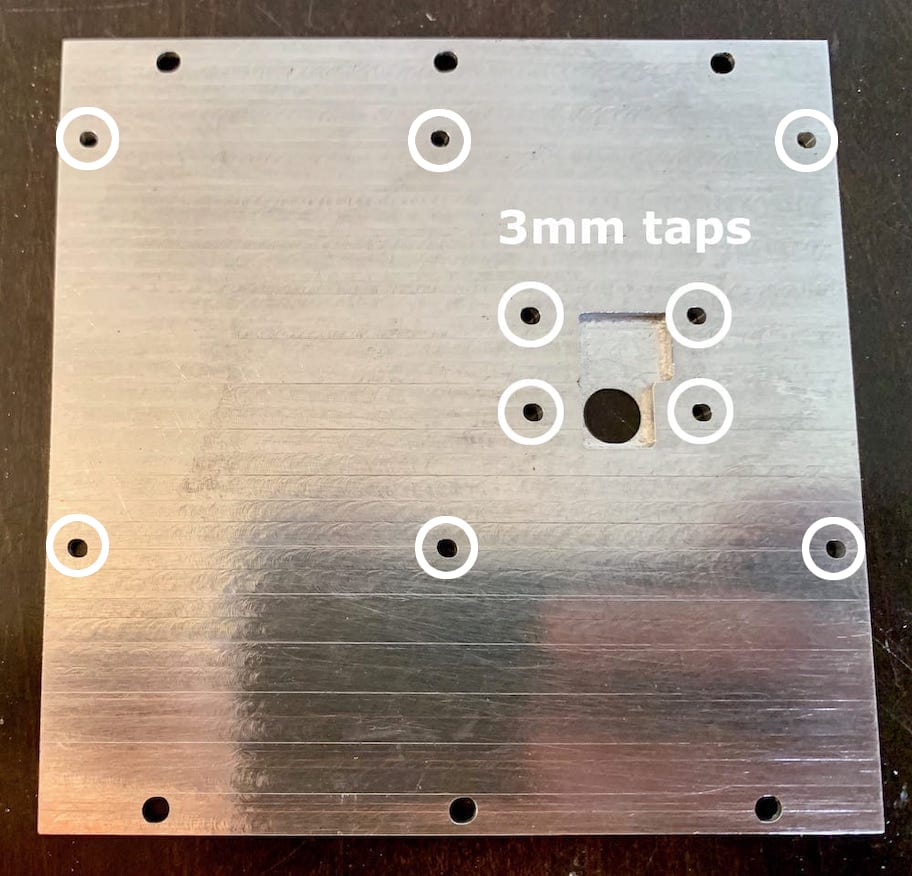

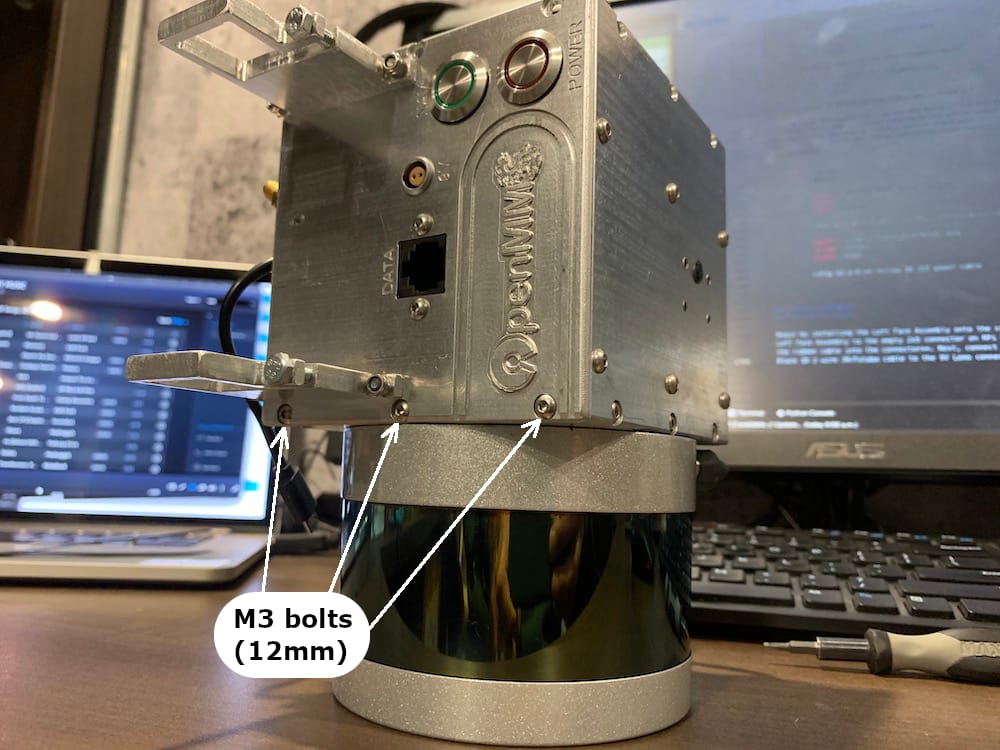

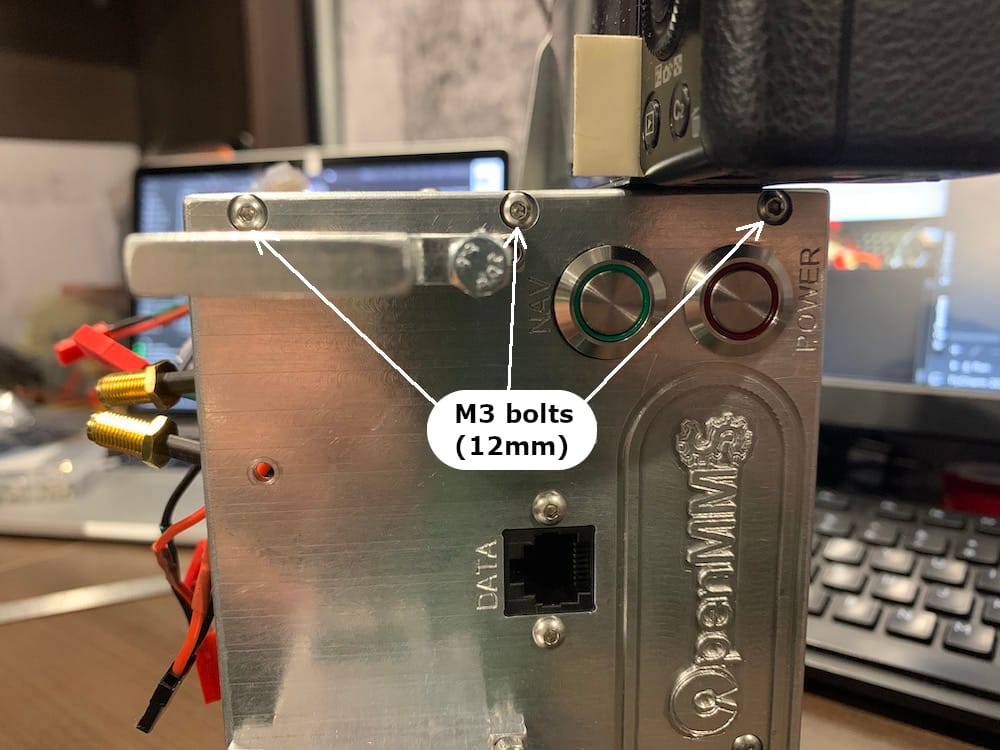

After all the holes in the top and bottom edge surfaces of the front and back aluminum faces have been drilled and tapped, the case needs to be re-assembled using 3mm bolts to attach the top and bottom faces and Nitto tape to attach the left and right faces. Once re-assembled, the six holes in the left face and the six holes in the right face can be drilled using the Proxxon rotary tool. The holes for the left and right faces need to be ~ 12mm deep. At this depth, the outermost holes (of each set of three) will not be deep enough to go through the thicker sections of the aluminum. Tapping these holes will be slightly more difficult due to the drilled holes not forming open tunnels through the aluminum faces. After the holes in the left and right faces have been drilled, the case needs to be disassembled, and the holes tapped with the same M3 x 0.5mm pitch tap. Finally, the case needs to be re-assembled one more time to check the fit of the faces. Use 3mm bolts when attaching the faces. The four corners of the left and right faces will not perfectly align with the rounded edges on the top and bottom faces. Rather than creating a new CNC process for rounding over the corners of the left and right sides, which would be rather time-consuming, the corners can be quickly rounded over using a metal file. At most, there will be a couple of millimeters that need to be filed off.

Fig 4.15-8. Top and bottom bolted, sides taped¶

Fig 4.15-9. Case assembled with 3mm bolts¶

Fig 4.15-10. Corners need to be filed round¶

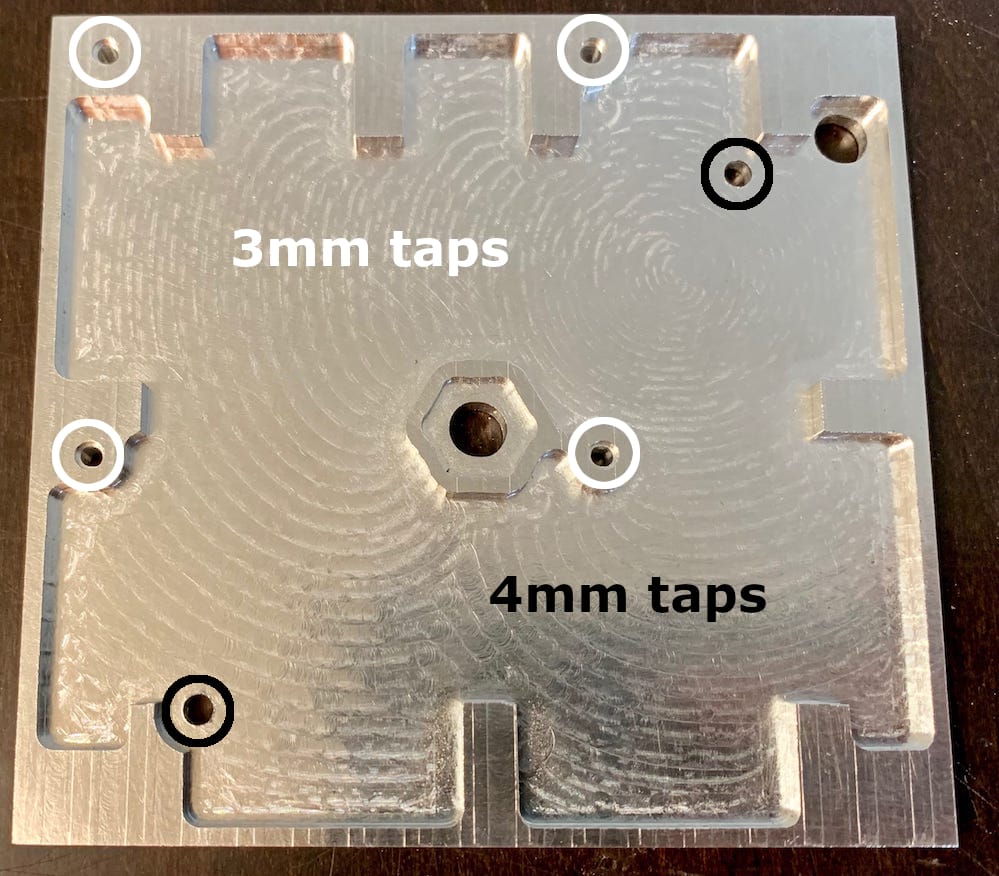

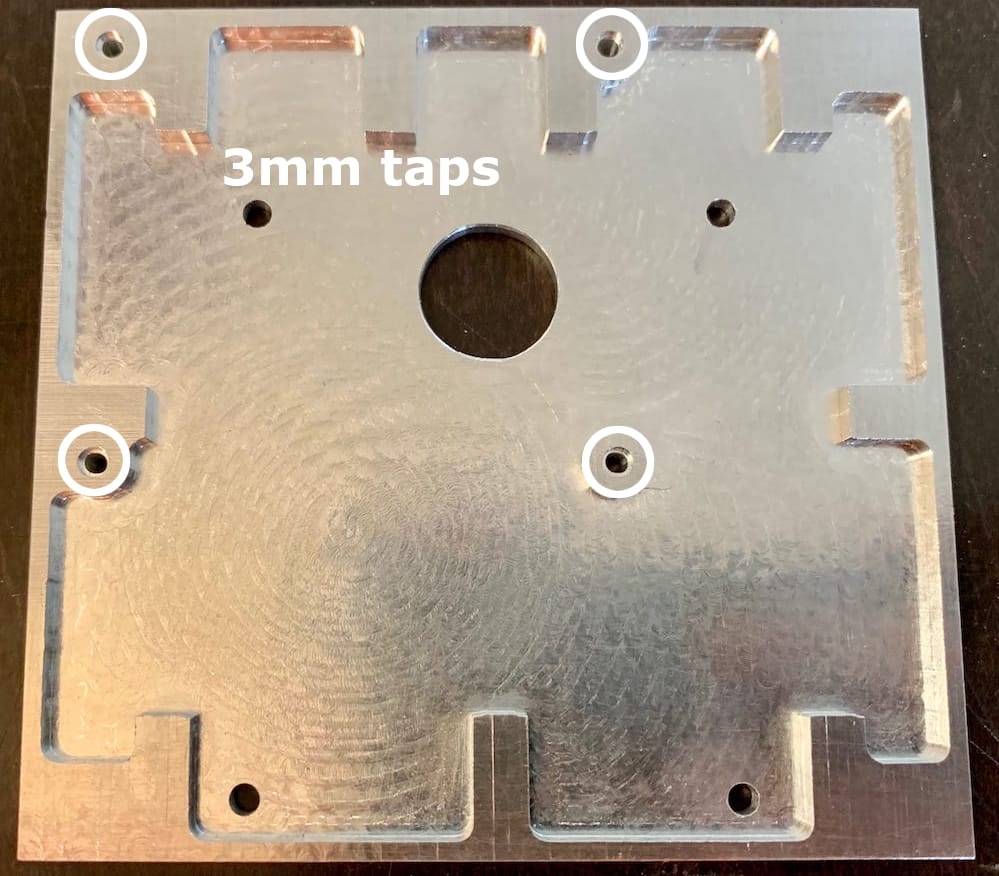

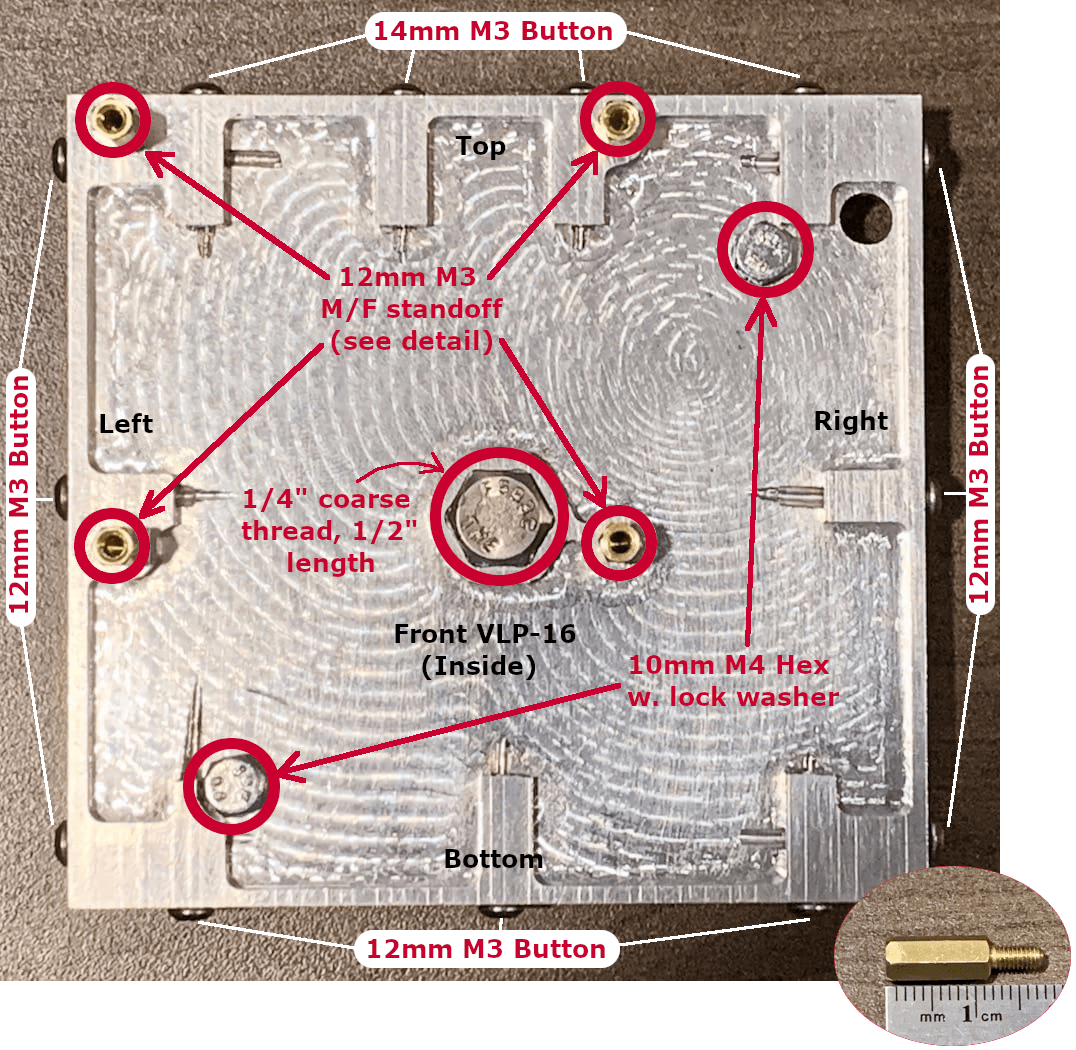

There are a few remaining holes on the front face and bottom face that require a 3mm tap. If you are using a Velodyne VLP-16 lidar sensor, and therefore manufacturing the VLP-16 specific front face, two additional holes require a 4mm tap. The figures below illustrate which holes need to be tapped.

4.15.2. GNSS Antenna Bracket Holes¶

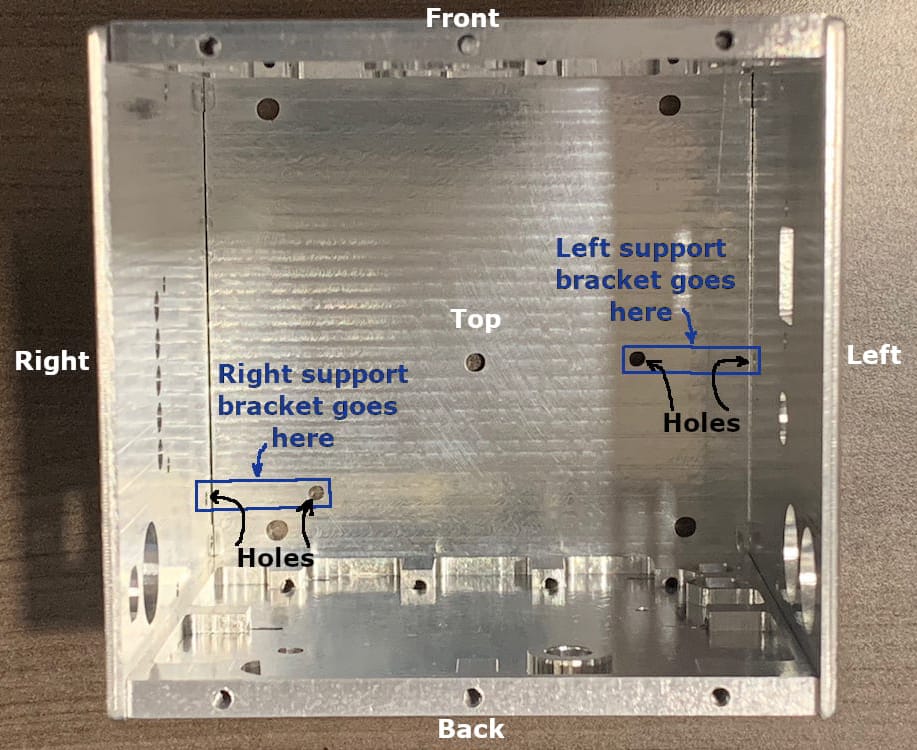

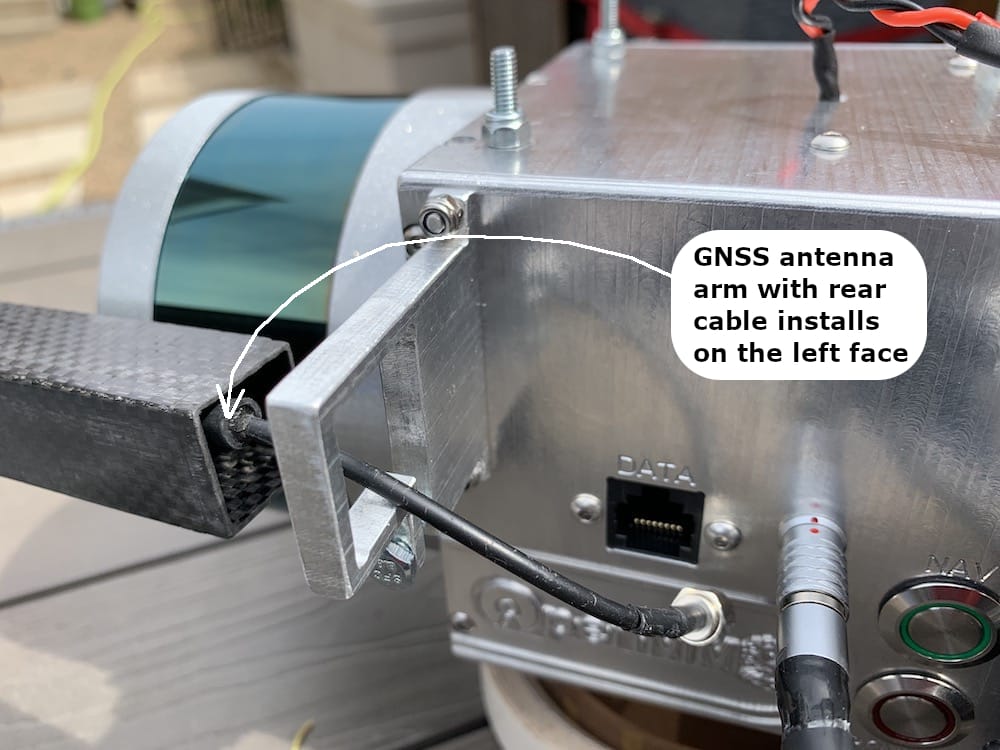

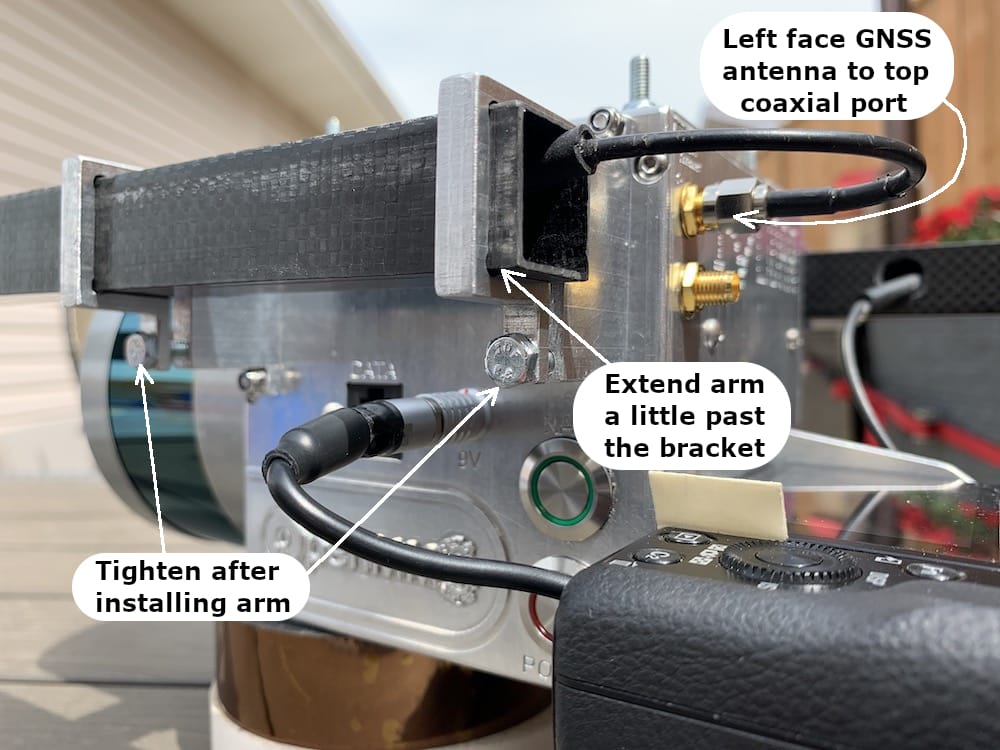

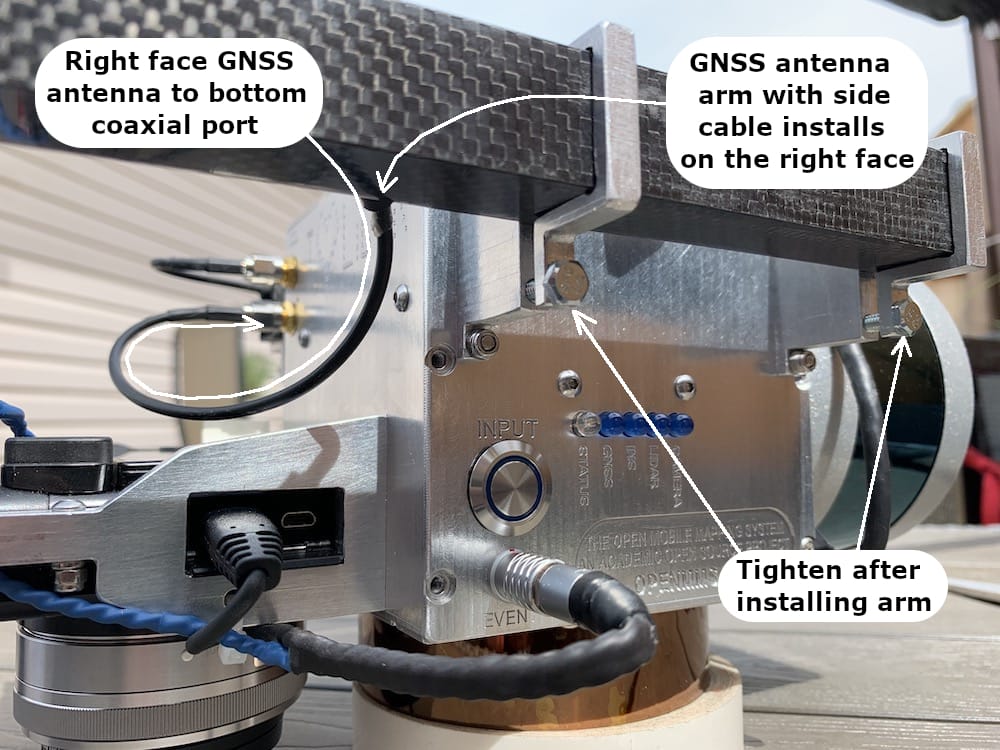

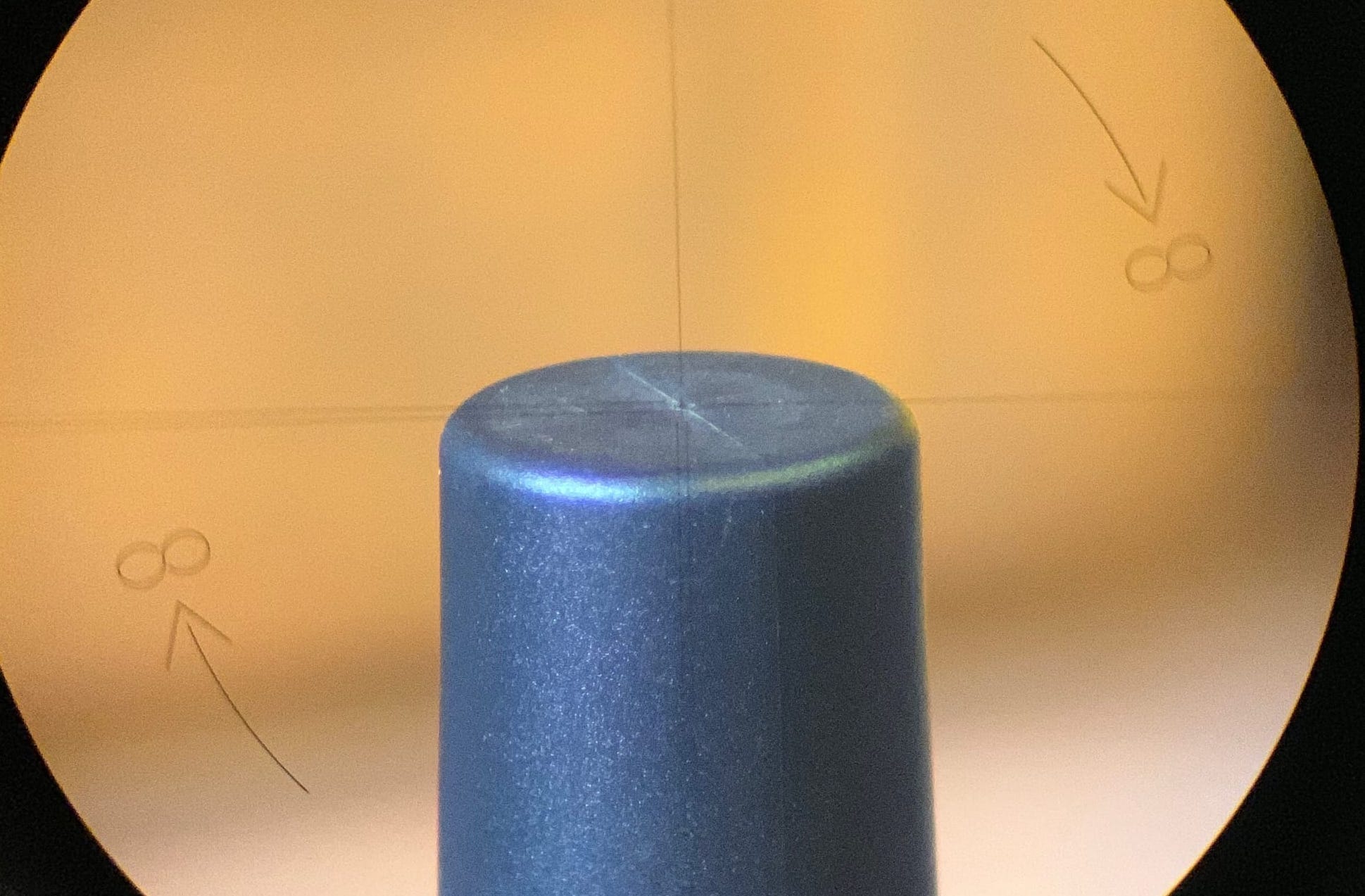

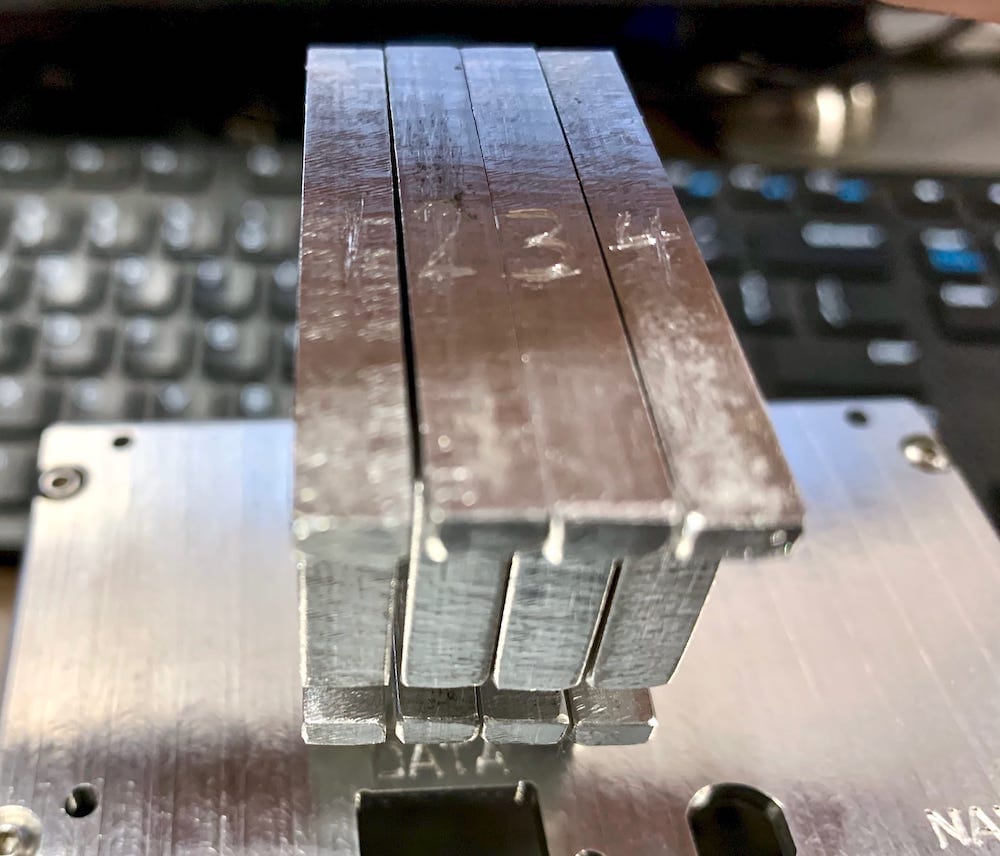

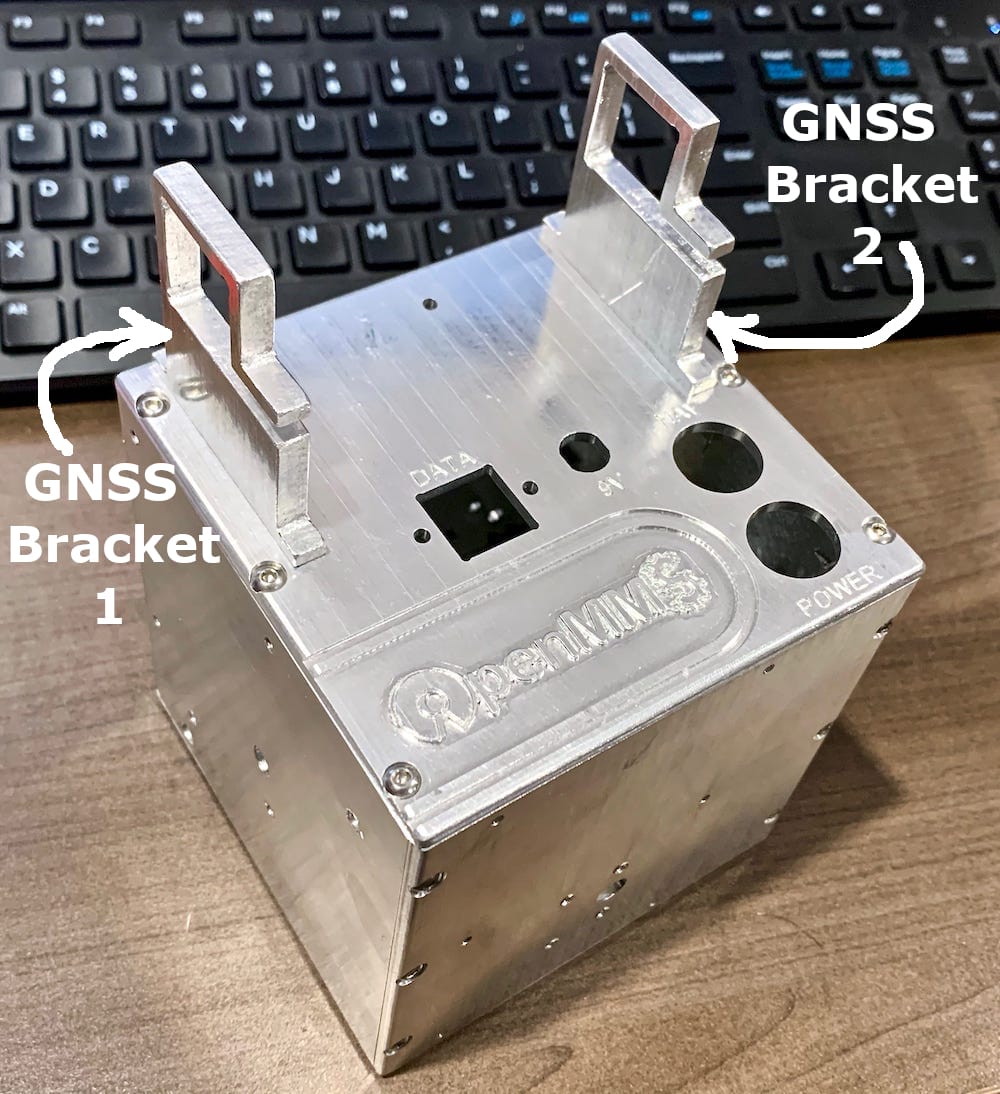

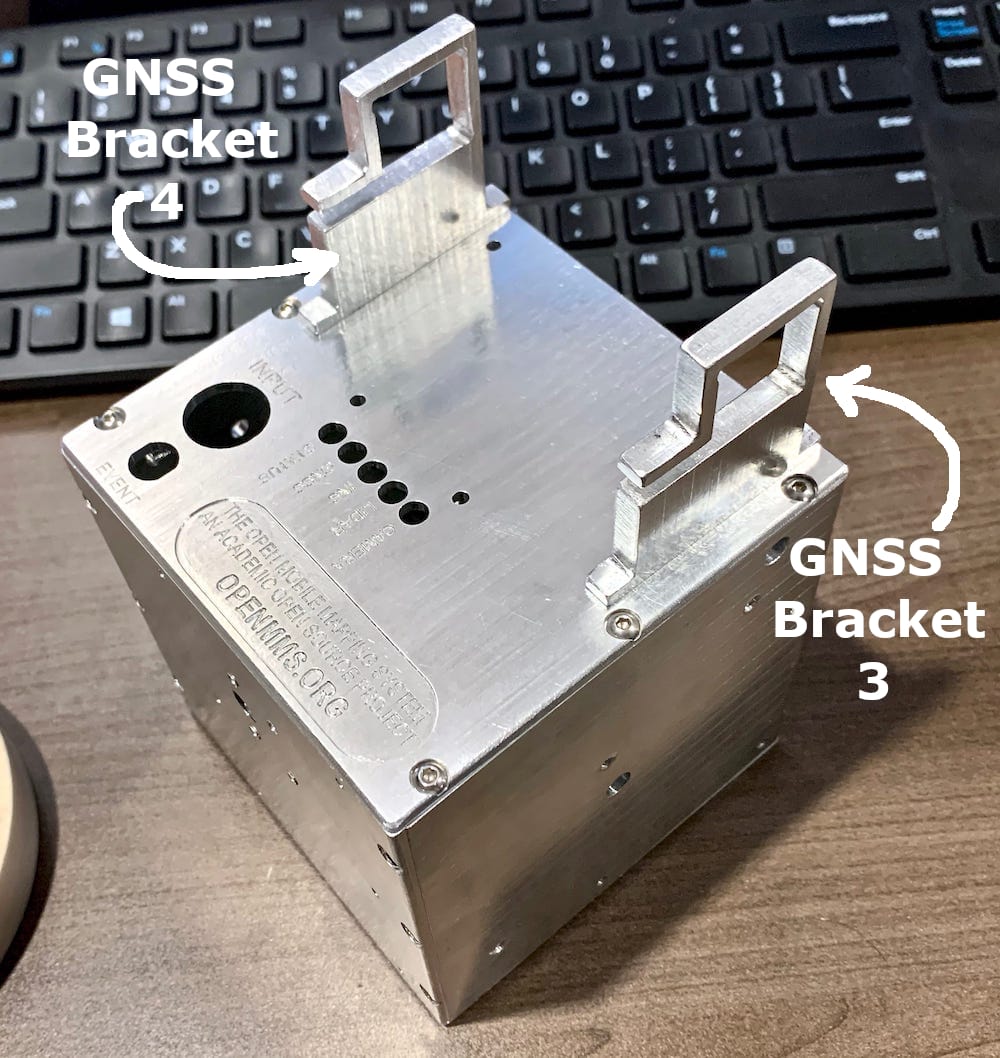

The next task focuses on completing the manufacturing of the four GNSS antenna brackets. On the bottom of each bracket, write or scribe a unique ID number (i.e., 1,2,3,4). The recommended numbering has brackets 1 and 2 installed on the left face, towards the front and back faces, respectively. Likewise, brackets 3 and 4 are installed on the right face towards the front and back faces, respectively.

Fig 4.15-14. GNSS antenna bracket ID numbers¶

Fig 4.15-15. Left face GNSS antenna brackets¶

Fig 4.15-16. Right face GNSS antenna brackets¶

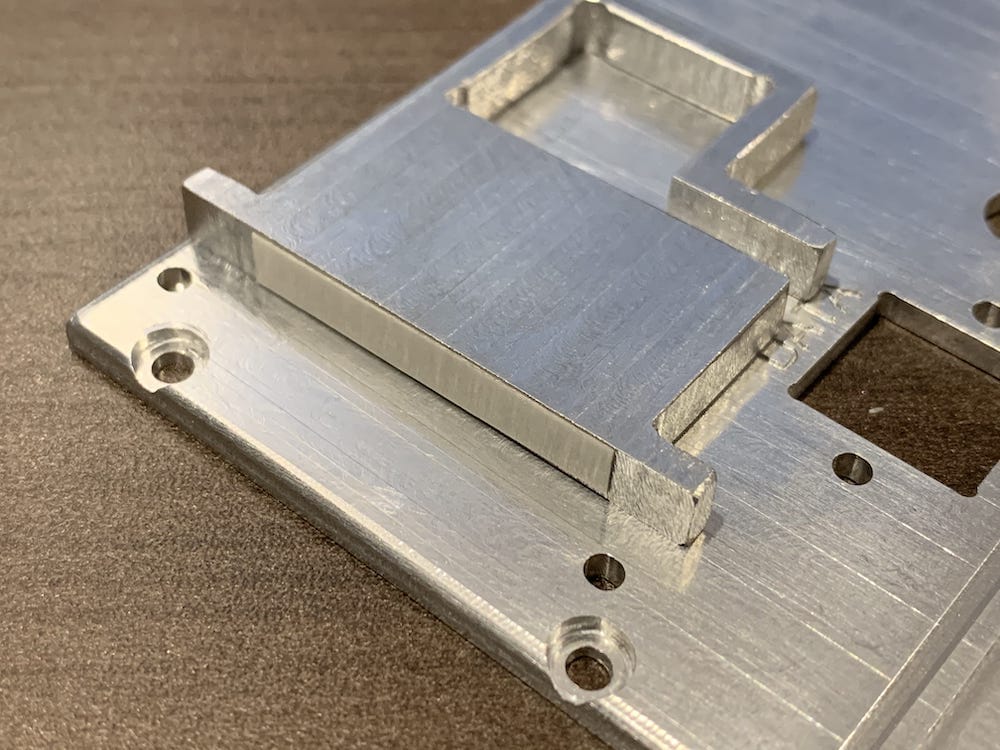

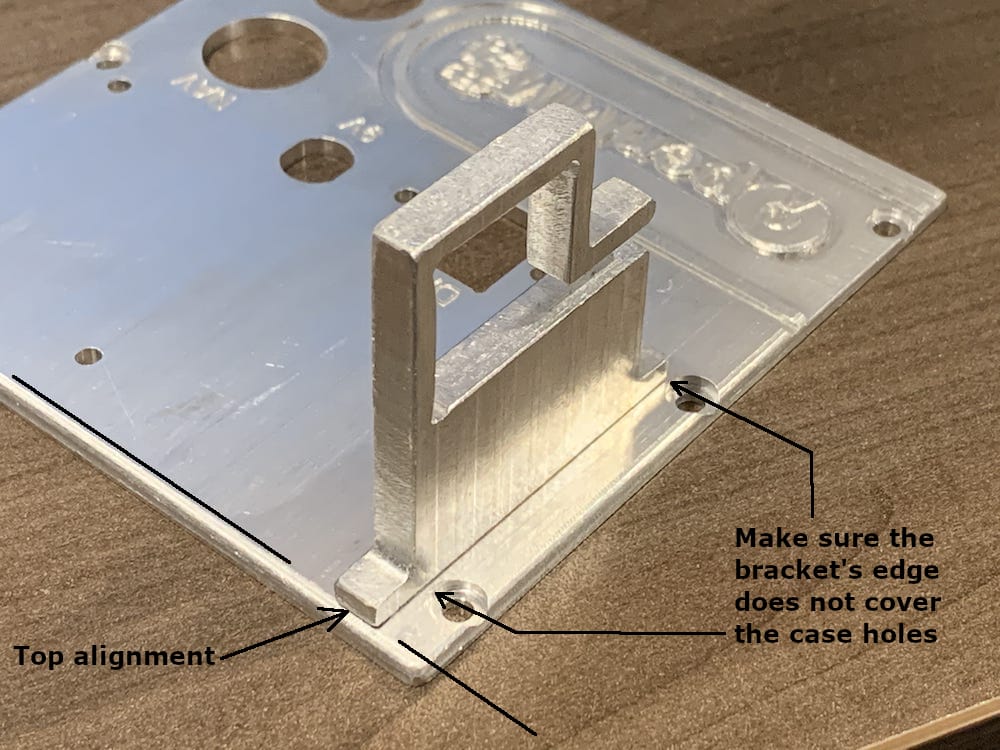

Next, remove the left and right faces from the assembled case. Place a piece of Nitto tape on the bottom surface of each GNSS antenna bracket, but be sure to leave the area underneath the mounting tabs free of tape. On the left face, align the top edge of the mounting tab on GNSS antenna bracket 1 with the ‘line’ where the top rounded edge of the left face starts, see Figure 4.15-18. Center the GNSS antenna bracket over the top holes near the front side of the left face. There should be a minimal gap between the front edge of the GNSS antenna bracket and the holes for assembling the case. Repeat this procedure for GNSS antenna bracket 2 on the rear side of the left face. Carefully flip the left face over and mark the hole locations on the backside of the mounting tabs on the GNSS antenna brackets. Remove the GNSS antenna brackets from the left face and remove the Nitto tape. Ideally, the marked hole locations should be on the center-line of the bracket. If the marked holes are not exactly in the center, that may still be ok. What is essential is that the marked holes form a line that is parallel to the edges of the bracket. If the line isn’t parallel, then the bracket will be installed with a twist in it, which will make it challenging to position the carbon fiber square tubing through both of the brackets. Repeat this process for all four GNSS antenna brackets.

Fig 4.15-17. GNSS bracket with Nitto tape¶

Fig 4.15-18. Bracket 1 in the correct position¶

Fig 4.15-19. Marking holes inside the left face¶

Fig 4.15-20. Marked holes to be drilled¶

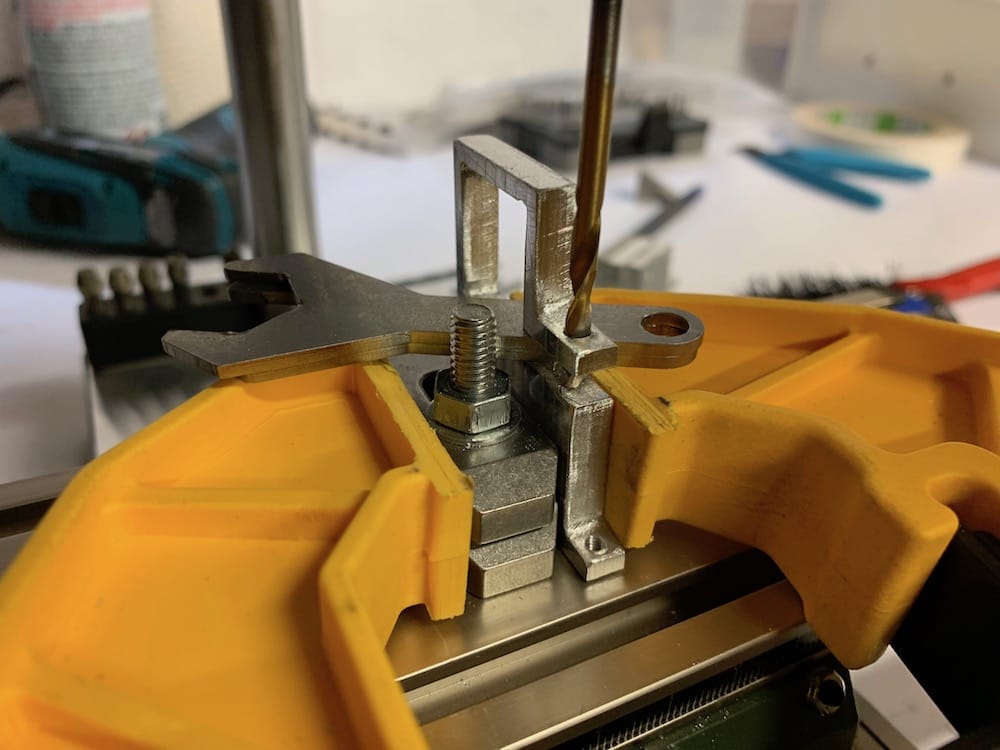

After the holes have been marked, as precisely as possible, drill the marked holes with the Proxxon Drill Press using a 3/32” drill bit. The GNSS antenna brackets will want to flex a little bit as you try to drill the holes. To help counteract this, wedge something within the opening of the brackets (e.g., a Bantam Tools Machine wrenches). Lastly, use the 3mm tap to create threads within the drilled holes.

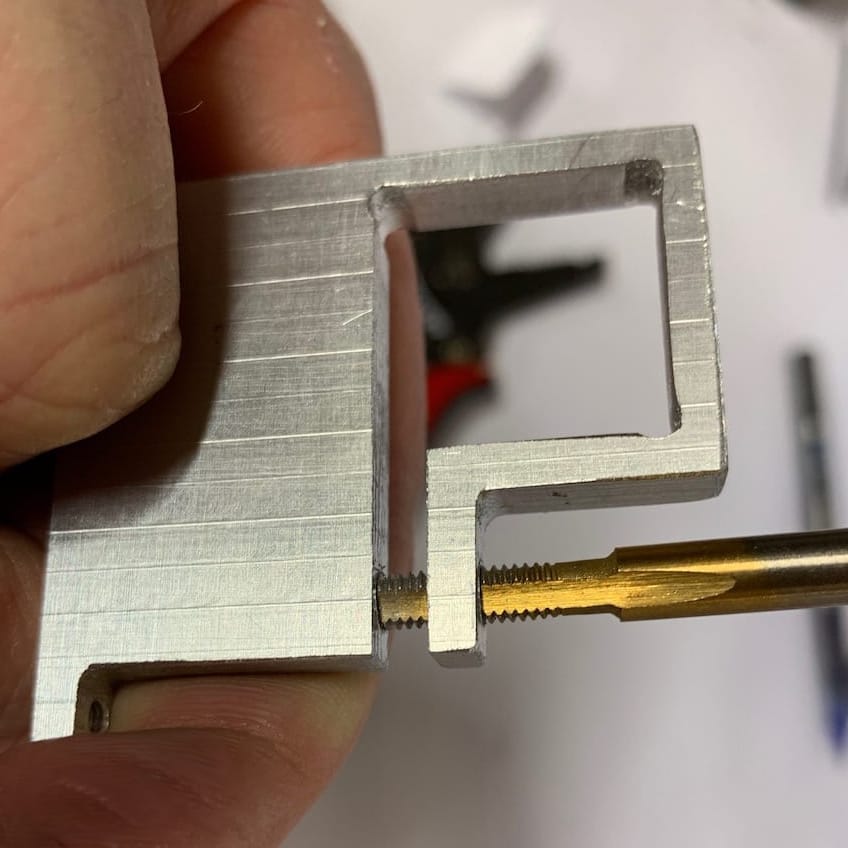

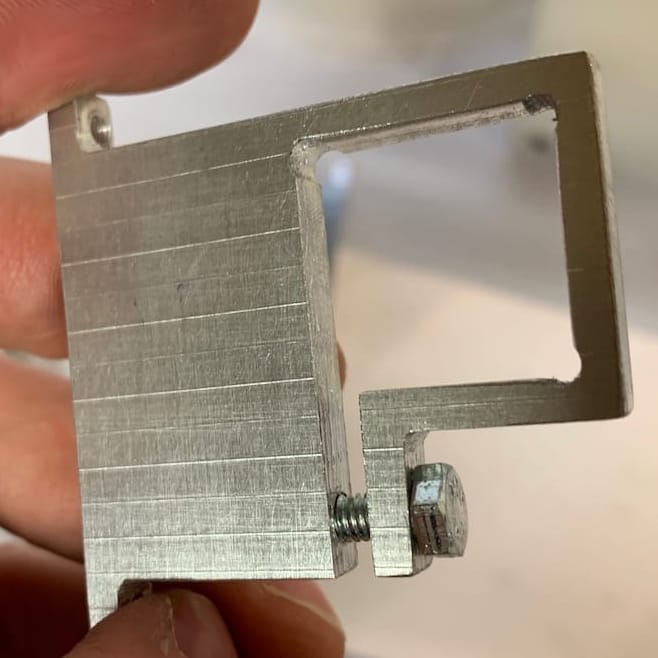

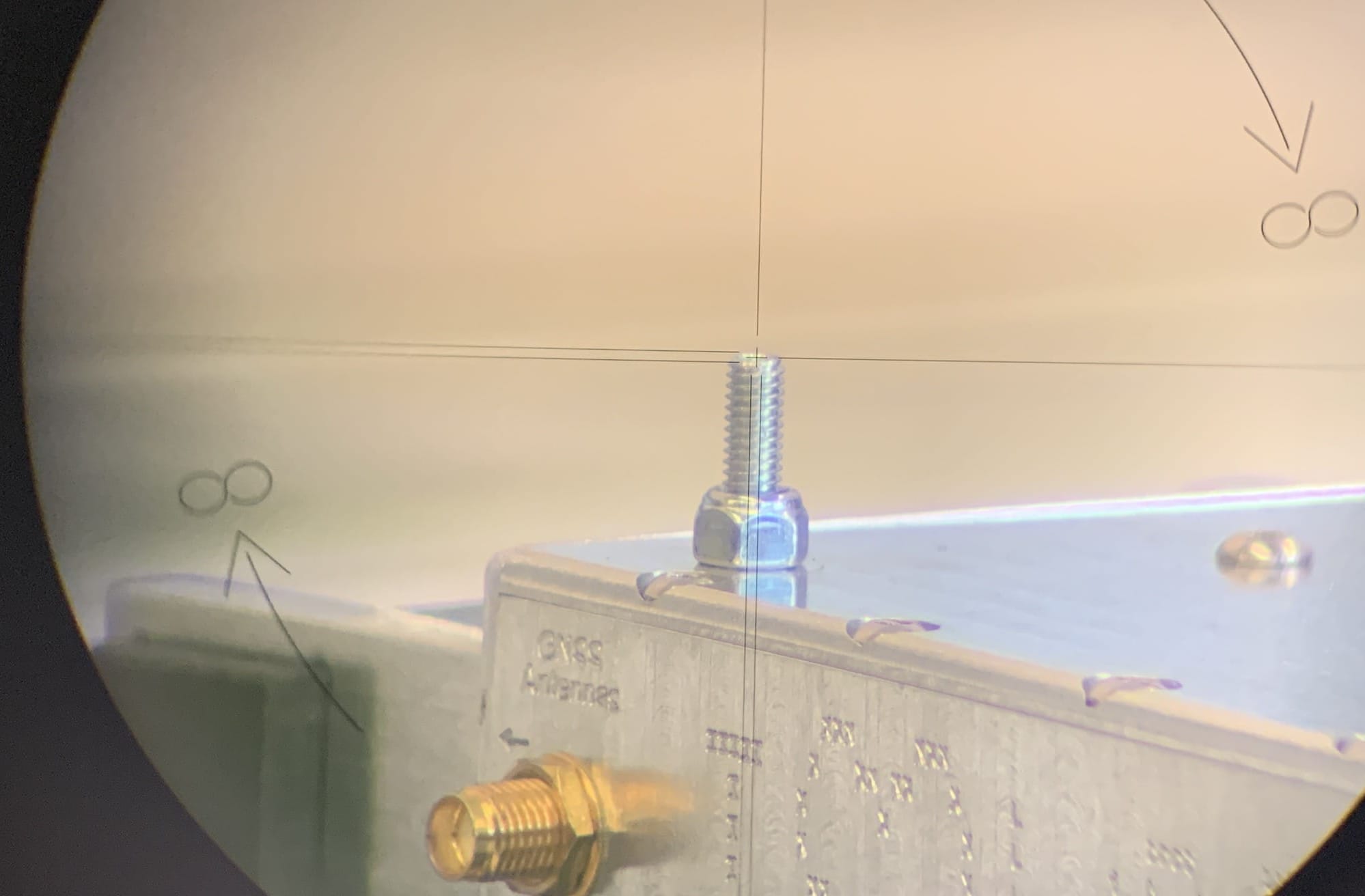

One final hole needs to be drilled and tapped into each of the GNSS brackets. On the closing tab, measure 4mm from the bottom edge, mark a line, and then find the midpoint across the closing tab and mark a line. The intersection of these lines is where the hole needs to be drilled, see Figure 4.15-23. Using the Proxxon Drill Press, install a 1/8” drill bit and drill a pilot hole to a depth of ~ 20mm (a 1/8” drill bit is the largest diameter bit that the Proxxon Rotary tool can use). Next, use a handheld electric drill to widen the 1/8” hole to a 9/64” hole (i.e., use a 9/64” drill bit in the handheld drill). Next, use a 3/16” drill to ONLY WIDEN THE TOP HOLE THROUGH THE CLOSING TAB. Next, use a 4mm tap to cut threads into the bottom part of the hole. Pass a 4mm hex bolt that is 10mm to 12mm in length through the wider top hole on the closing tab and thread it into the bottom hole. Lastly, ensure that the 20mm x 20mm carbon fiber square tubes fit through all four of the GNSS antenna brackets. The fit may be a bit tight, in which case the inside edges of square opening in the middle of the GNSS antenna brackets need to be filed down. It is not recommended to file down the carbon fiber tubes as they are relatively thin and can begin to crack and break if filed excessively.

4.15.3. Reinforcing Bracket Holes¶

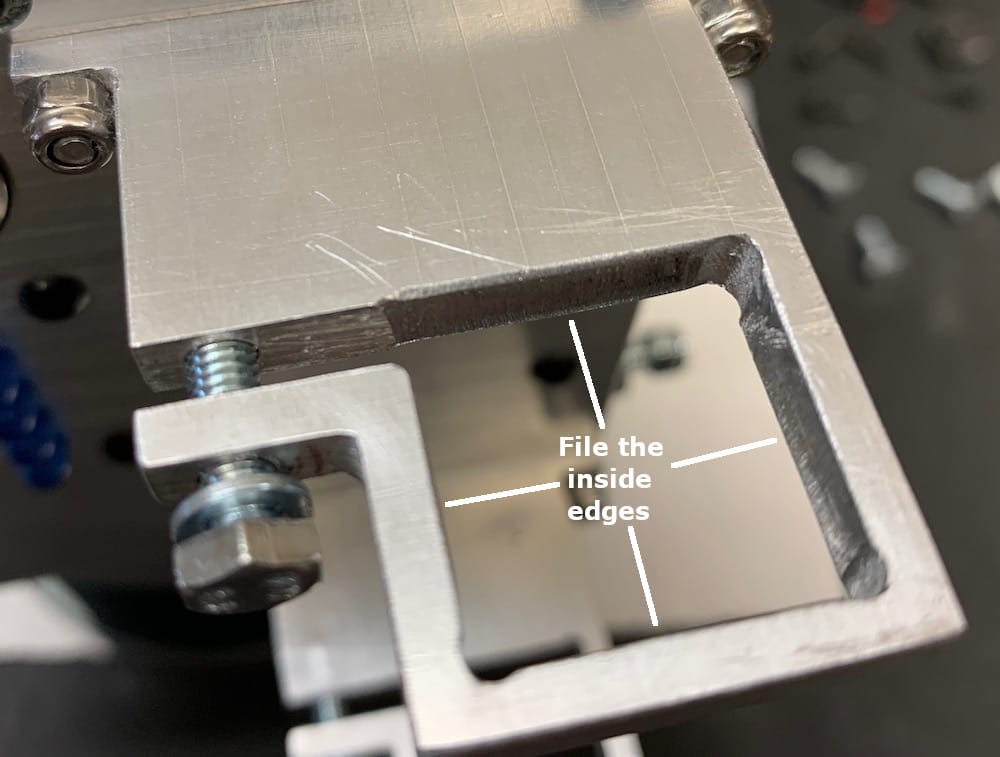

The next task focuses on completing the manufacturing of the two support brackets. Assemble the case using 3mm bolts, except leave the bottom face open. Mark/scribe the two support brackets with unique IDs. The recommended IDs are L and R. Using Nitto tape, if necessary, position the support brackets inside the case, as shown in the figure below. Carefully mark the position of the respective holes in the left and right faces ONLY on the support brackets. Remove the support brackets and drill the marked holes with the Proxxon Drill Press using a 3/32” drill bit. Cut threads into the drilled holes using a 3mm tap. Install the supports using 3mm bolts through the left and right faces. Once bolted into place, align the support brackets to cover their respective holes through the top face. Mark the hole locations, unbolt the brackets from the left and right faces, drill 3/32” holes, and cut threads using a 3mm tap. Reinstall the support brackets to ensure a correct fit.

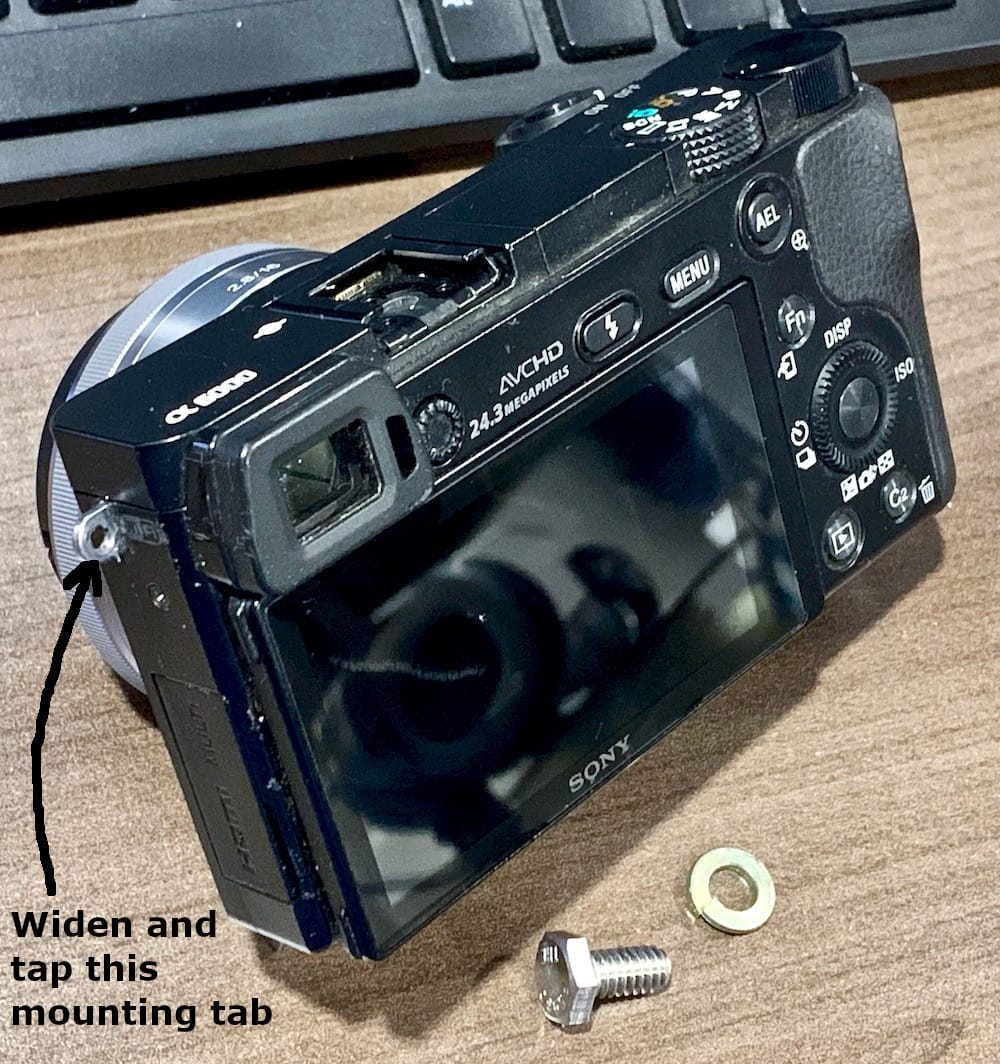

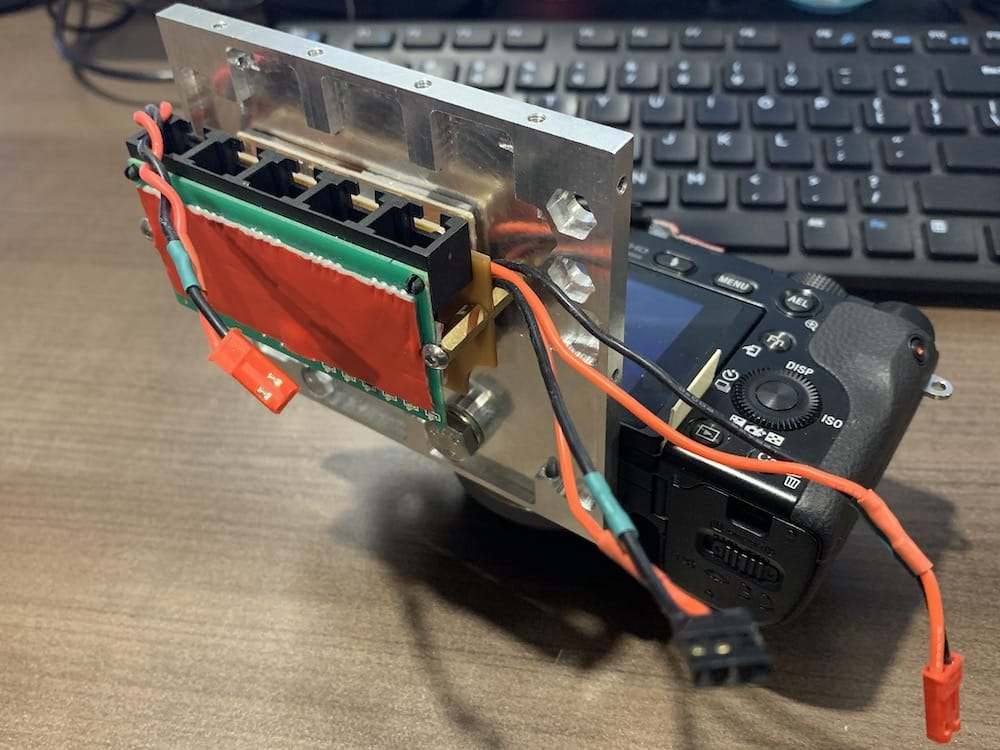

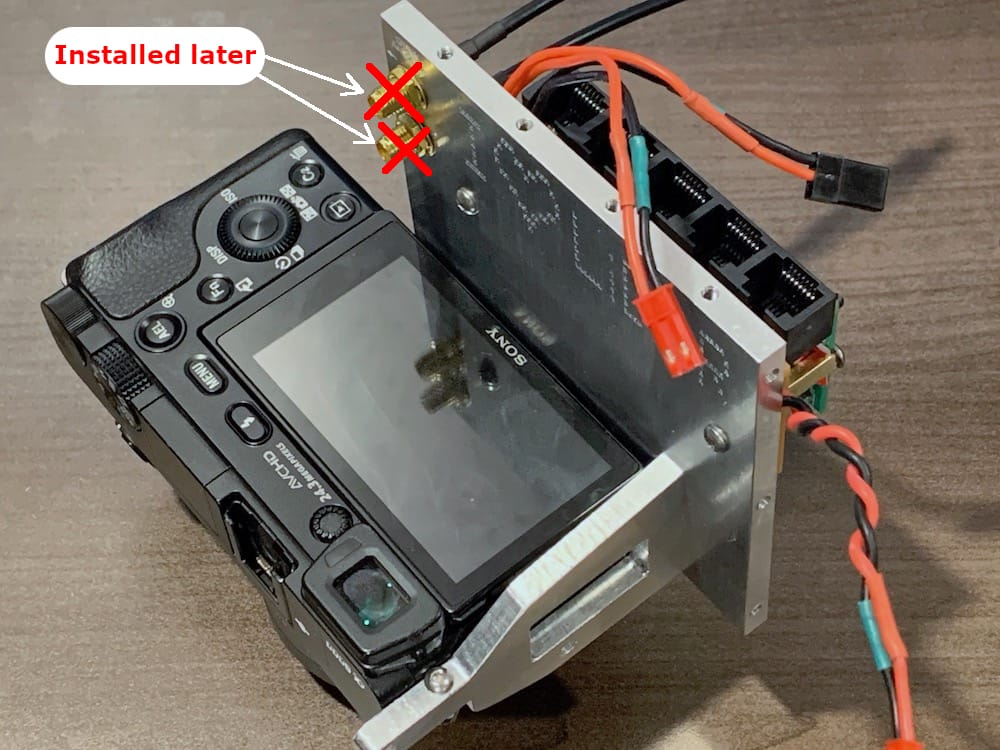

4.15.4. Sony Bracket Holes¶

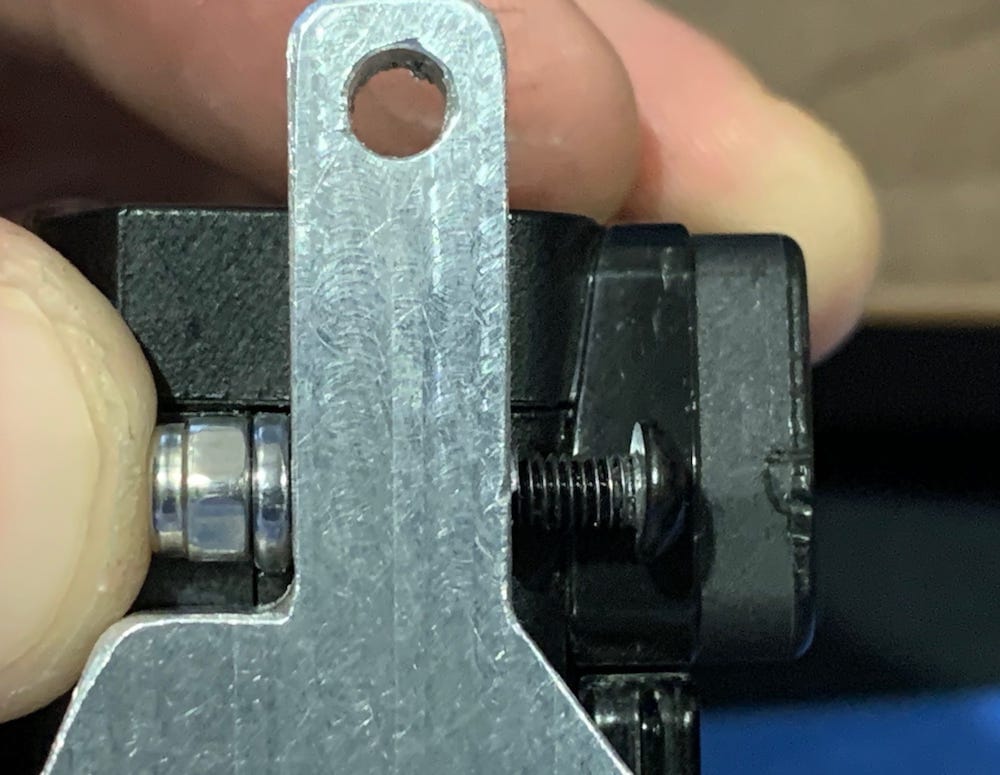

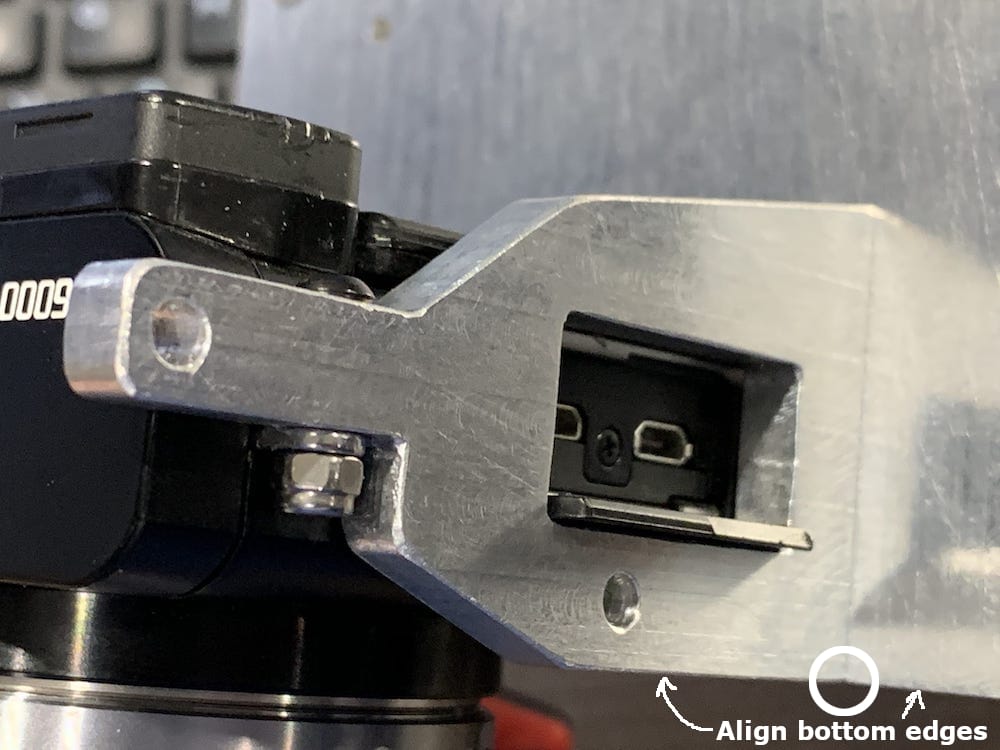

The next task focuses on completing the manufacturing of the Sony bracket. Remove the back face of the case, so it is free. First, with a handheld electric drill, carefully widen the left mounting tab on the Sony A6000 camera itself using a 3/32” drill bit (yes, you read this correctly!). Cut threads into this mounting tab using a 3mm tap. Next, insert a 1/2” long, 1/4” coarse threaded bolt and lock washer through the large hole on the back face. Thread the bolt into the mounting hole located on the bottom of the Sony A6000 camera, and gently tighten it until the camera feels secure on the back face but can still easily be rotated by hand (DO NOT OVERTIGHTEN THE 1/4” BOLT).

Fig 4.15-32. Adjust Sony mounting tab¶

Fig 4.15-33. 1/4” coarse threaded bolt and lock washer¶

Fig 4.15-34. Sony A6000 attached to the back face¶

Next, position the Sony bracket tight against the left side of the camera. The bottom surface of the Sony bracket should be flush against the back face, in line with the two holes through the back face, and aligned with the bottom edge, see Figure 4.15-38. The left mounting tab of the Sony A6000 camera should be touching the ‘underside’ of the Sony bracket. Also, ensure that the HDMI/Multi connection panel on the camera is open and fits through the opening in the bracket. Next, mark the two holes’ positions through the back face, on the bottom surface on the bracket. Using the Proxxon Drill Press with a 1/8” drill bit, drill the two marked holes to a depth of ~ 12mm. Using a handheld electric drill with a 9/64” drill bit, widen the 1/8” pilot holes. Cut threads into the holes using a 4mm tap. Attach the Sony bracket to the back face using 4mm by 10mm length bolts and lock washers. Next, CAREFULLY tighten the 1/4” bolt until it is firmly snug. The camera’s mounting tab touching the underside of the Sony bracket will help resist the camera from rotating while the 1/4” bolt is tightened (though the camera may turn a little bit, and this is ok). Next, mark the position of the mounting tab hole on the underside of the Sony bracket. Remove the Sony bracket from the back face. Using the Proxxon Drill Press with a 1/8” drill bit, drill the marked hole through the Sony bracket. THIS HOLE IS NOT TAPPED! Reattach the Sony bracket to the back face using the 4mm bolts and lock washers. Insert a 3mm bolt ~ 14mm in length through the drilled hole on the Sony bracket’s topside. Position a Nyloc nut directly under the mounting tab and thread the bolt through the Sony A6000 camera mounting tab and then through the Nyloc nut.

4.16. Part Cleaning and Finishing¶

The final task in this step focuses on cleaning and finishing all the aluminum parts to ensure that no loose pieces of metal swarf remain that may damage the electronic components inside the case. Sticking with the desktop manufacturing only approach, no ultrasonic cleaners, tumble deburring machines, etc. were used in this task. However, if you have access to these cleaning and finishing solutions (and know what you are doing), they certainly can be used.

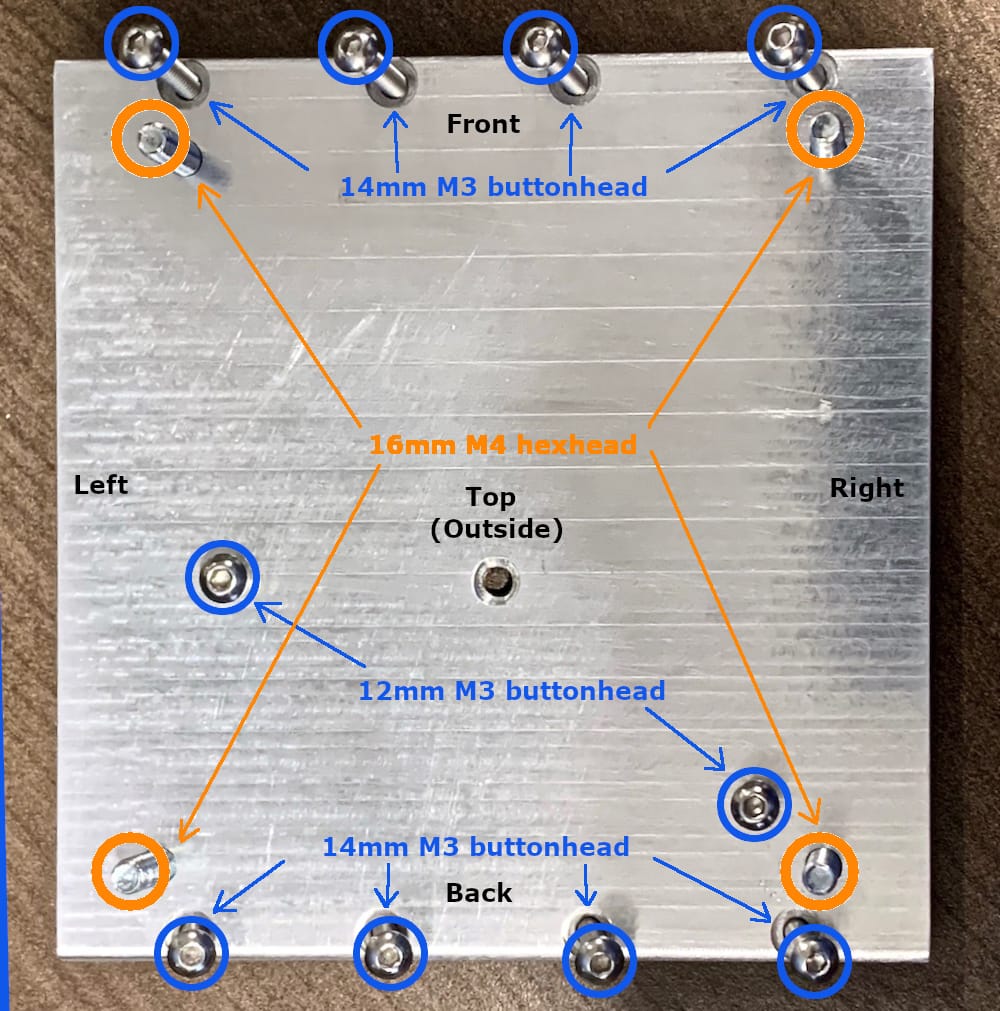

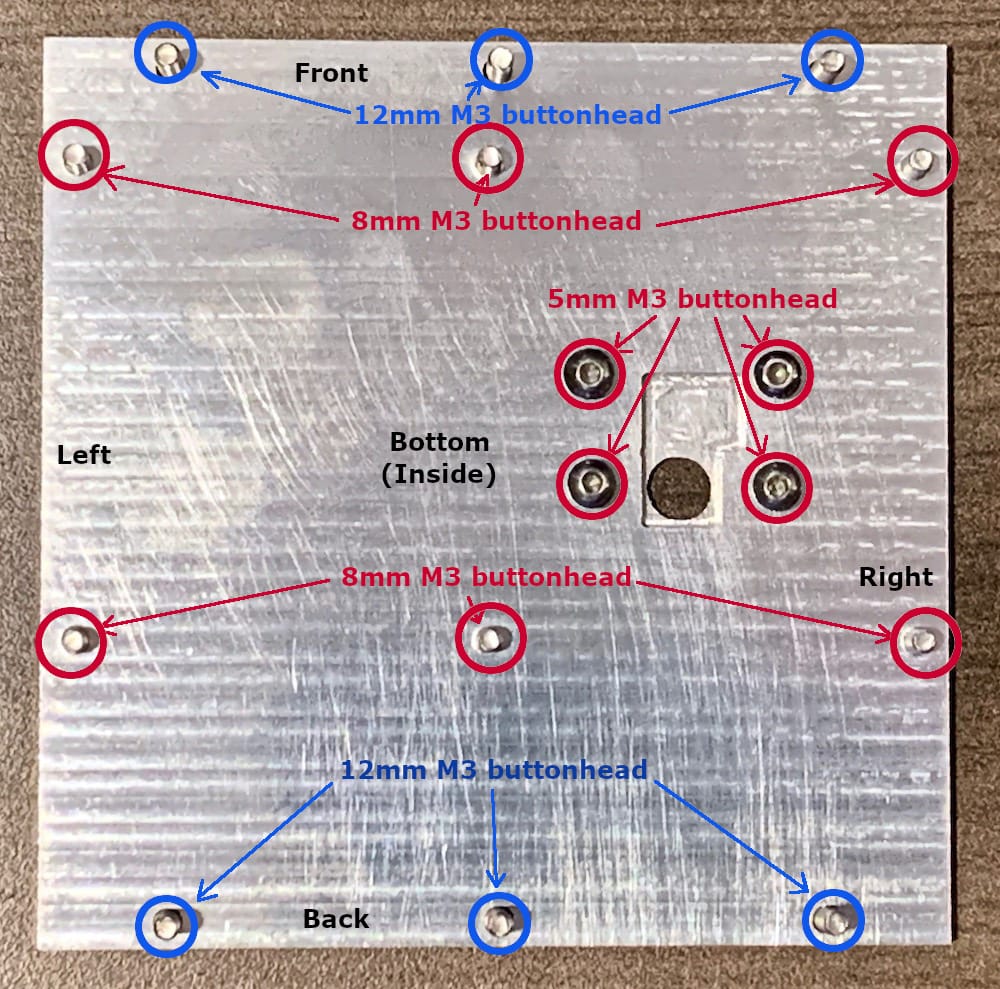

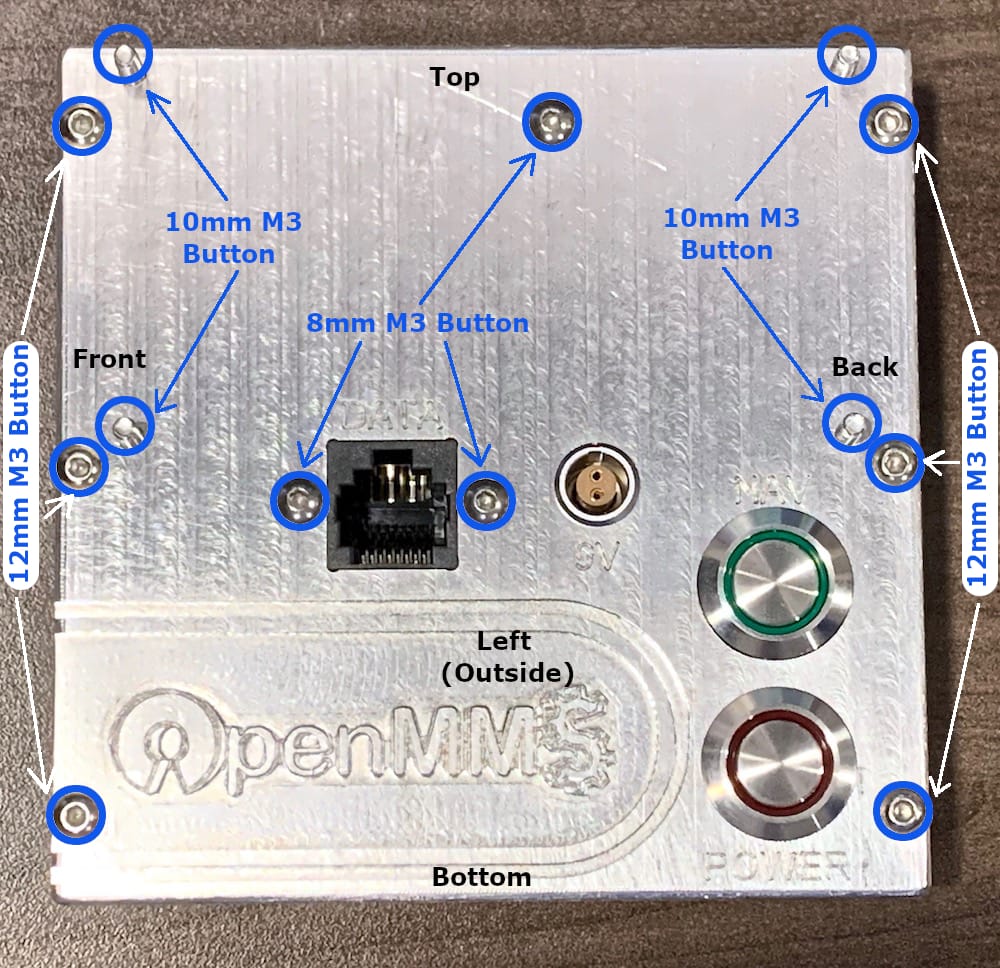

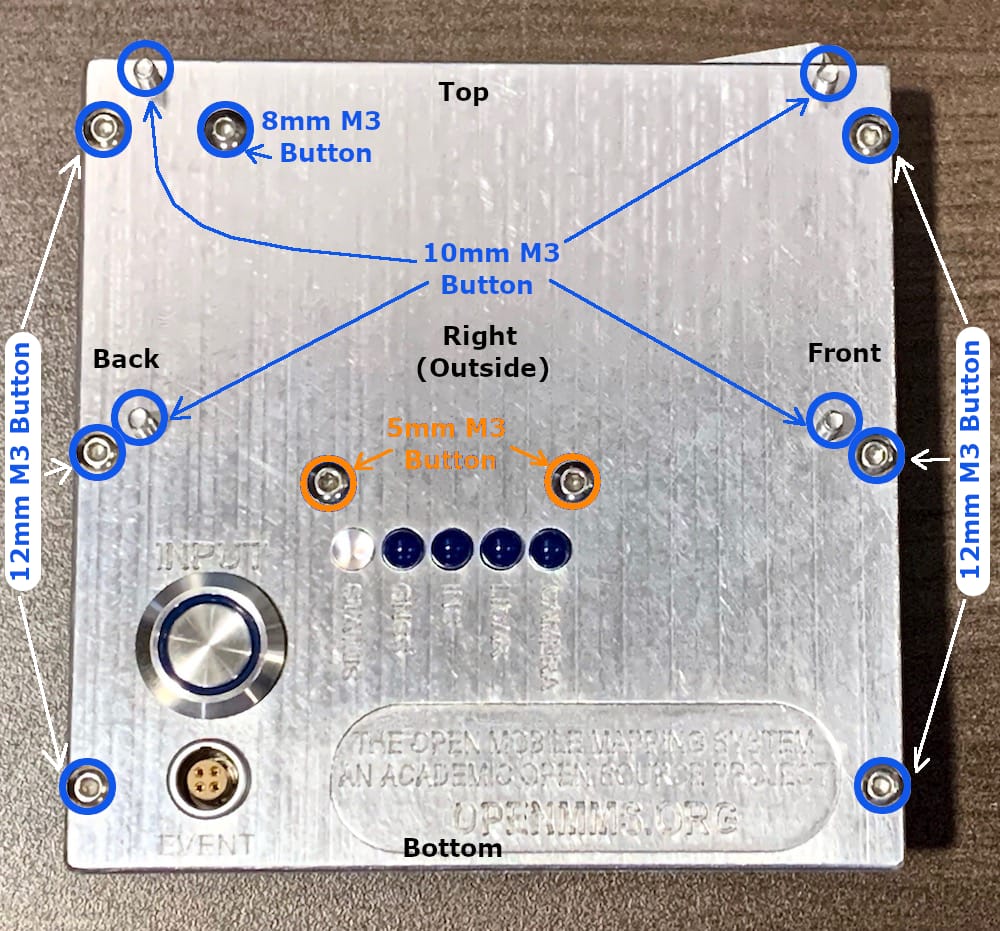

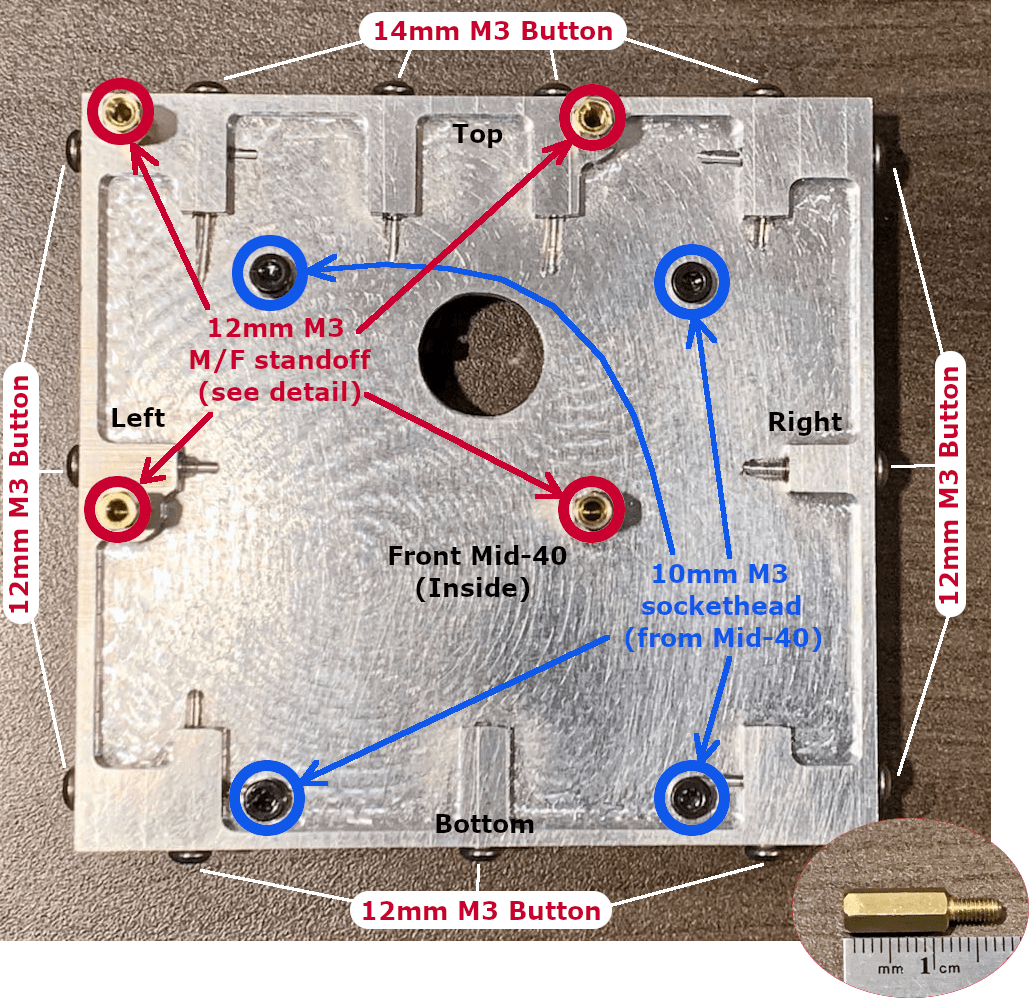

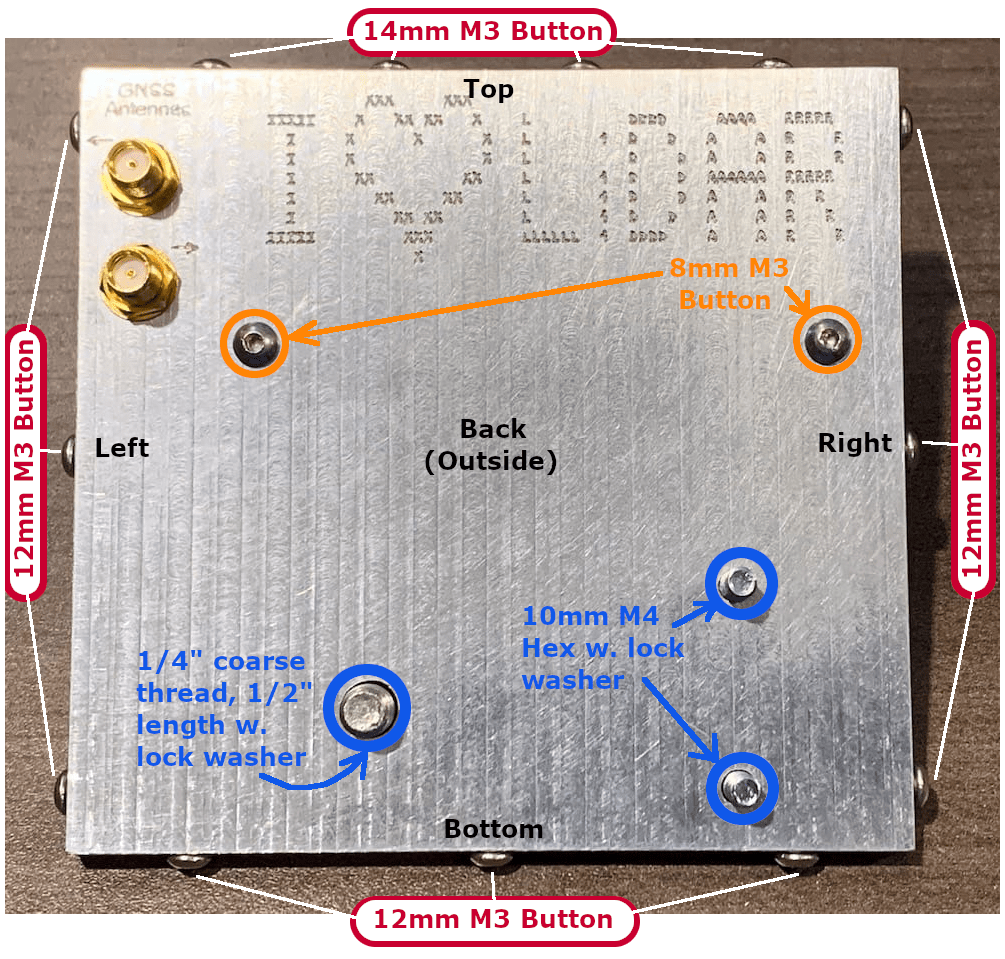

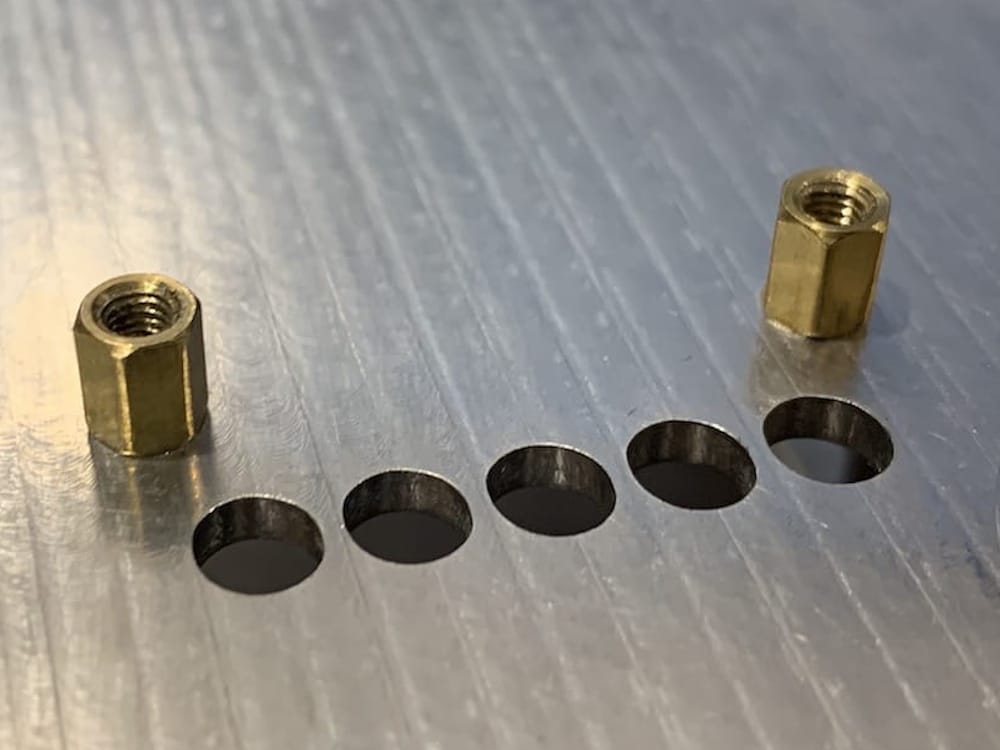

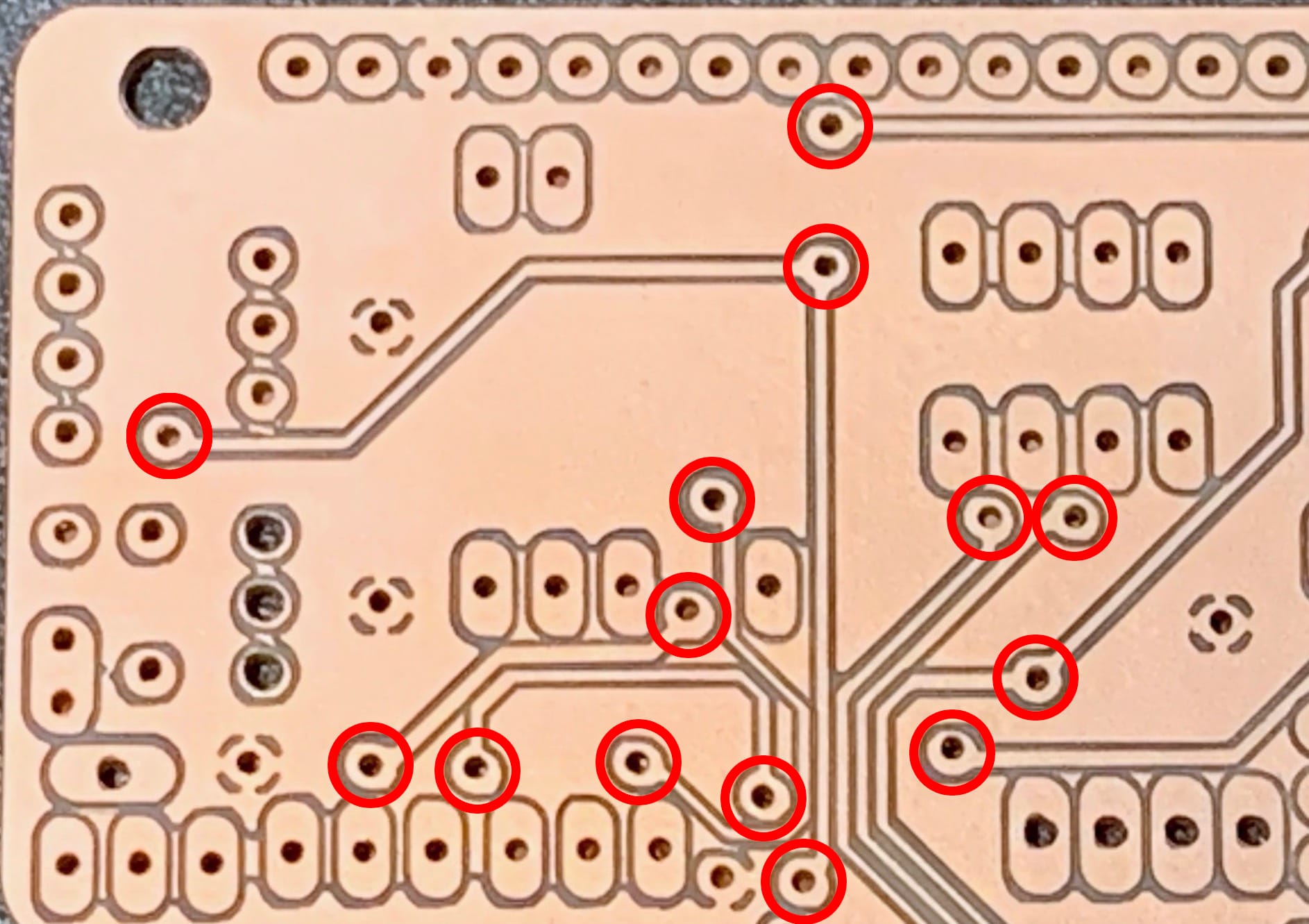

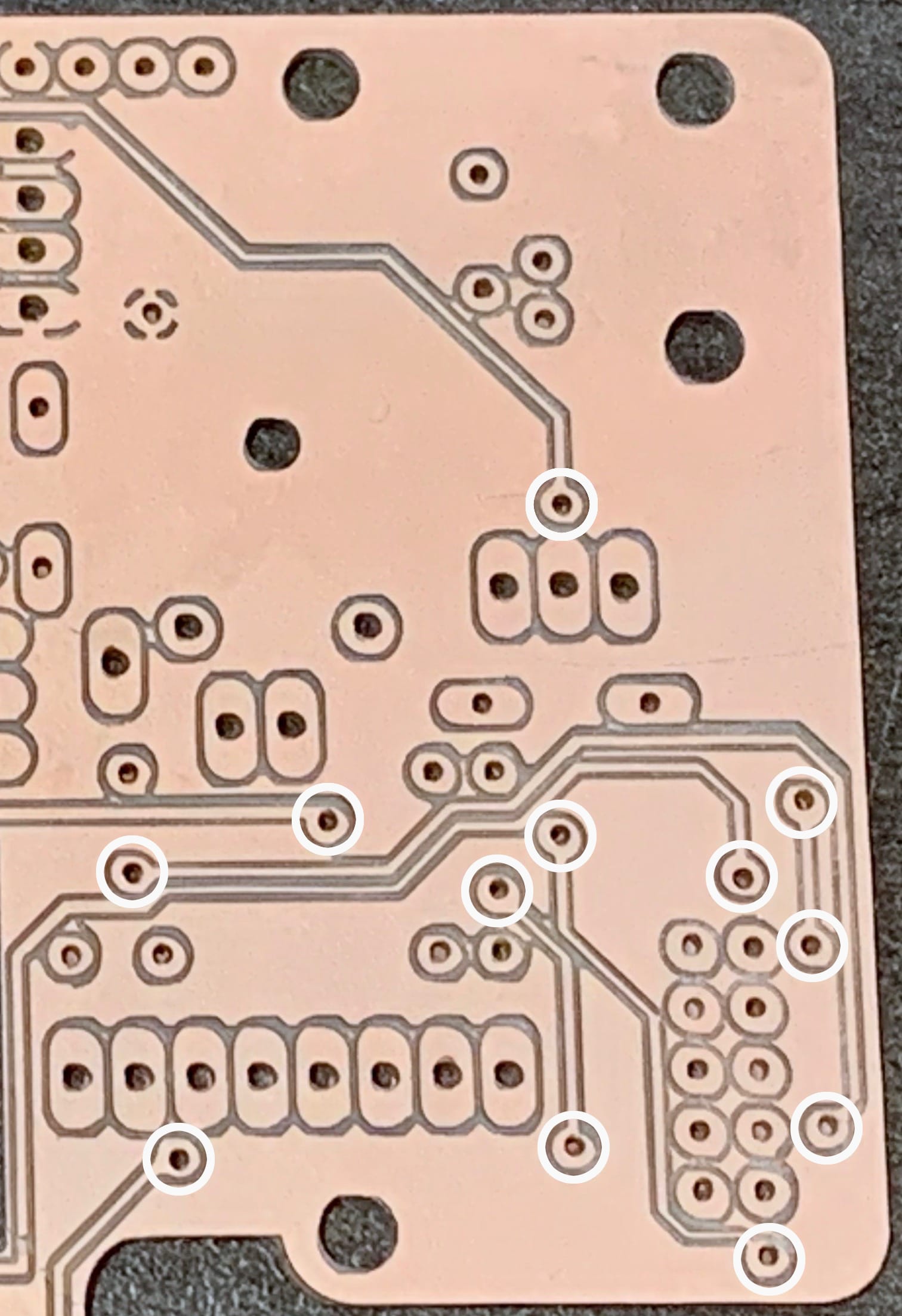

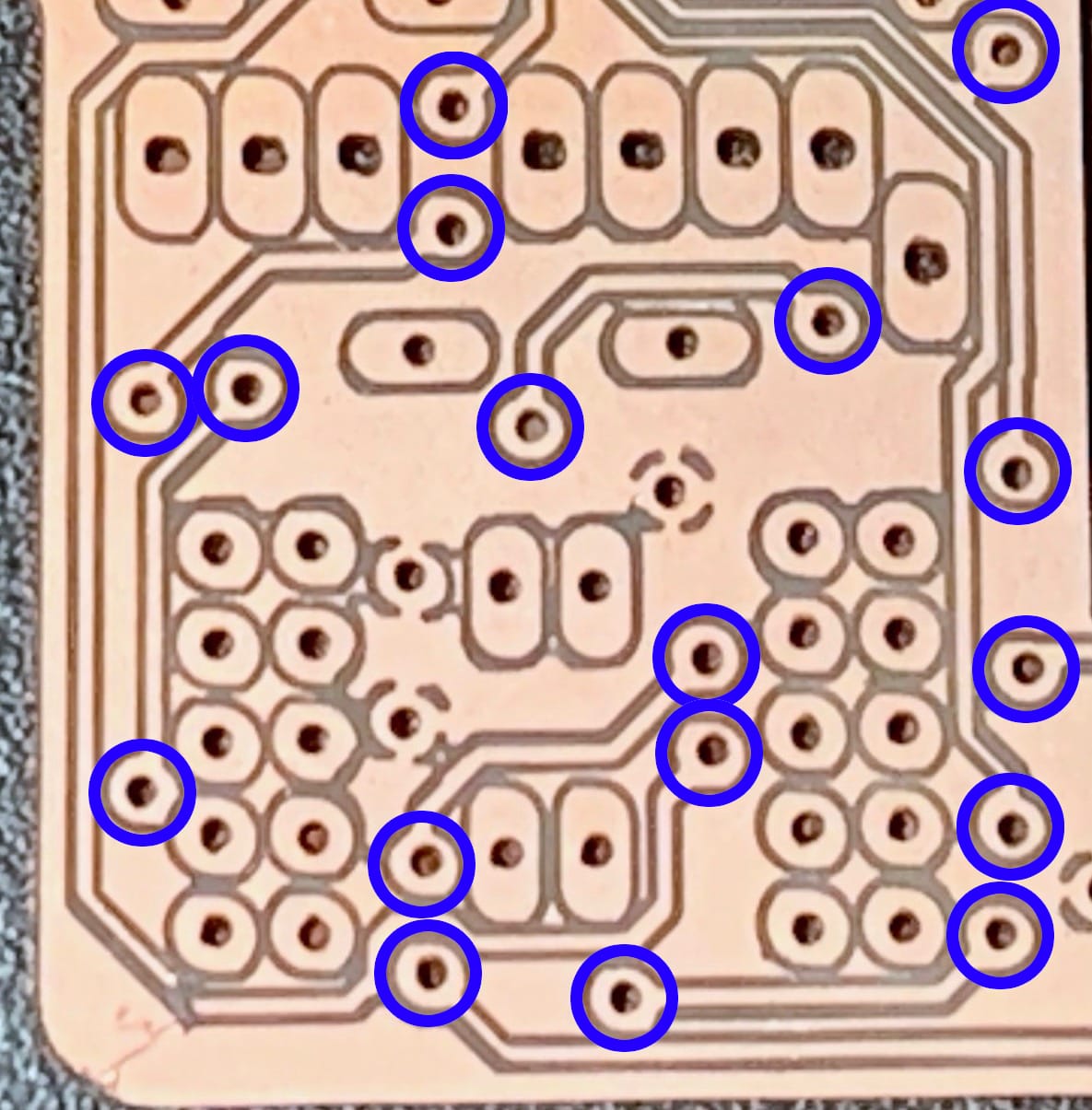

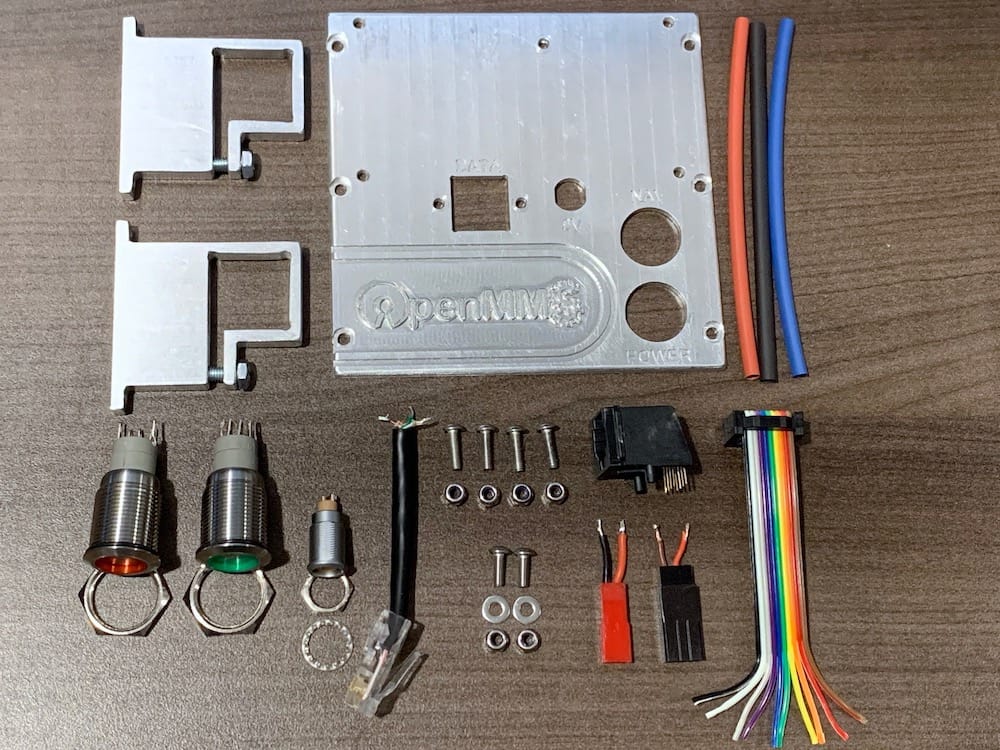

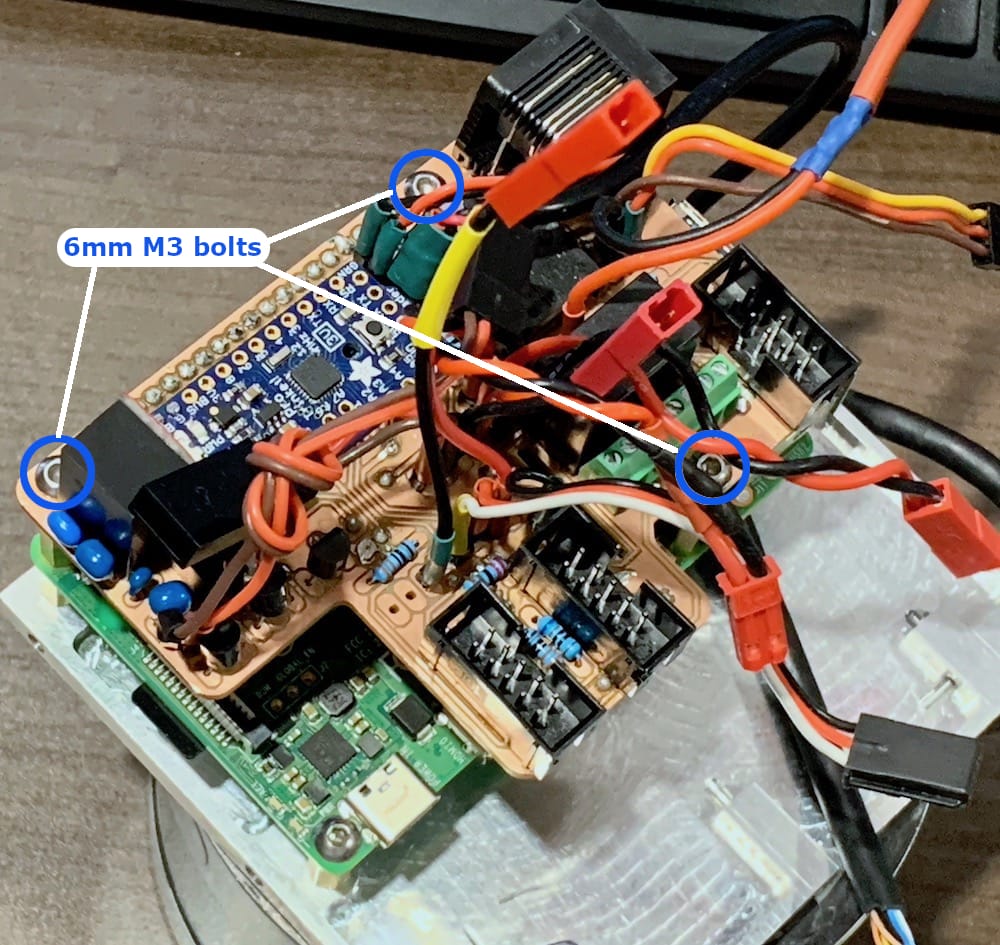

First, it is recommended to affix ALL of the hardware components (i.e., bolts, standoffs, pushbuttons, Lemo connectors, etc.) to the six faces of the case. The intention is to make sure the hardware fits within the machined or manually drilled and tapped holes of the case. Some of the machined holes (i.e., holes created by the Bantam Tools Machine) may be a bit snug, and hence the respective bolts do not easily fit into the holes, but rather require the bolts to be threaded in using a driver. Ideally, all the machined holes should allow for bolts to slide easily, though not loosely, through the holes and not requiring them to be threaded in using a driver. The figures below illustrate which hardware components go where for each face. BLUE CIRCLED BOLTS NEED TO BE ABLE TO SPIN FREELY WITHIN THEIR RESPECTIVE HOLES. The red circled bolts are going through threaded holes, and therefore SHOULD NOT SPIN FREELY. It does not matter if the orange circled bolts spin freely or not.

Fig 4.16-1. Top face hardware¶

Fig 4.16-2. Bottom face hardware¶

Fig 4.16-3. Left face hardware¶

Fig 4.16-4. Right face hardware¶

Fig 4.16-5. Front face (VLP-16) hardware¶

Fig 4.16-6. Front face (MID-40) hardware¶

Fig 4.16-7. Back face hardware¶

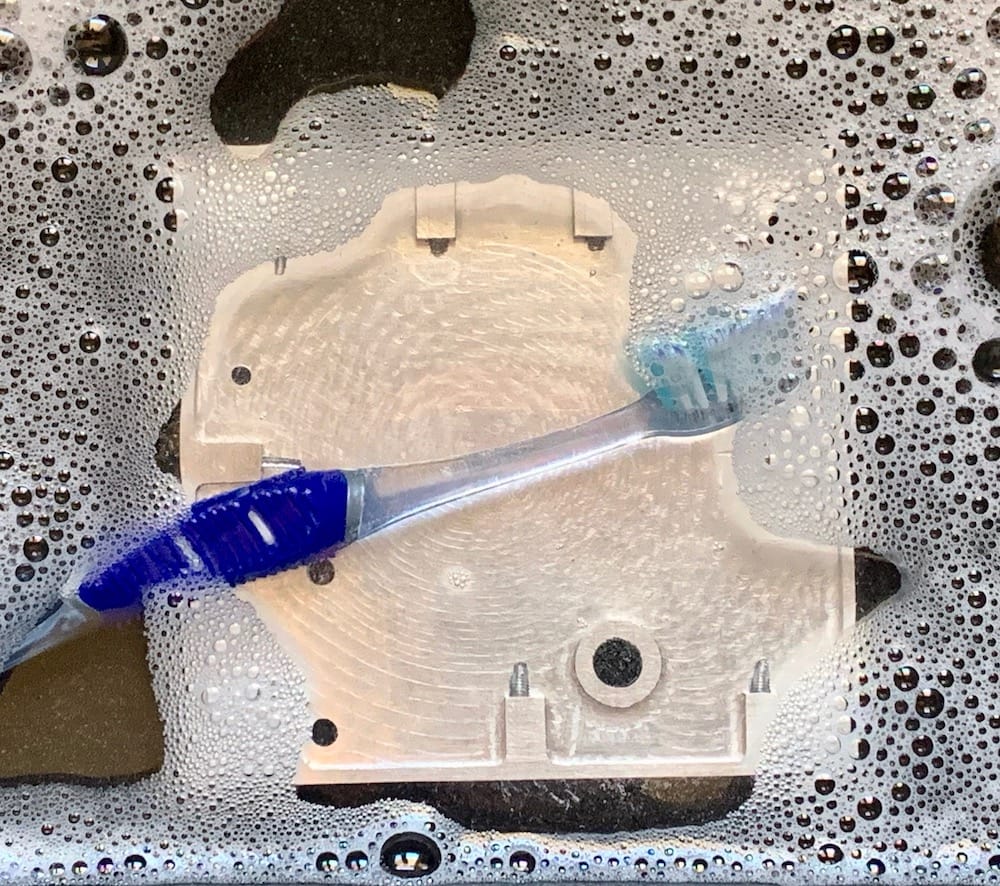

Ensure that all the hardware fits within the respective holes, then take it all apart until the six faces are separated and free of the hardware. The next task is to repeat the instructions discussed in the After Machining step. Pay close attention to the starting point and ending point (if visible) of all the manually drilled holes. Look for small pieces of aluminum that appear loosely attached to the part and remove them. Using compressed air to blow through the drilled and tapped holes can help remove unwanted (and potentially damaging) minute pieces of aluminum hidden within the holes. Take your time with this step; attention to detail is important. After completing this step, no more machining or adjusting of the aluminum parts will be performed! The final task is to thoroughly clean all the parts using warm water and a mild cleaning/degreasing solution. Scrub all the surfaces of the parts, rinse with clean water, and leave to air dry.

Fig 4.16-8. Thoroughly scrub each aluminum part¶

CONGRATULATIONS!

YOU HAVE NOW FINISHED MANUFACTURING THE ALUMINUM PARTS!

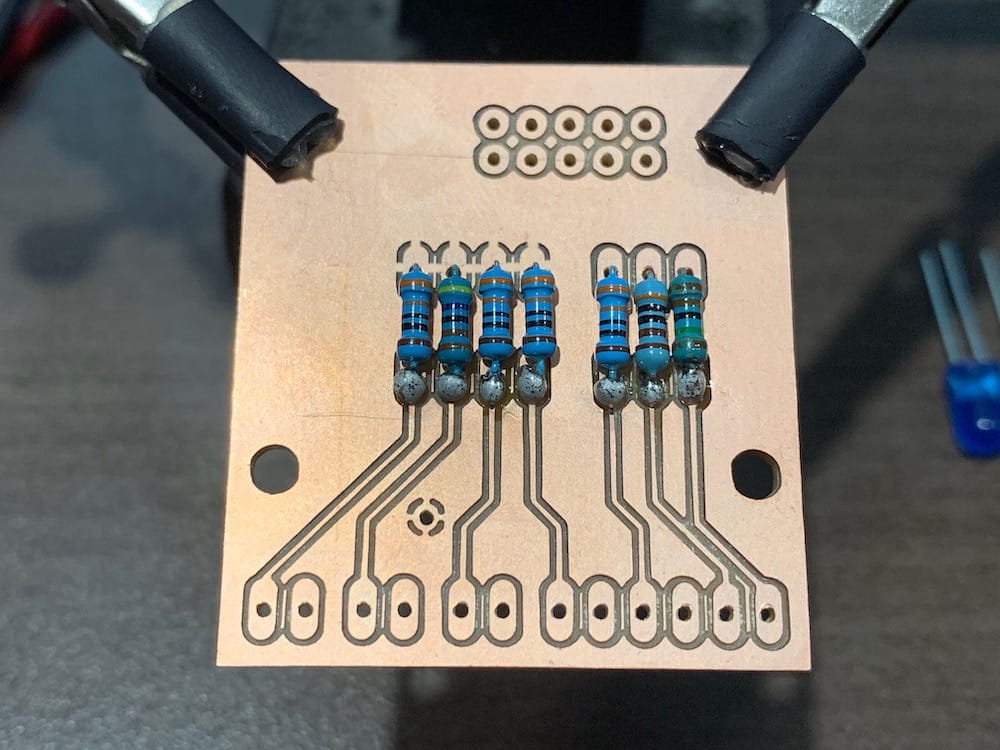

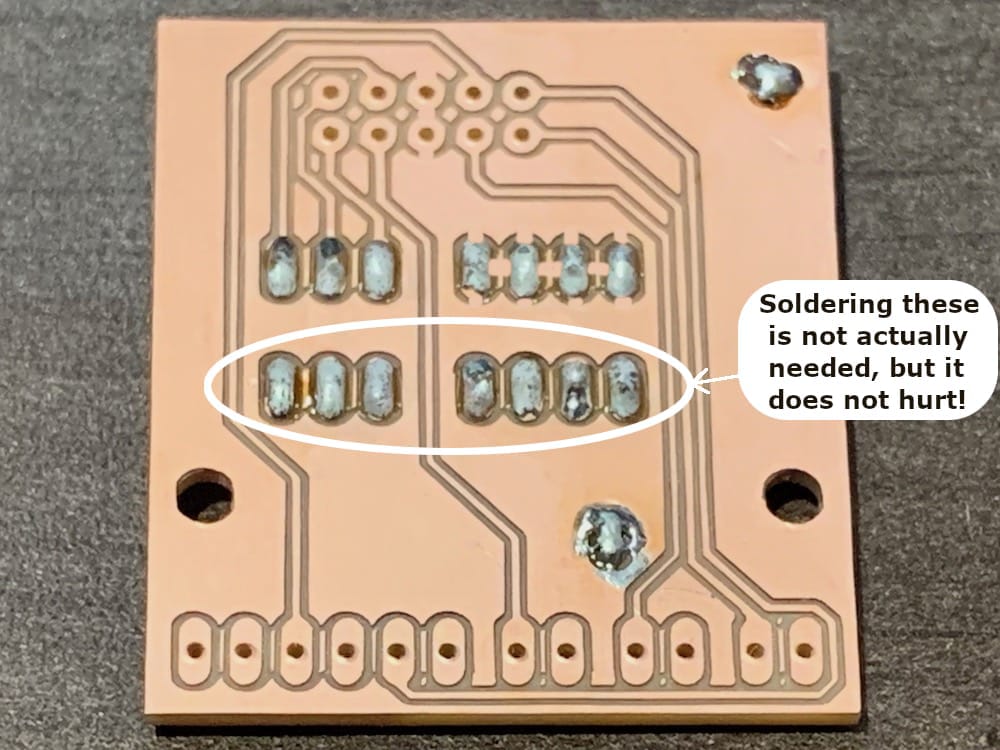

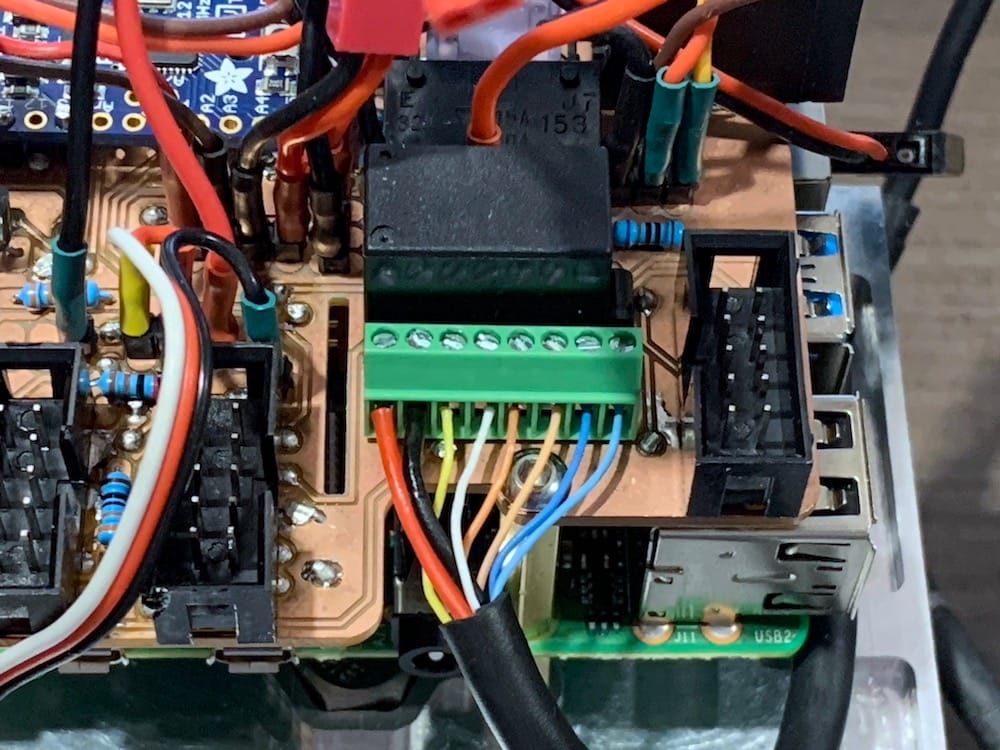

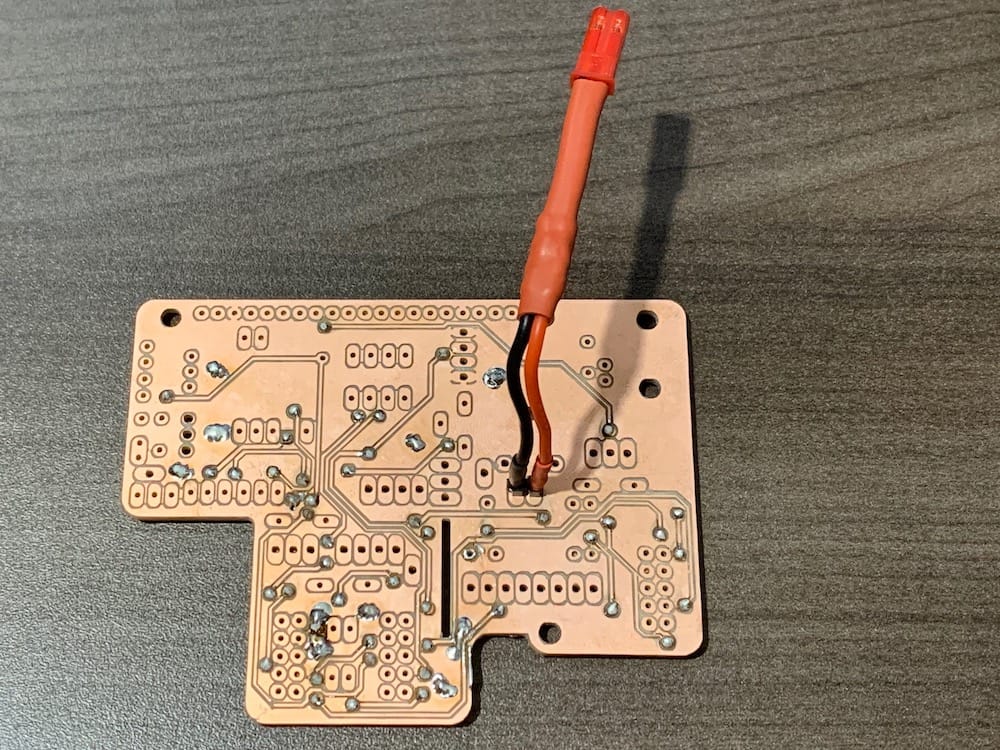

5. Printed Circuit Boards Manufacturing¶

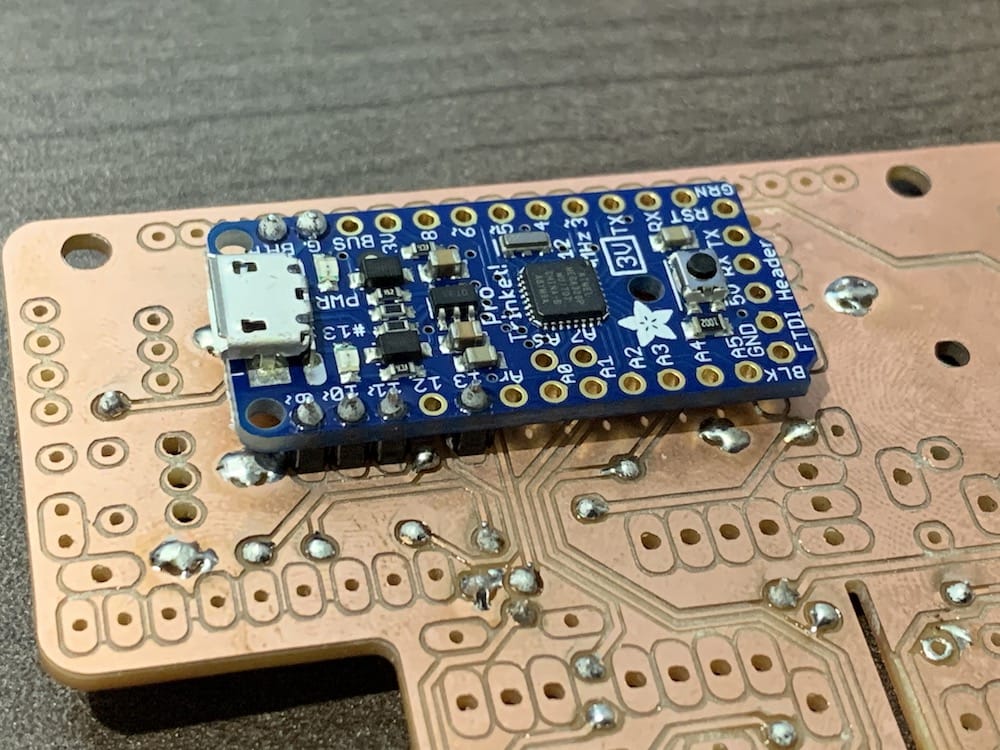

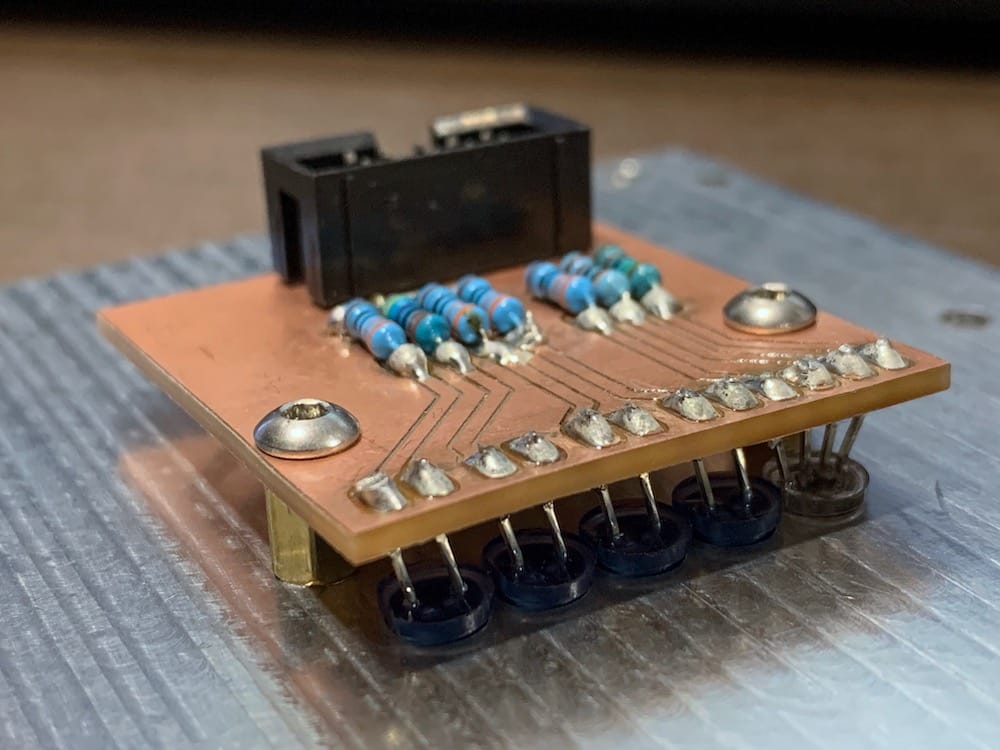

5.1. Overview¶

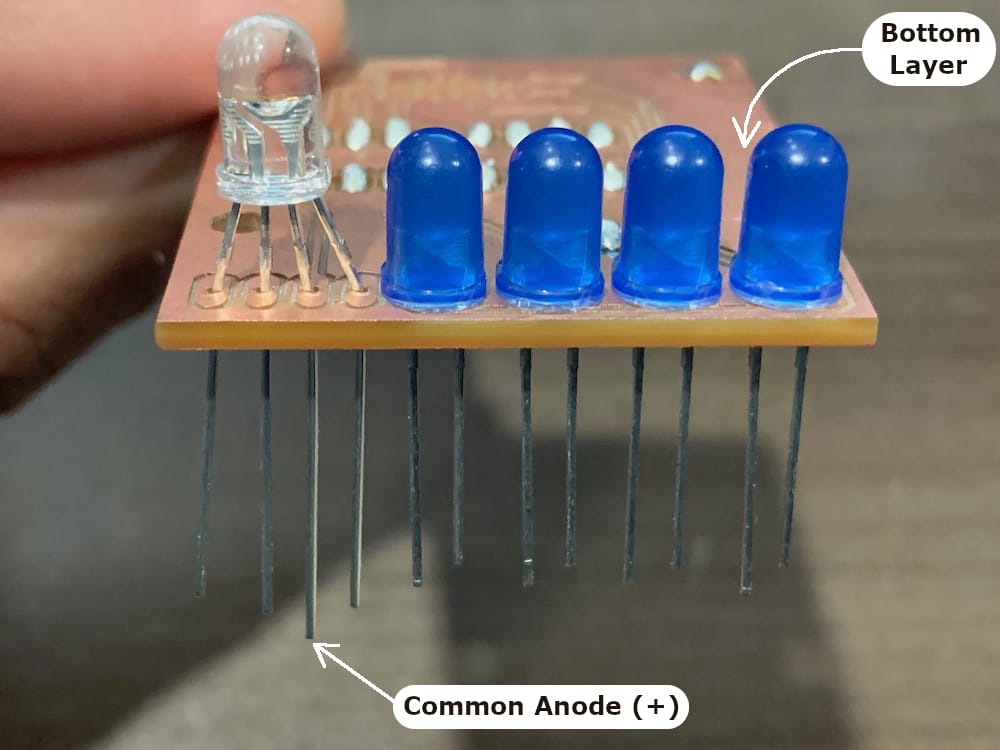

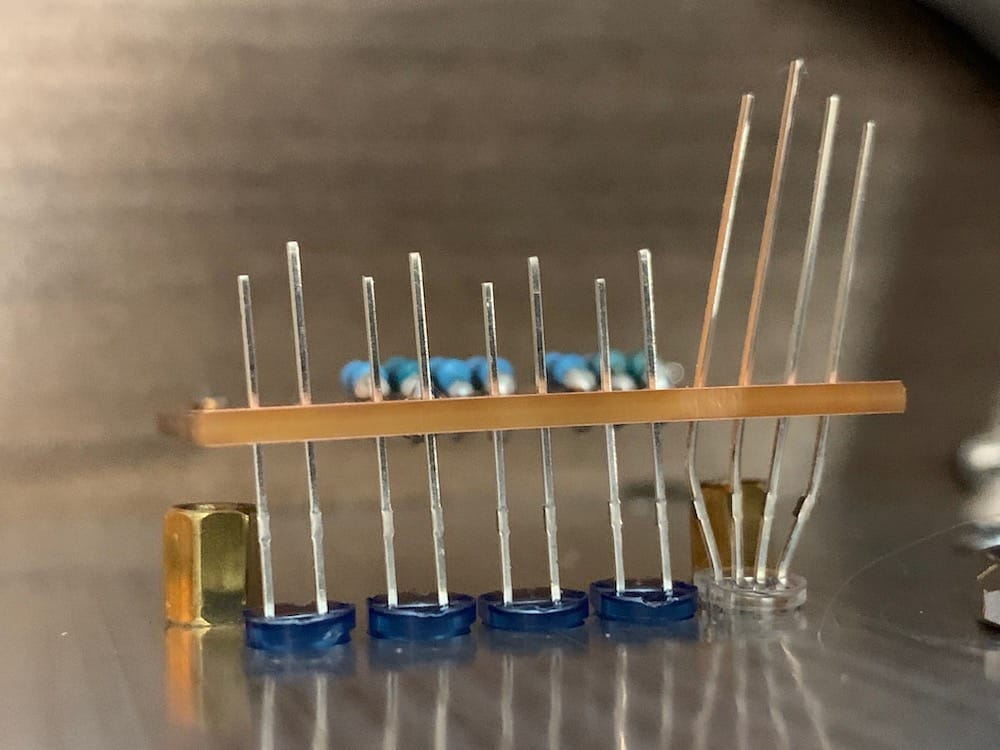

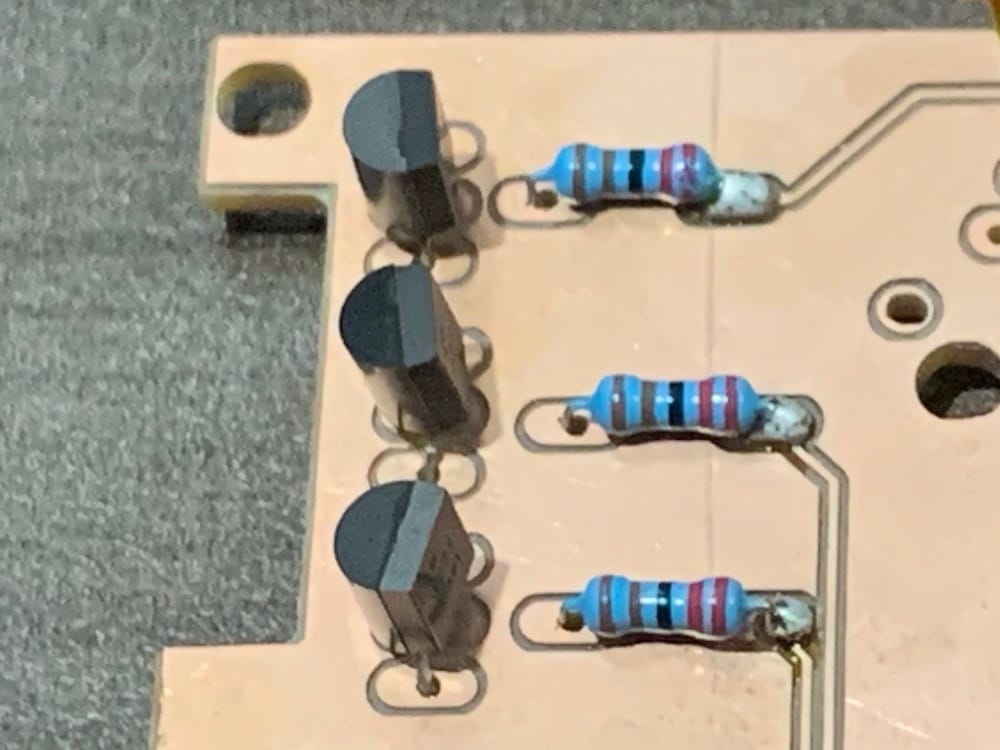

There are a total of three printed circuit boards that need to be manufactured using the Bantam Tools Machine. The LED, APX-18, and R.Pi boards are machined out of double-sided PCB blanks. Each PCB requires the use of the same three End Mills (1/16” Flat, 1/32” Flat, 0.005” PCB Engraving). Pay close attention to the required End Mill for each milling operation and ensure that the Bit Fan is always installed on each End Mill. The Bantam Tools Machine should be cleaned of dust and removed PCB materials whenever safely possible. The Fine Dust Collection System or Vacuum Port performance upgrades are highly recommended.

The reader is strongly encouraged to work through the Bantam Tools Light Up PCB Badge - Getting Started Project before proceeding with manufacturing the OpenMMS PCBs. The Getting Started Project provides excellent explanations, does and don’ts, and other valuable information on PCB milling using the Bantam Tools Machine.

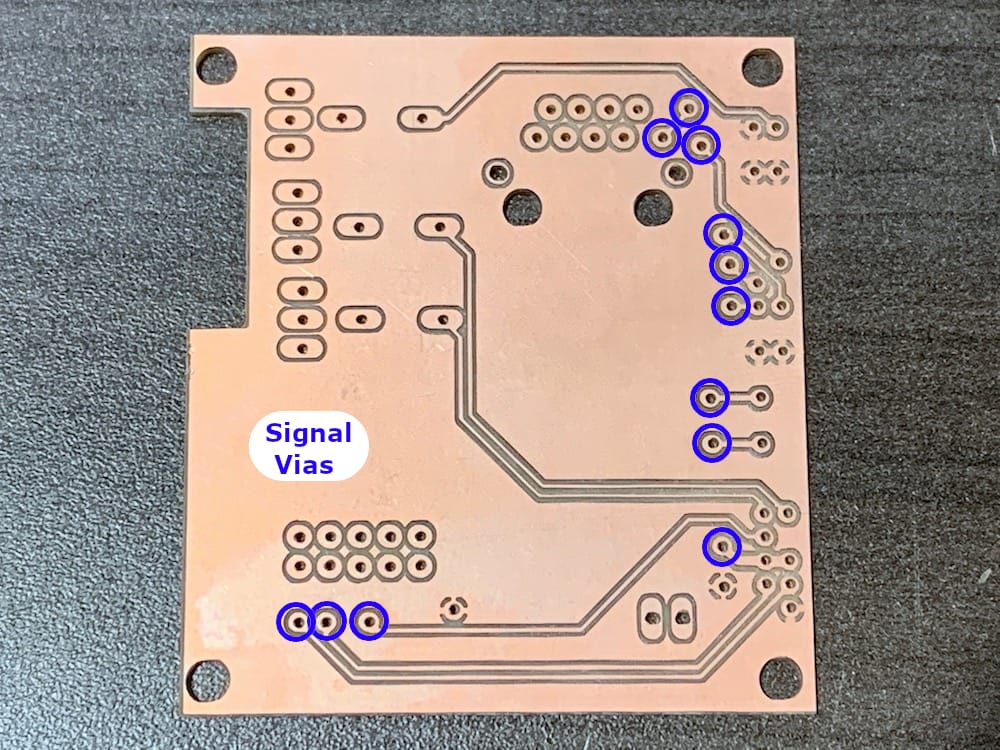

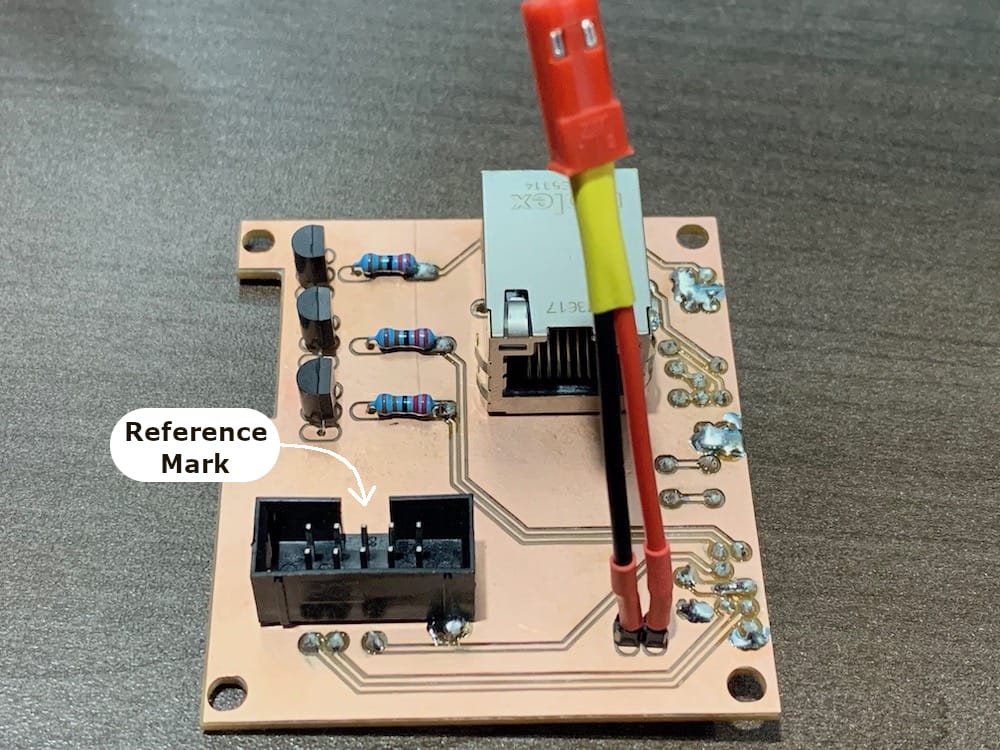

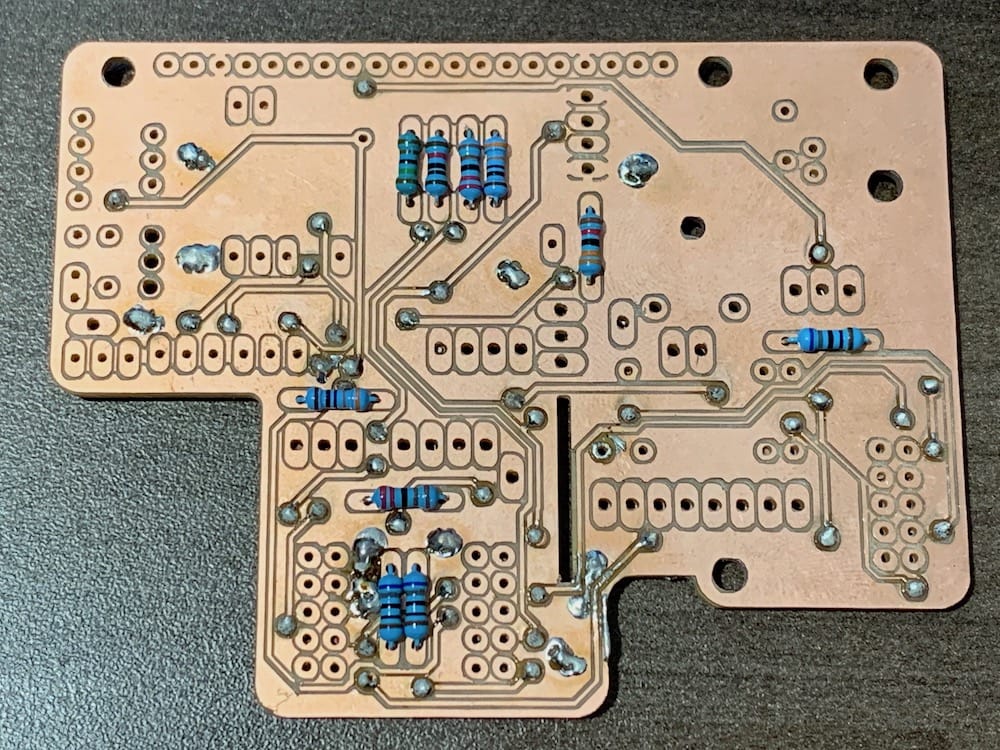

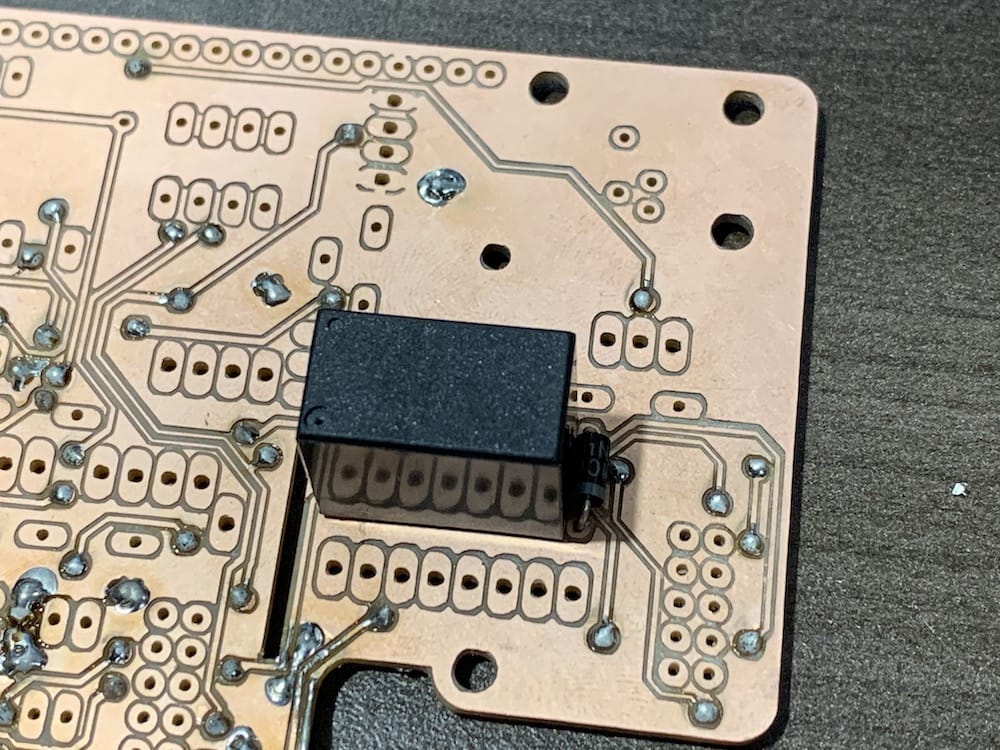

Autodesk Eagle software was used to design the PCBs. All of the design information and digital files are included below for each PCB. Each PCB has two sets of design information. The 1st set is for a design that can be manufactured by the end-user using the Bantam Tools Machine. The PCB tables below include the design information and manufacturing steps for creating the PCBs using the Bantam Tools Machine. The 2nd set of designs for each PCB contains the information that can be sent to a commercial PCB manufacturer. These designs are included in the Commercially Made PCBs section below. The design differences are the trace widths, via sizes, use of plated through holes, and some hole sizes. The Bantam Tools PCBs do not use plated through holes. The PCBs’ vias need to be manually soldered, and the boards do not have a conformal coating. Therefore, precise soldering is an essential skill required to produce the PCBs successfully.

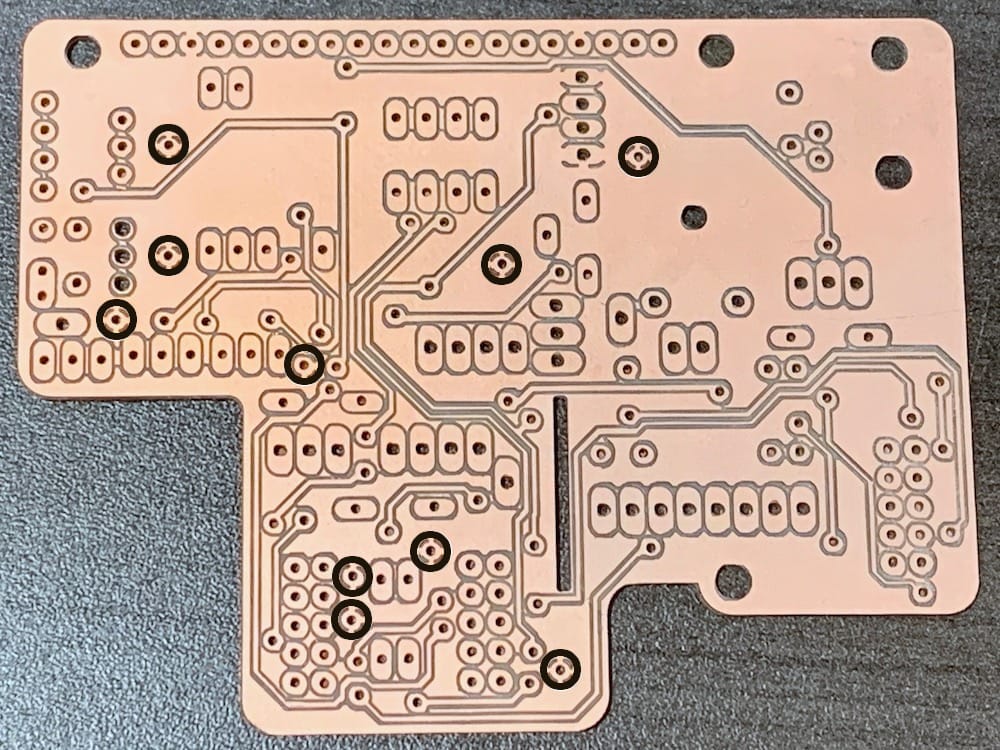

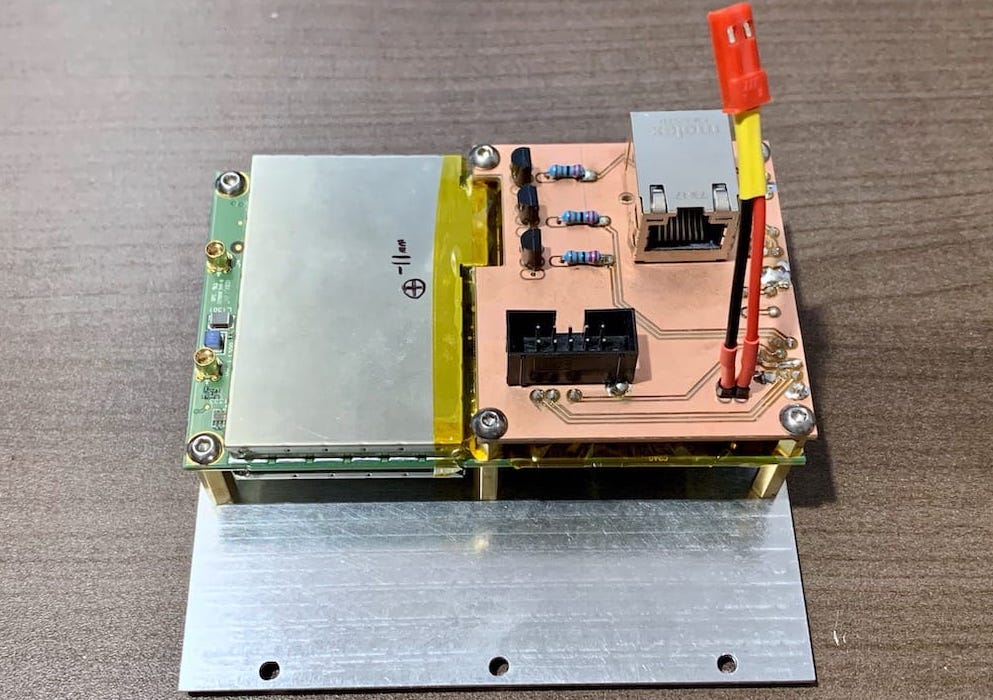

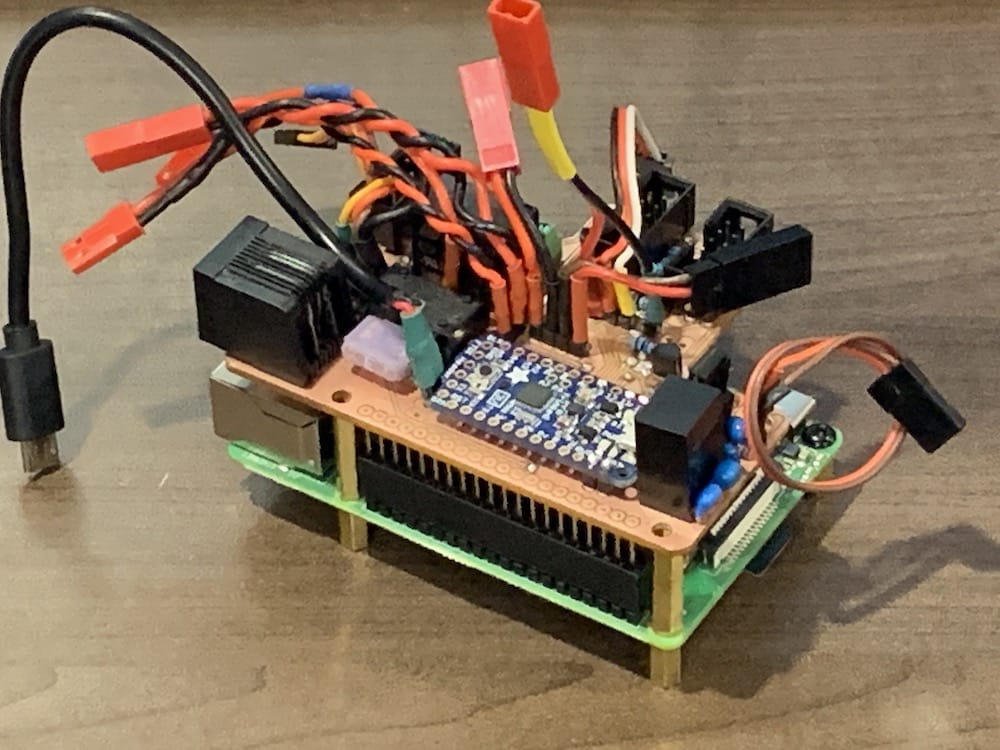

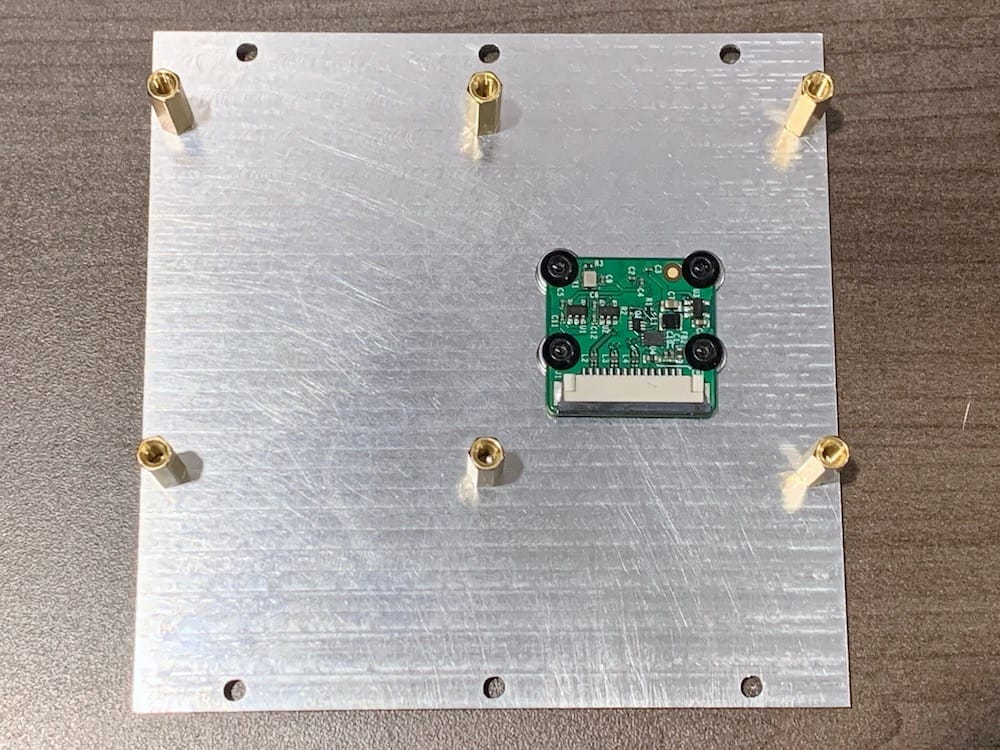

Fig 5.1-1. OpenMMS Printed Circuit Boards¶

5.2. Instructions¶

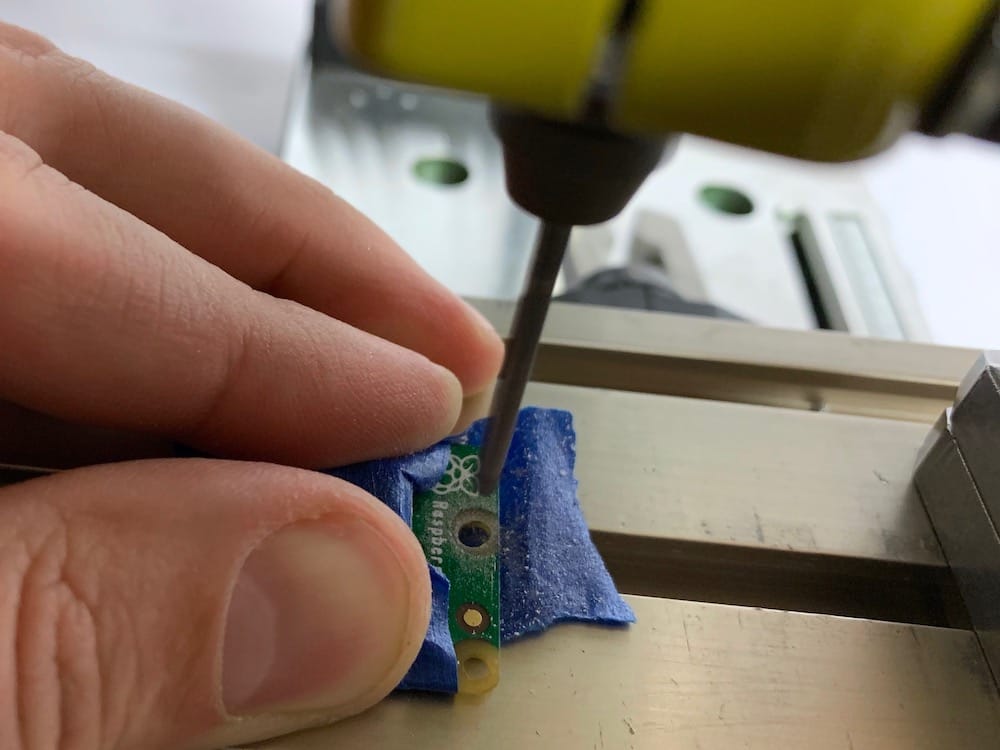

Manufacturing PCBs using the Bantam Tools Machine is more straightforward than the aluminum parts. However, the final manufacturing quality of the PCBs is much more critical than for the aluminum parts. All milling operations are performed using the 3rd Bantam Tools Machine Setup (BTMS). See the previous Bantam Tools Machine Setups section for details. Strong double-sided tape is required to hold the PCB blanks while being machined. Special care needs to be used when removing the PCBs from the spoilboard. Using isopropyl alcohol to release the strong tape is a MUST, or you run the risk of damaging the PCB while trying to remove it from the machine!

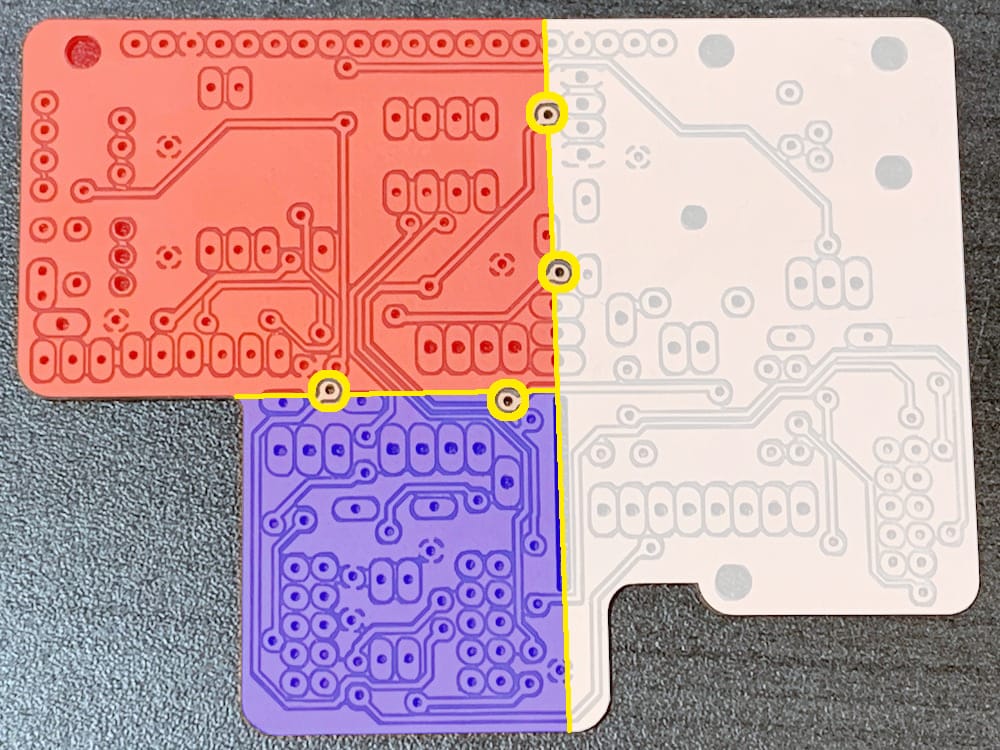

All three PCBs can be squeezed onto one double-sided PCB blank, and therefore manufactured at the same time. It is crucial to pay close attention to the Bantam Tools Software Configuration settings for each PCB milling operation as there are NO individual GCODE files used for milling the PCBs. Instead of GCODE files, the Eagle produced board design files (.brd files) are used directly within the Bantam Tools software, and the software generates all the milling commands based on the design. There are two top PCB operations and three bottom PCB operations required to complete each board.

Fig 5.2-1. All three PCBs being milled (forgot to turn on the vacuum, oops)¶

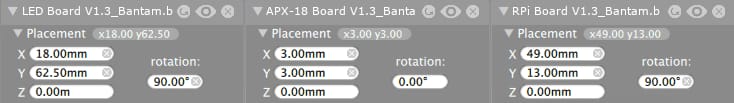

Because all three PCBs can be milled from the same double-sided PCB blank, the same type of milling operation (i.e., holes, or traces, or outlines) can be performed sequentially for each PCB. Continuous milling operations can be accomplished by selecting the same type of milling operation for all three PCBs within the Bantam Tools software and then clicking the ‘Mill All Visible’ button at the bottom of the right side column. Equivalently, you can perform ALL the 1st milling operations on the three PCBs, then ALL the 2nd milling operations, until lastly ALL the 5th milling operations are completed. The figure below illustrates the Bantam Tools software Part Placement settings for each PCB that allows all of them to fit on a single PCB blank.

Fig 5.2-2. Bantam Tools software part placement settings for the PCBs¶

Attention

For those interested in viewing/editing the Autodesk Eagle projects for the PCBs, you will need to download the OpenMMS Eagle Libraries and Design Rules and add them to your local Eagle environment. The author of this documentation is a beginner user of Autodesk Eagle software, and therefore the PCB designs and schematics are simplistic and likely appear unconventional. Community contributions in this area of the project would be most welcomed!

5.3. Commercially Made PCBs (optional)¶

If a reader is interested in having the OpenMMS PCBs manufactured by a commercial printed circuit board shop, the following design information for each PCB should be used. Included within these design information zip files are:

Autodesk Eagle project file.

Eagle schematic file (.sch)

Eagle board file (.brd)

CAMOutputs directory, this contains all the Gerber files that a commercial PCB manufacturer will require.

PDF file showing the electrical schematic for the PCB

PDF file showing the layout of the PCB (both sides)

Table H11: Production Version PCBs Design Files

PRODUCTION VERSION

PCB DESIGN FILES2D/3D Viewer

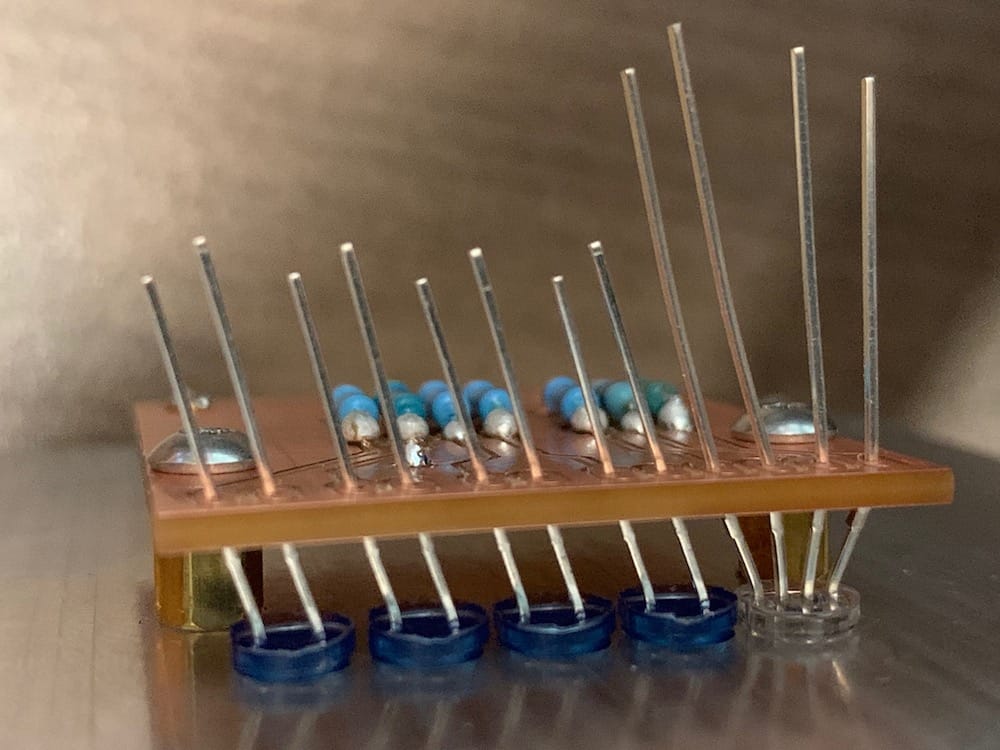

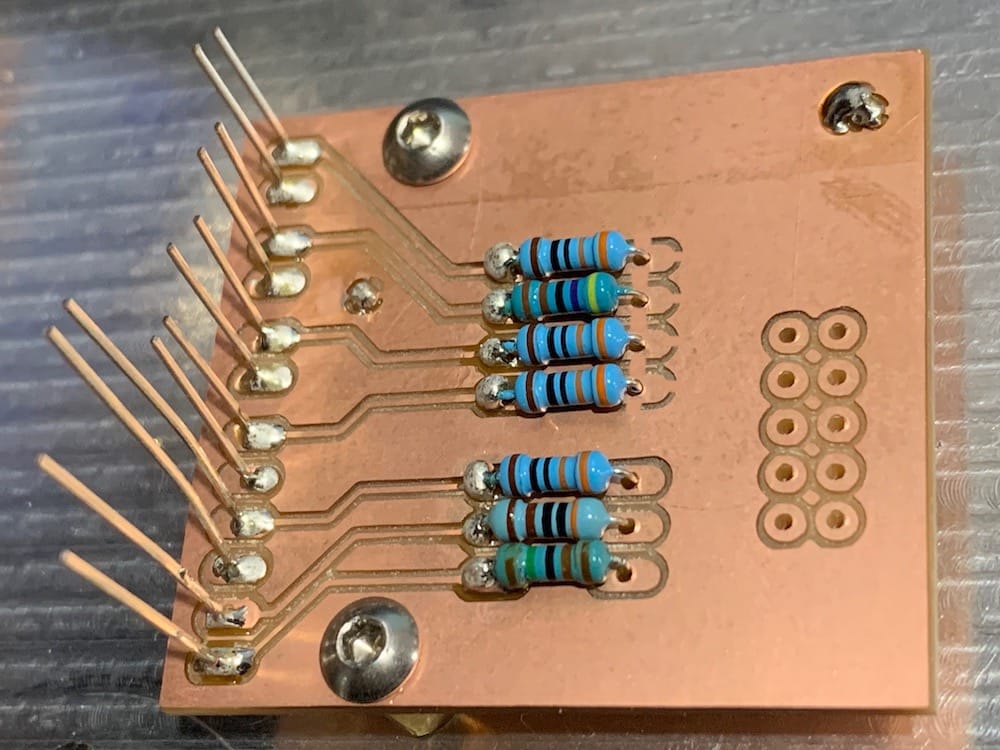

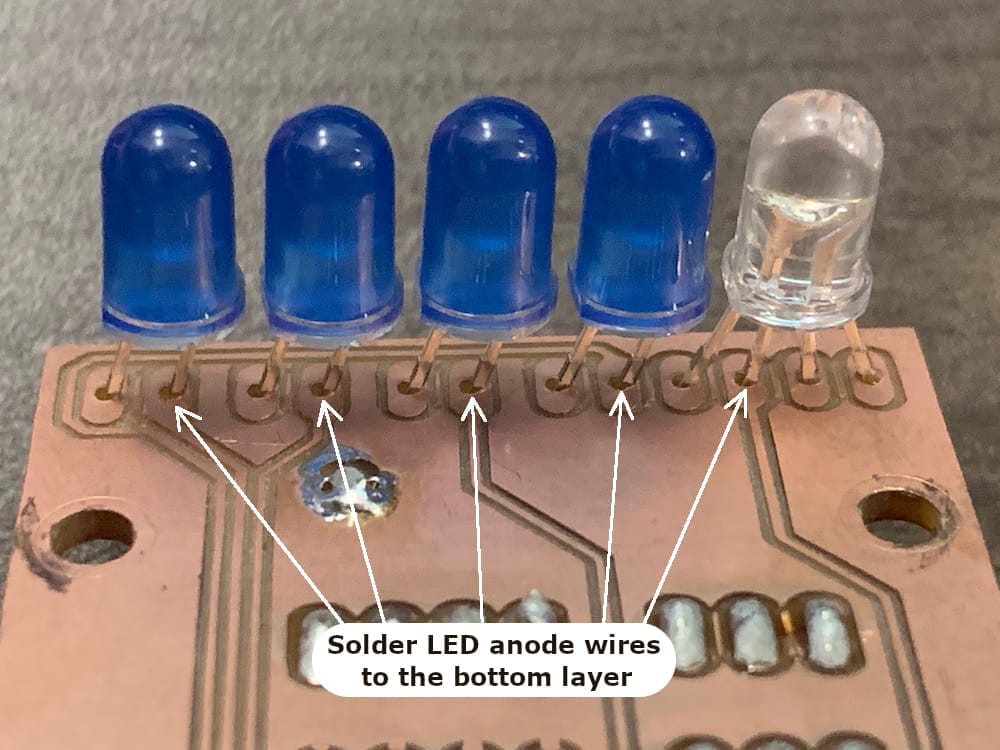

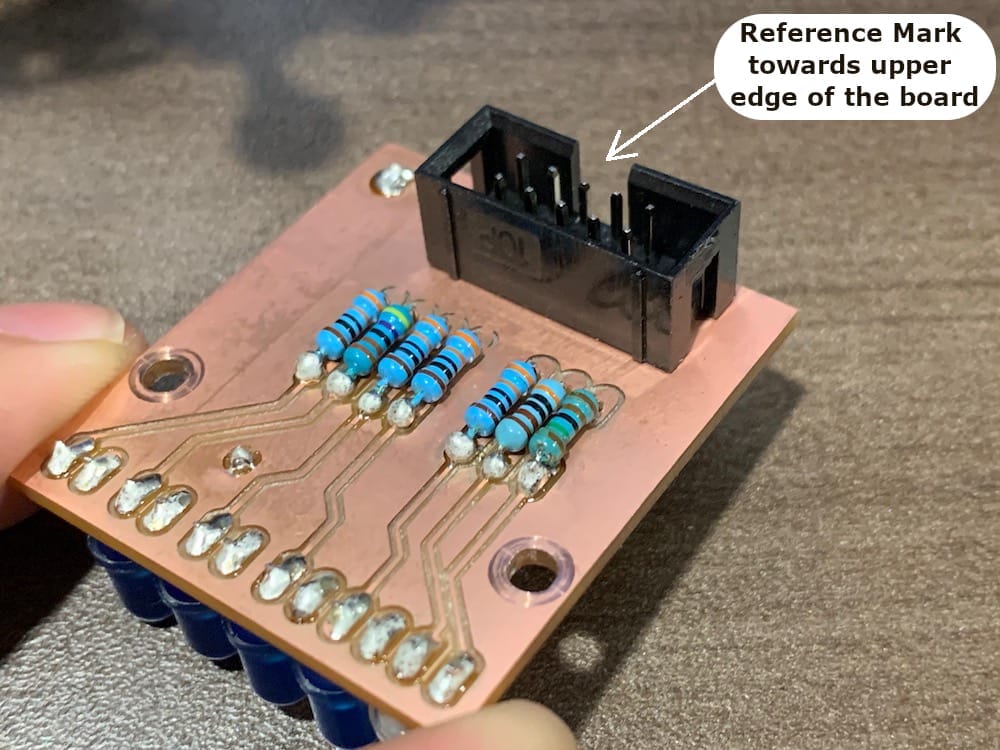

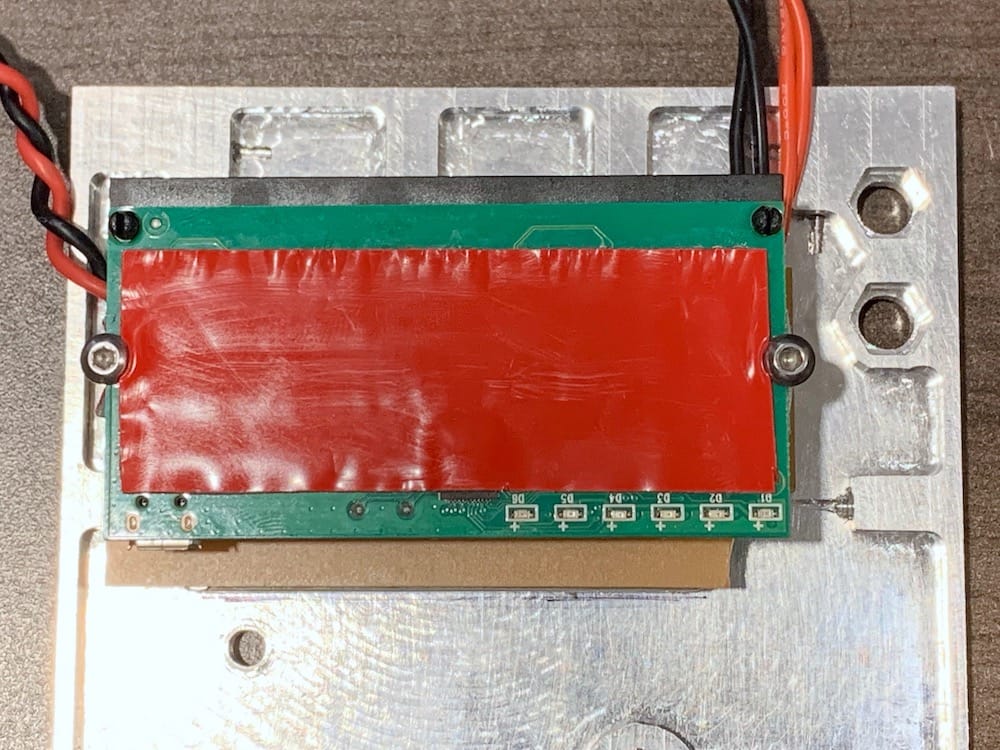

5.4. LED Board¶

Table H12: LED Board Design and Manufacturing Files

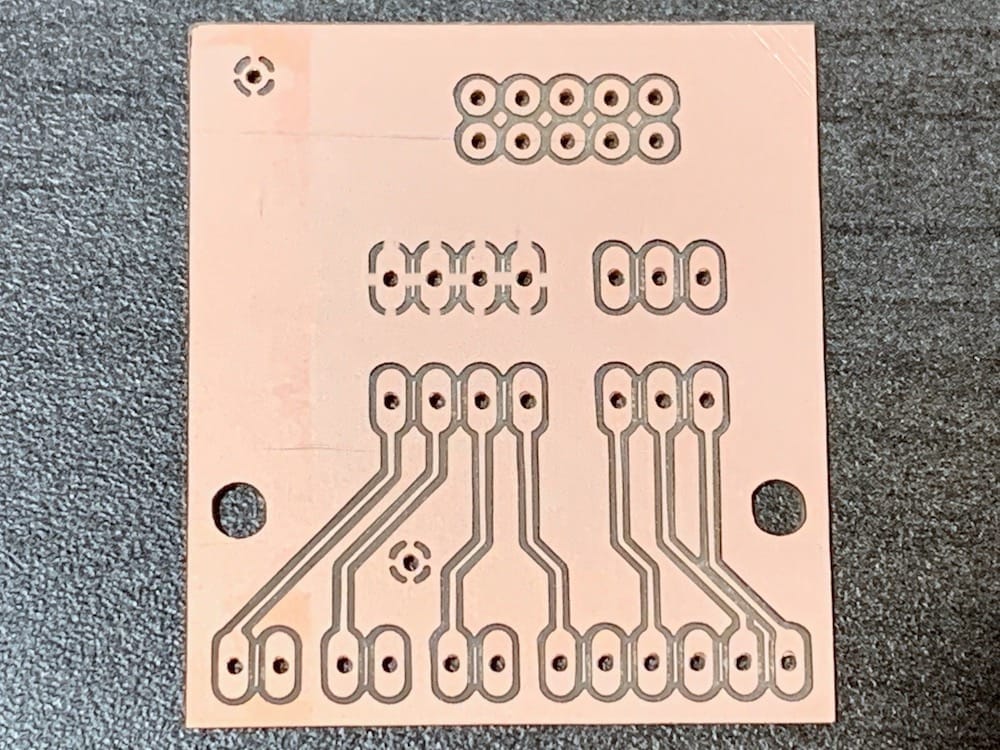

Fig 5.4-1. LED Board (Top)¶

Fig 5.4-2. LED Board (Bottom)¶

Version: 1.3

Quantity: 1

Material:

FR-1 Double-sided PCB Blank

End Mills Required:

Blank Dimensions:

127.0mm x 101.6mm x 1.6mm

1/16” Flat End Mill (16F)

1/32” Flat End Mill (32F)

0.005” PCB Engraving Bit (5E)

BANTAM VERSION PCB DESIGN:

2D/3D Viewer:

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

Eagle Board File:

Bantam Tools Software Configurations

1

2

3

4

5

Traces

Holes

Holes

Traces

Outline

3

3

3

3

3

Top

Top

Bottom

Bottom

Bottom

5E

32F

32F

5E

16F

LED Board V1.3_Bantam.brd

SAME

SAME

SAME

SAME

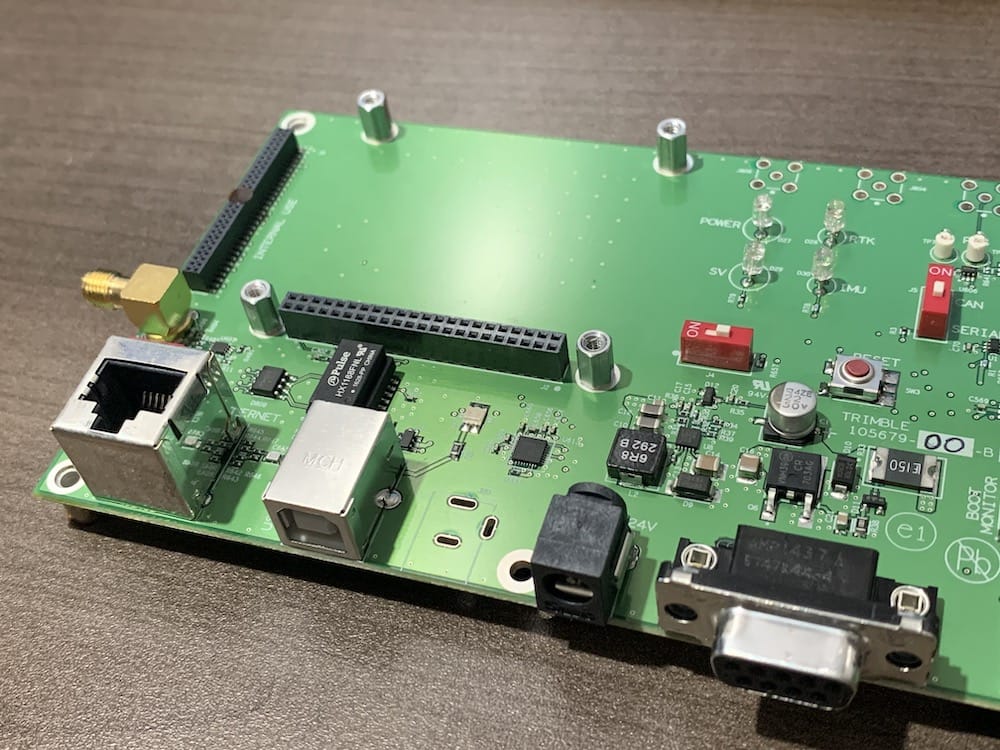

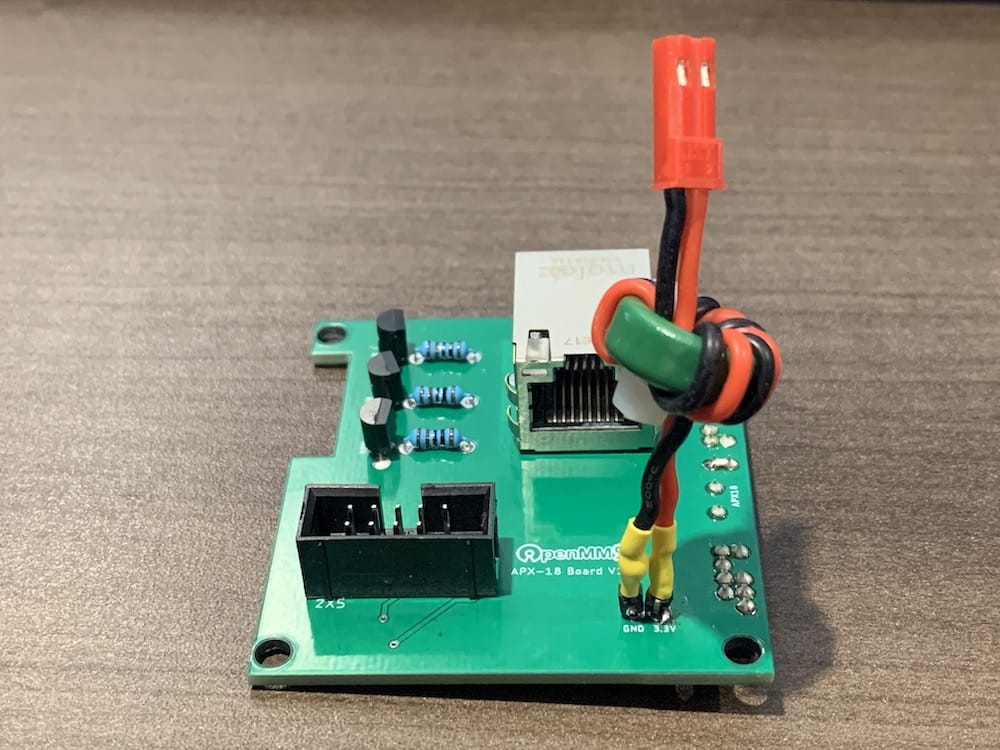

5.5. APX-18 Board¶

Table H13: APX-18 Board Design and Manufacturing Files

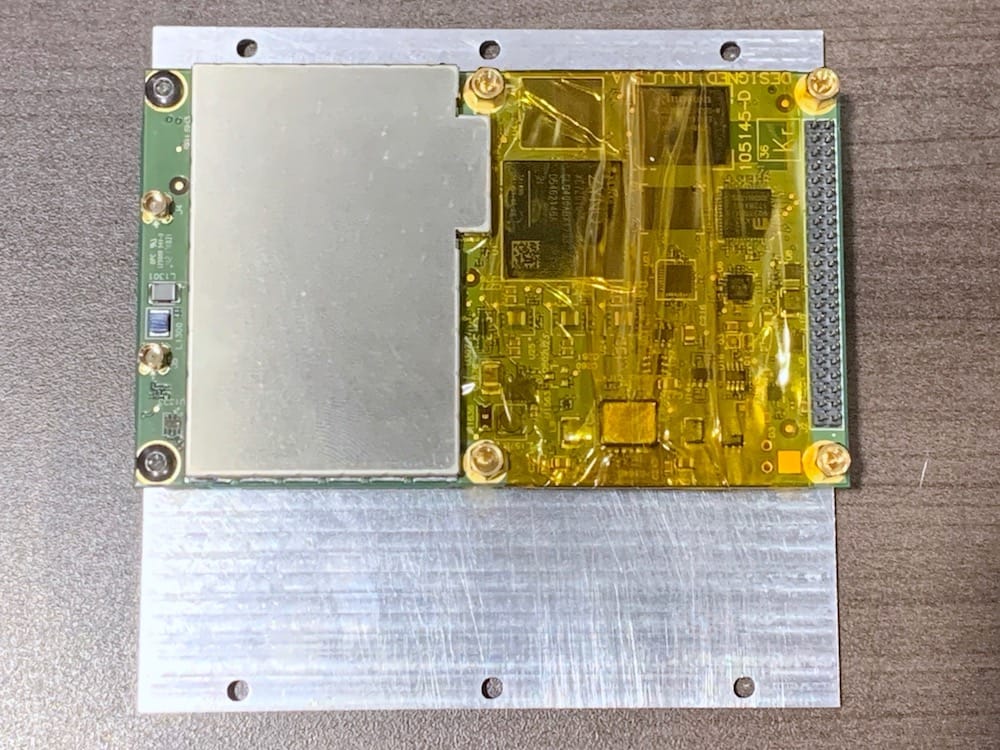

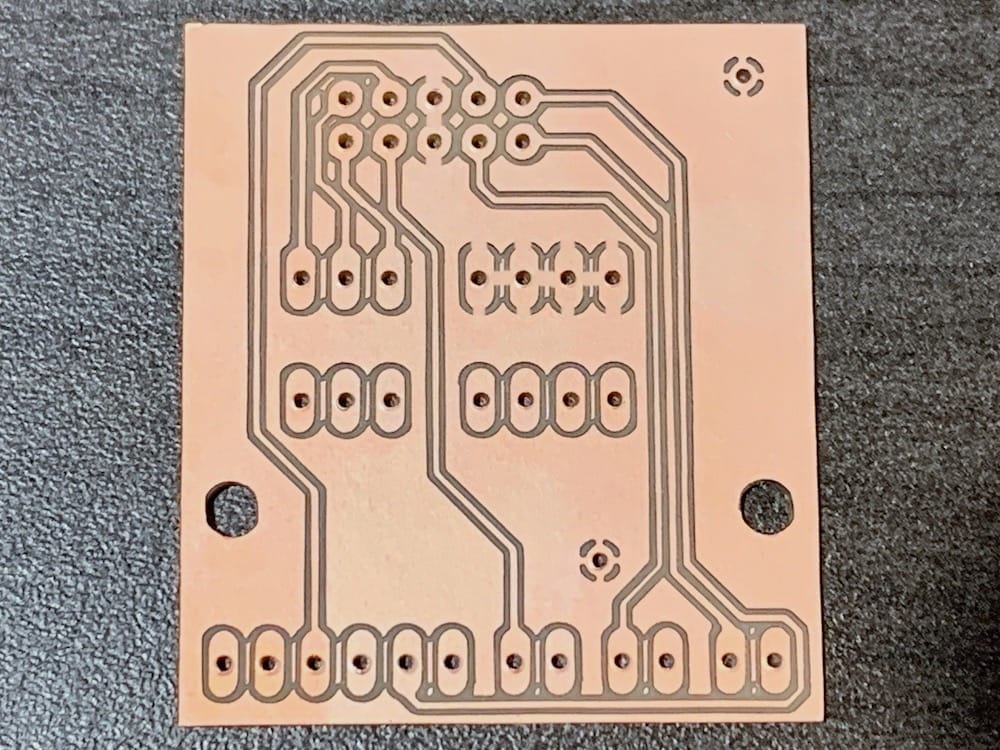

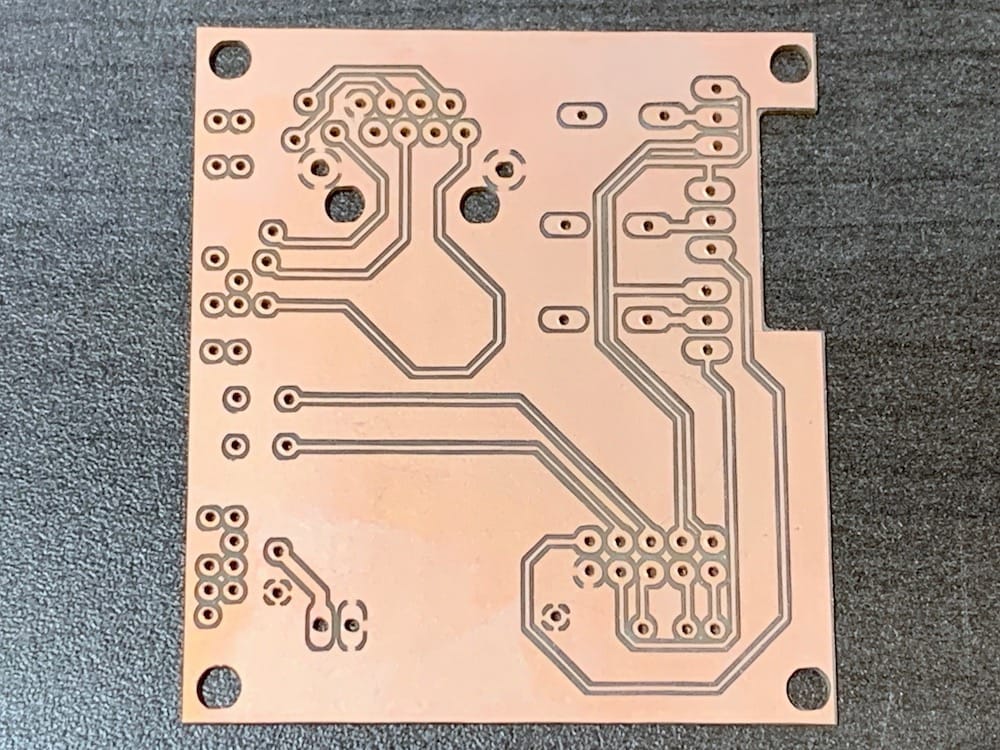

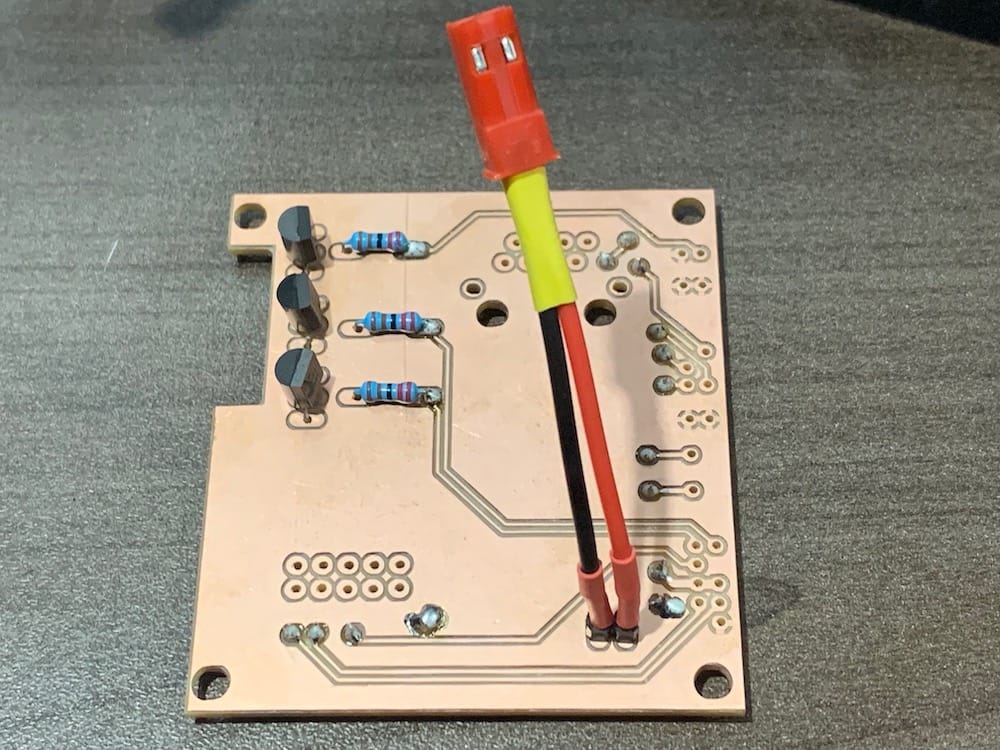

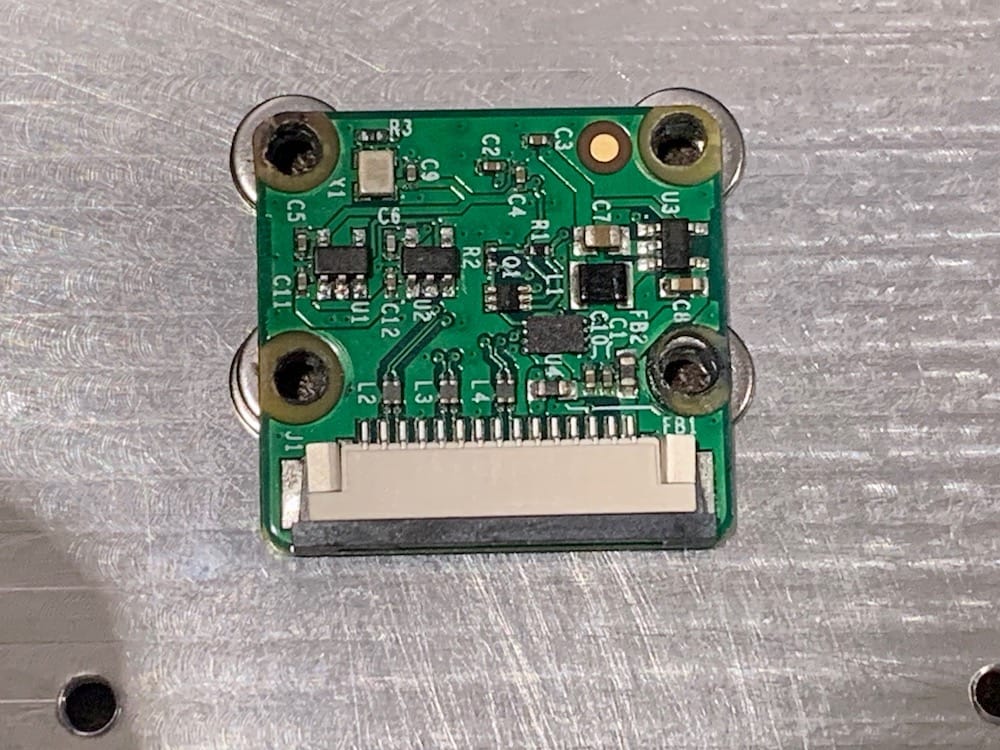

Fig 5.5-1. APX-18 Board (Top)¶

Fig 5.5-2. APX-18 Board (Bottom)¶

Version: 1.3

Quantity: 1

Material:

FR-1 Double-sided PCB Blank

End Mills Required:

Blank Dimensions:

127.0mm x 101.6mm x 1.6mm

1/16” Flat End Mill (16F)

1/32” Flat End Mill (32F)

0.005” PCB Engraving Bit (5E)

BANTAM VERSION PCB DESIGN:

2D/3D Viewer:

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

Eagle Board File:

Bantam Tools Software Configurations

1

2

3

4

5

Traces

Holes

Holes

Traces

Outline

3

3

3

3

3

Top

Top

Bottom

Bottom

Bottom

5E

32F

32F

5E

16F

APX-18 Board V1.3_Bantam.brd

SAME

SAME

SAME

SAME

5.6. RPi Board¶

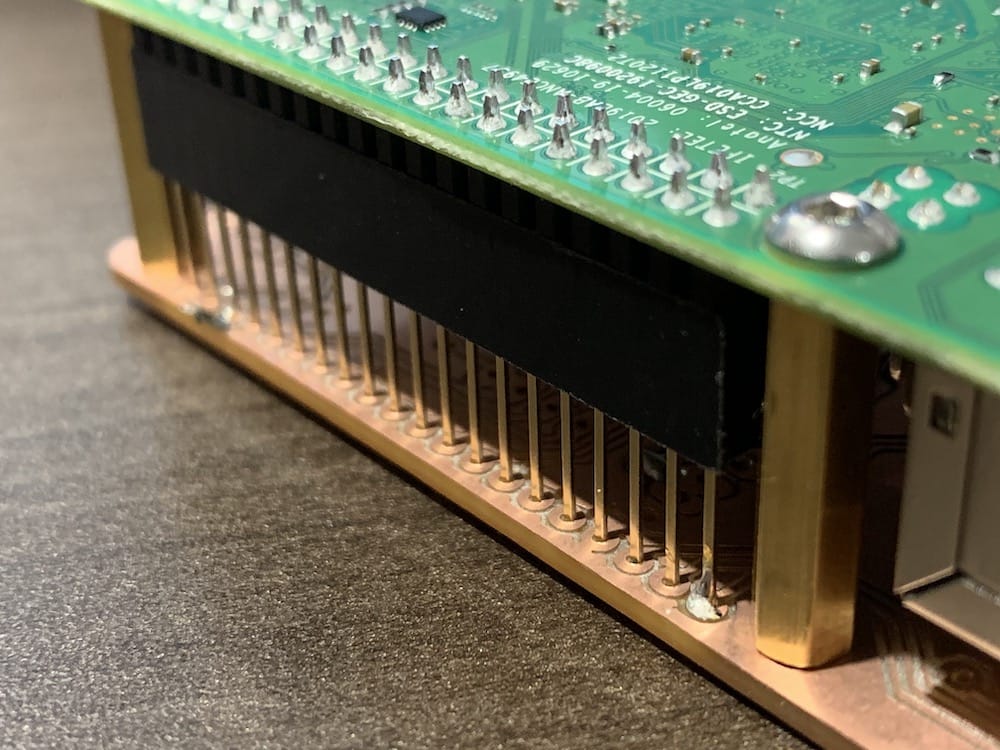

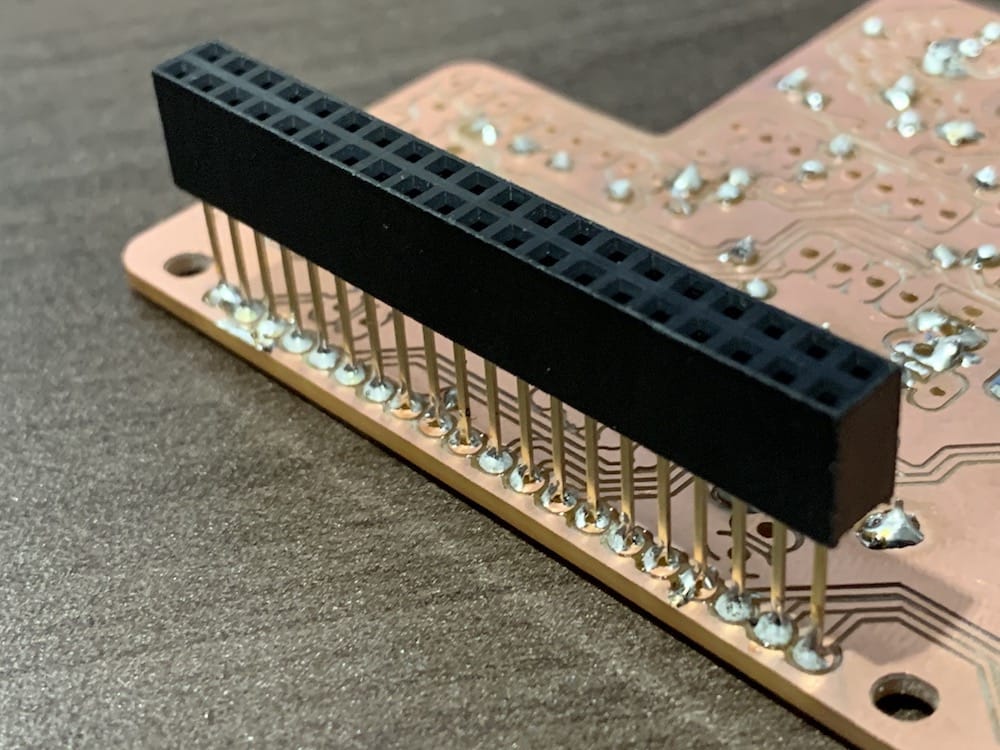

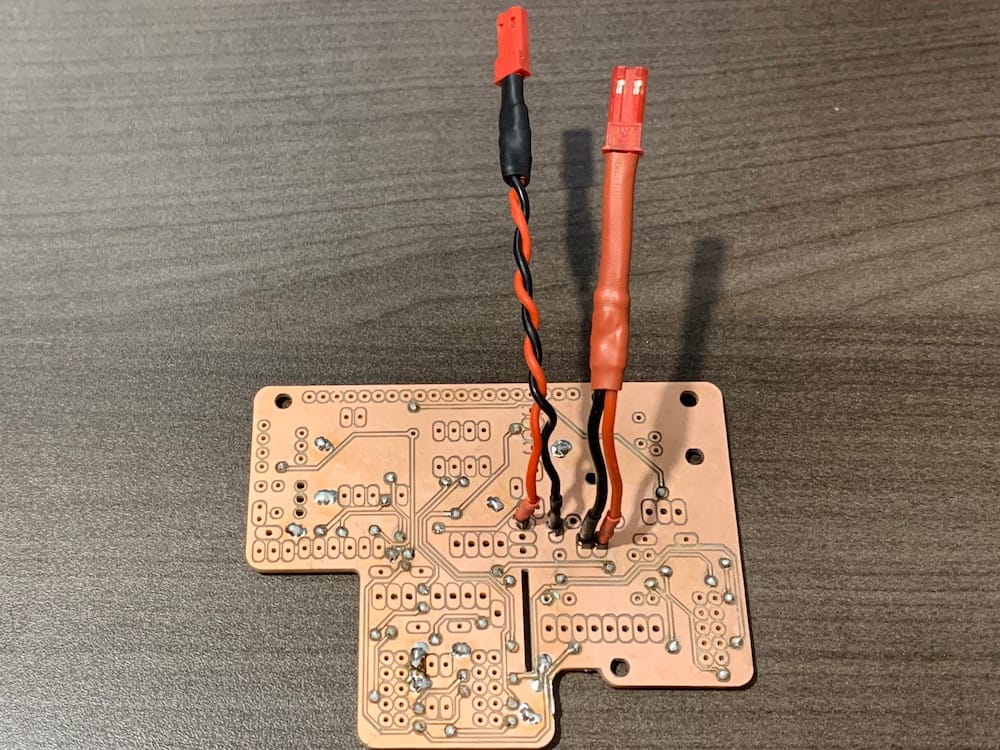

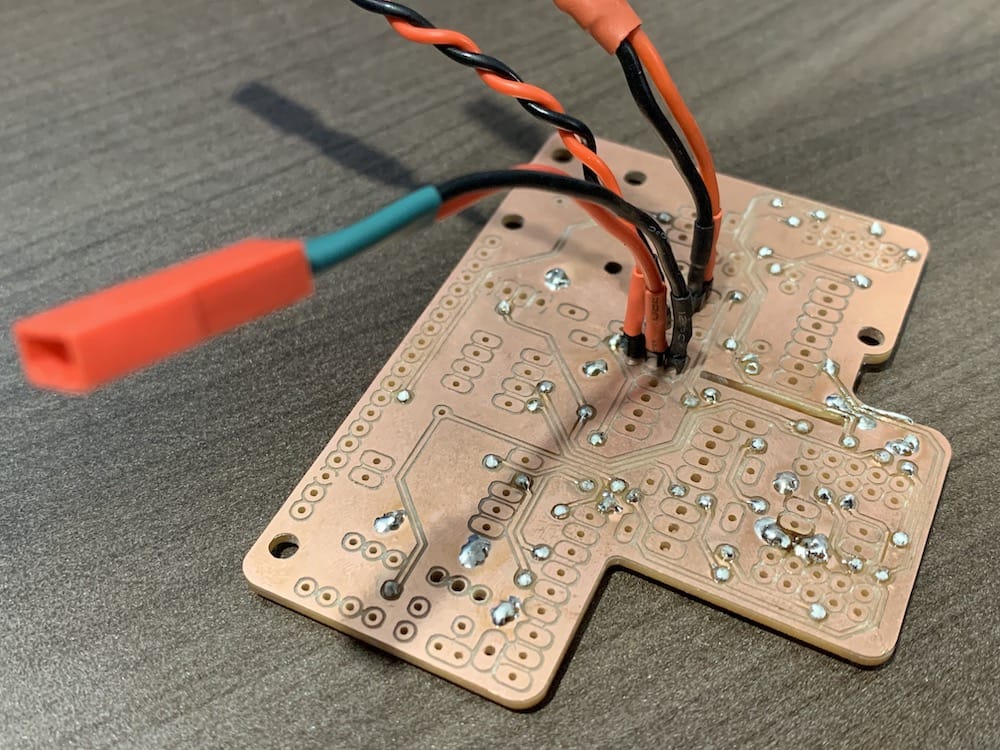

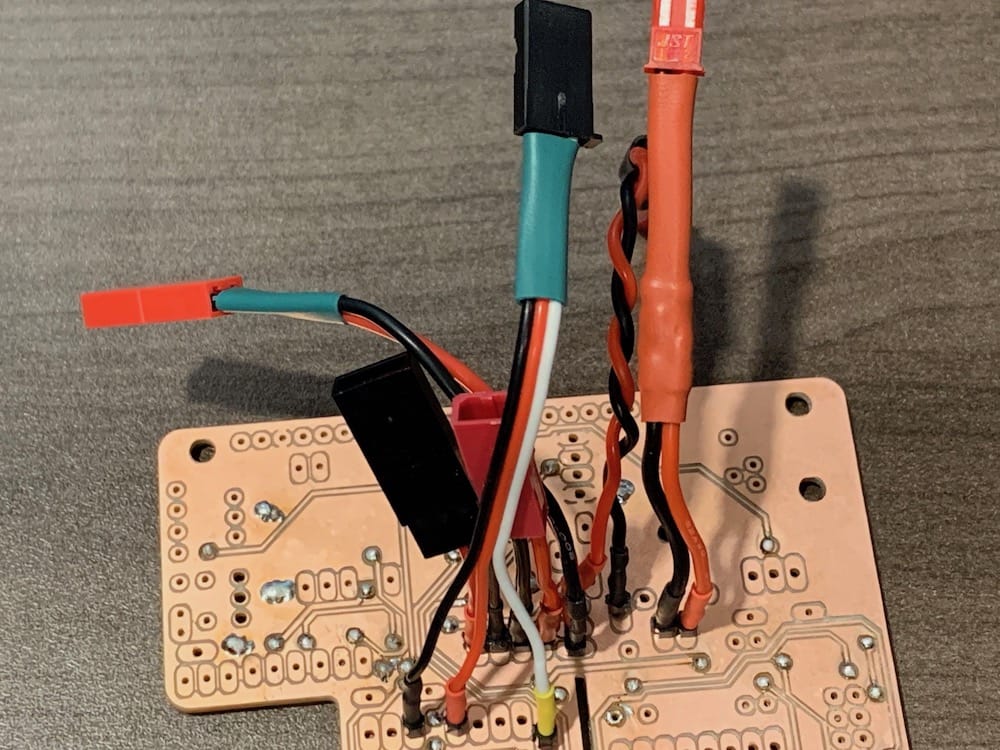

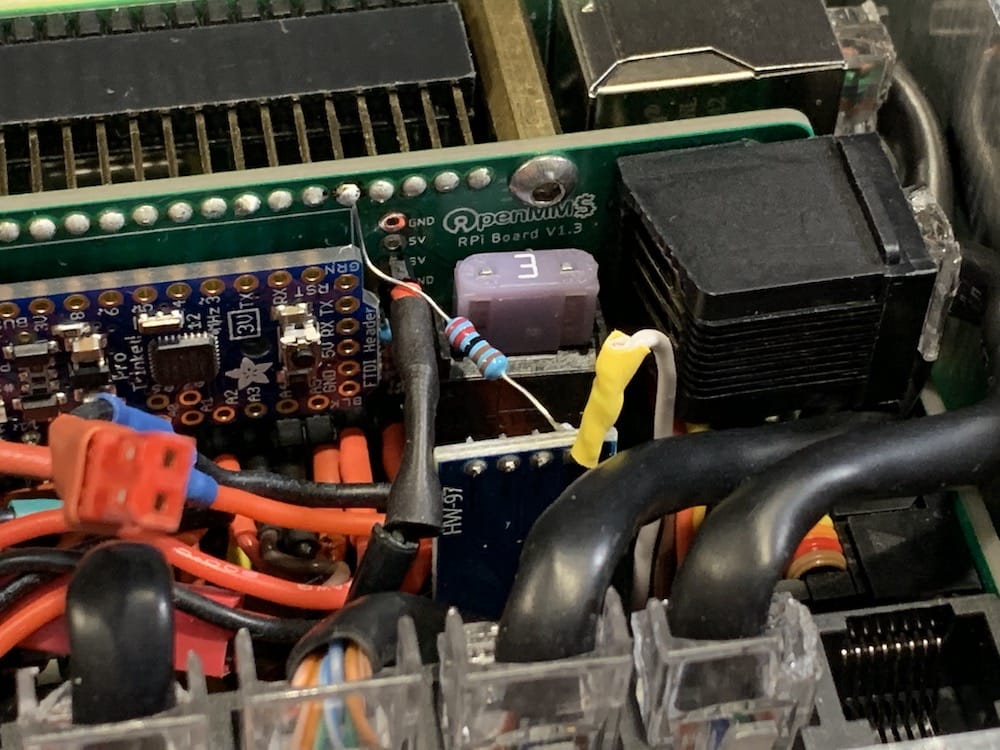

Table H14: RPi Board Design and Manufacturing Files

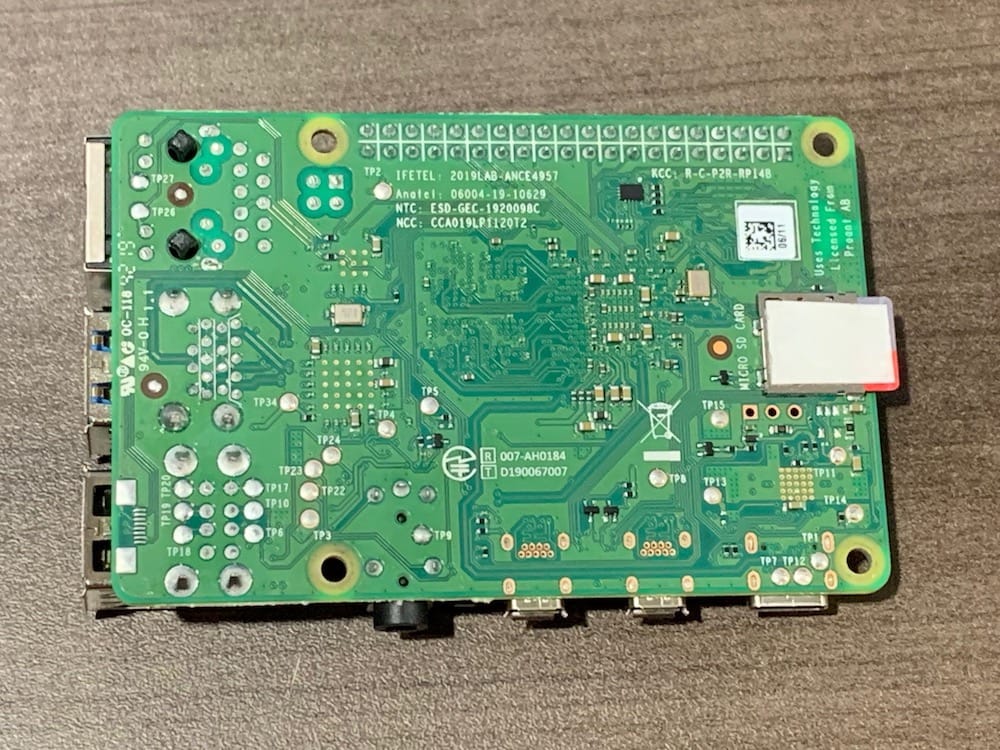

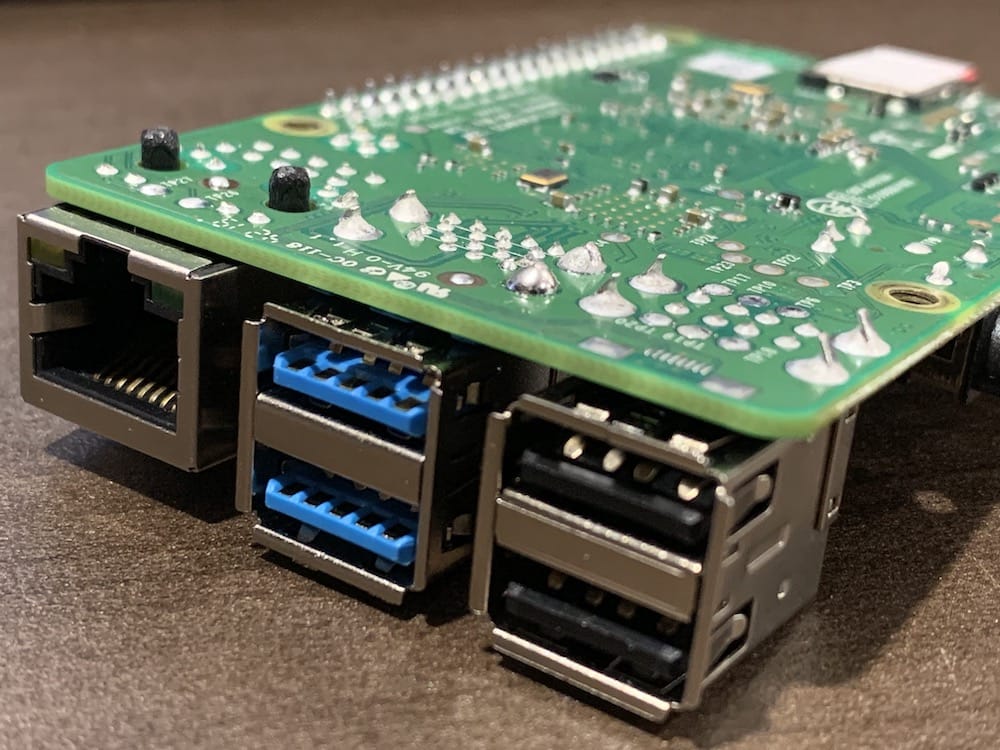

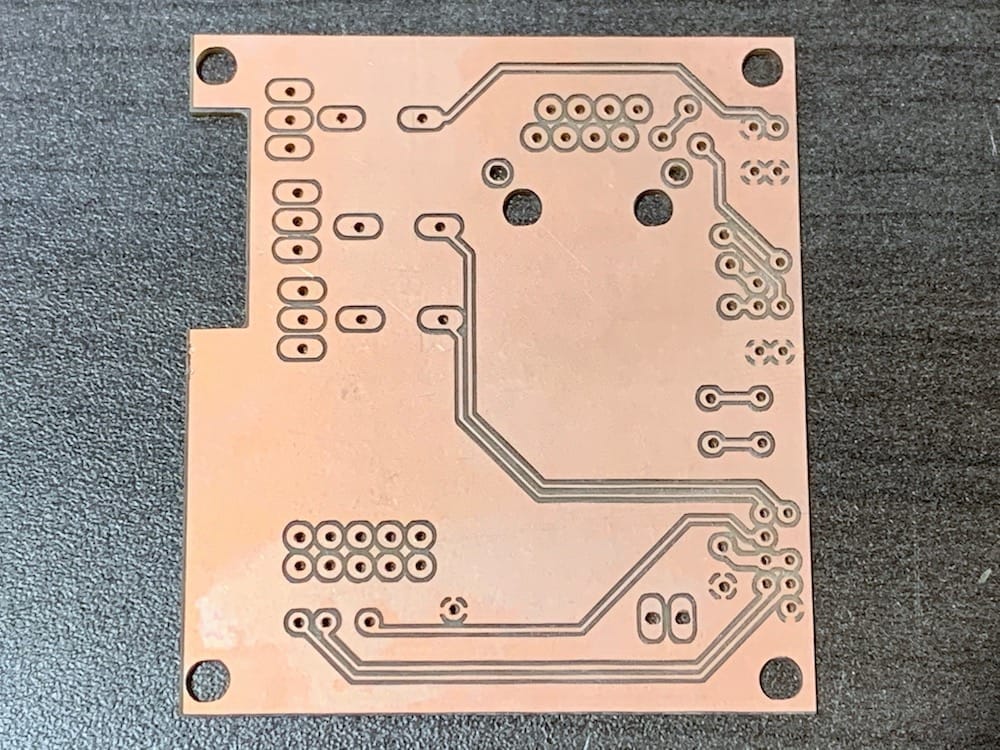

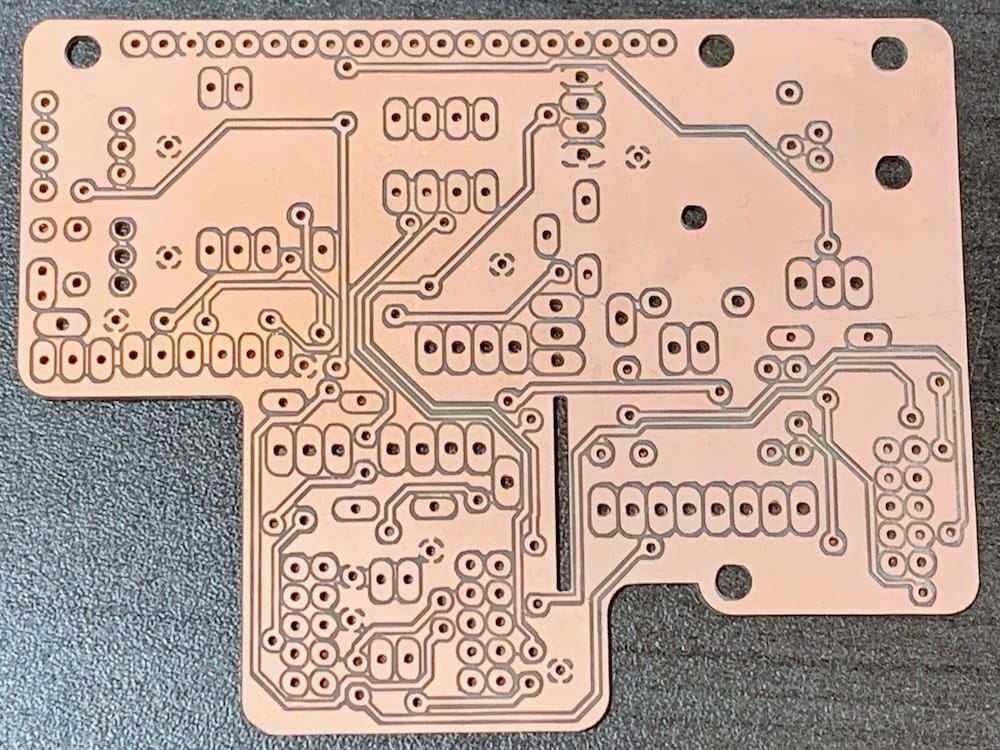

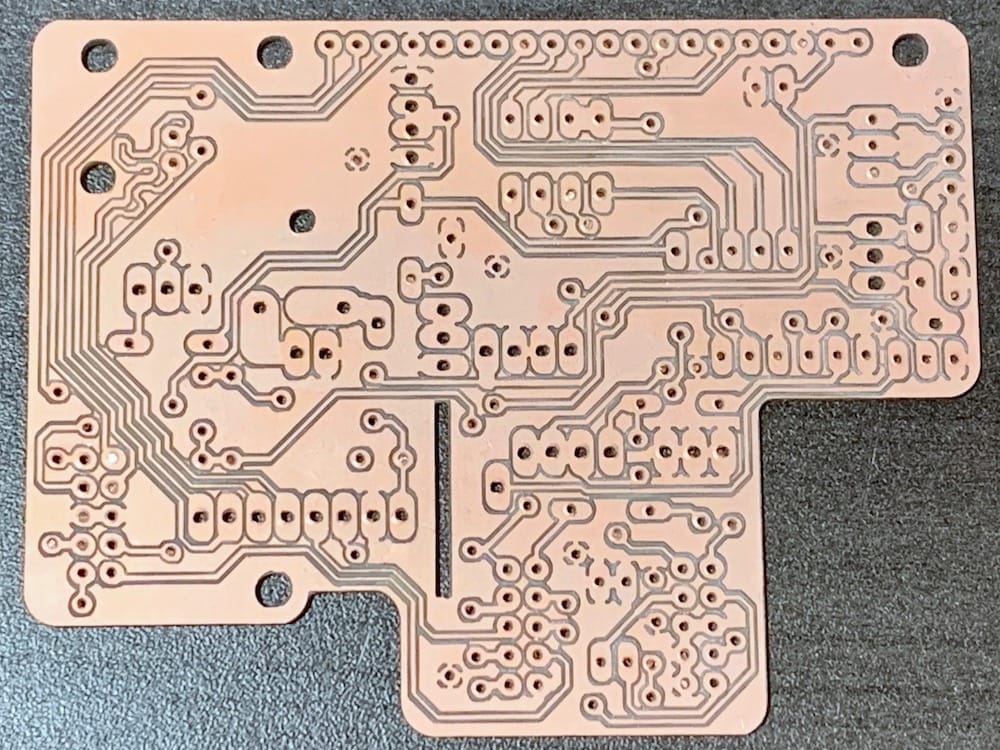

Fig 5.6-1. RPi Board (Top)¶

Fig 5.6-2. RPi Board (Bottom)¶

Version: 1.3

Quantity: 1

Material:

FR-1 Double-sided PCB Blank

End Mills Required:

Blank Dimensions:

127.0mm x 101.6mm x 1.6mm

1/16” Flat End Mill (16F)

1/32” Flat End Mill (32F)

0.005” PCB Engraving Bit (5E)

BANTAM VERSION PCB DESIGN:

2D/3D Viewer:

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

Eagle Board File:

Bantam Tools Software Configurations

1

2

3

4

5

Traces

Holes

Holes

Traces

Outline

3

3

3

3

3

Top

Top

Bottom

Bottom

Bottom

5E

32F

32F

5E

16F

RPi Board V1.3_Bantam.brd

SAME

SAME

SAME

SAME

5.7. Support Board¶

An additional ‘part’ is also machined out of PCB material. It does not contain any electronic circuitry, but once installed in the case its copper-covered side(s) will act as a ground plane. This ‘part’ is called the Support Board and it can be machined out of a single-sided PCB blank (or a double-sided PCB blank if that is all you have). There is a single GCODE file for creating the Support Board using a 1/8” Flat End Mill.

Table H15: Support Board Design and Manufacturing Files

Fig 5.7-1. Support Board (Single-sided PCB)¶

Version: 1.3

Quantity: 1

Material:

FR-1 Single (or Double) sided PCB Blank

End Mills Required:

Blank Dimensions:

127.0mm x 101.6mm x 1.6mm

1/8” Flat End Mill (8F)

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE Files:

Bantam Tools Software Configurations

1

Cut

3

Top

8F

5.8. After Milling¶

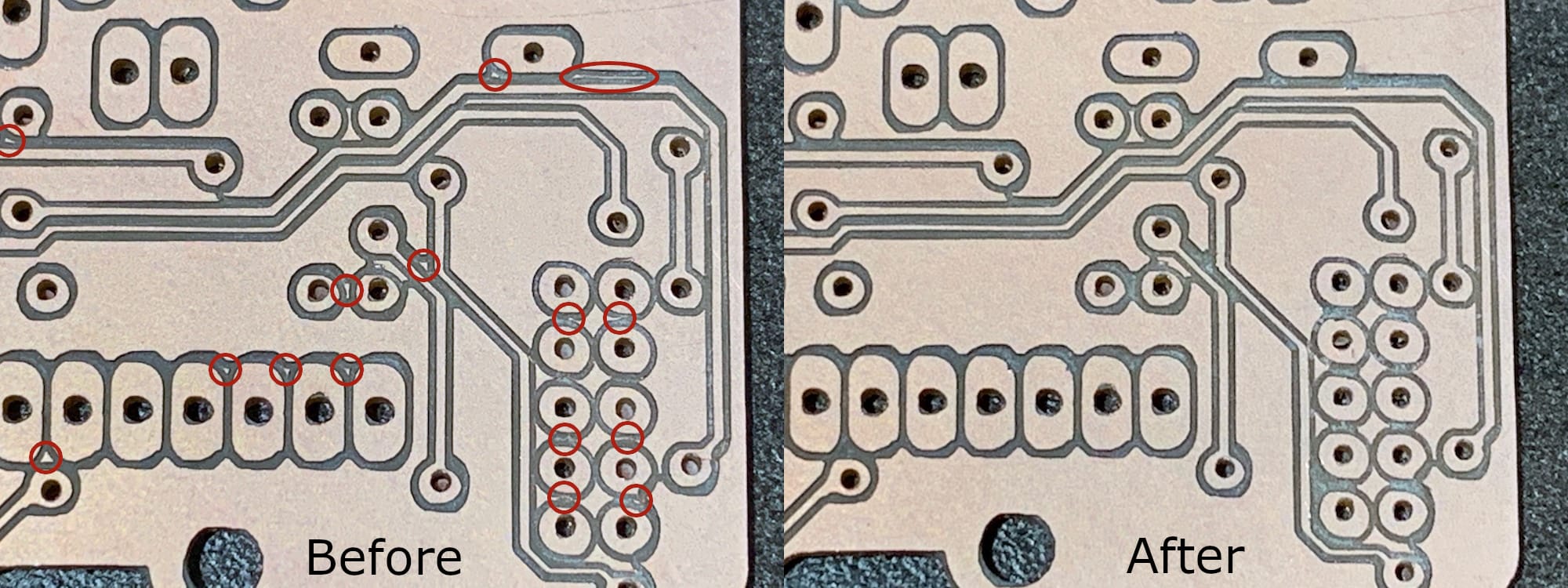

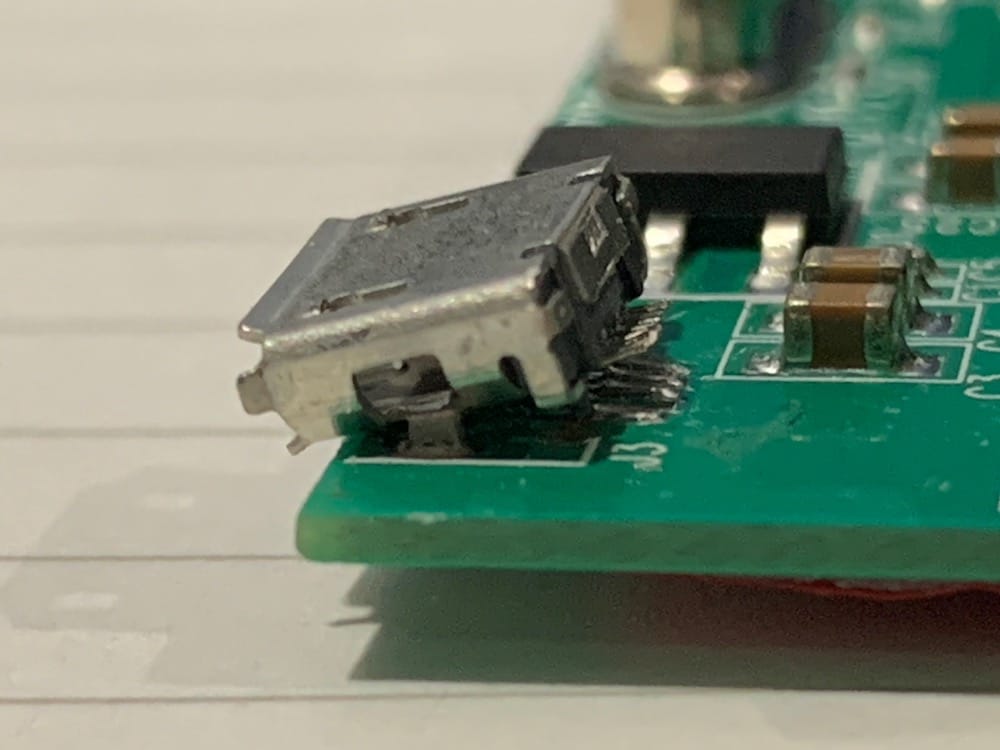

It is recommended to use a metal file to gently round the sharp 90 degree edges of the Support Board after being milled by the Bantam Tools Machine. Once installed, several power wires run across the edges of the Support Board. The rounded edges prevent the wires from having their protective sheathing cut, potentially causing a short circuit. Next, carefully examine both sides of the printed circuit boards and identify small pieces of copper that could come free. Using the pinpoint tip of an X-Acto knife, carefully remove these pieces of copper. Lastly, it is recommended to scour both sides of the printed circuit boards lightly. A coarse plastic brush works well for this task. The goal is to remove any loose pieces of copper from the printed circuit boards. These pieces of copper could cause electrical damage (i.e., create short-circuits) on the sensitive (and costly) sensors and components inside the case.

Fig 5.8-1. PCB area before and after removing loose/potentially loose pieces of copper¶

CONGRATULATIONS!

YOU HAVE NOW FINISHED MANUFACTURING THE PRINTED CIRCUIT BOARDS!

6. Carbon Fiber Parts Manufacturing¶

Danger

Machining parts from carbon fiber material can create potentially hazardous carbon fiber dust in the air. It is the responsibility of the person(s) using these instructions to produce their own (i.e., the manufacturer of an) OpenMMS sensor, to ensure that satisfactory air quality requirements are met or exceeded, during any process discussed within these instructions when working with carbon fiber material.

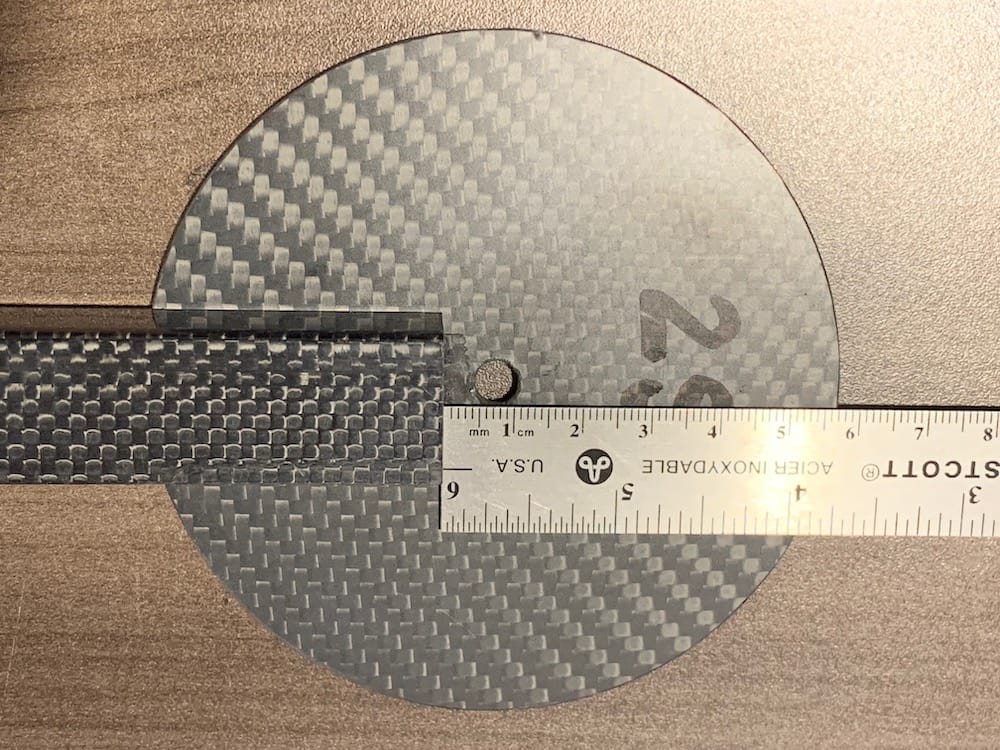

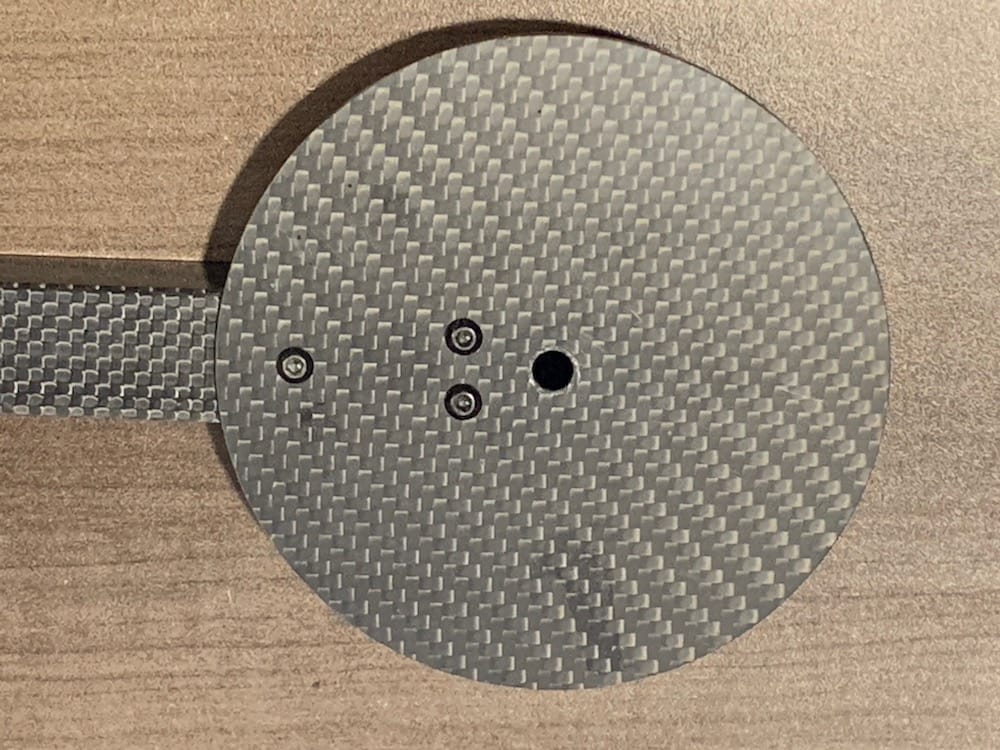

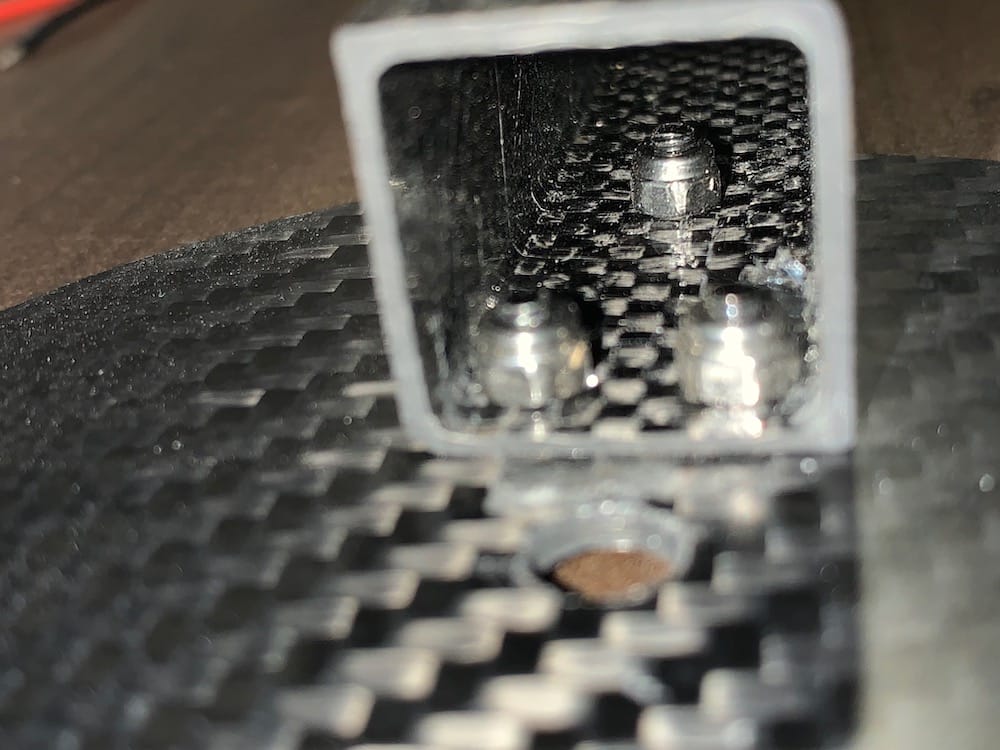

6.1. Overview¶

There are 2 carbon fiber parts that need to be manufactured using the Bantam Tools Machine. The parts are identical and are used as ground planes for the GNSS Antennas connected to the Applanix APX-18 GNSS-INS sensor. The parts are machined out of 2mm thick carbon fiber plate, using a 1/16” Flat End Mill. Ensure that the Bit Fan is installed on the End Mill. The Fine Dust Collection System performance upgrade is HIGHLY RECOMMENDED. As a minimum, the Vacuum Port performance upgrade should be used to remove as much potentially hazardous carbon fiber dust as possible.

6.2. Instructions¶

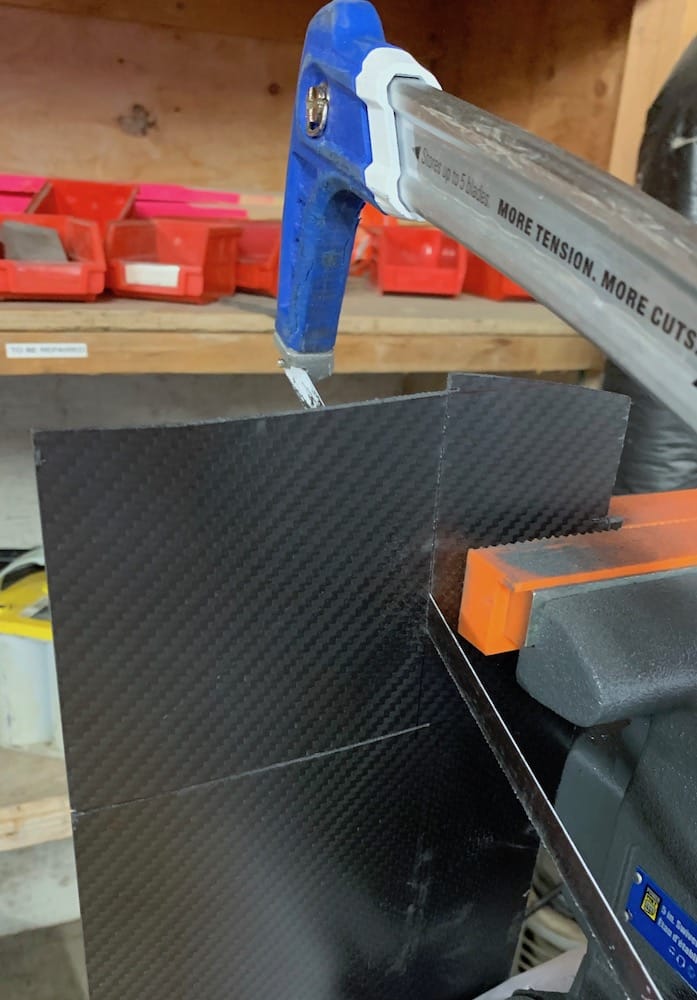

Firstly, the 2mm thick carbon fiber plates need to be manually cut into 105mm x 105mm (min.) to 110mm x 110mm (max.) square pieces. Using a bench vise and a sharp hacksaw can make this an easy task. Mount the carbon fiber blank into the Bantam Tools machine using the 4th Bantam Tools Machine Setup (BTMS) and install a 1/16” Flat End Mill into the machine. Run the single milling operations to manufacture the GNSS Antenna ground plane. Repeat this procedure to create a total of two ground planes.

6.3. Ground Plane¶

Table H16: Ground Plane Design and Manufacturing Files

Fig 6.3-1. Carbon Fiber Ground Plane¶

Version: 1.3

Quantity: 2

Material:

2mm thick carbon fiber plate

End Mills Required:

Blank Dimensions:

105mm x 105mm (min.) to 110mm x 110mm (max.) x 2mm

1/16” Flat End Mill (16F)

Fusion 360 File(s):

MILLING OPERATIONS

Order

Purpose

BTMS

Install @

End Mill

GCODE Files:

Bantam Tools Software Configurations

1

Cut

4

Arbitrary

16F

6.4. After Milling¶

It is recommended to use a metal file to gently round the sharp 90 degree edges of the Ground Planes after being milled by the Bantam Tools Machine. Carbon fiber can be very sharp once cut. It is also electrically conductive, so it is crucial to make sure that the GNSS antenna cables do not rub against any sharp carbon fiber edges.

CONGRATULATIONS!

YOU HAVE NOW FINISHED MANUFACTURING THE CARBON FIBER PARTS!

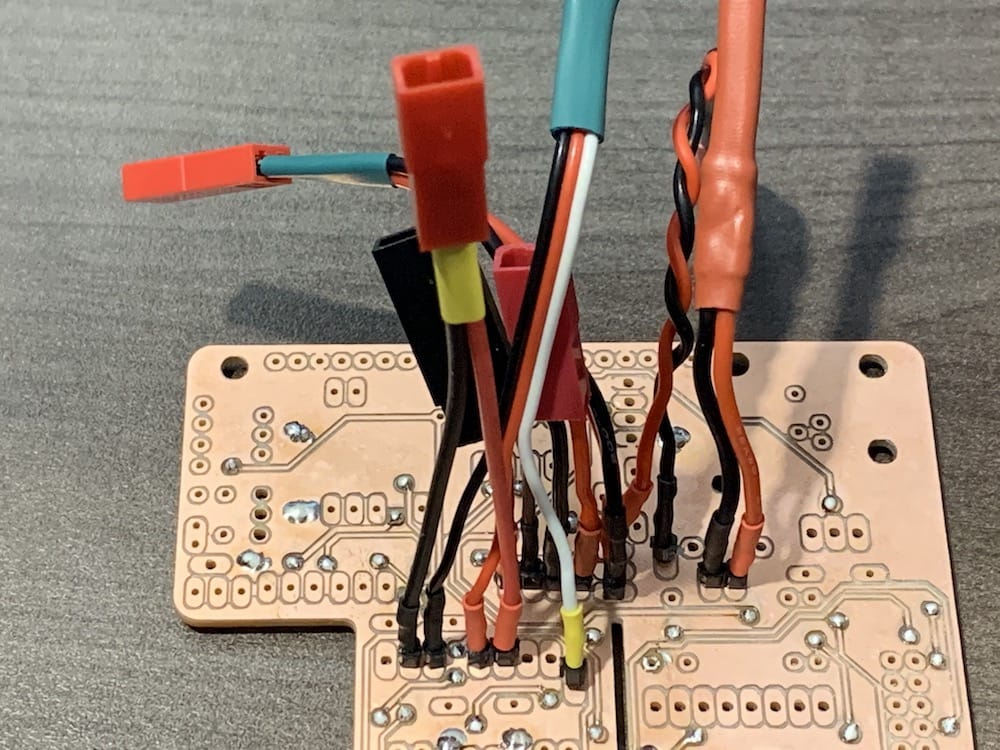

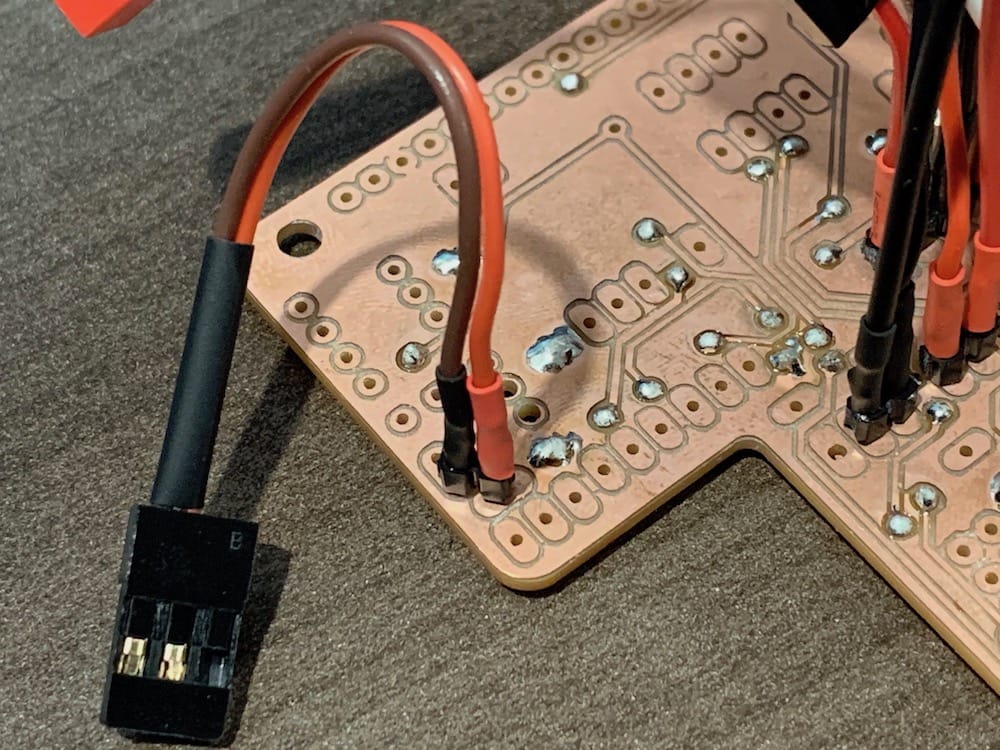

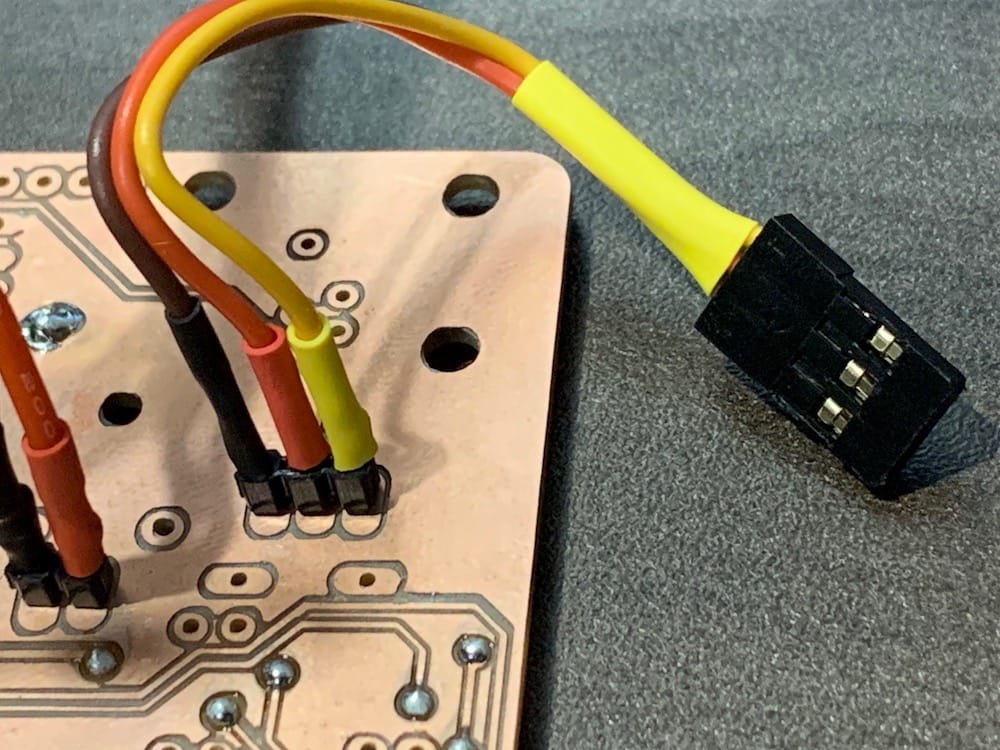

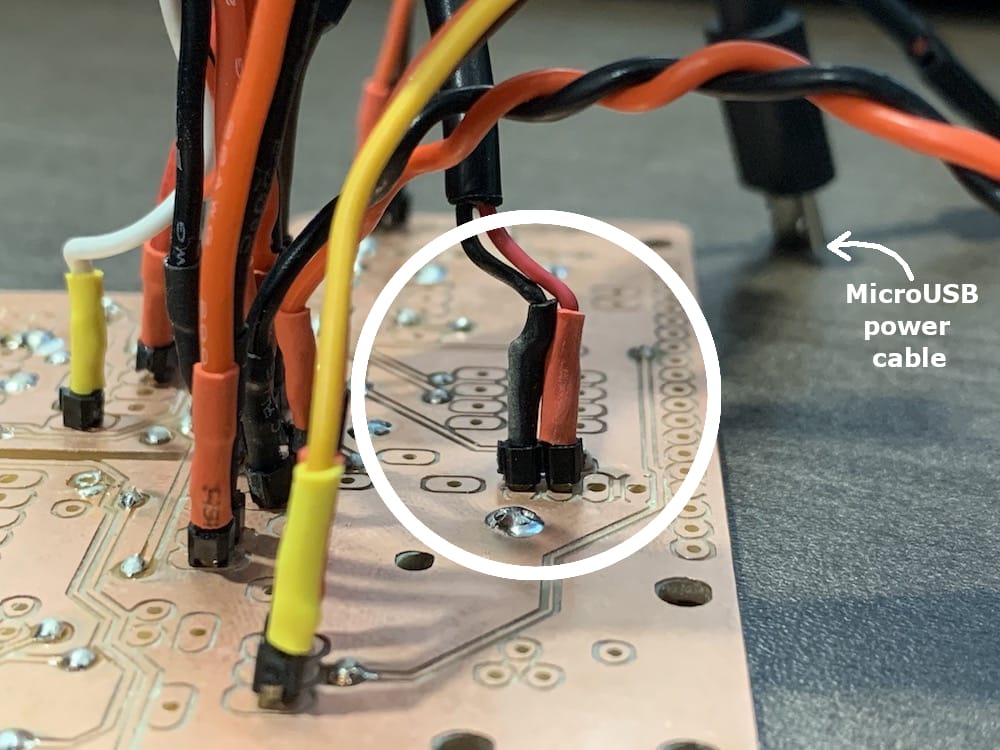

7. Cables Assembly¶

7.1. Overview¶

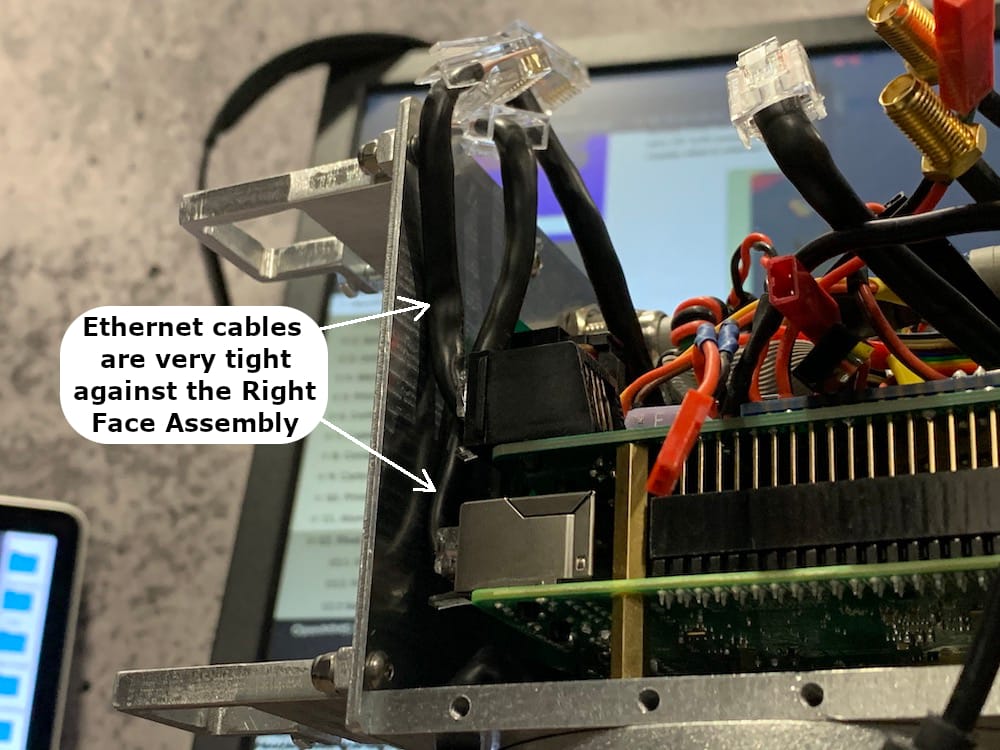

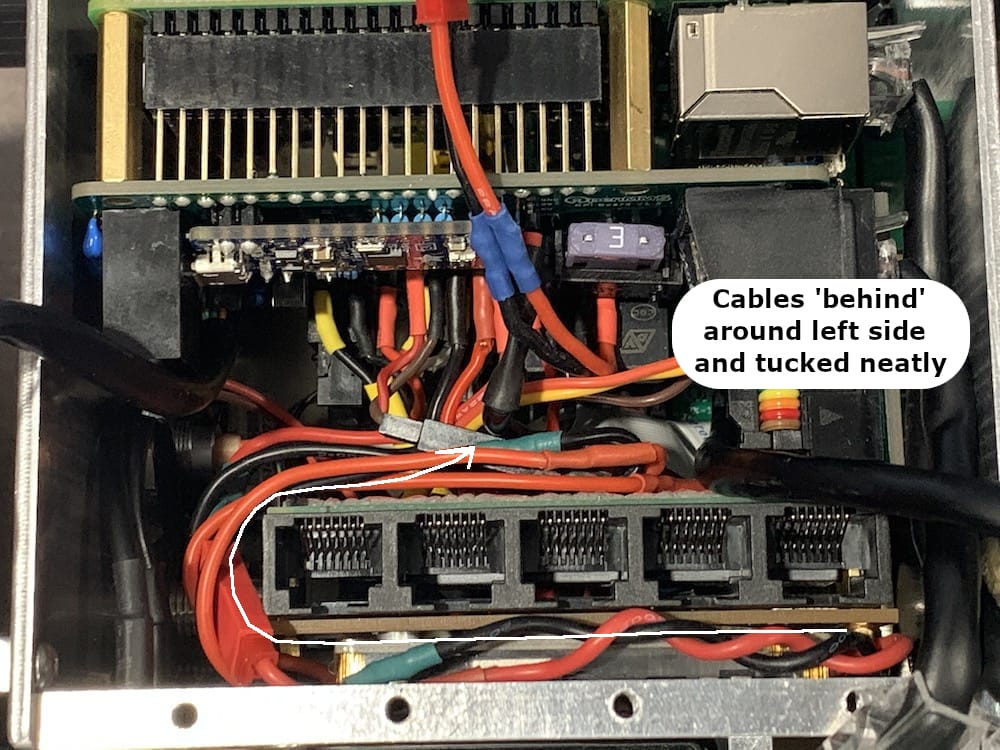

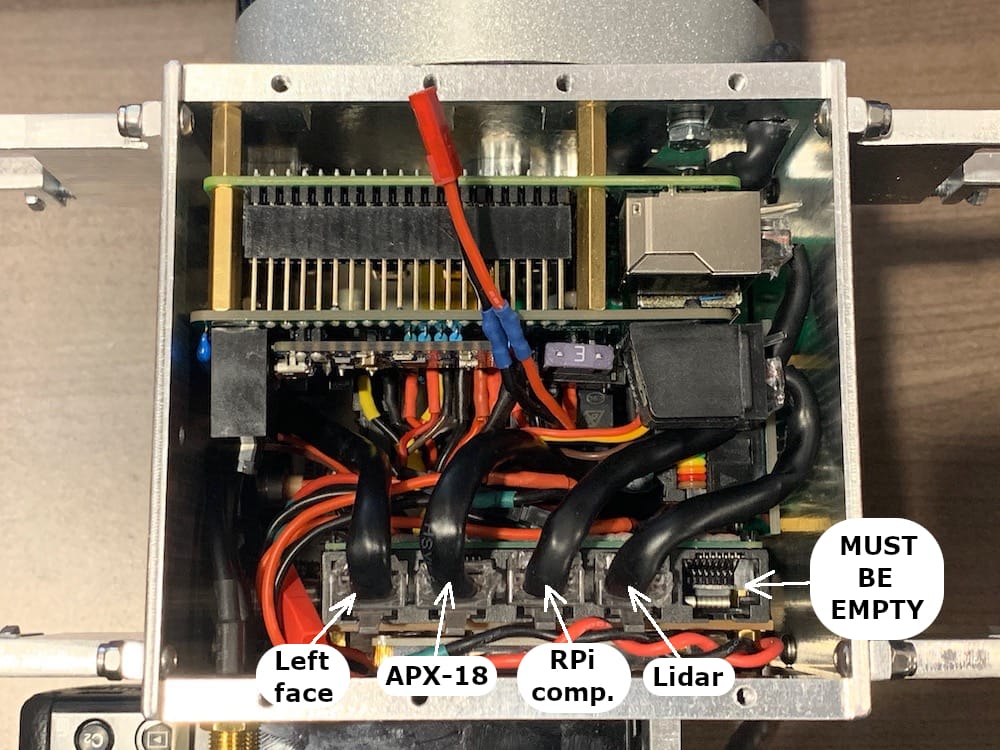

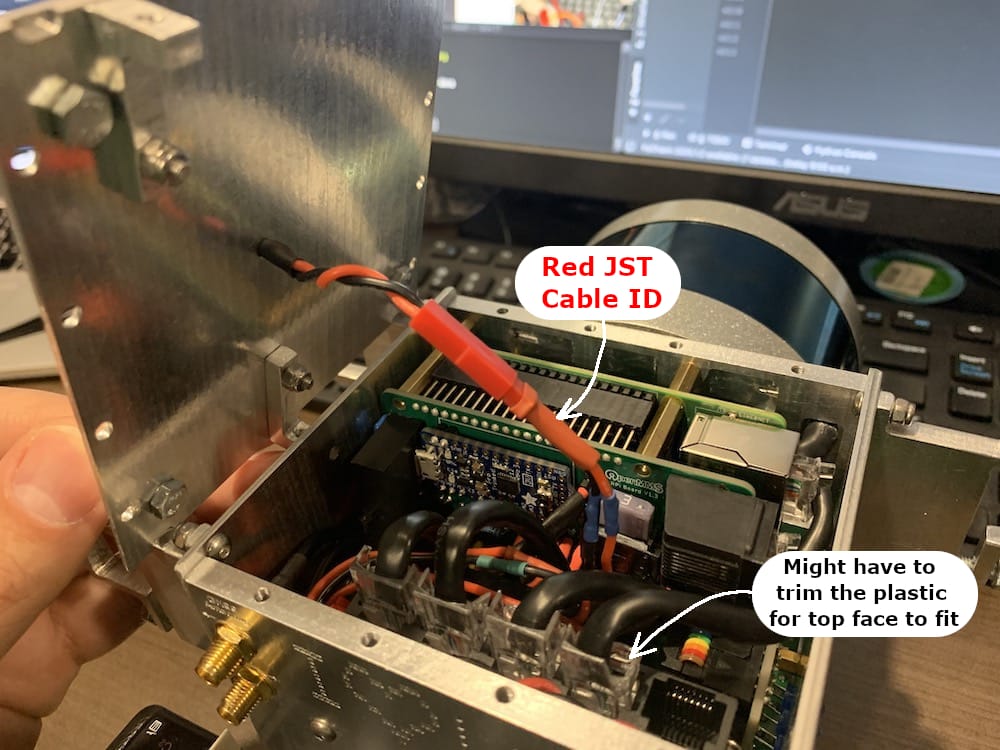

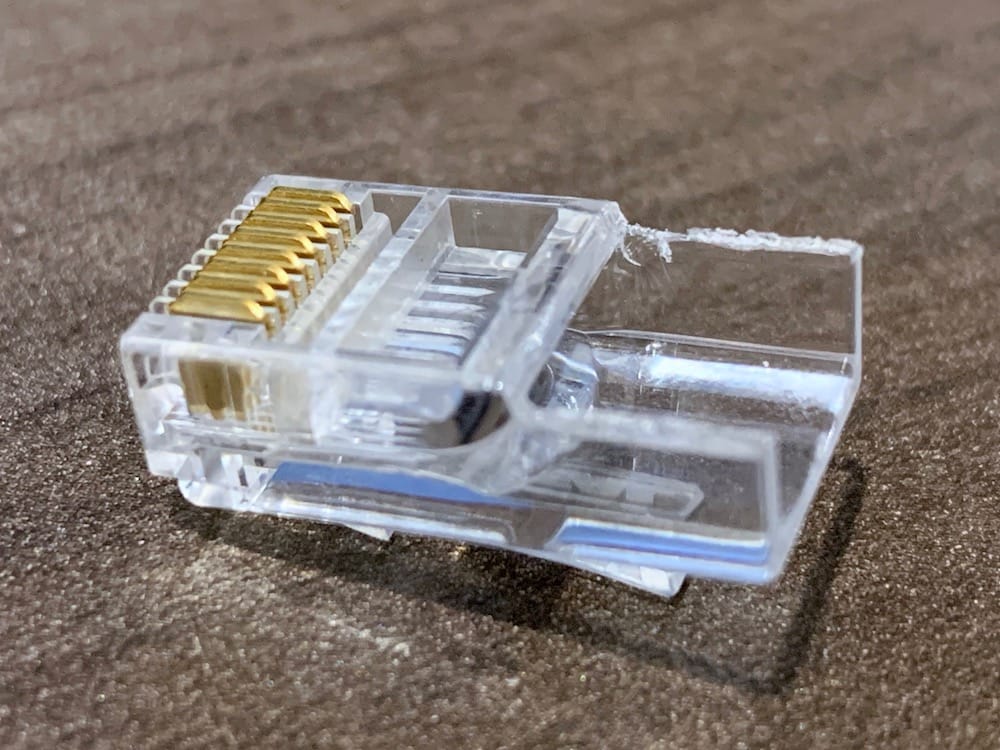

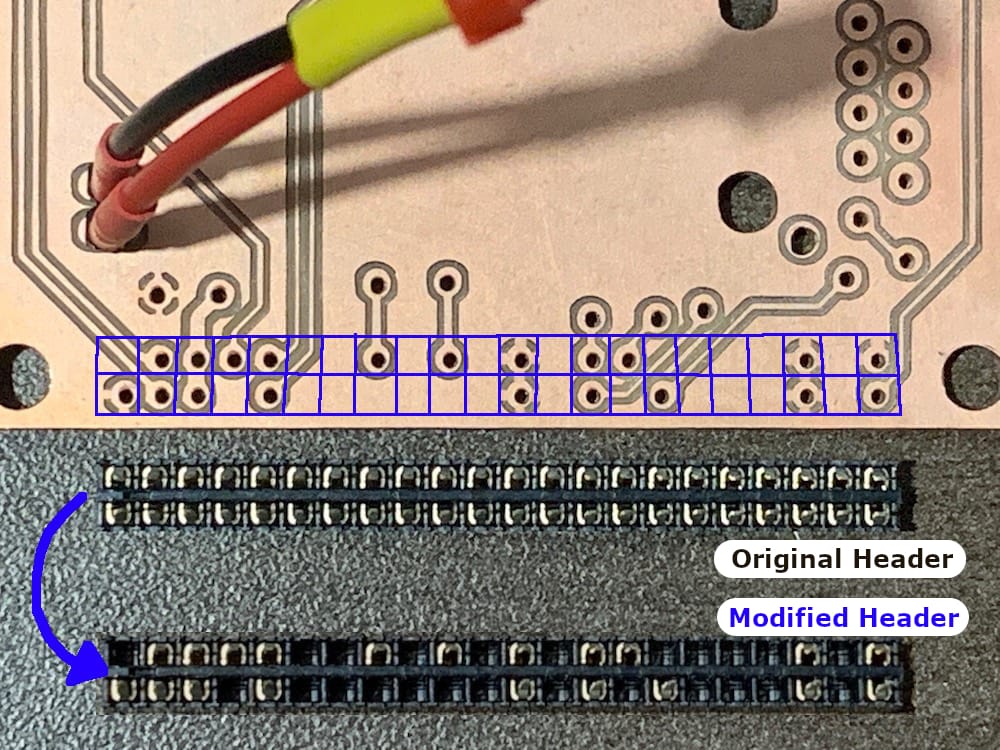

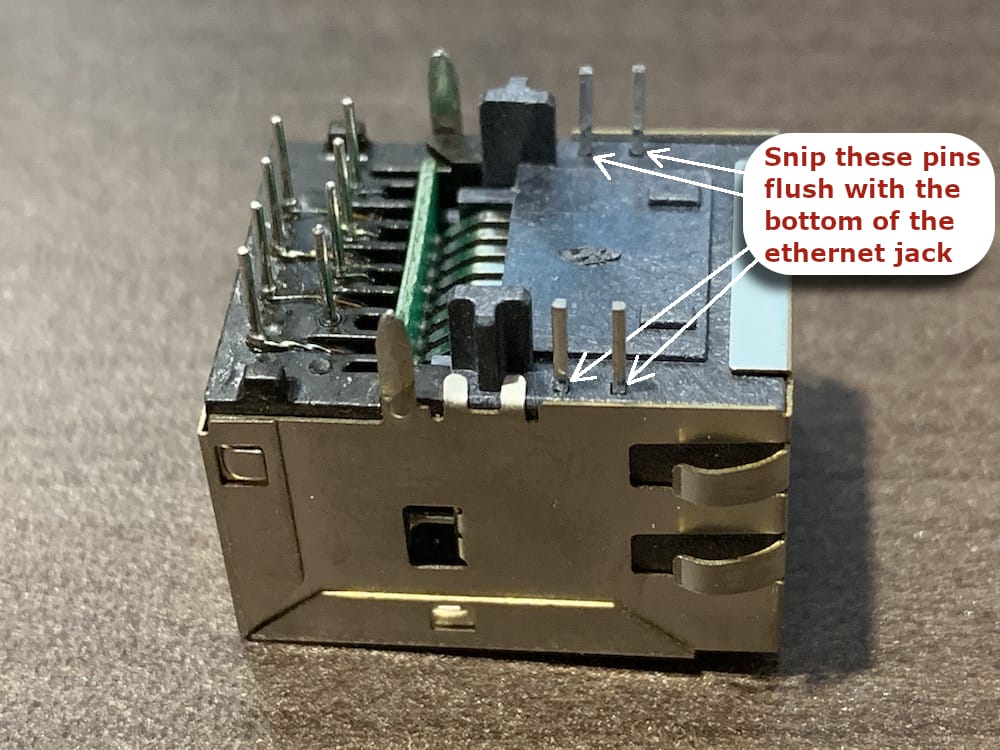

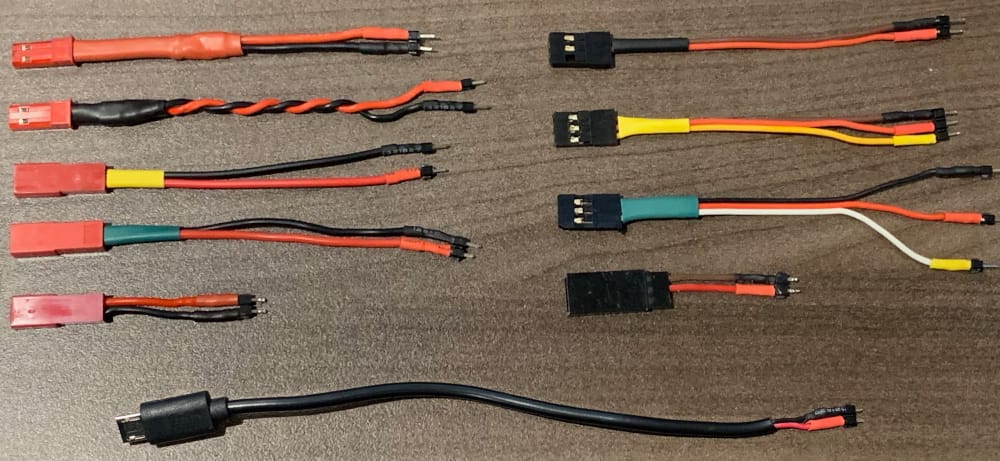

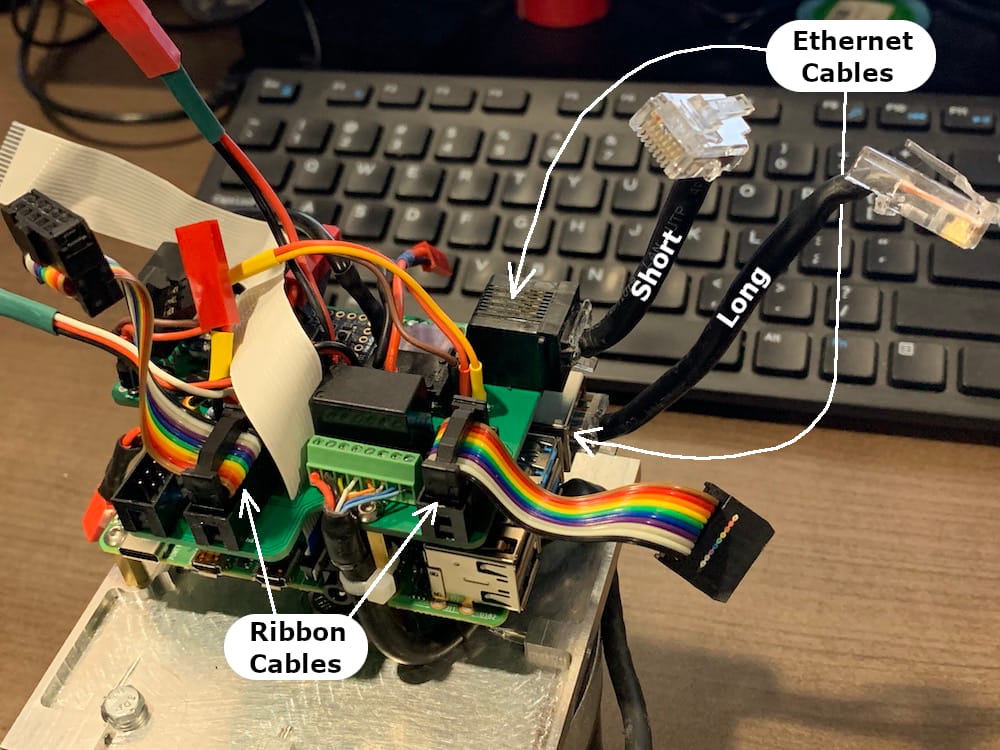

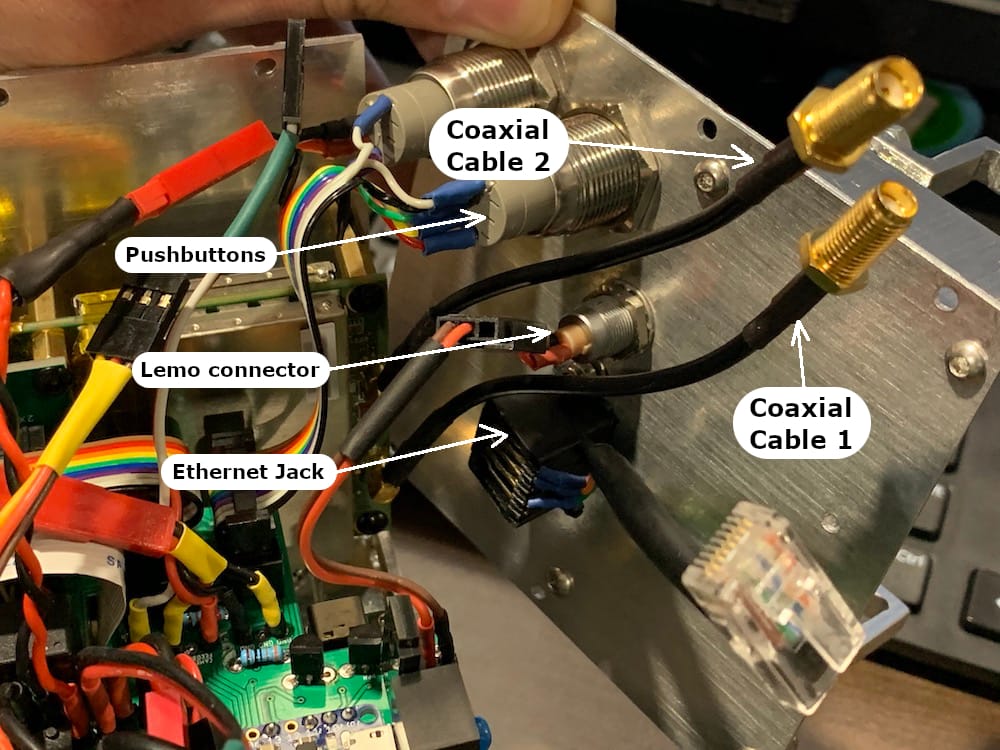

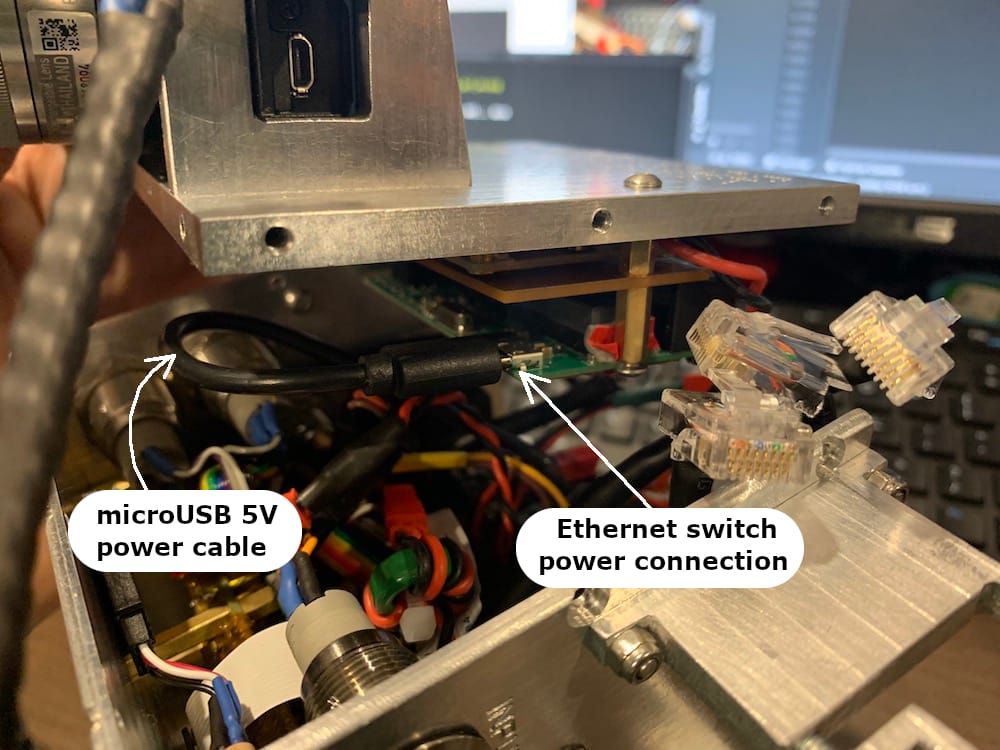

There is a total of eleven cables of five different types that need to be assembled. Seven of the cables are installed inside the case, while the other four cables are used outside the case to connect specific components. Custom length ethernet cables with modified RJ45 connector ends need to be made due to the extremely tight fit of these cables inside the case. Therefore, RJ45 connector ends, Cat5/6 ethernet cable, and an RJ45 crimping tool are required.

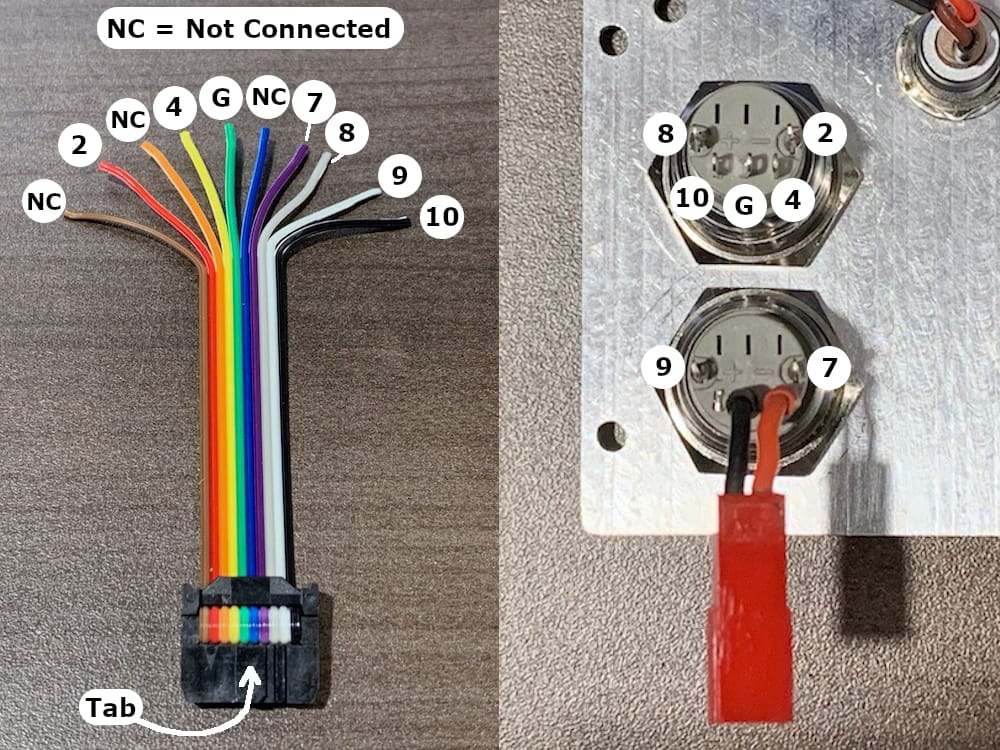

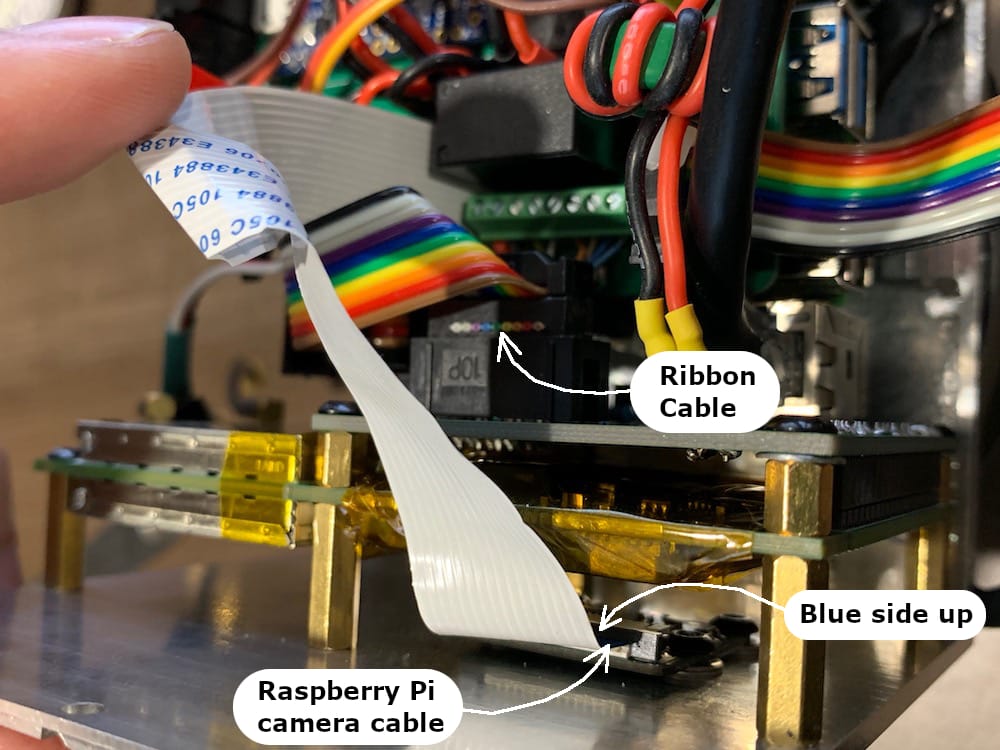

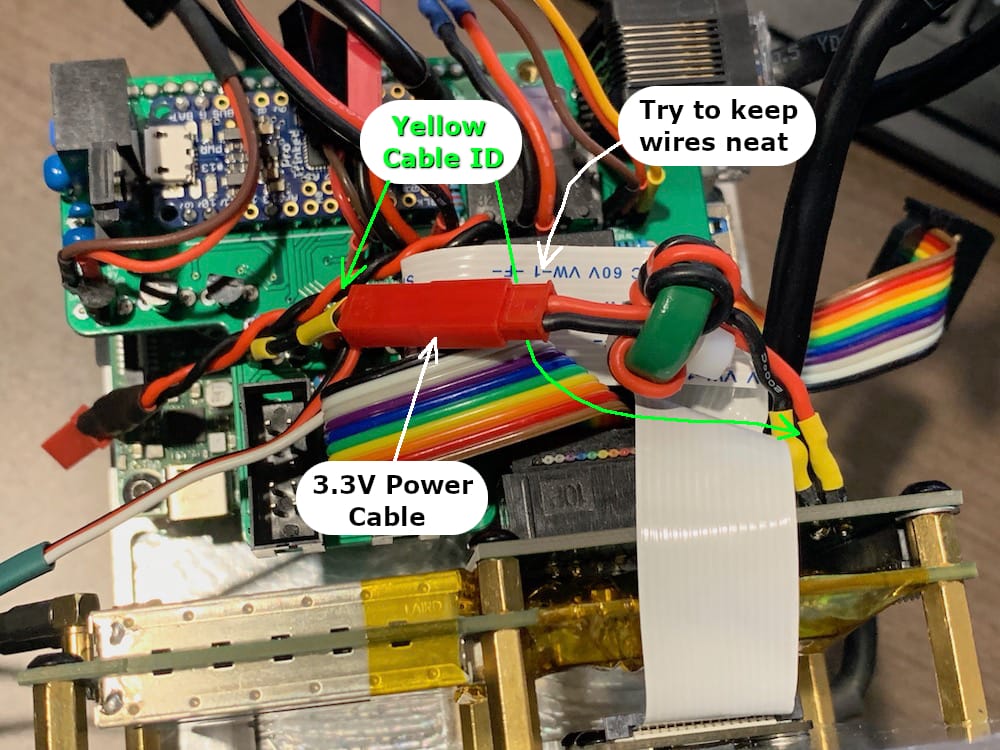

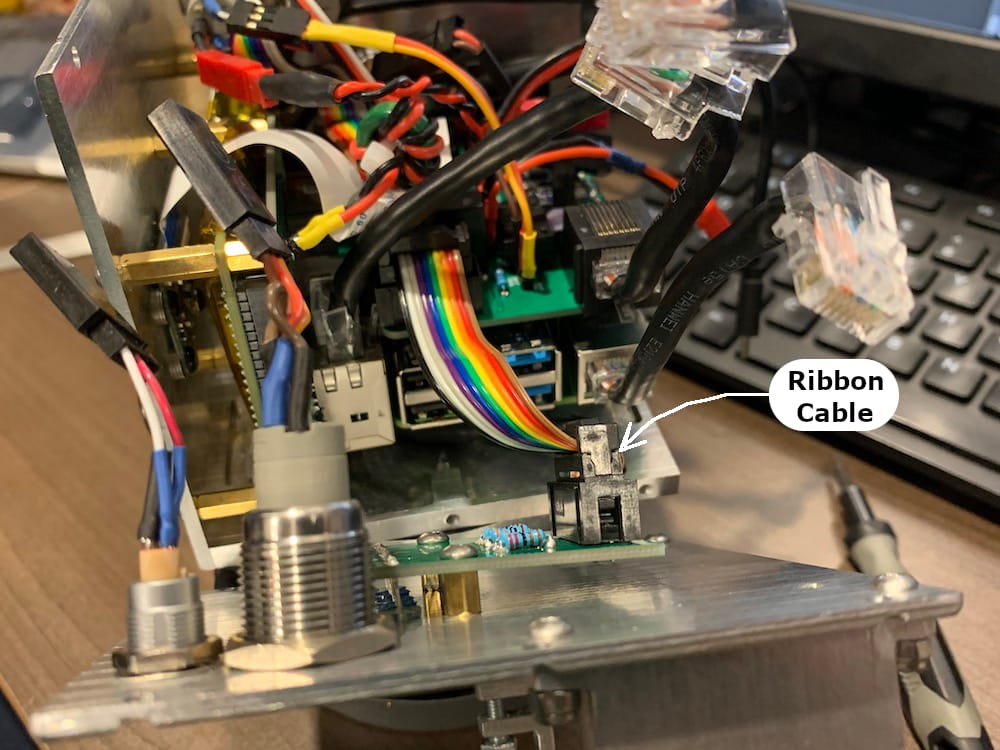

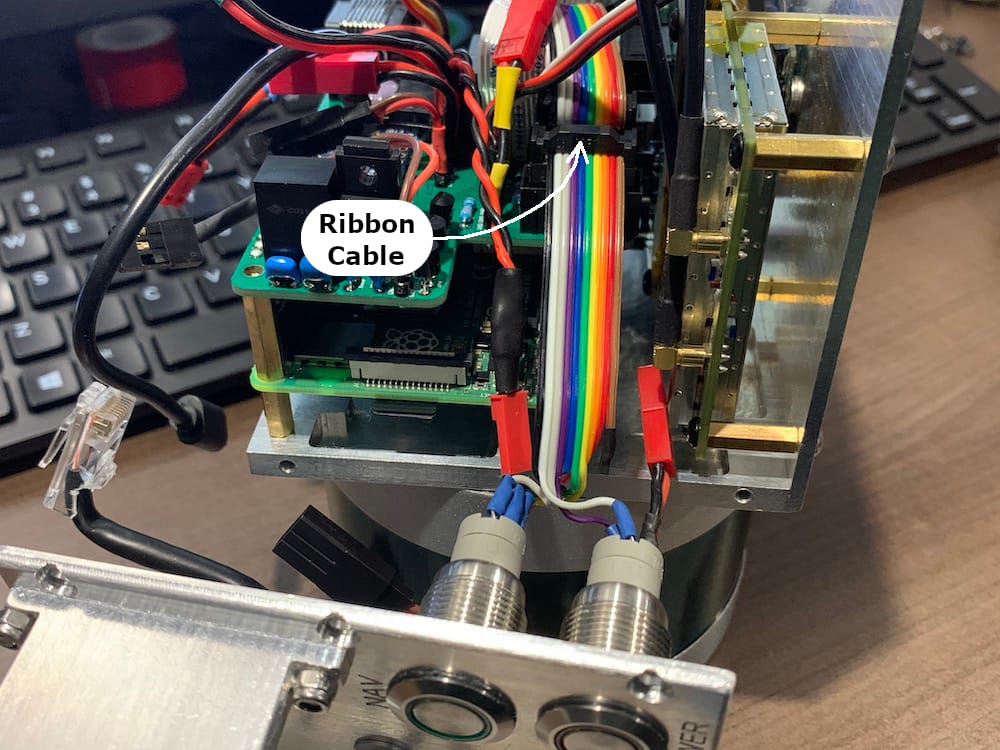

7.2. 10-wire Ribbon Cables¶

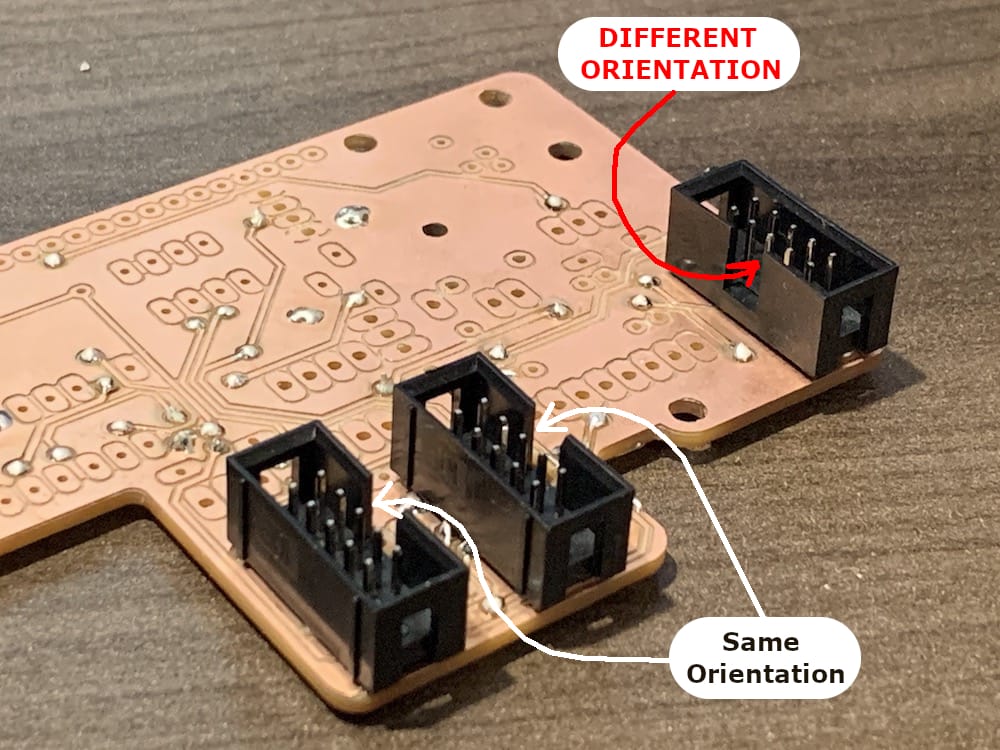

A total of three 10-wire ribbon cables need to be assembled. Two of the cables are identical and can be installed between the respective PCBs without any attention to which end goes where. The remaining cable only has a connector on one end, while the other end is directly soldered to the respective components on the Left Face of the case (see the Left Face Assembly section for the details).

The following components are needed to assemble the three 10-wire ribbon cables.

5 @ 10-wire male housing/female pin connectors

3 @ 10-wire ribbon cable, 9cm in length

Fig 7.2-1. Components needed to assemble the 10-wire ribbon cables¶

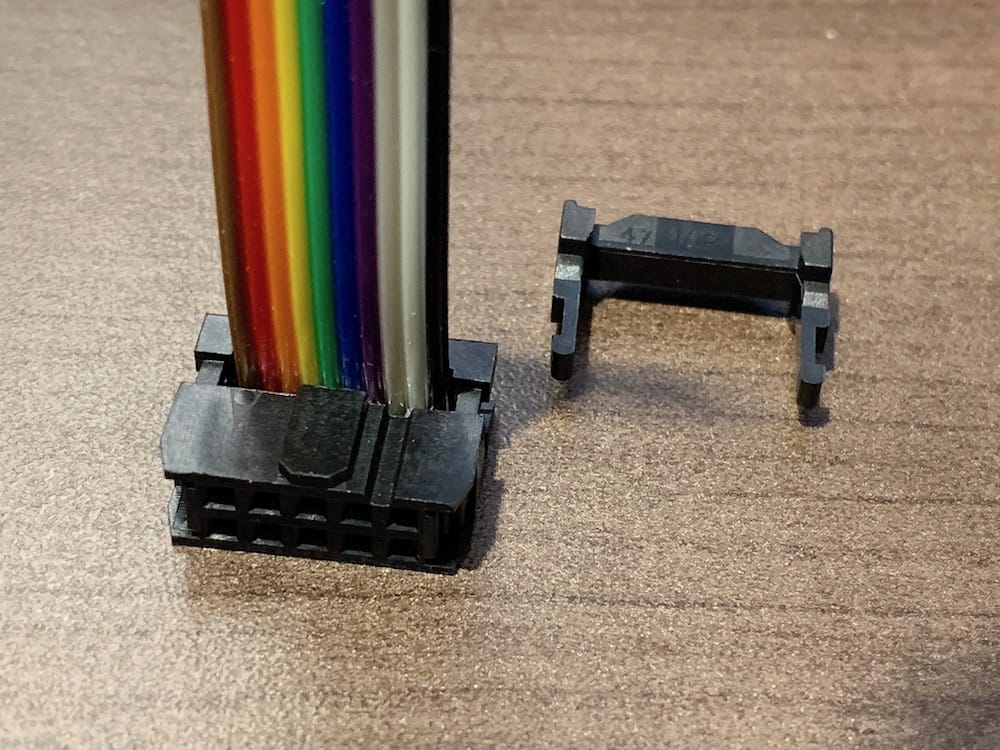

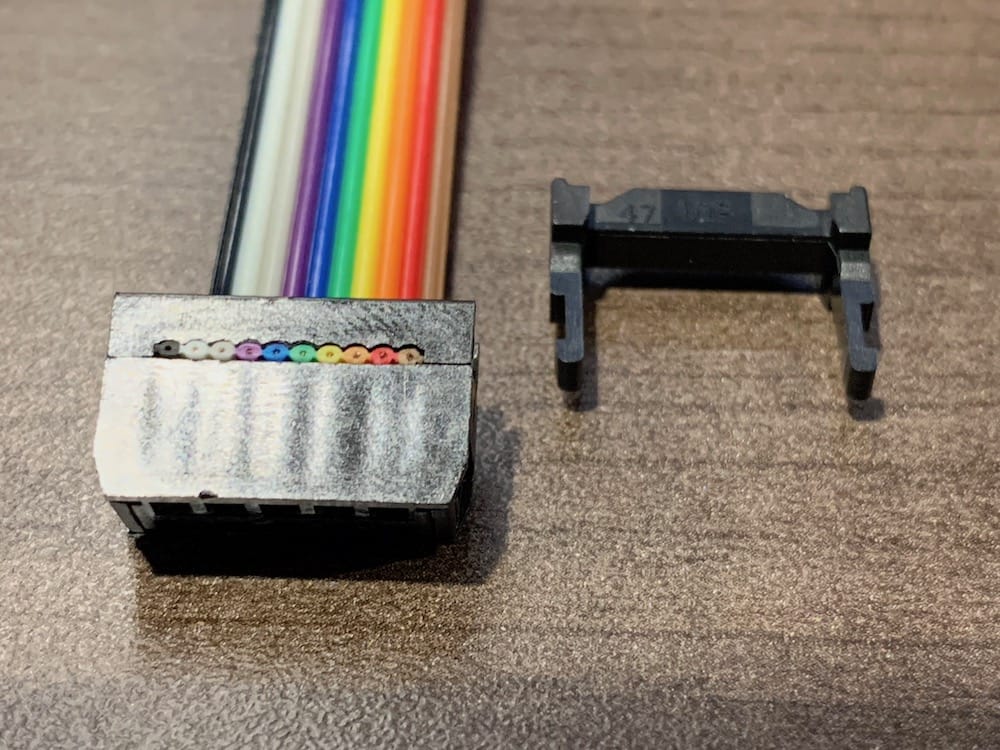

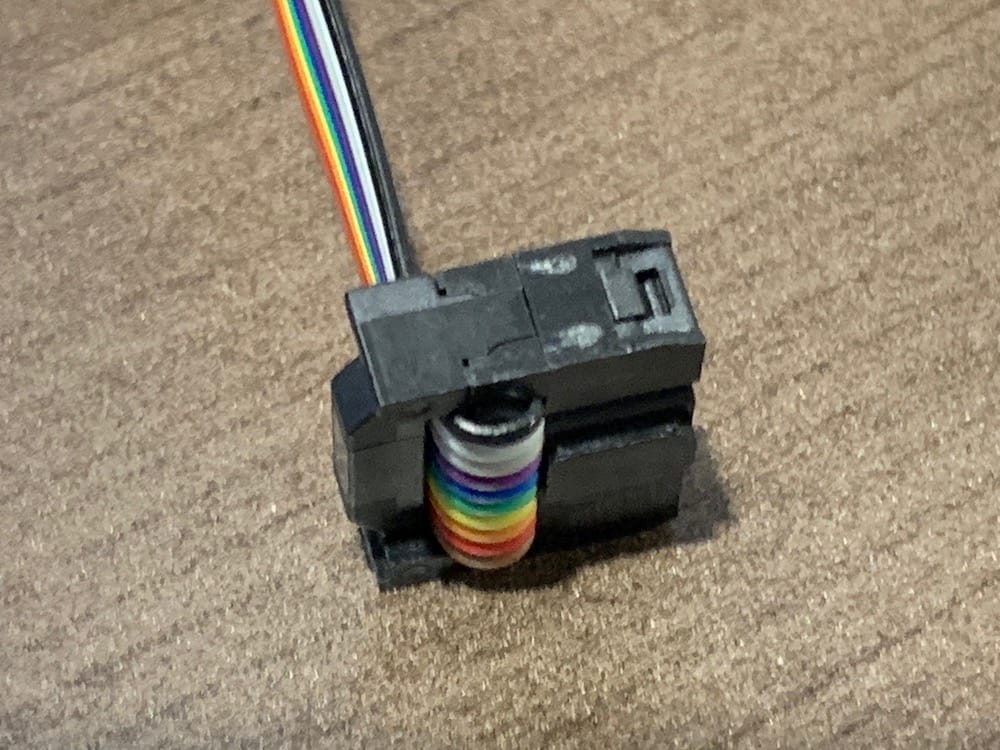

Each connector is attached to the ribbon cable in the same way. Start by removing the locking bar from the top of the connector. Find the face of the connector that has the orientation tab on it. Insert the ribbon cable into the connector going through the face with the orientation tab first. If your ribbon cable has multiple colors of wires, pay close attention to the wires’ order as each connector must have the same order of colored wires. Position the cable, so it is flush with the opposite face of the connector and crimp the connector closed. Lastly, flip the cable over the top of the connector and secure the locking bar into the connector. Repeat these instructions for all five connectors on the three cables.

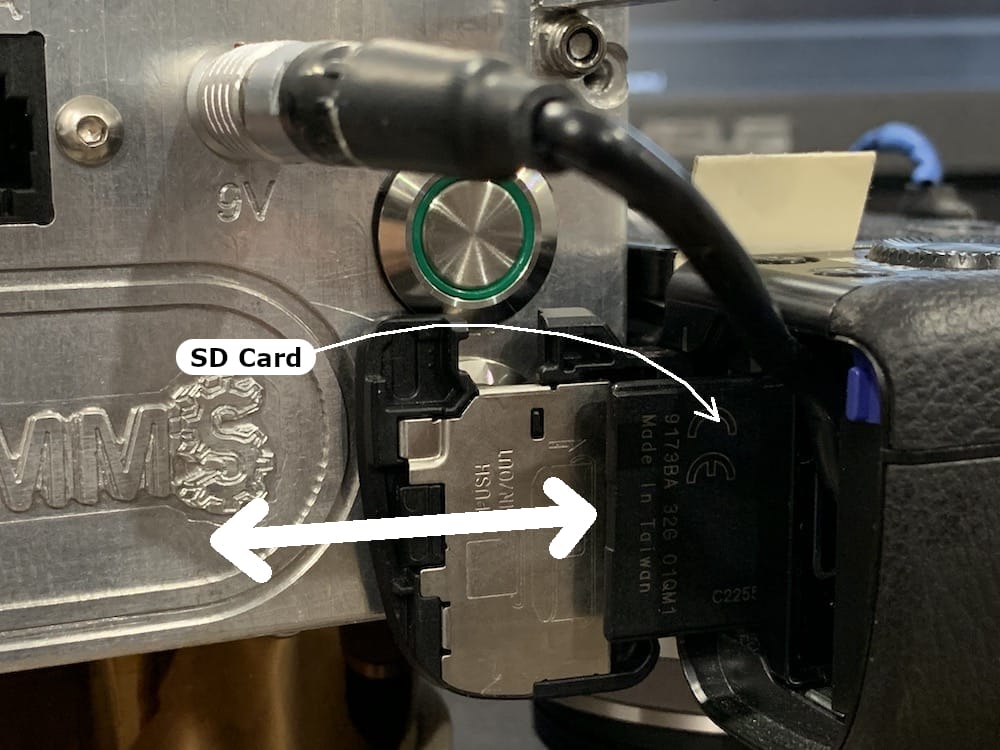

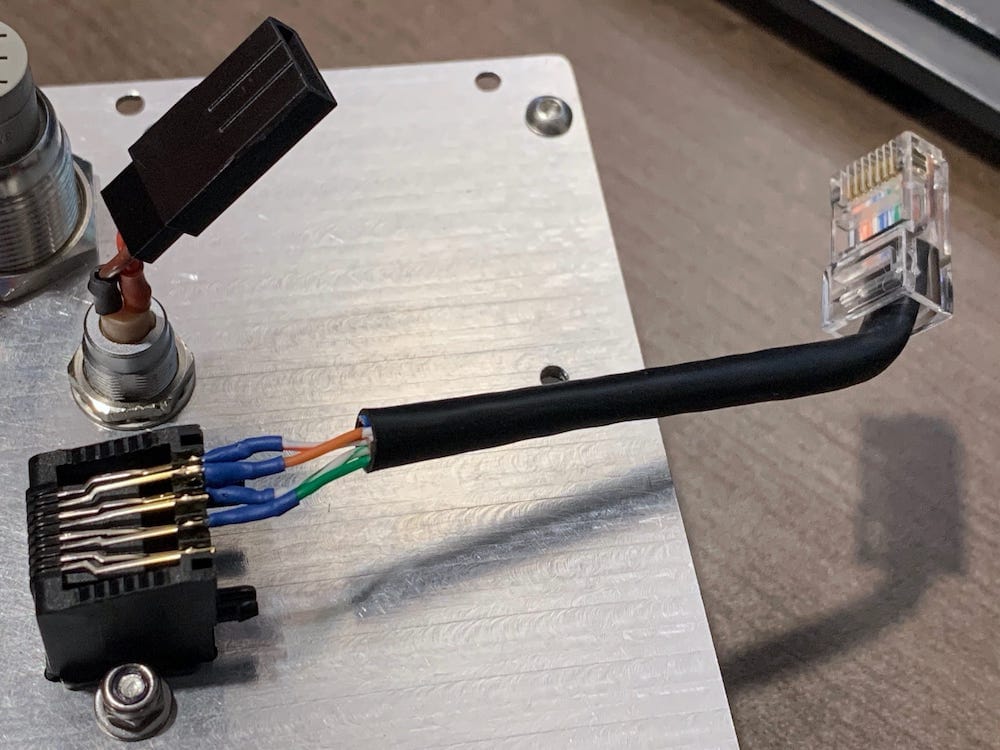

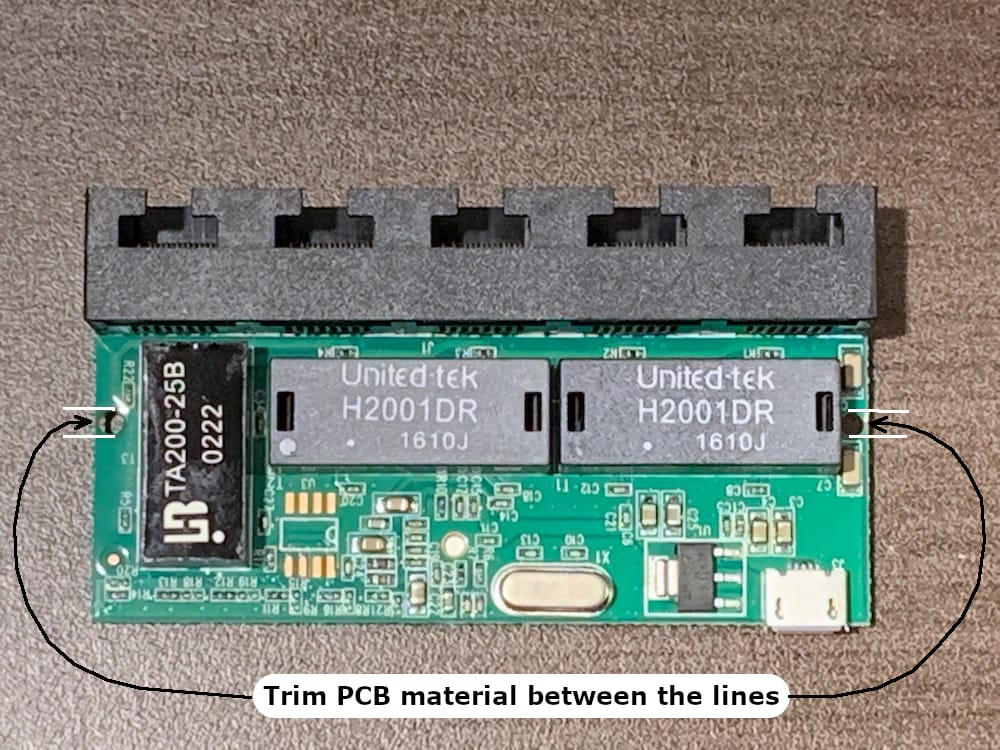

7.3. Ethernet Cables¶

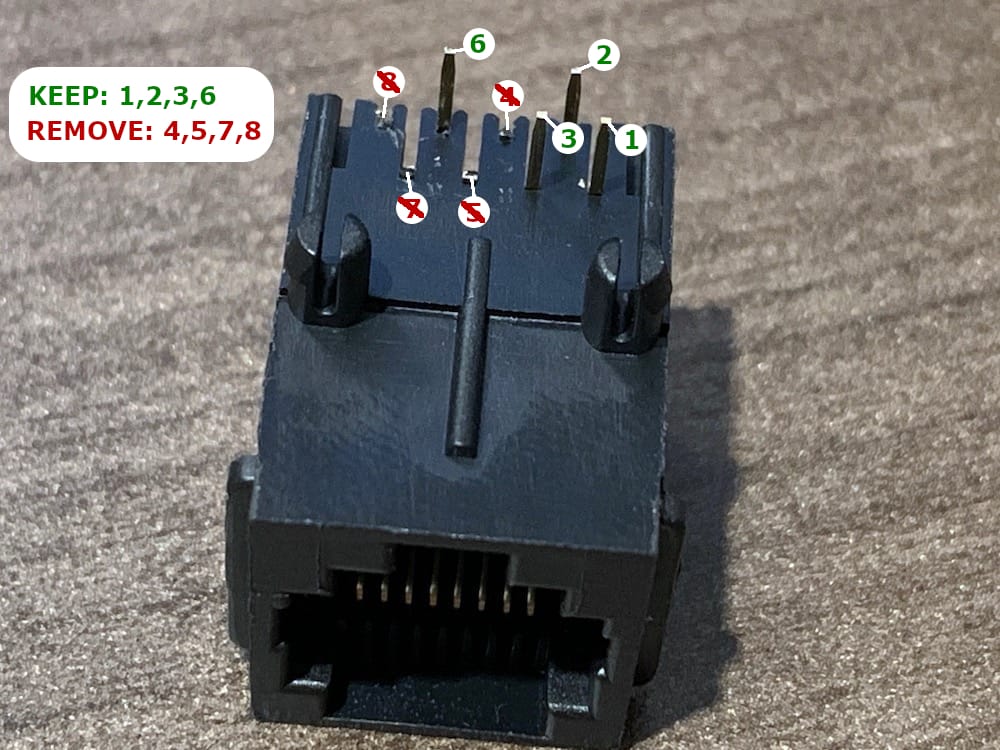

A total of four ethernet cables need to be assembled. Three of the cables are standard straight-through ethernet cables with RJ45 connectors on both ends. Due to the tight fit of these cables inside the case, the RJ45 connectors need to be modified. The remaining cable has an RJ45 connector on one end only, while the other end is directly soldered to the respective RJ45 jack on the Left Face of the case (see the Left Face Assembly section for the details).

The following components are needed to assemble the four ethernet cables.

2 @ Cat5/6 ethernet cable, 12cm in length

1 @ Cat5/6 ethernet cable, 10cm in length

1 @ Cat5/6 ethernet cable, 8cm in length

7 @ RJ45 crimp connectors

Fig 7.3-1. Components needed to assemble the ethernet cables¶

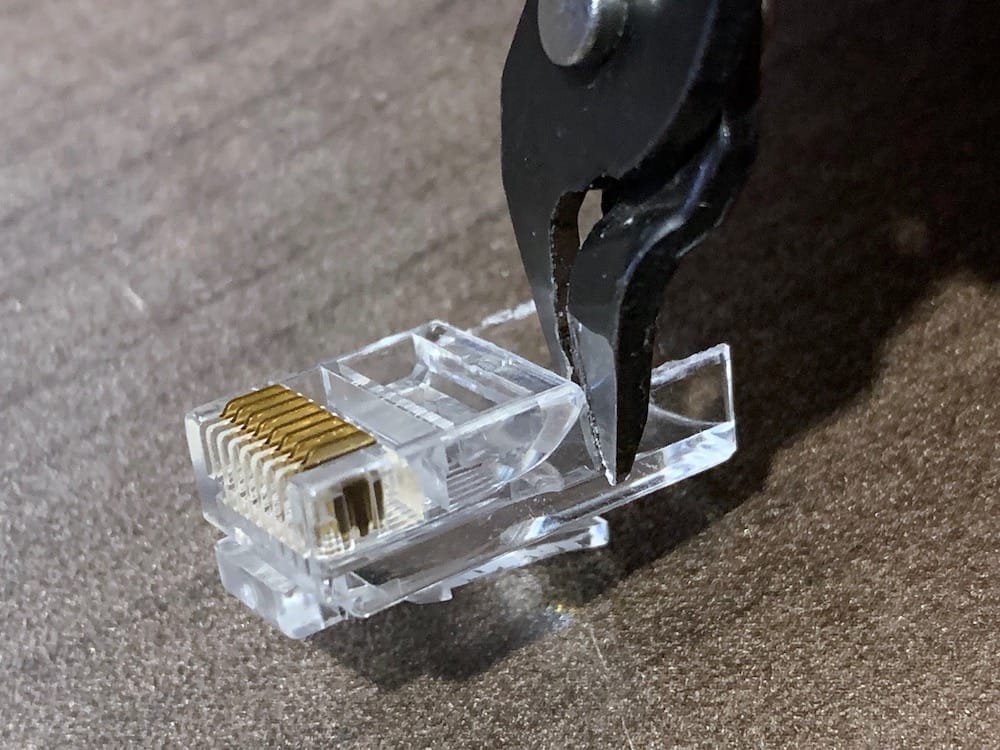

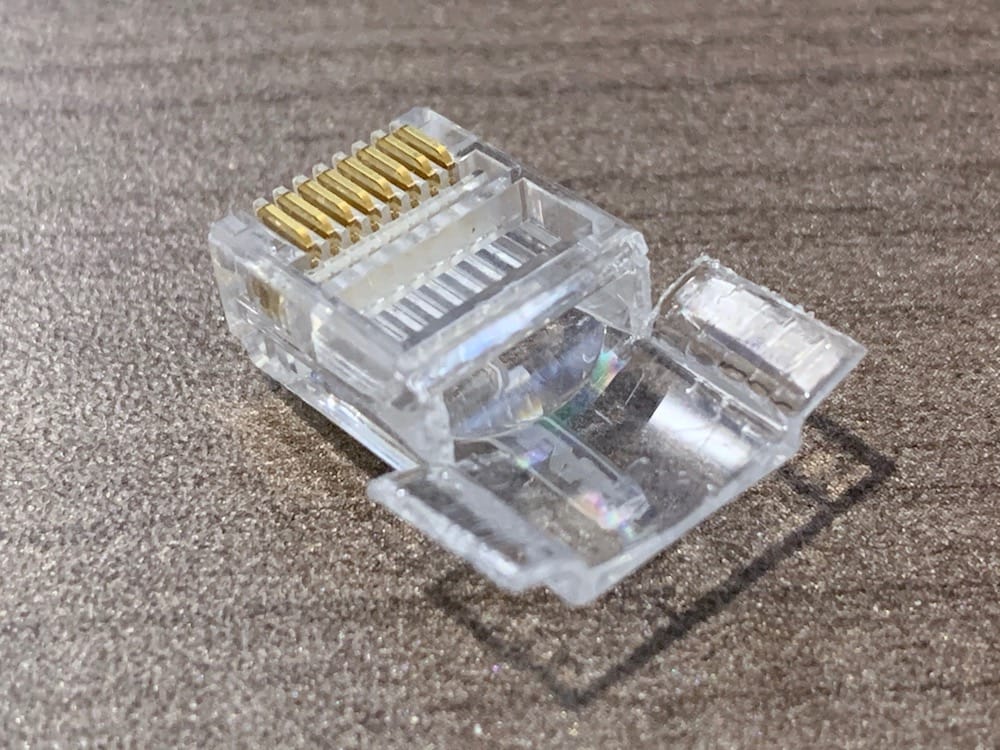

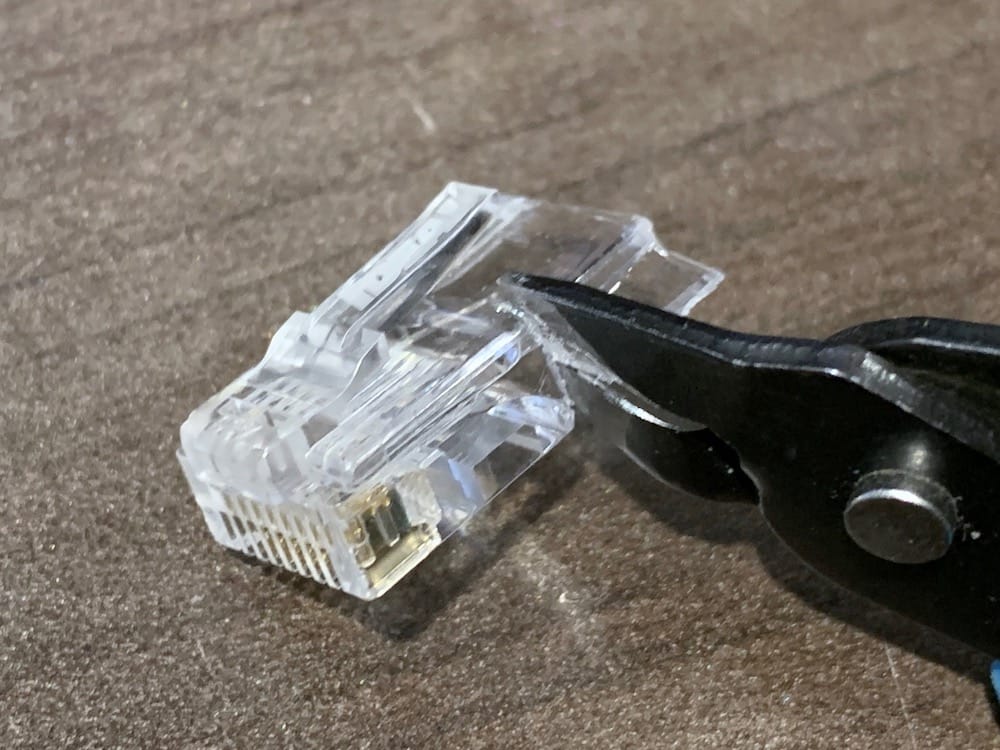

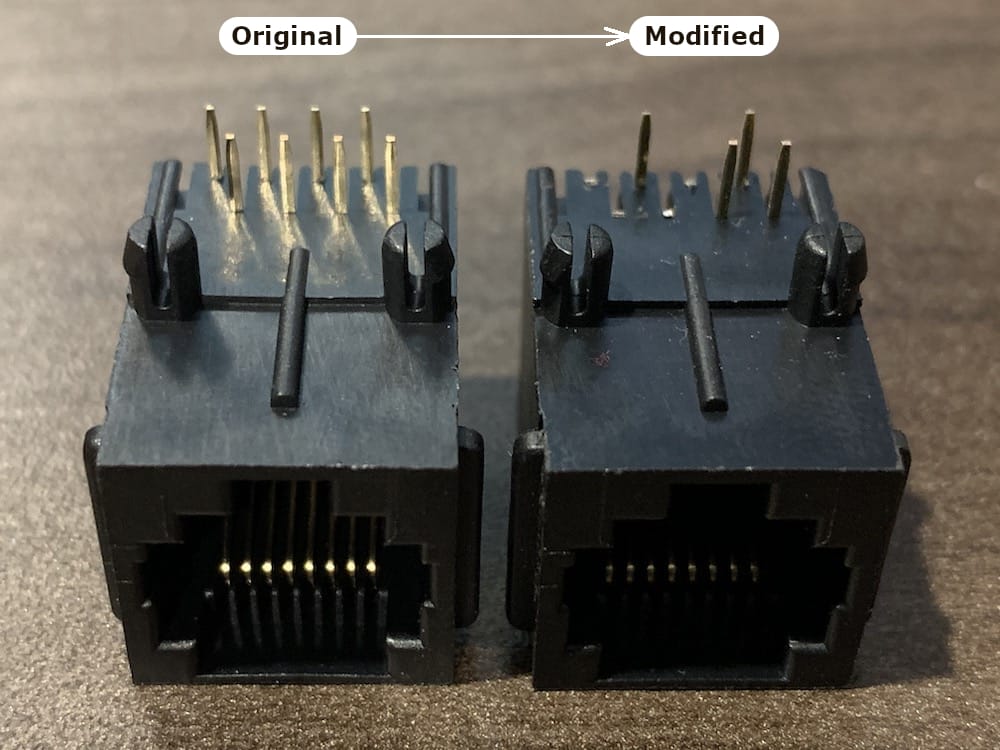

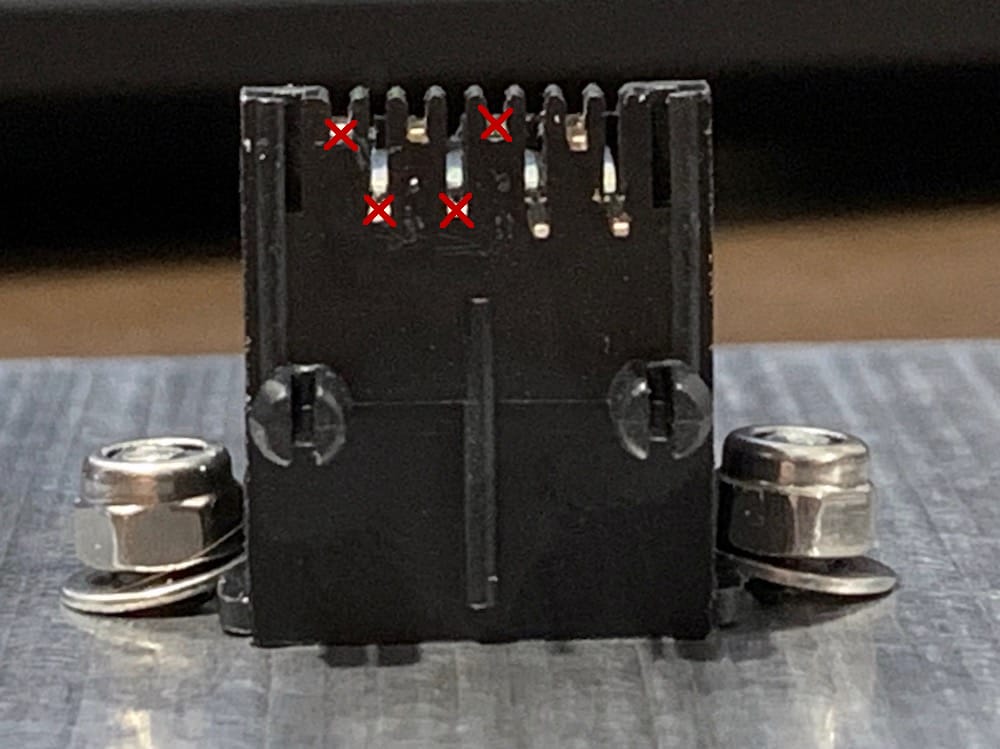

Four of the RJ45 connectors need to be modified by trimming away one side of the crimping collar opposite the side of the connector with the latching clip. Trimming the connectors is necessary to allow the ethernet cables to be bent inside the case. Start by cutting along the outside edges of the side to be removed. Next, grab the side with small pliers and bend it back and forth. Eventually, the side will come free and should leave a clean ‘cut’ where the side was connected.

Fig 7.3-2. RJ45 side to remove¶

Fig 7.3-3. Cut the outside edges¶

Fig 7.3-4. Bend side up and down¶

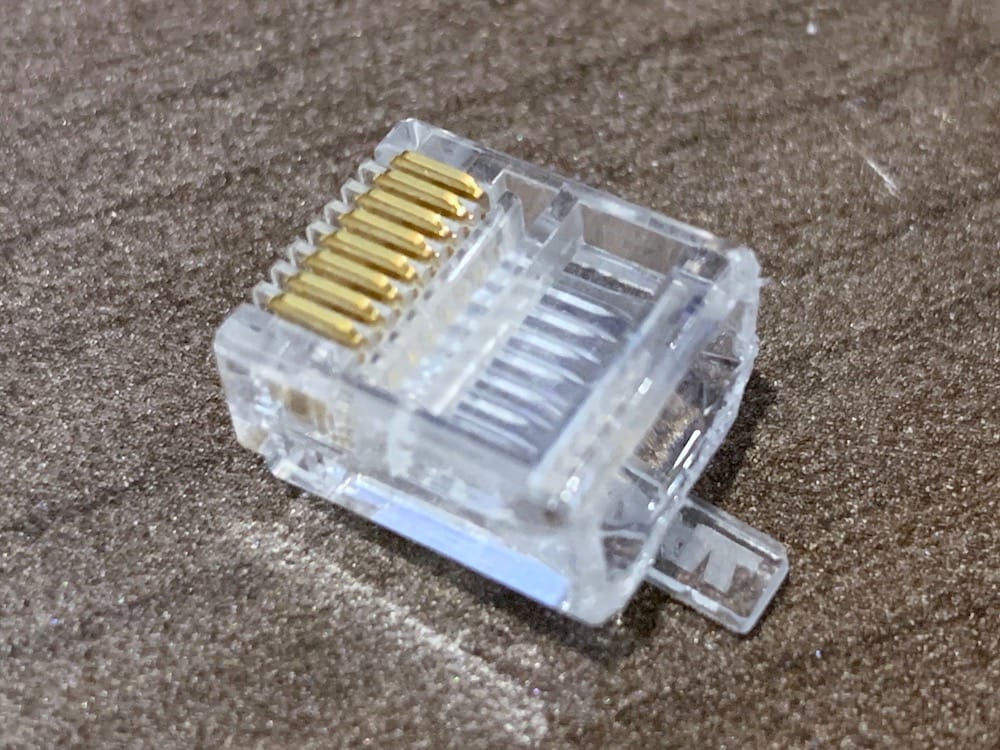

Fig 7.3-5. Modified connector A¶

The remaining three RJ45 connectors also need to be modified by trimming away the entire crimping collar. Trimming the connector is necessary to allow the ethernet cables to be inserted into their respective components and be allowed to bend inside the case. Start by performing the same modification, as described above. Next, make vertical cuts along the edges and then bend the edges so they are flat and in line with the crimping collar’s remaining side. Next, make small cuts across the flattened corner where the edge meets the remaining side. Lastly, grab the flattened side with small pliers and bend it back and forth. Eventually, the side will come free and should leave a clean ‘cut’ where the side was connected.

Fig 7.3-6. Vertical edge cuts¶

Fig 7.3-7. Flatten the edges¶

Fig 7.3-8. Snip the edge corners¶

Fig 7.3-9. Modified connector B¶

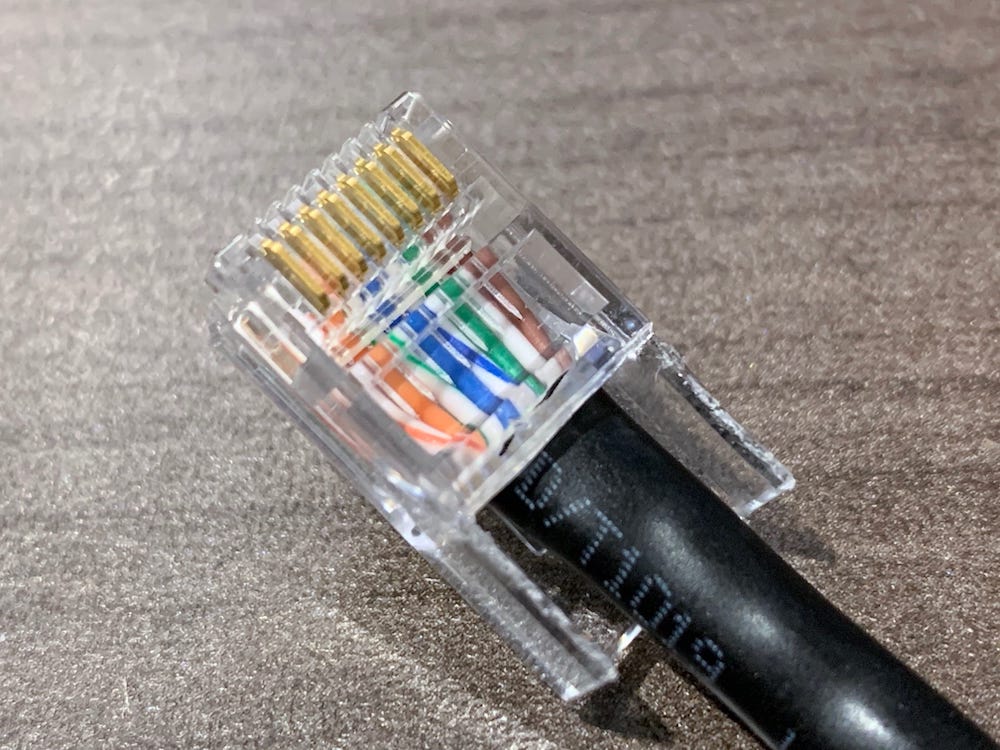

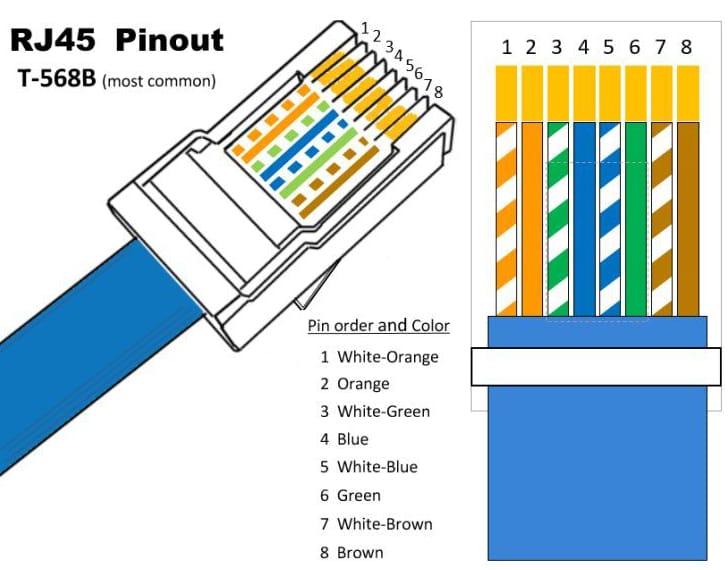

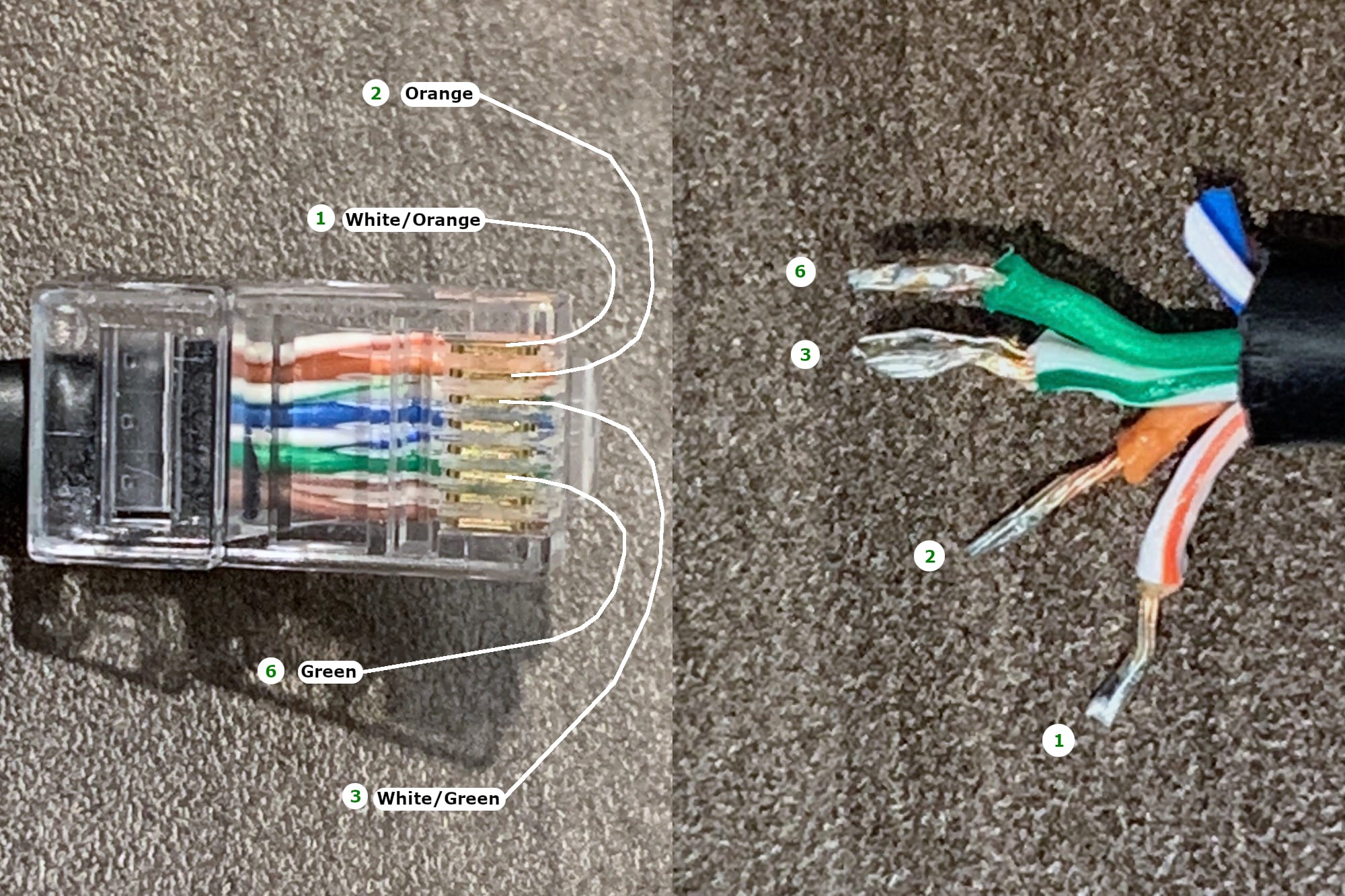

Watch this video for information on how to properly use an RJ45 crimping tool. The OpenMMS ethernet cables follow the RJ45 T-568B connection standard, which defines the order of the eight colored wires inside each connector. The following figure illustrates the T-568B standard.

Fig 7.3-10. RJ45 T-568B connection standard¶

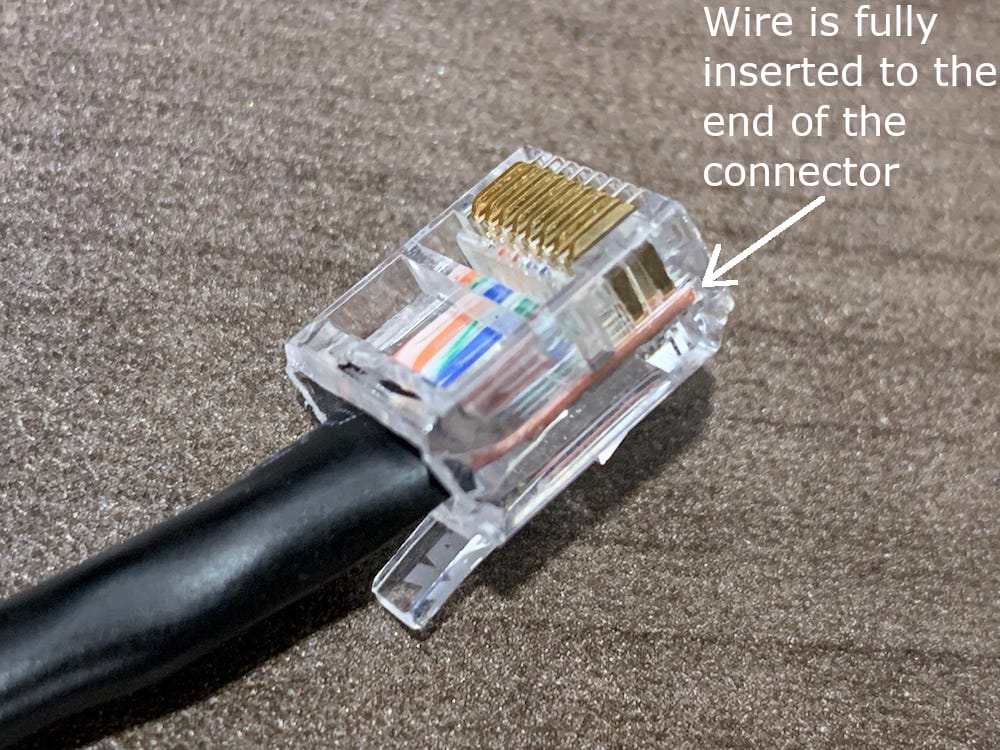

Each of the four ethernet cables has a modified connector A crimped to one end. The two 12cm long cables and the 8cm long cable, have a modified connector B crimped to the other end. Therefore, the 10cm long cable only has a connector on one end. Be sure the individual wires are in the correct order, following the T-568B standard, and fully inserted into the RJ45 connector before crimping the connector. It is practically impossible to undo a crimped RJ45 connector to fix a mistake, so be sure the wires are correct before committing to the crimp.

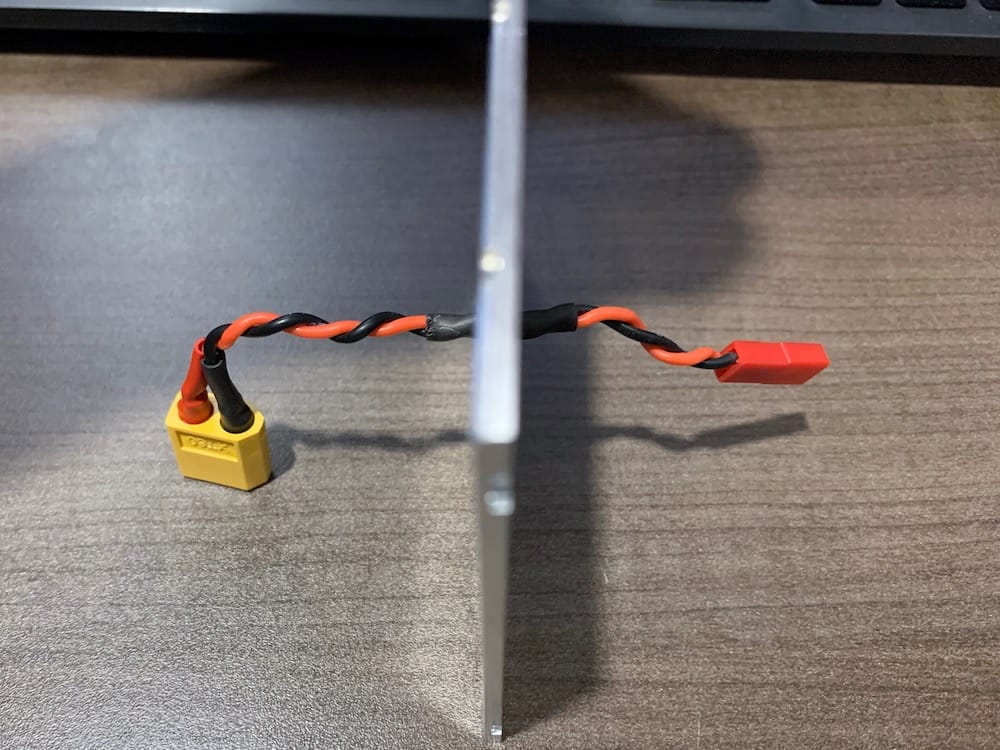

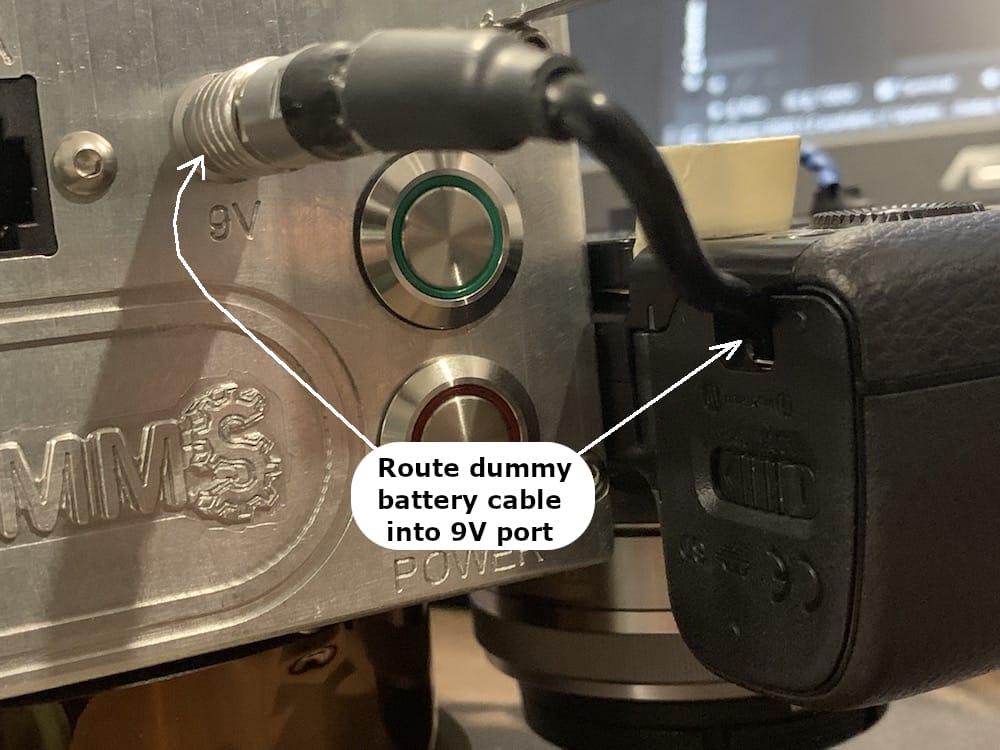

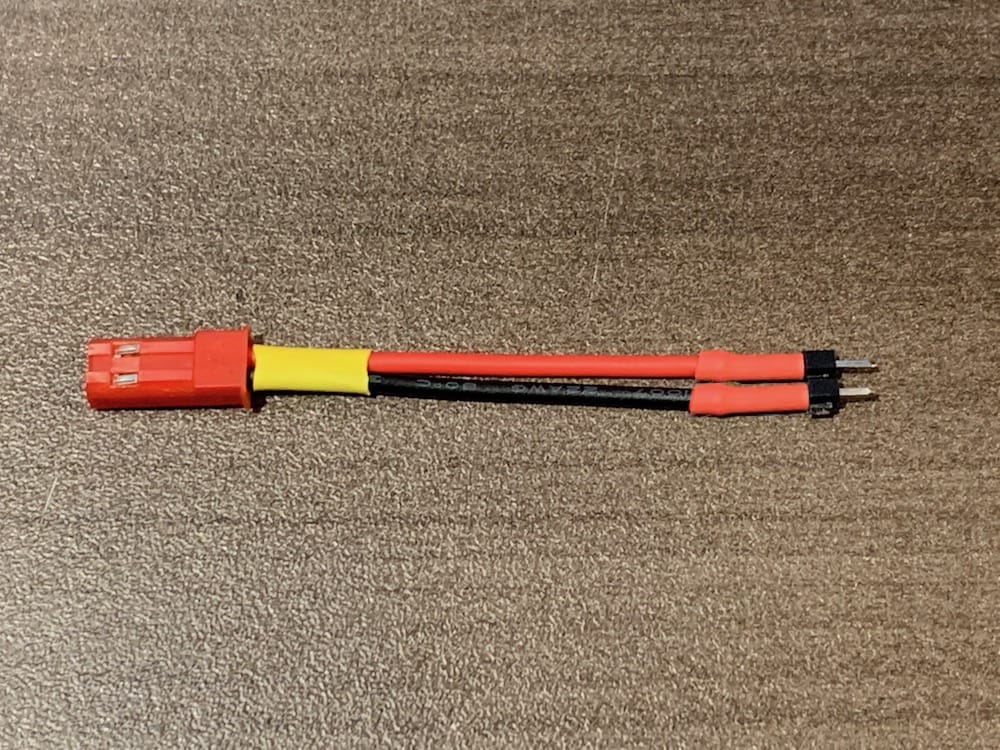

7.4. Sony Battery Cable¶

The OpenMMS sensor is designed to provide power to the Sony A6000 high-resolution RGB imagery camera. To do this, a ‘dummy’ battery is used in place of the original Sony battery. The dummy battery has a cable attached to it, which runs external to the camera and plugs into the Left Face of the OpenMMS case via a 2-pin Lemo connector. Unfortunately, the Sony batteries for the A6000 camera do not only provide a positive voltage connection and a ground connection to the camera. There is a 3rd connection that transfers data between the camera and the battery. Because of this fact, the dummy battery must transfer the necessary data between itself and the camera. Thankfully ‘smart’ dummy batteries are commercially available and are required for making the OpenMMS Sony Battery Cable. An original Sony A6000 battery can be used instead of the OpenMMS Sony battery cable if desired. However, the user needs to ensure the battery is adequately charged before the OpenMMS sensor is used.

The following components are needed to assemble the Sony Battery Cable.

1 @ Smart Dummy Battery replacement for the NP-FW50 battery

1 @ 2 pin Lemo 0B series connector

Fig 7.4-1. Components needed to assemble the Sony Battery Cable¶

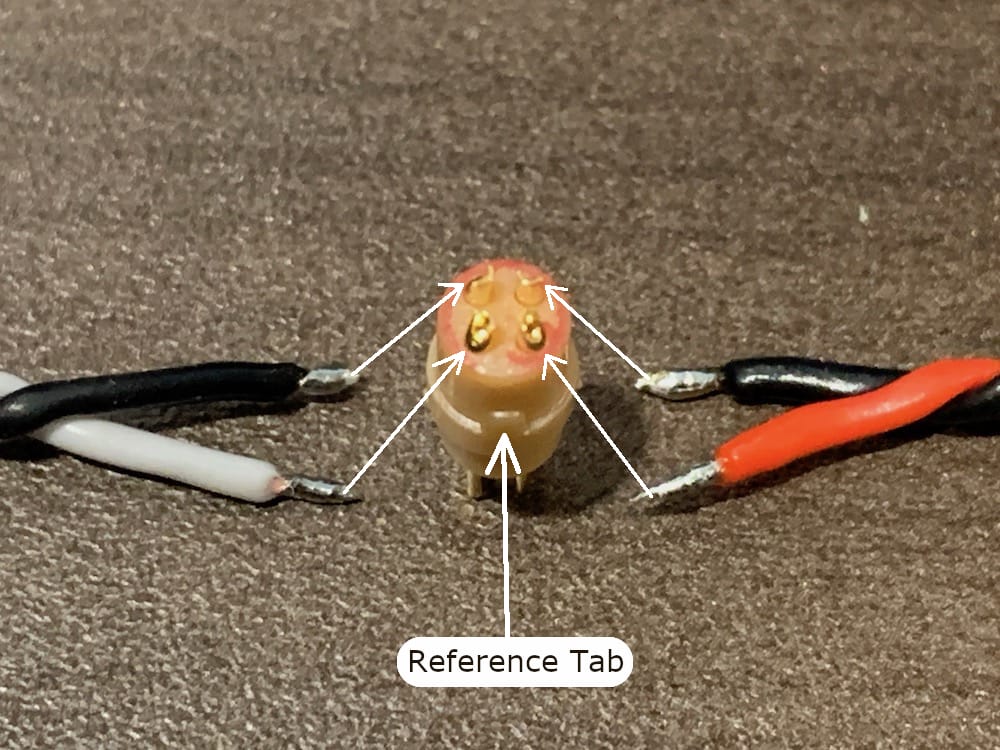

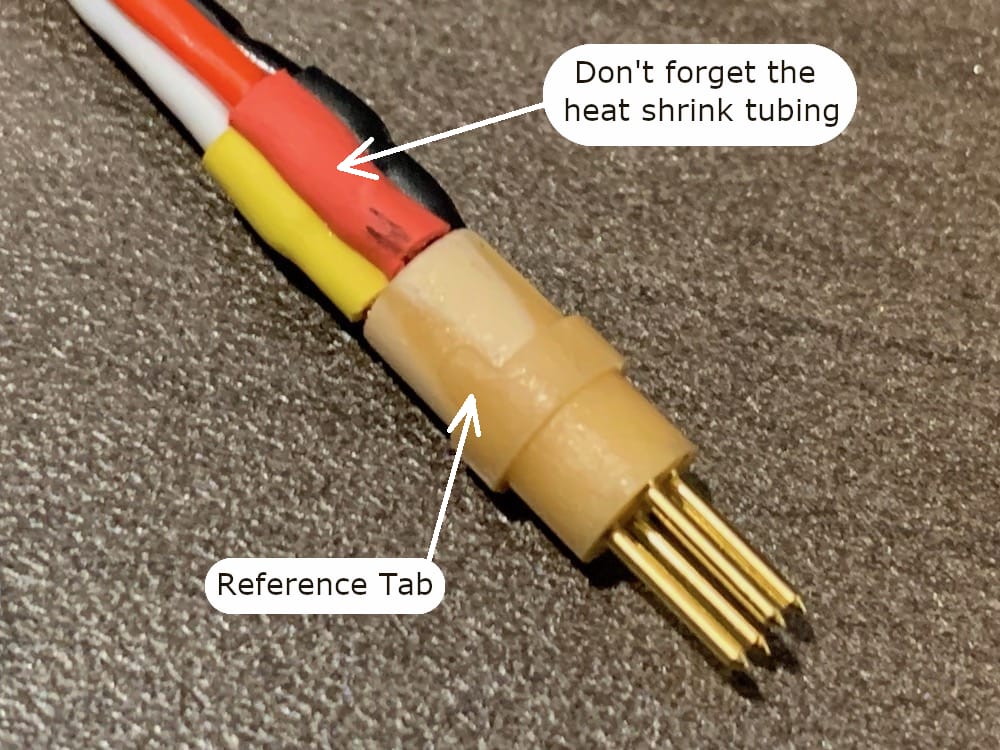

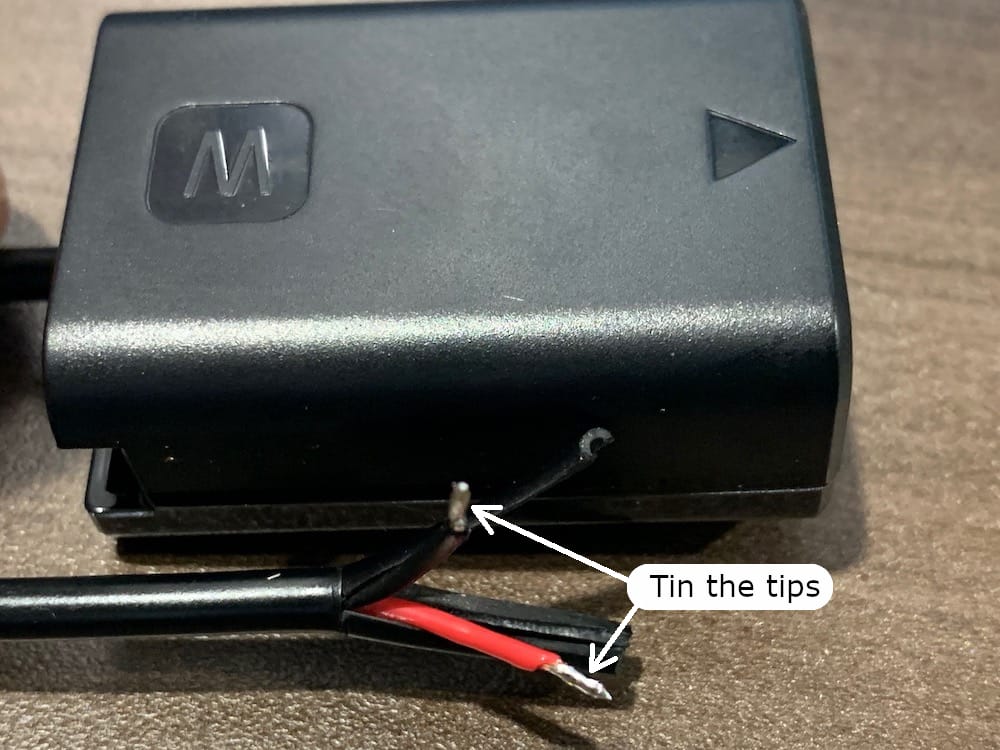

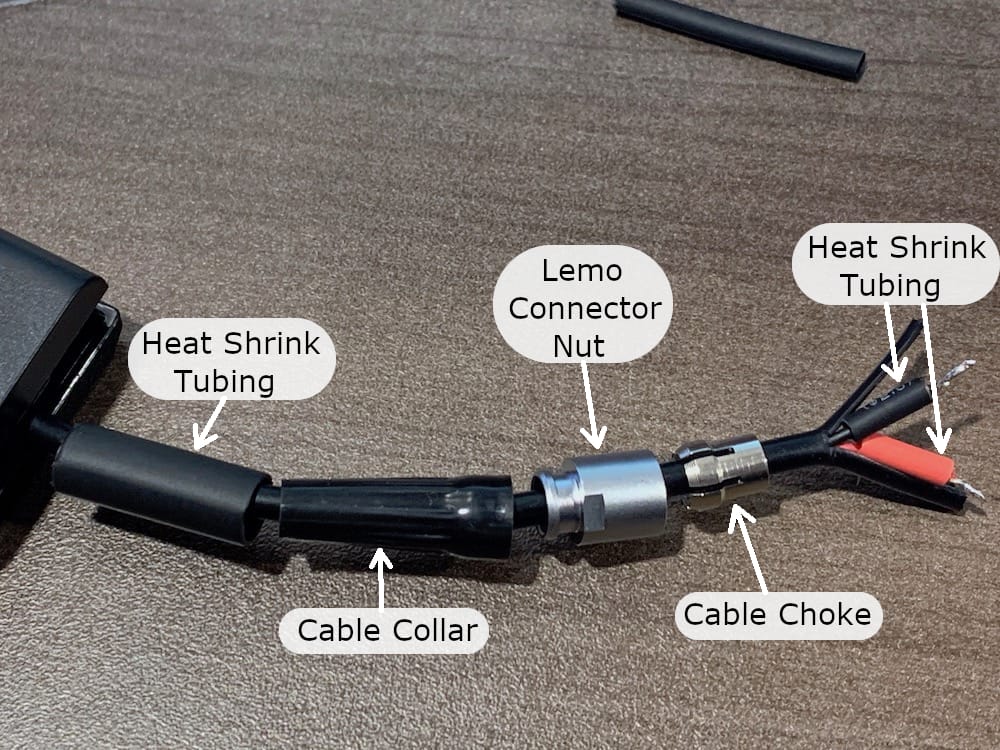

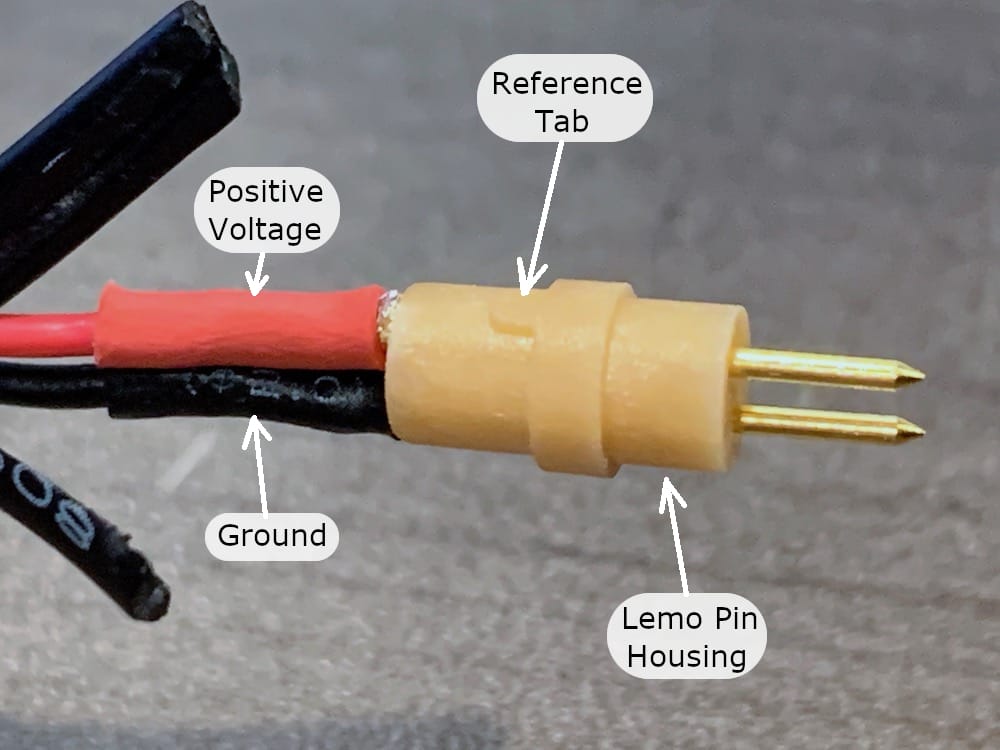

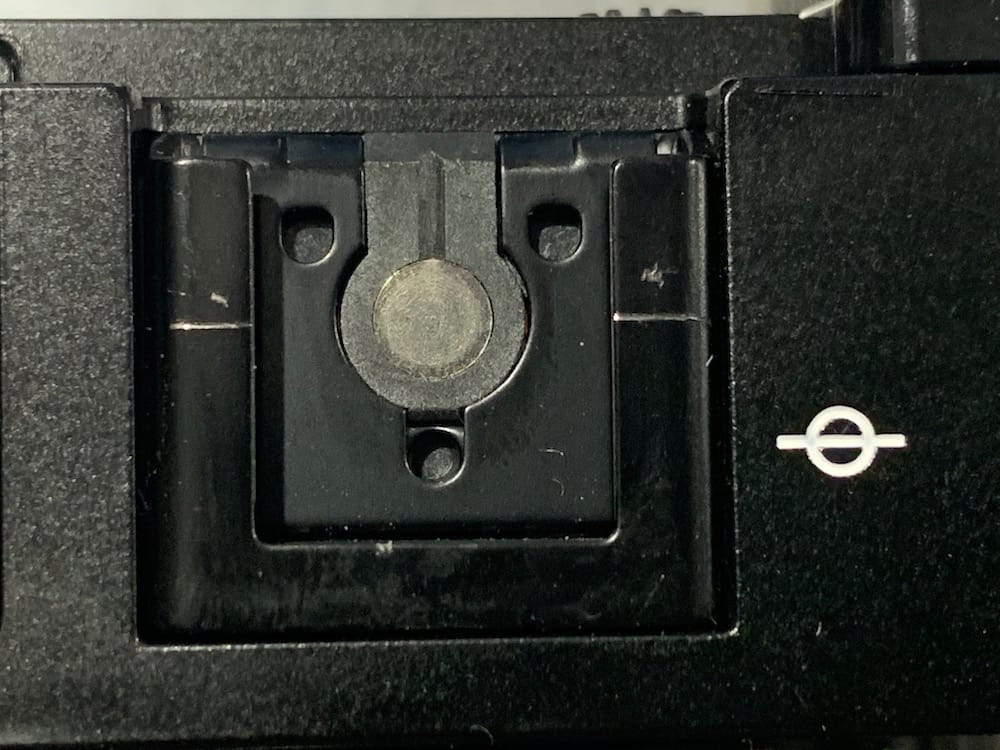

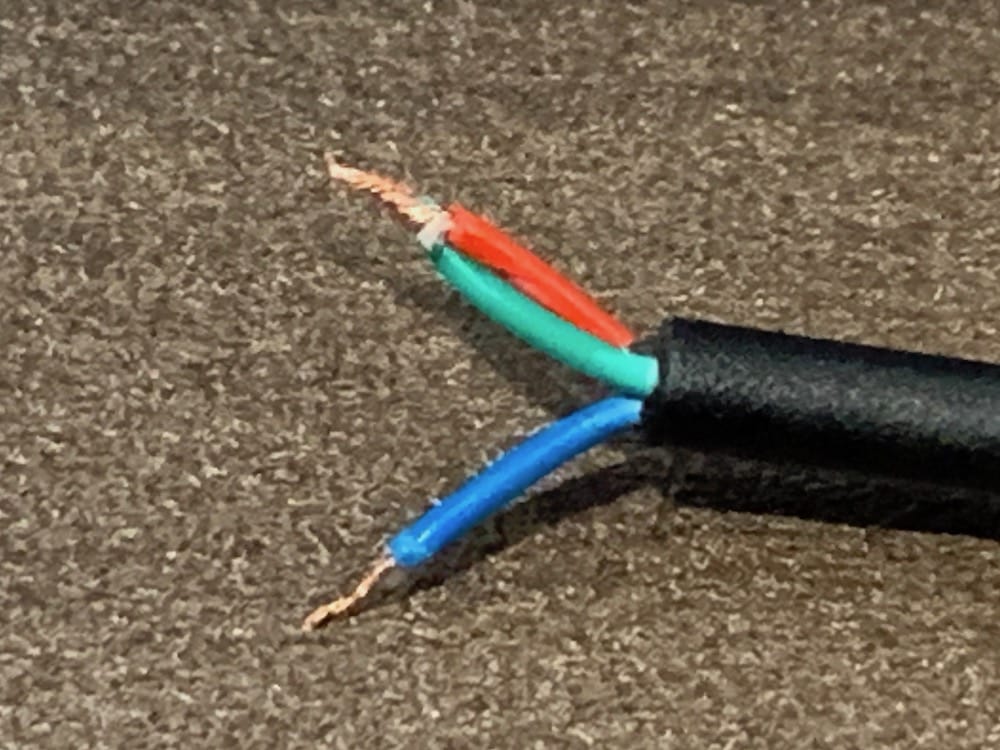

Start by cutting the cable coming out of the dummy battery to a length of 12cm and disassembling the 2-pin Lemo connector components. Next, carefully strip about 15mm of the sheathing at the cut end of the battery cable, and expose the red positive voltage and black ground wires. Strip a few millimeters of sheathing from each of the wires and then ‘tin the tip’ of each wire using a soldering iron and melting a small amount of solder onto and throughout the exposed wires. Tinning the tips makes soldering the wires to the small Lemo connector pins much easier. Next, slide the Lemo connector components - IN THE CORRECT ORDER - onto the battery cable. It is recommended to include a small piece of heat shrink tubing on the cable before the Lemo components. Cut small pieces of heat shrink tubing and place them over each of the wires. Next, solder the red positive voltage wire to the top Lemo pin. The top pin is defined as the pin that is closest to the reference tab on the Lemo pin housing. Solder the black ground wire to the bottom Lemo pin.

Fig 7.4-2. Cable cut to length¶

Fig 7.4-3. Cable and wires stripped¶

Fig 7.4-4. Ordered Lemo components¶

Fig 7.4-5. Lemo pin housing¶

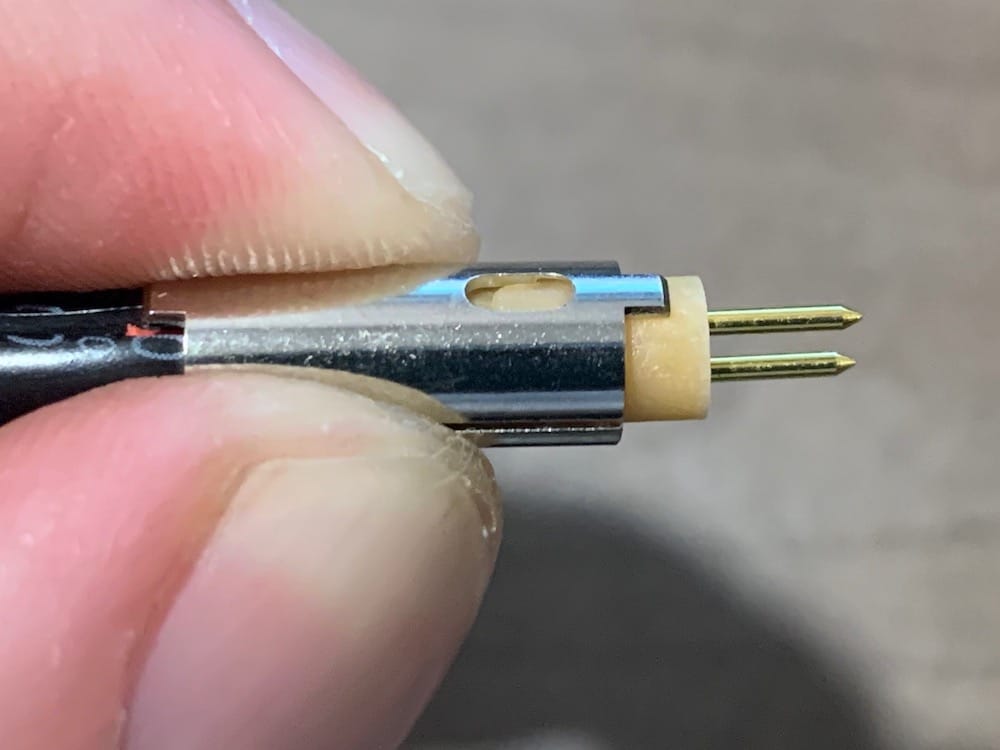

Next, install the two halves of the Lemo cable guide around the pin housing. Pay close attention to the machined grooves on the insides of the two halves of the cable guide. The guide can only be properly installed one way. The halves need to be held in place by hand. Next, insert the pin housing and cable guide into the Lemo connector. The notch on the top half of the cable guide needs to be in line with the Lemo connector’s reference dot. An excellent way to ensure they are aligned is to purposely misalign the notch on the top while inserting the pin housing into the connector. Then slowly rotate the pin housing while applying forward pressure on the cable. You should feel the cable move farther into the connector when the correct alignment is realized. While keeping forward pressure on the cable within the Lemo connector, slide the cable choke, followed by the Lemo connector nut, up the cable and into the backside of the connector. Thread the Lemo connector nut onto the threads on the backside of the connector and tighten. The nut and connector both have flat sides where a small wrench or pliers can be used to tighten the nut firmly. Next, slide the cable collar up the cable and force it onto the Lemo connector nut’s locking edge.

Fig 7.4-6. Lemo cable guide¶

Fig 7.4-7. Cable choke in place¶

Fig 7.4-8. Lemo connector nut¶

Fig 7.4-9. Cable collar in place¶

Lastly, if utilized, slide the heat shrink tubing up the cable and have it adequately cover a portion of the cable collar and a portion of the cable itself. Apply heat to set the tubing in place.

Fig 7.4-10. Completed OpenMMS Sony battery cable¶

7.5. Sony Trigger and Event Cable¶

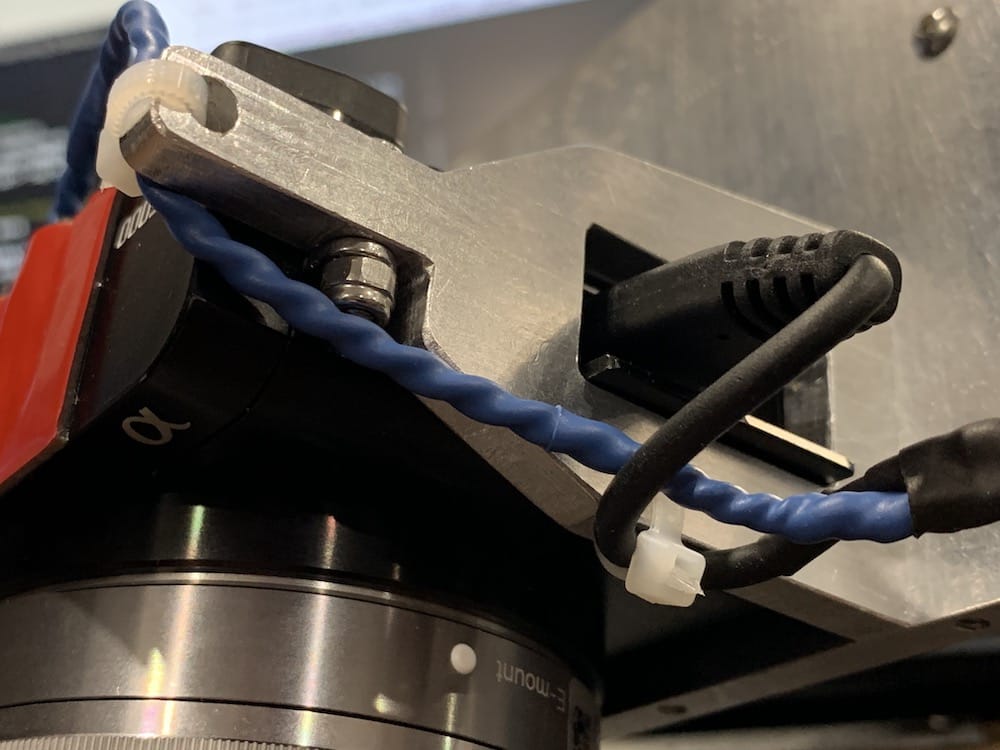

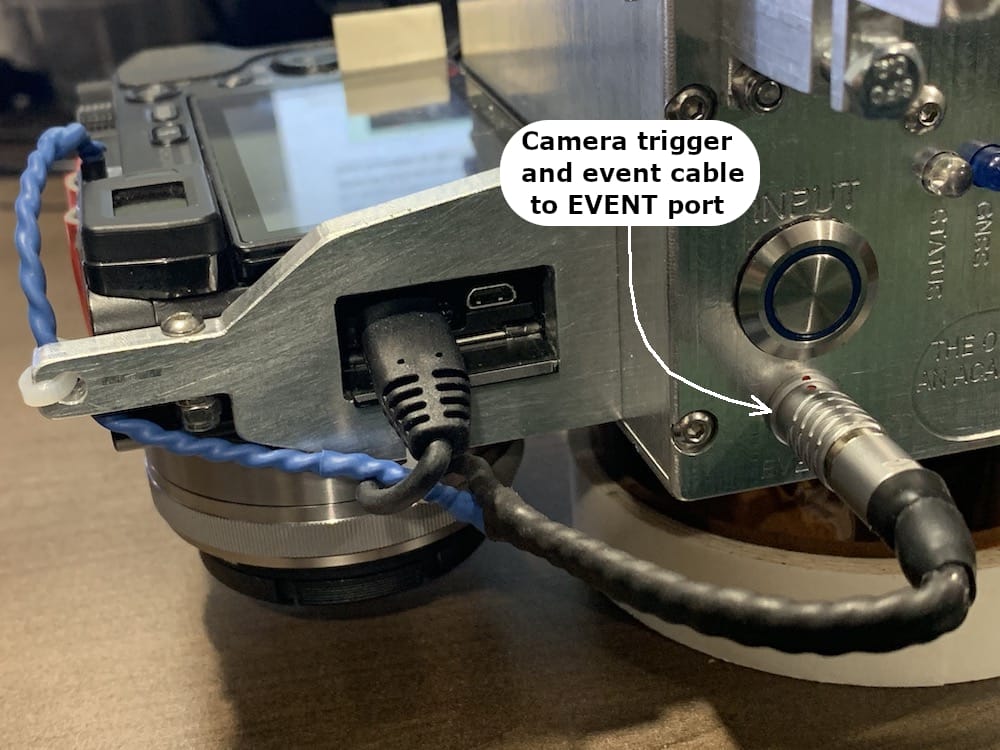

The OpenMMS sensor is designed to control when the Sony A6000 camera takes a photo, based on a user-specified time interval (currently the only available option). However, it takes the Sony A6000 camera a variable amount of time after receiving the command, before it takes the photo. It is also possible that the camera may not take a photo even though it received the command. To capture the precise time each photo was taken, a sensor is installed in the Sony A6000’s external flash ‘hot-shoe’ connector. The camera sends a signal to the flash connector at the precise time when the camera’s shutter is opened. The sensor captures this signal and, after being conditioned, sends it to the Applanix APX-18 GNSS-INS sensor, where the precise timing is recorded as an Event. A single cable needs to be created that provides both the camera triggering functionality and capturing when a photo Event occurs.

The following components are needed to assemble the Sony Trigger and Event Cable.

1 @ TuffWing - Hot-shoe precision geotag cable

1 @ Vello - Sony shutter release cable

1 @ 4 pin Lemo 0B series connector

Some extra 26 AWG flexible wire (not shown)

Fig 7.5-1. Components needed to assemble the Sony Trigger and Event Cable¶

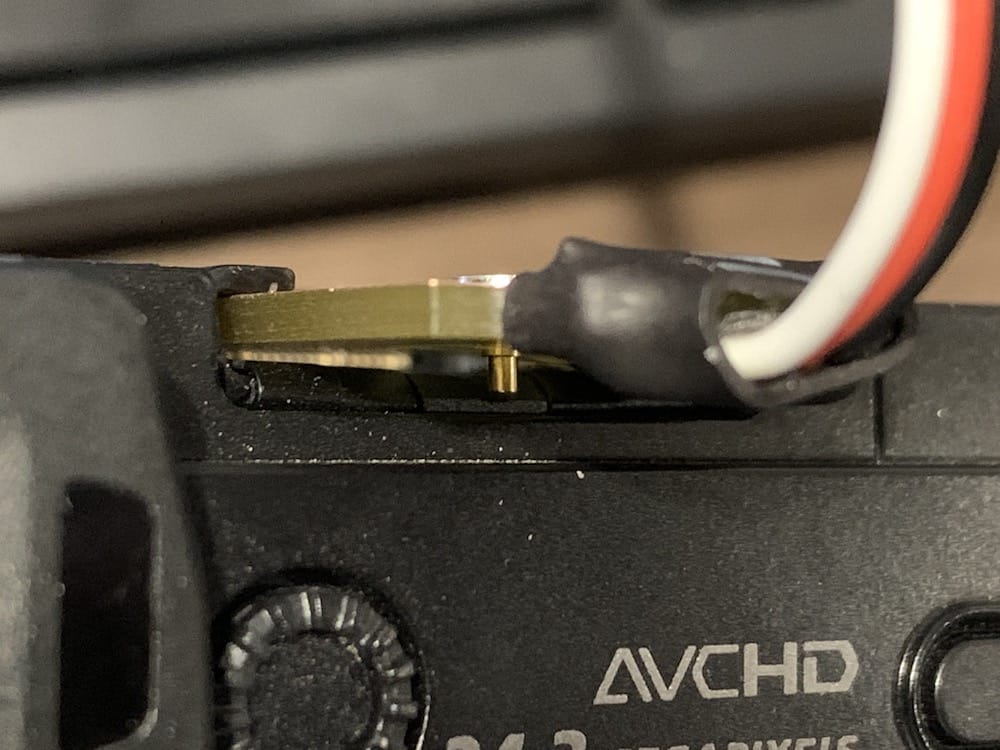

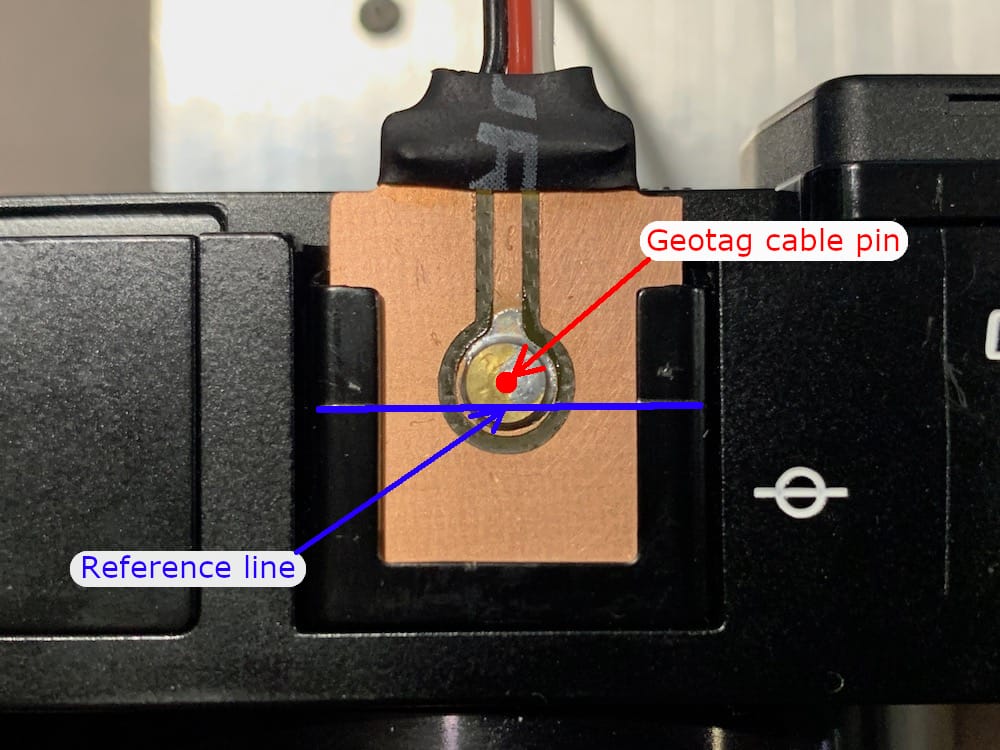

Start by taking the Sony A6000 camera and making a reference line across the flash hot shoe connector that aligns with the silver pad near the center. Next, carefully insert the TuffWing hot-shoe precision geotag cable into the hot-shoe connector, making sure to depress the center pin with a thin, rigid object. Seat the geotag cable as far into the hot-shoe connector as possible. Compare the reference line previously made with the center pad on the backside of the geotag cable. If the geotag cable’s center pad is above the reference line, the bottom edge of the geotag cable’s PCB needs to be adjusted. If the geotag cable’s center is below the reference line, no adjustments need to be made.

Fig 7.5-2. Reference line¶

Fig 7.5-3. Geotag cable center pin¶

Fig 7.5-4. Center pin is depressed¶

Fig 7.5-5. Initial fit in hot-shoe¶

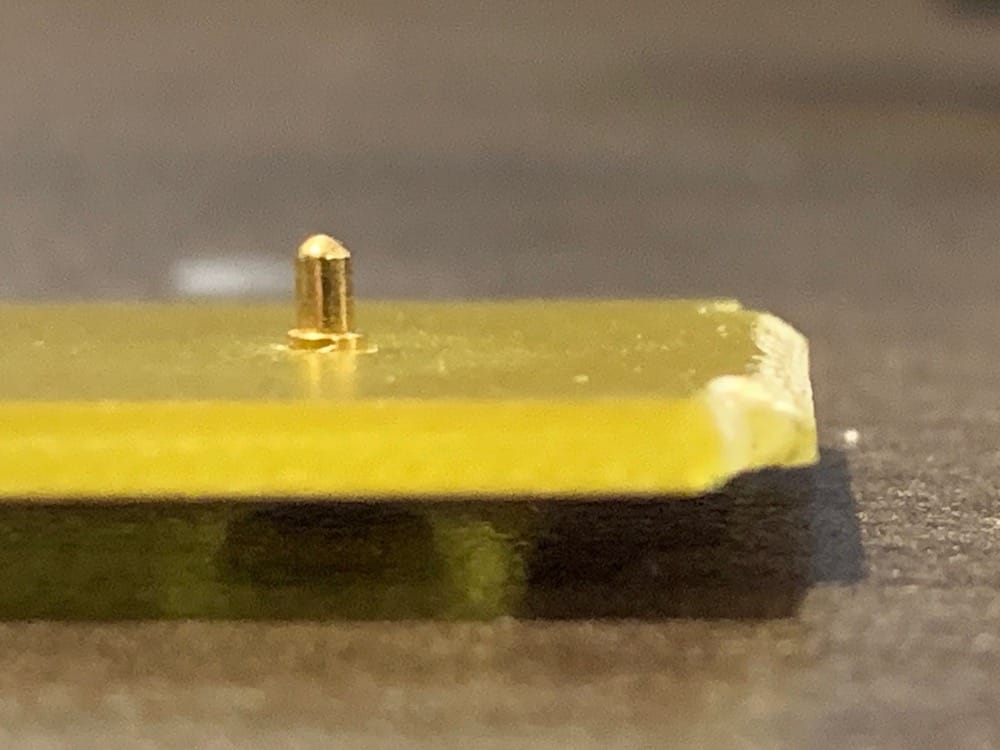

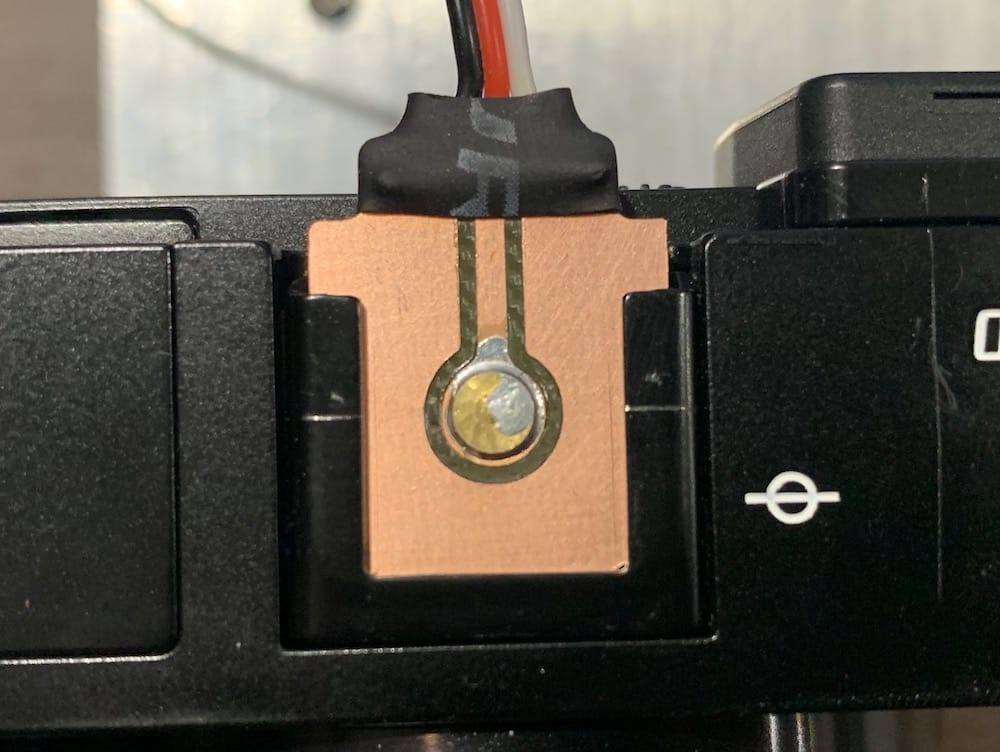

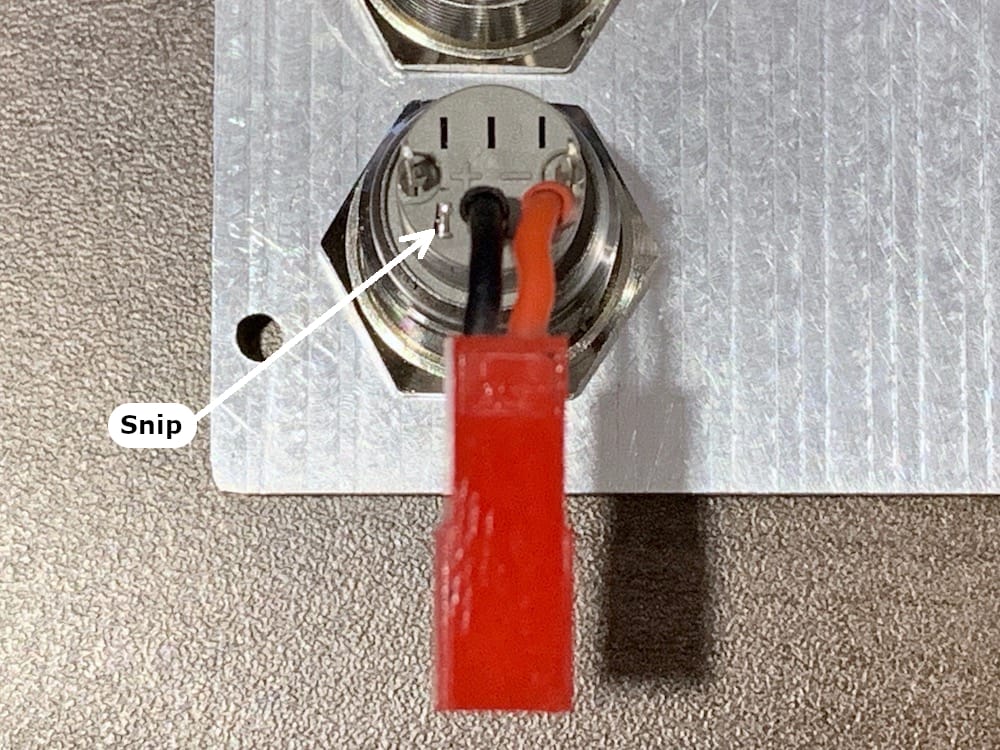

If the geotag cable’s center is above the reference line, the bottom corners of the cable’s PCB should be carefully snipped away. Approximately a 3mm (left to right) by 1.5mm (top to bottom) area should be removed from each corner. The bottom edge on the PCB’s non-copper side must also be filed at a 45 deg angle to create a tapered edge. Lastly, reinsert the geotag cable into the hot shoe and observe if the adjustments have improved the center pin’s alignment with the reference line. Continue to make small adjustments until the alignment is correct. Remove the geotag cable from the camera before continuing.

Fig 7.5-6. Adjusted bottom corners¶

Fig 7.5-7. Tapered bottom edge¶

Fig 7.5-8. Correct alignment in hot shoe¶

Next, take the Vello shutter release (trigger) cable and cut it on the USB (multi) connector side just before the cable begins to twist. Strip the cable’s sheathing approximately 20mm from the cut end, being very careful not to damage any of the three wires inside. Expose and red, green, and blue wires and strip away 5mm of their sheathings. These wires also have pieces of nylon thread inside them. It is recommended to cut away these nylon threads to make soldering them easier and cleaner. Next, using a multimeter with a continuity tester, confirm that the blue wire is connected to the ground surface of the USB (multi) connector (it should be). If the blue wire is not connected to ground for some reason, then one of the other two wires must be. There should only be one ground wire in the cable. Next, take the two other (non-ground) wires and connect them together. Tin the tips of the joined pair of wires and the ground wire. Extend the two wires by soldering the extra 26 AWG flexible wire so the Vello release cable is approximately 17cm in length measured from the back end of the USB (multi) connector. It is strongly recommended that the ground wire be extended using a black-colored wire and the connected pair of wires be extended using a red-colored wire.

Fig 7.5-9. Cut Vello release cable here¶

Fig 7.5-10. Ground (B), focus (G), shutter (R)¶

Fig 7.5-11. Focus & shutter connected together¶

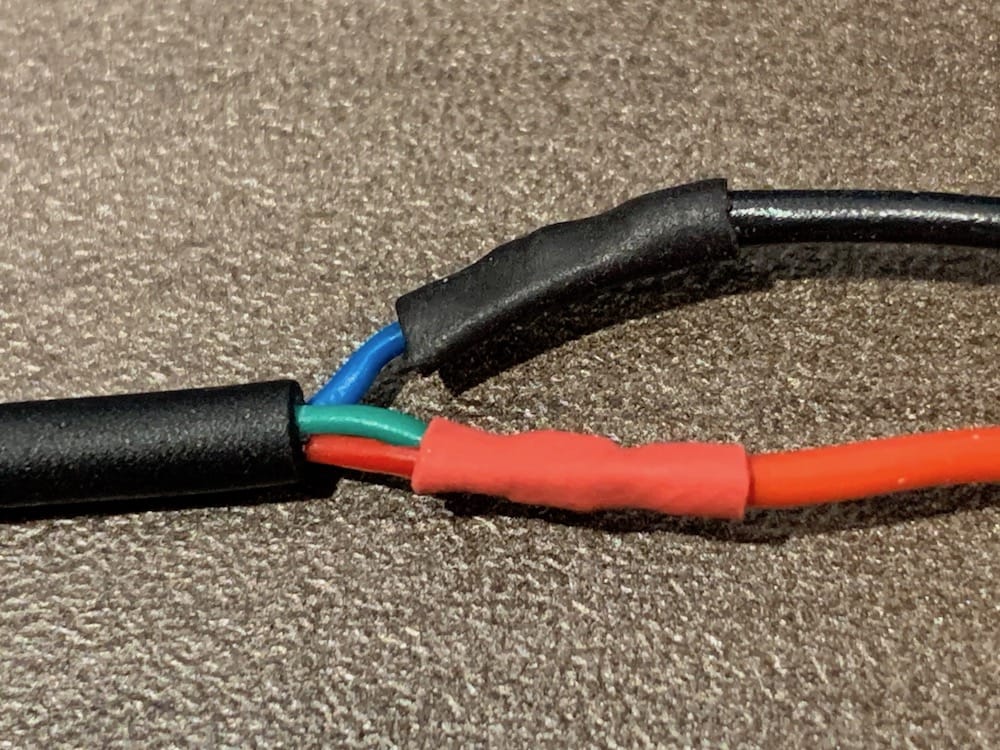

Next, cut and discard the JR connector end from the TuffWing hot-shoe precision geotag cable. Remove the center (red) wire from the three wires, as it is not connected to the PCB and, therefore, not needed. Strip away 5mm of sheathing from the remaining two wires and extend them by soldering the extra 26 AWG flexible wire, so the TuffWing geotag cable is approximately 20cm in length measured from the back end of the PCB connector. It is strongly recommended that the geotag cable wires be extended using wires of the same color (e.g., white and black shown here). Next, apply heat shrink tubing individually to the entire length of the extended Vello release cable and the TuffWing geotag cable. Apply an additional 8cm length of heat shrink tubing around BOTH cables to join them together. Ensure 2-3cm of the exposed individual wires is outside the additional heat shrink tubing to allow for the individual wires to be soldered to the Lemo connector.

Fig 7.5-12. Extended cable lengths¶

Fig 7.5-13. Heat shrink tubing around each cable¶

Fig 7.5-14. Additional heat shrink to join the cables¶

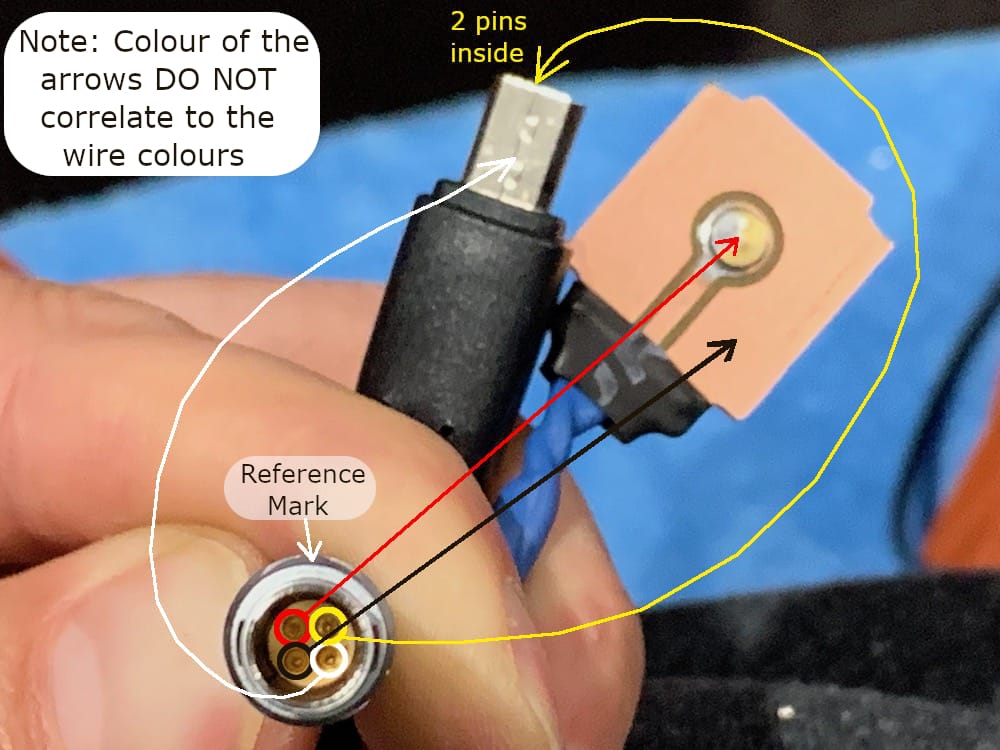

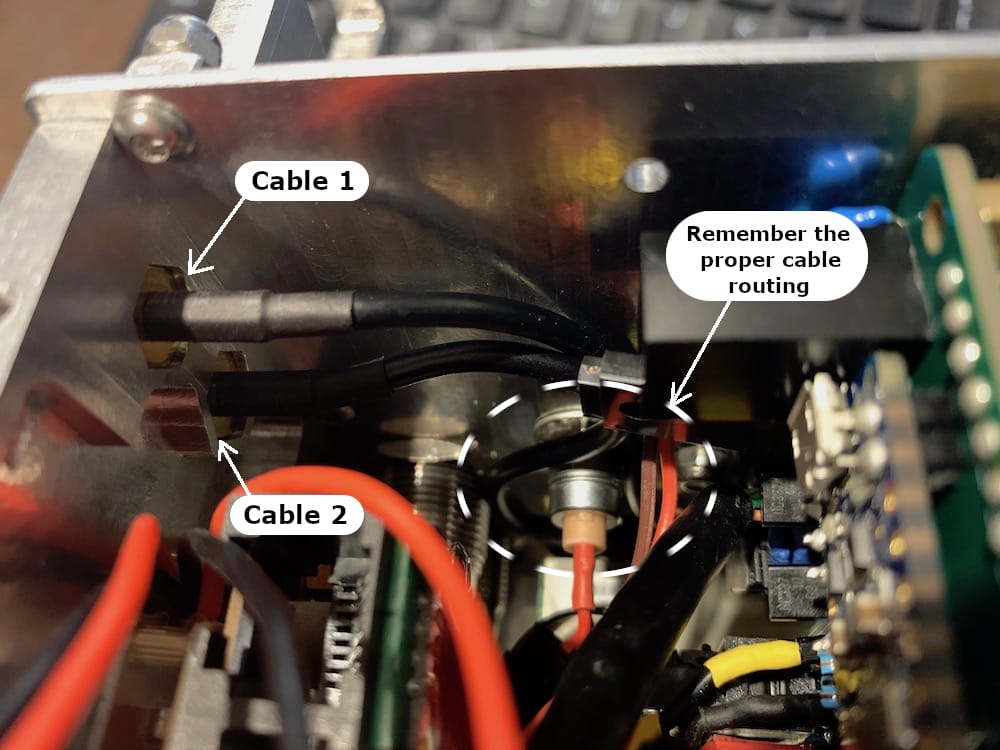

Next, disassemble the 4-pin Lemo connector and slide the respective components (IN THE CORRECT ORDER) onto the cable (see Sony Battery Cable section for Lemo connector details). It is recommended to cut the black Lemo cable collar approximately in half to allow for better cable flexibility. Include a piece of heat shrink tubing as the first component to slide onto the cable. Solder the four wires to the respective pin connectors on the backside of the Lemo pin housing, as shown in the figure below. Use heat shrink tubing around each soldered wire to insulate them from each other and the Lemo connector housing. Remember the black wires are ground wires, the red wire is the trigger wire, and the white wire is the Event wire, within this example. AFTER SOLDERING, IT IS STRONGLY RECOMMENDED TO TEST FOR SHORT CIRCUITS ACROSS ALL FOUR PINS TO ENSURE NONE EXIST! Next, slide the Lemo components pre-installed on the cable to the Lemo connector to complete the cable assembly. Check for continuity between the Lemo pins and the Vello and TuffWing connectors on the cable, as shown in the figure below.

7.6. GNSS Antenna Cables¶

Attention

The following instructions will create GNSS antenna cables with the proper end connectors for connecting the Applanix APX-18 GNSS-INS sensor to Trimble AV14 GNSS antennas. If different GNSS antennas are utilized, it is the reader’s responsibility to ensure that suitable GNSS antenna cables are used.

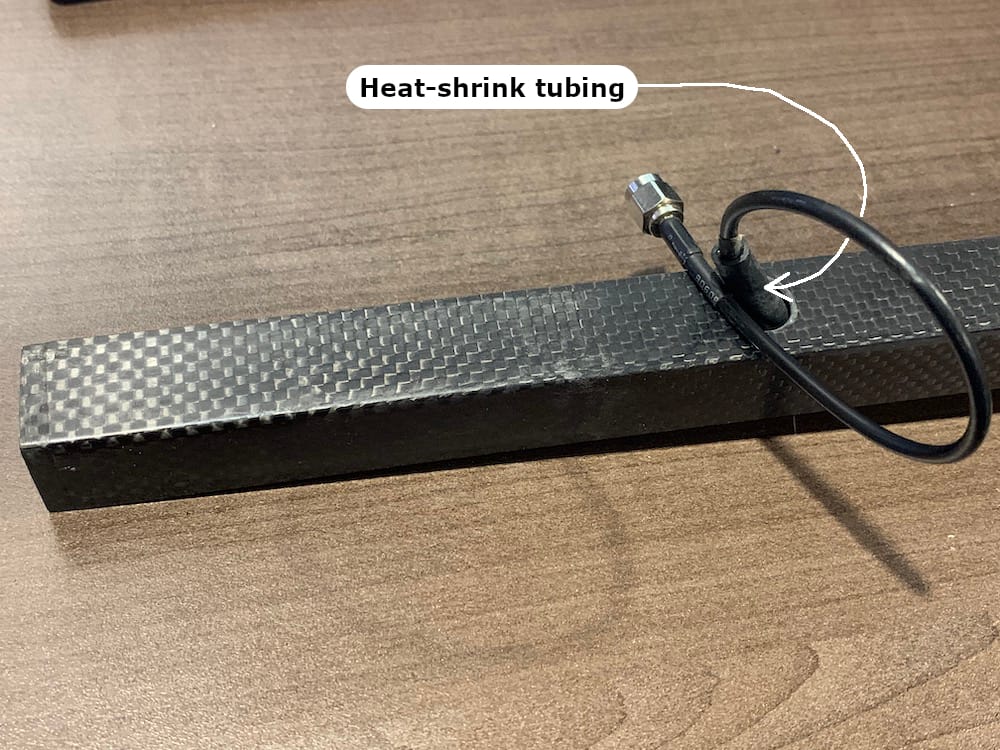

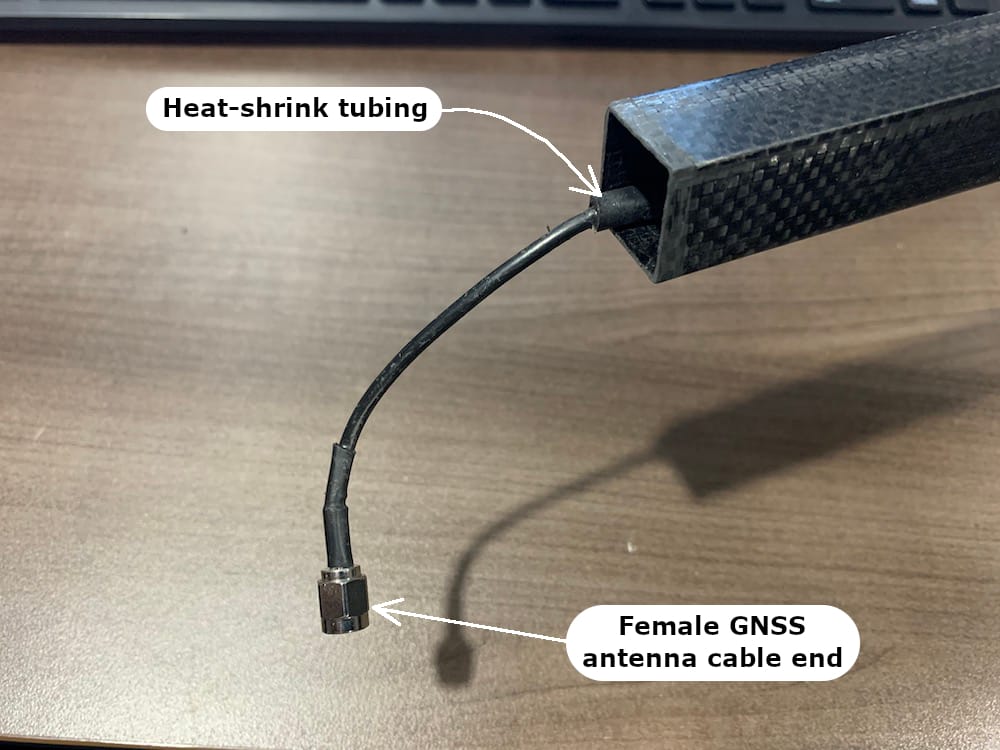

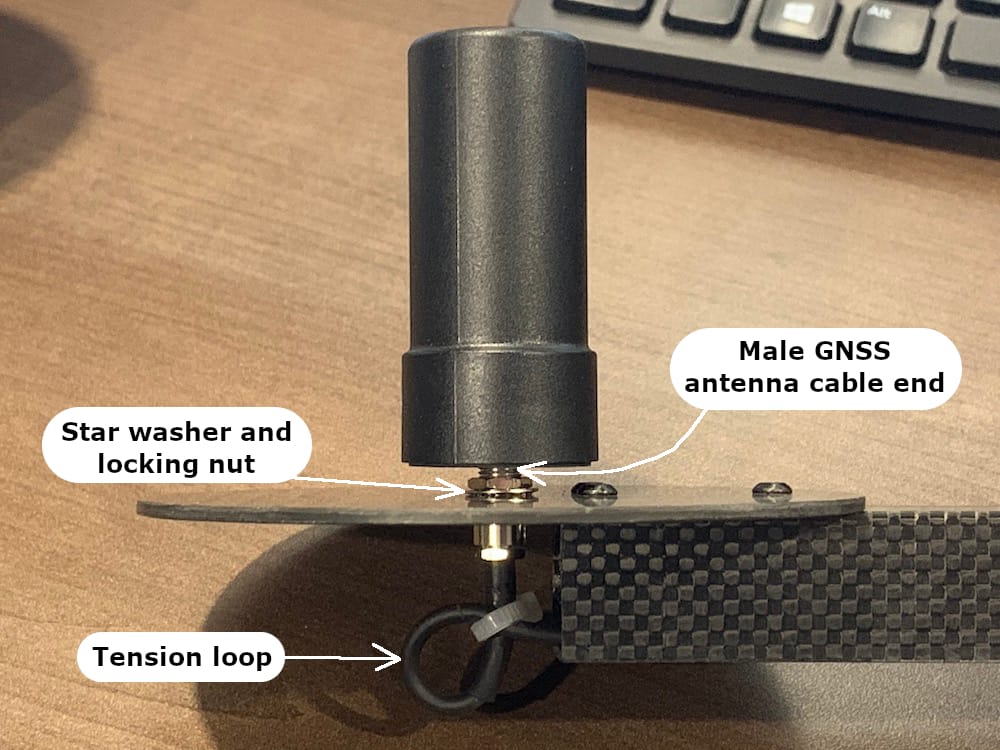

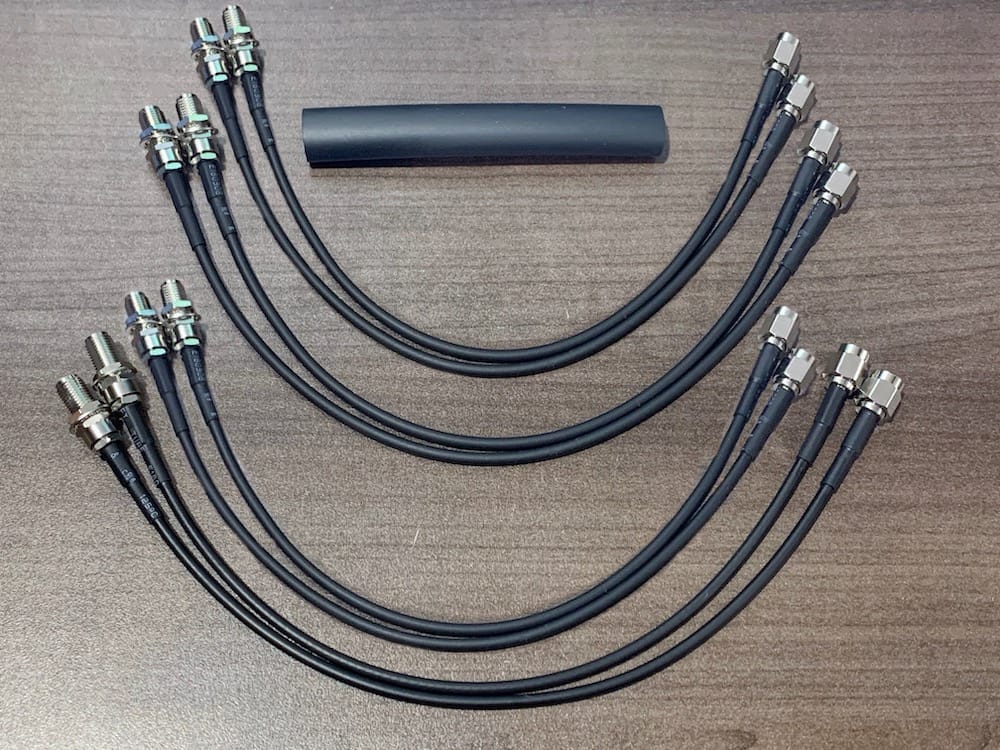

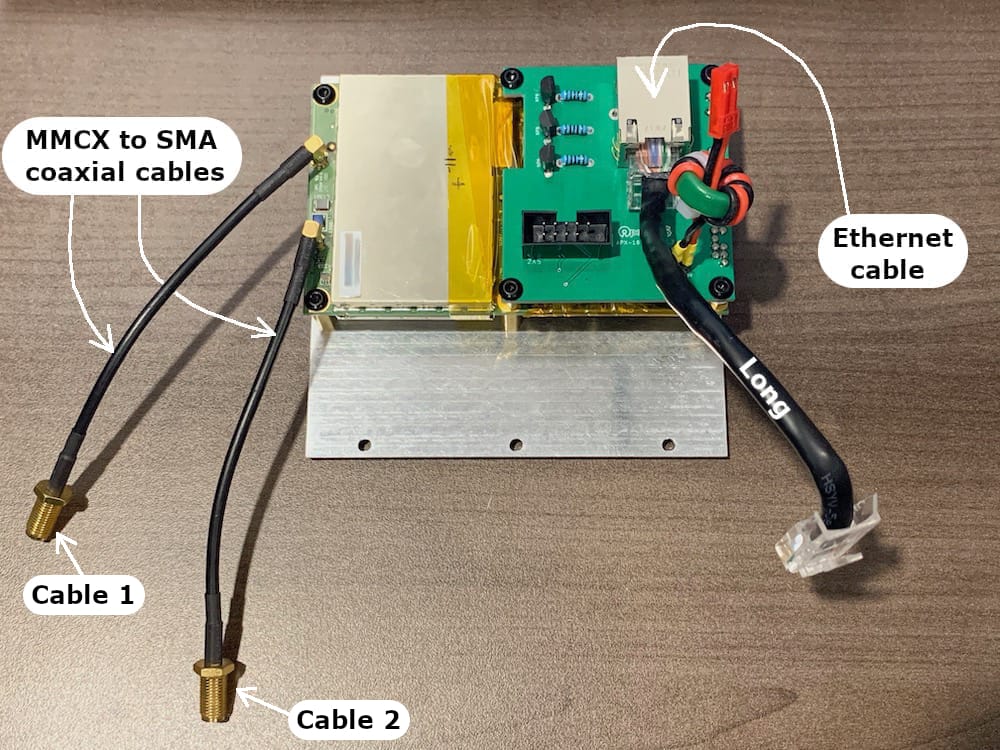

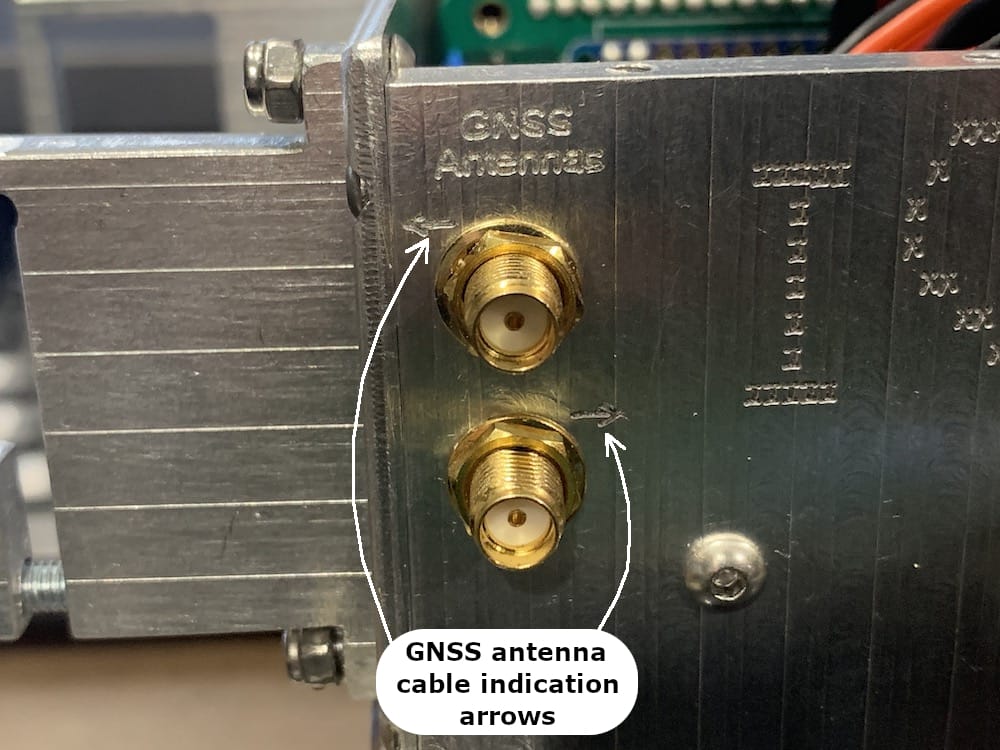

A total of two GNSS antenna cables need to be assembled. Cables that are directly ready to use could be purchased from other sources than those listed in the Getting Started –> List of Sensors and Electronics section. An interested reader could explore the Classic Builder tool on www.onlinecables.com. The GNSS antenna cables need to have an SMA male connector (straight or right-angle) on one end, a 50 Ohm shielded coaxial cable (e.g., RG-174), a straight SMA female connector on the other end, and be 100cm in length.

The following components are needed to assemble the two GNSS antenna cables using the parts listed in the Getting Started section.

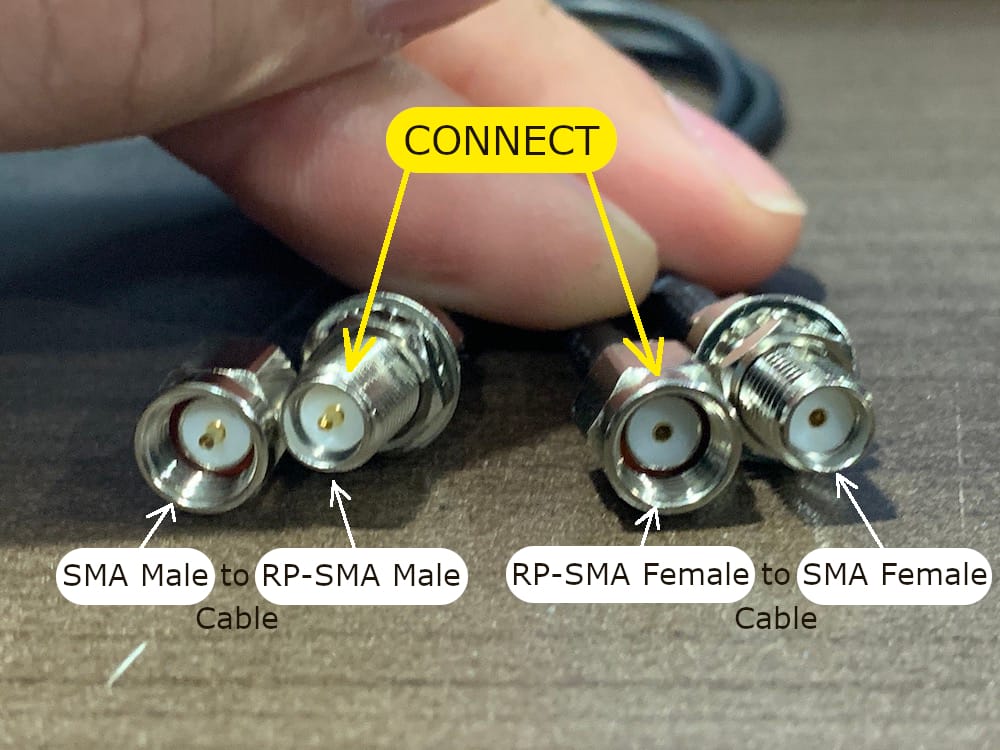

4 @ SMA Male to RP-SMA Male coaxial cable, 25cm in length each

4 @ RP-SMA Female to SMA Female coaxial cable, 25cm in length each

Heat-shrink tubing

Fig 7.6-1. Components needed to assemble the GNSS antenna cables¶

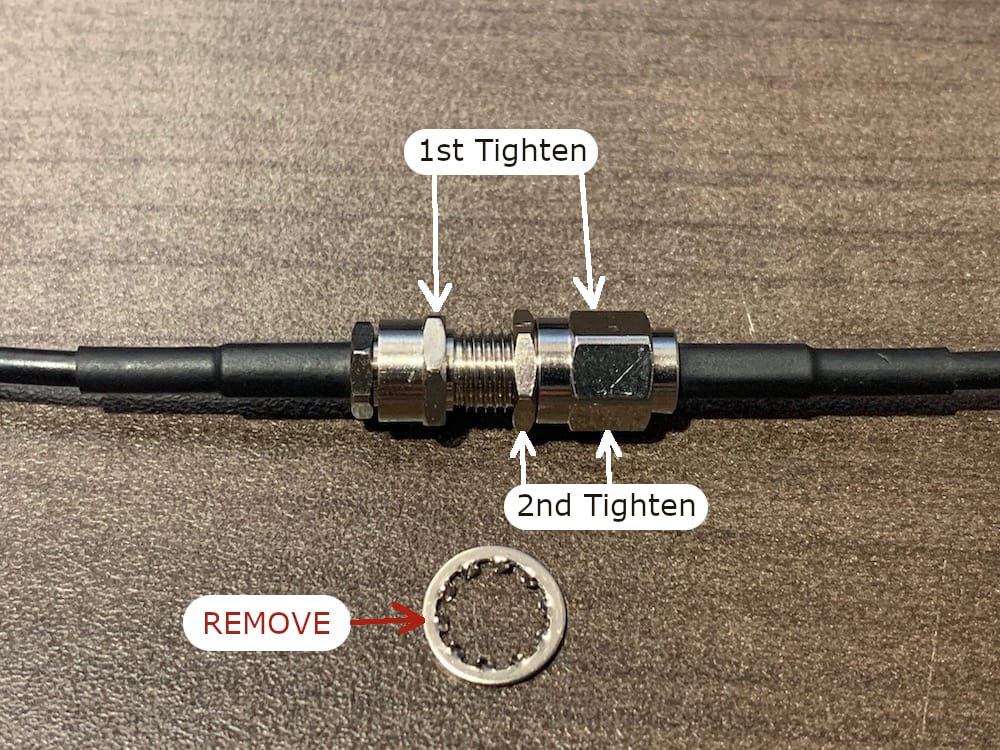

If the listed coaxial cables are used, the first step is to connect one of the SMA Male to RP-SMA Male cables with one of the RP-SMA Female to SMA Female cables. Please pay close attention that the right ends of each cable are connected, as it is possible to connect the wrong ends, see the figure below. The star washer should be removed where the cables connect as it does not provide any benefit to the connection. However, the nut needs to be used, so ensure it is put back onto the connector after removing the star washer. Tighten the connectors together first, and then tighten the nut. Apply an adequate size piece of heat-shrink tubing over the connection and set it in place with a heat gun. Repeat this assembly step four times, creating four ~ 50cm length coaxial cables with the necessary SMA male and SMA female connectors. Lastly, to create the correct length of coaxial cables, two ~50cm length cables are connected following the previous instructions. Ensure to leave the star washer on the SMA female connector of the final cables as it will be used when attaching the cables to the carbon fiber GNSS antenna arms.

CONGRATULATIONS!

YOU HAVE NOW FINISHED ASSEMBLING ALL OF THE CABLES!

8. Component Configurations¶

8.1. Overview¶

There are six OpenMMS components that need to be individually configured before being installed within the OpenMMS sensor. Some of the following configuration instructions require the reader to possess certain computer networking skills (e.g., DHCP vs. static IP address assignment). When possible, links to helpful articles/videos are provided to help the reader acquire the necessary skills. Detailed explanations of these skills are not provided within the OpenMMS documentation.

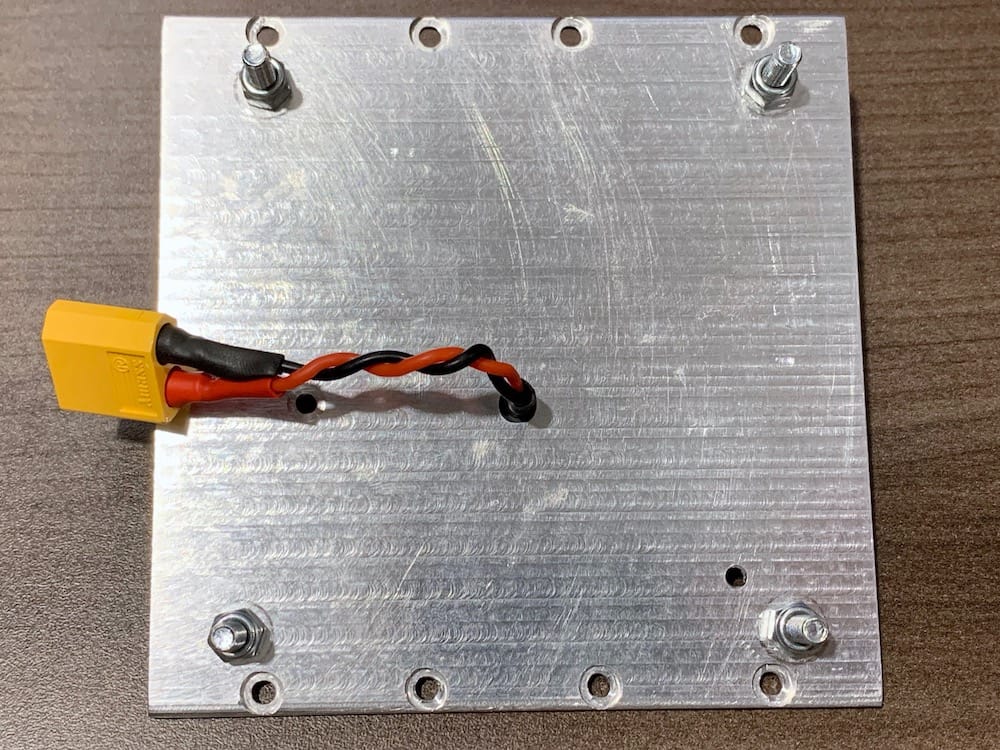

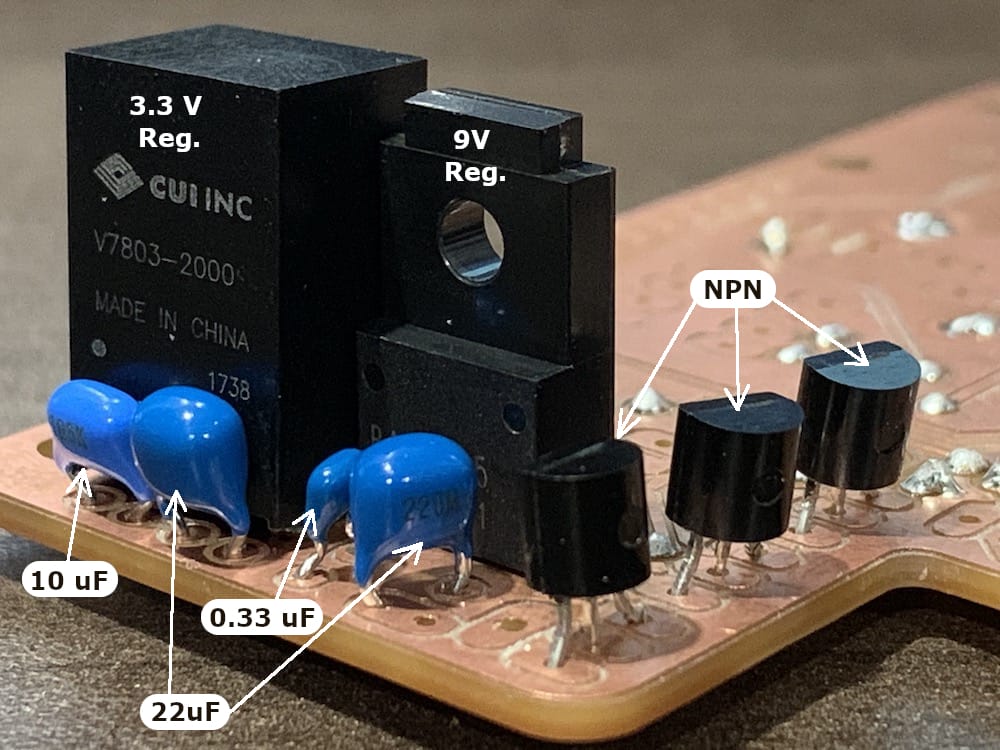

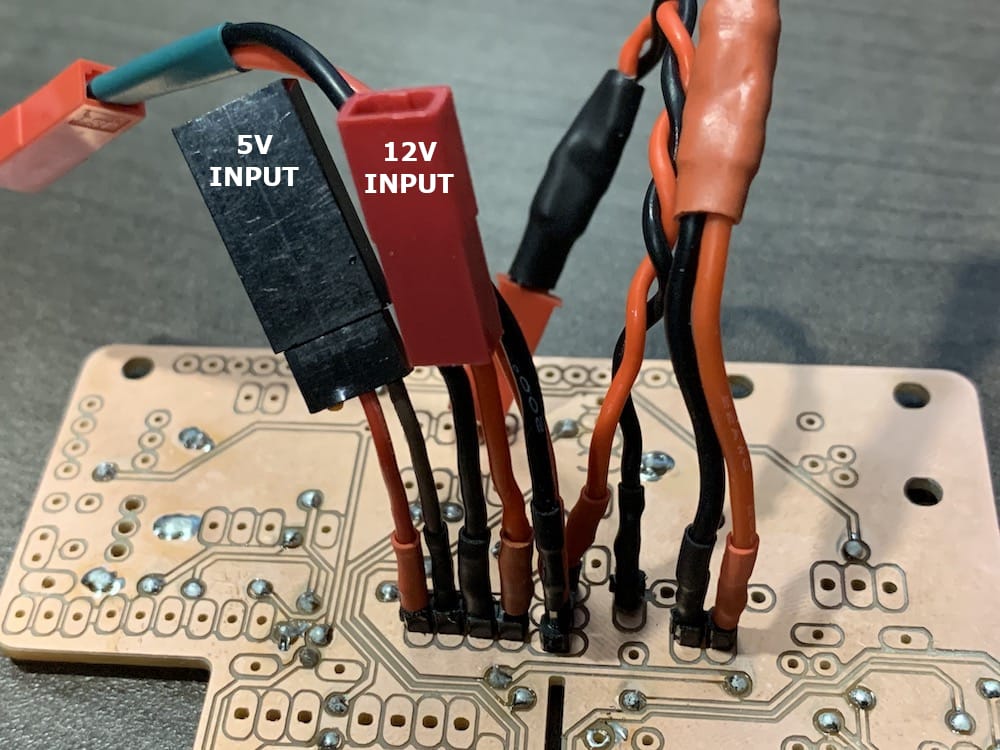

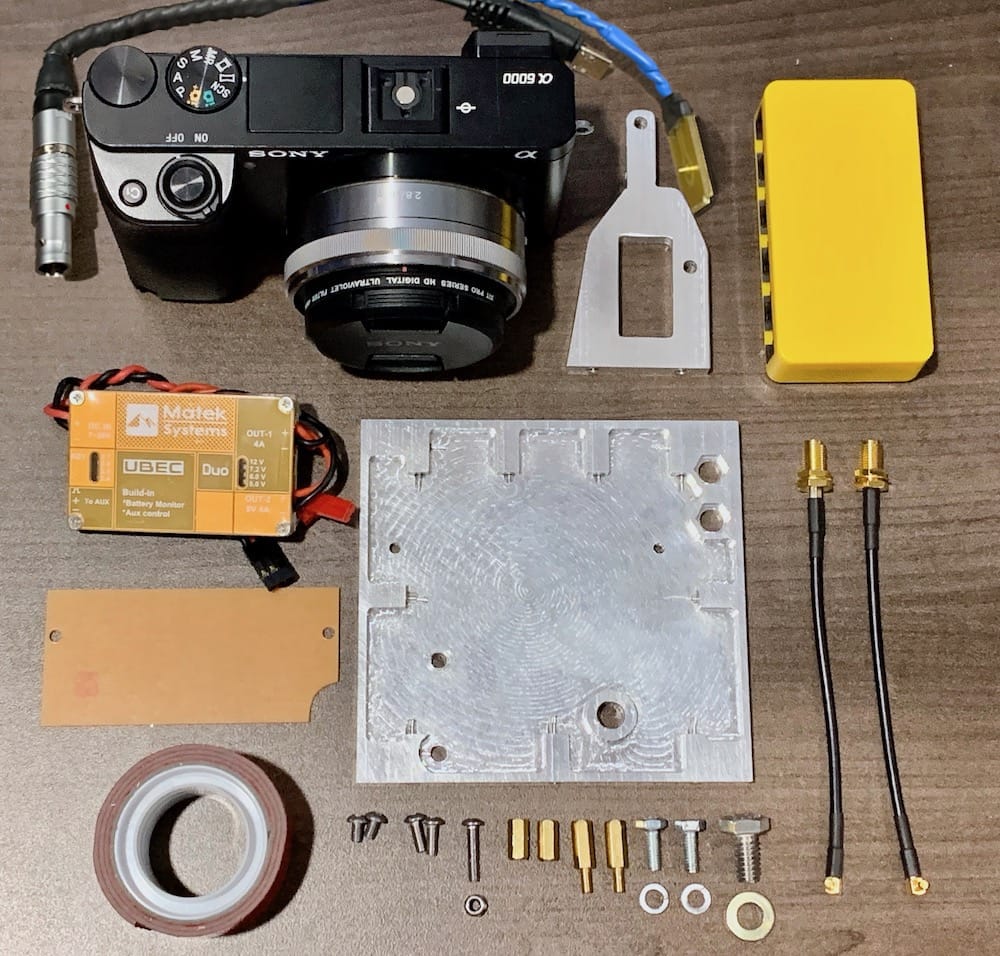

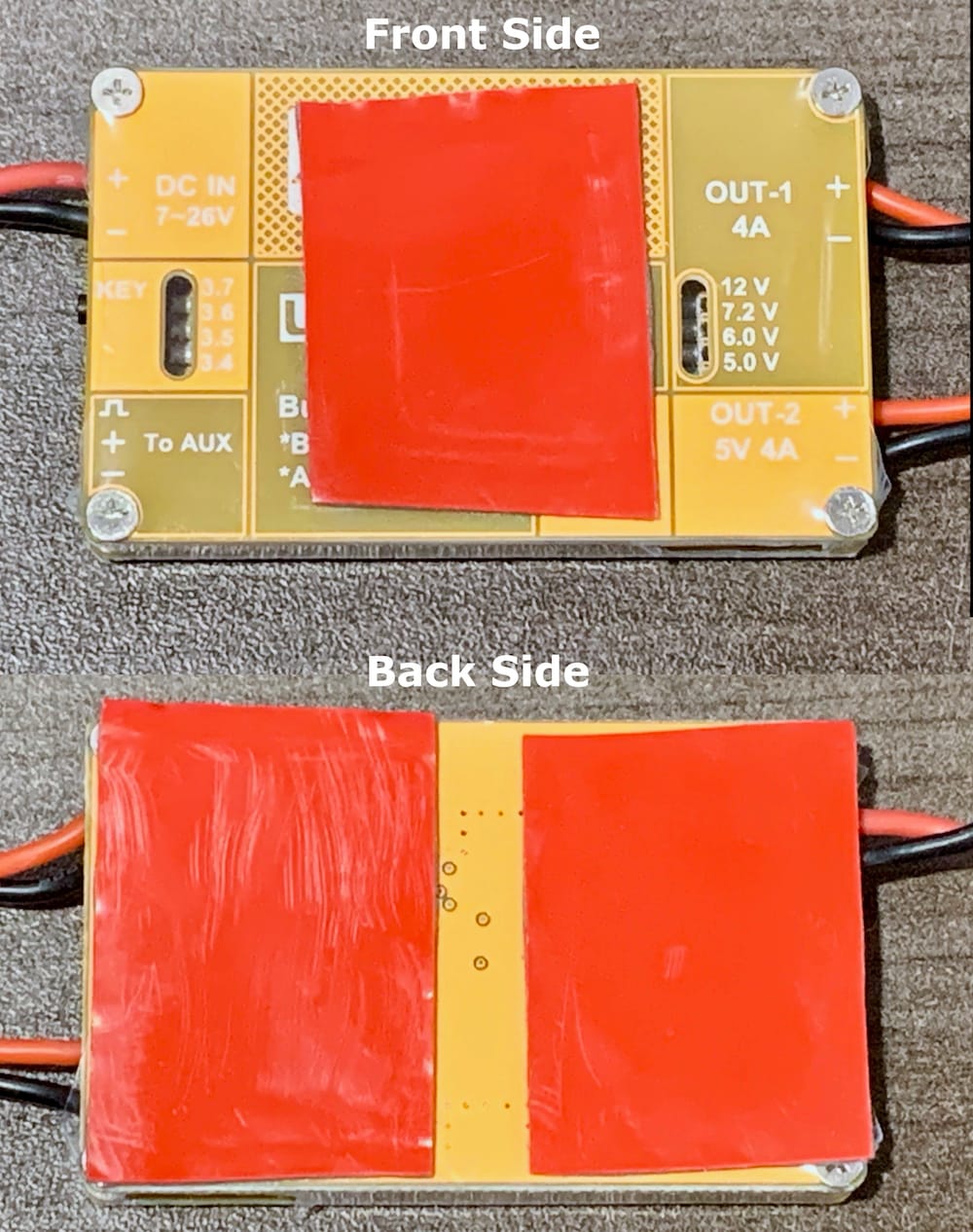

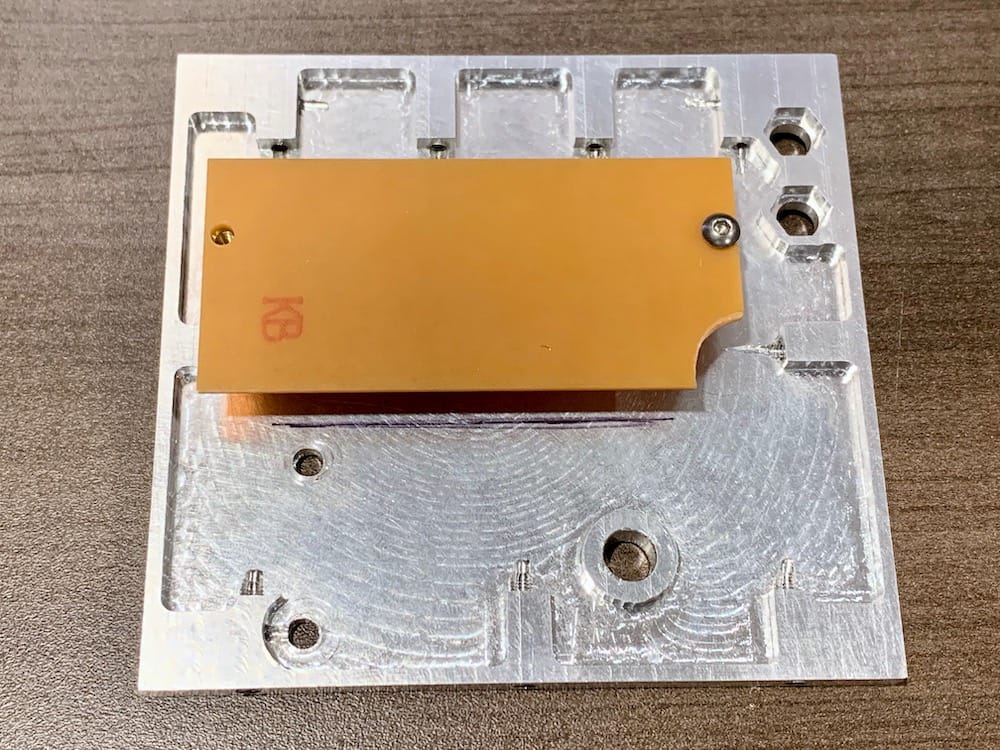

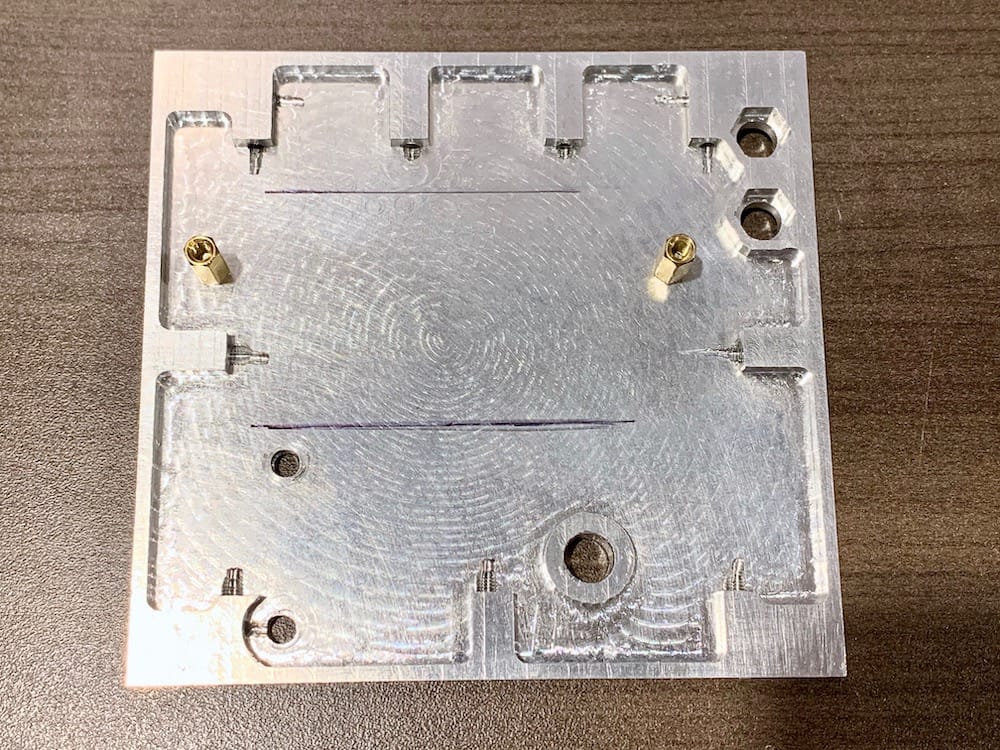

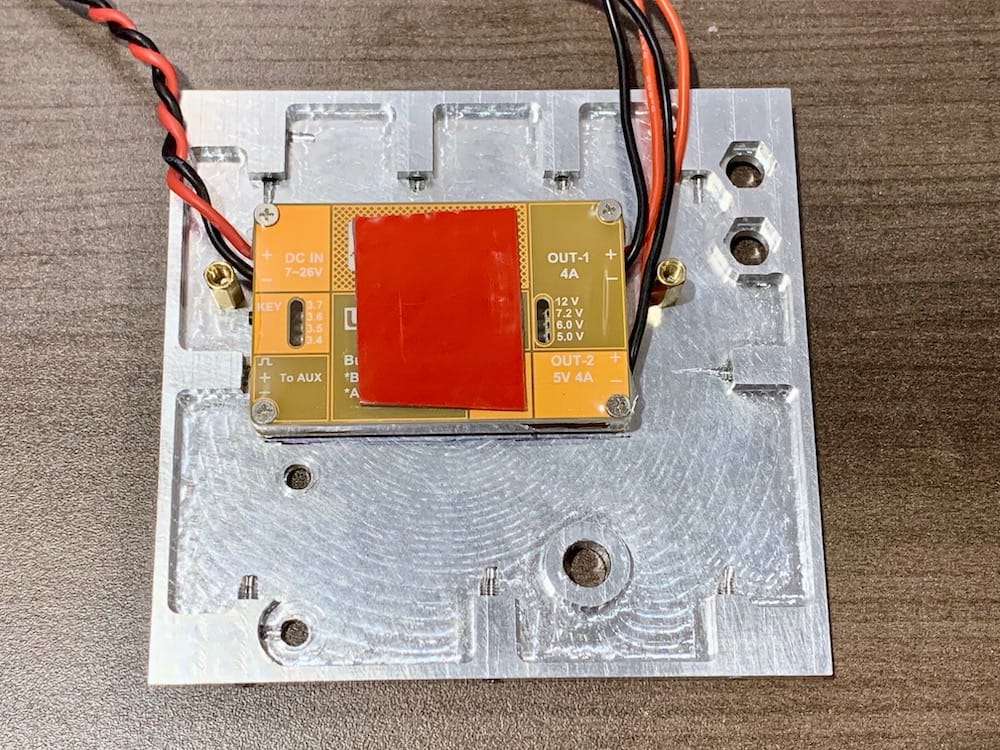

8.2. Matek Systems UBEC Duo¶

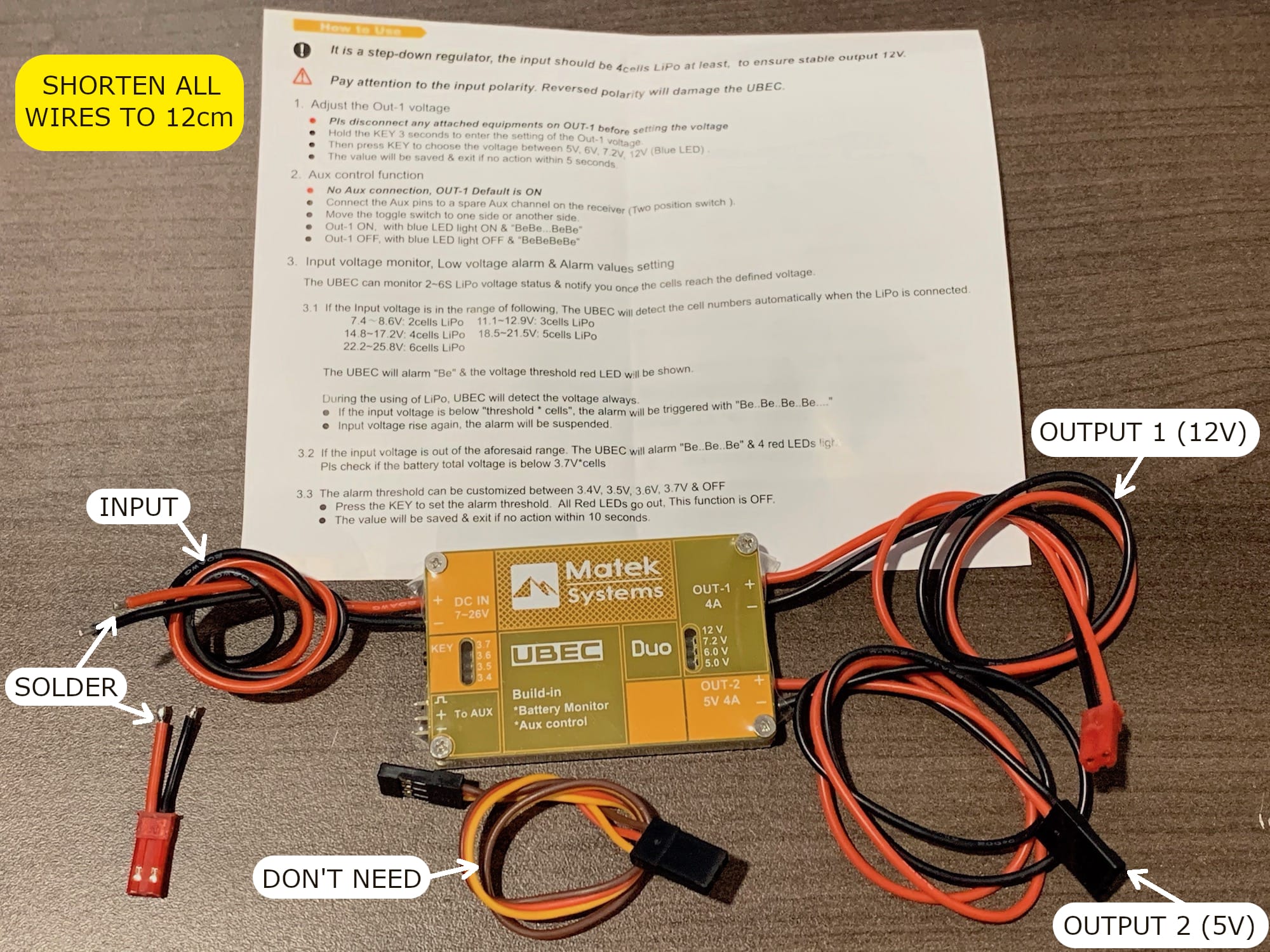

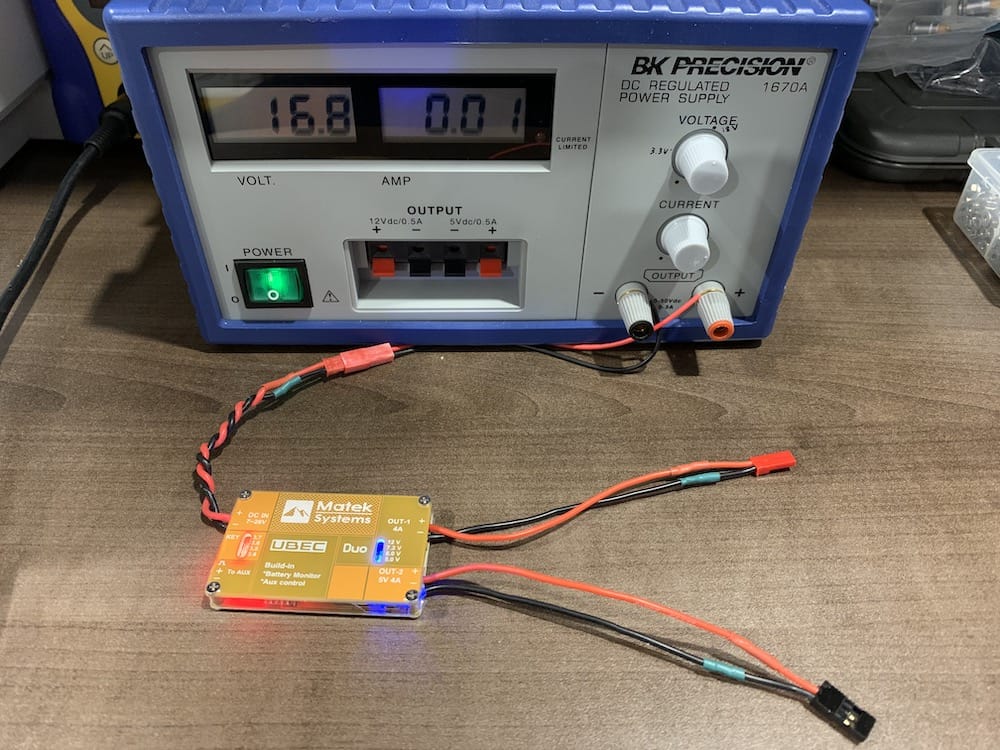

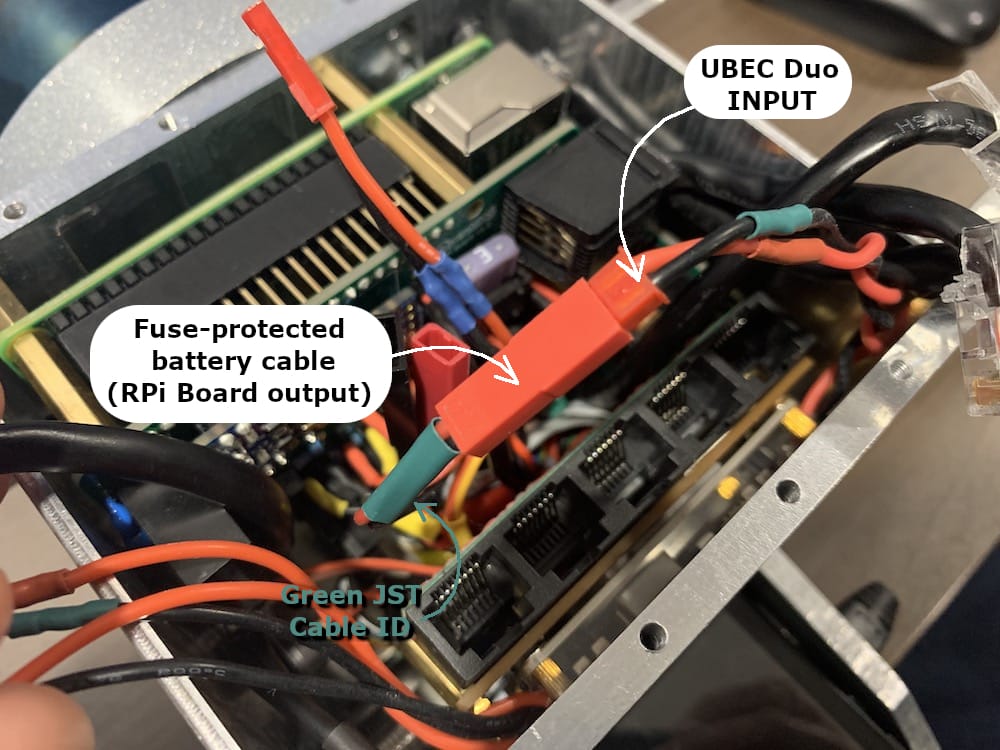

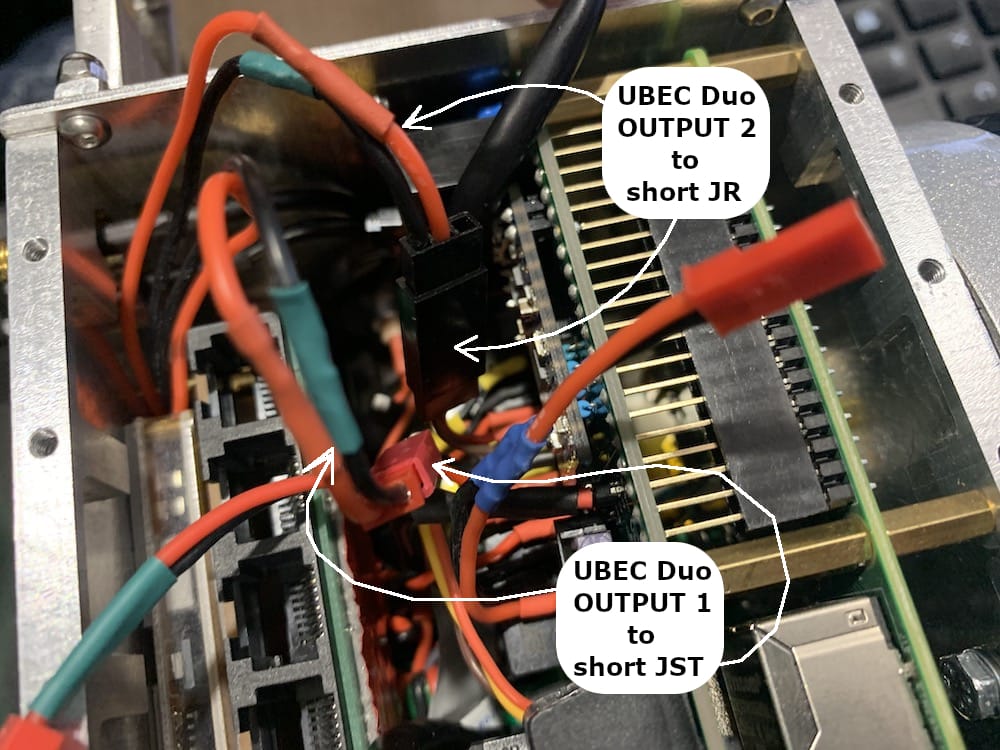

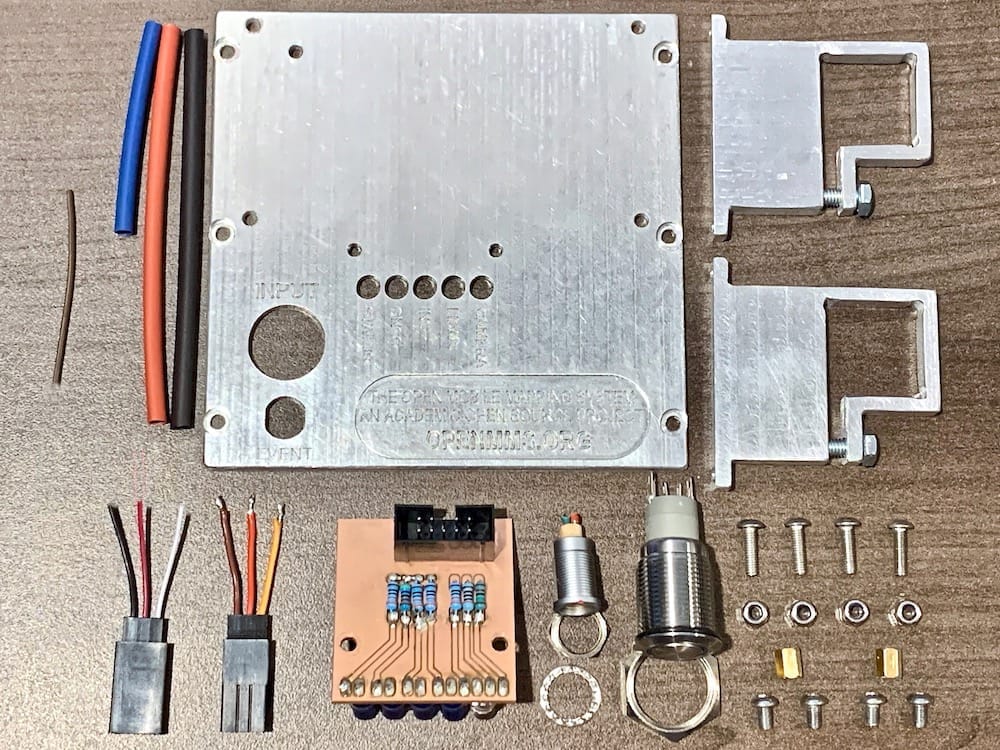

The UBEC Duo serves as the primary voltage regulator for the OpenMMS sensor. It supports unregulated input voltages between 12V (OpenMMS minimum) and 26V (i.e., 4-6S LiPo batteries). It provides two regulated output voltages, the first (OUT-1) is configurable and can to set to 5V, 6V, 7.2V, or 12V, and the second (OUT-2) is fixed at 5V. Both outputs provide a maximum current of 4A, which is more than enough for the OpenMMS sensor.

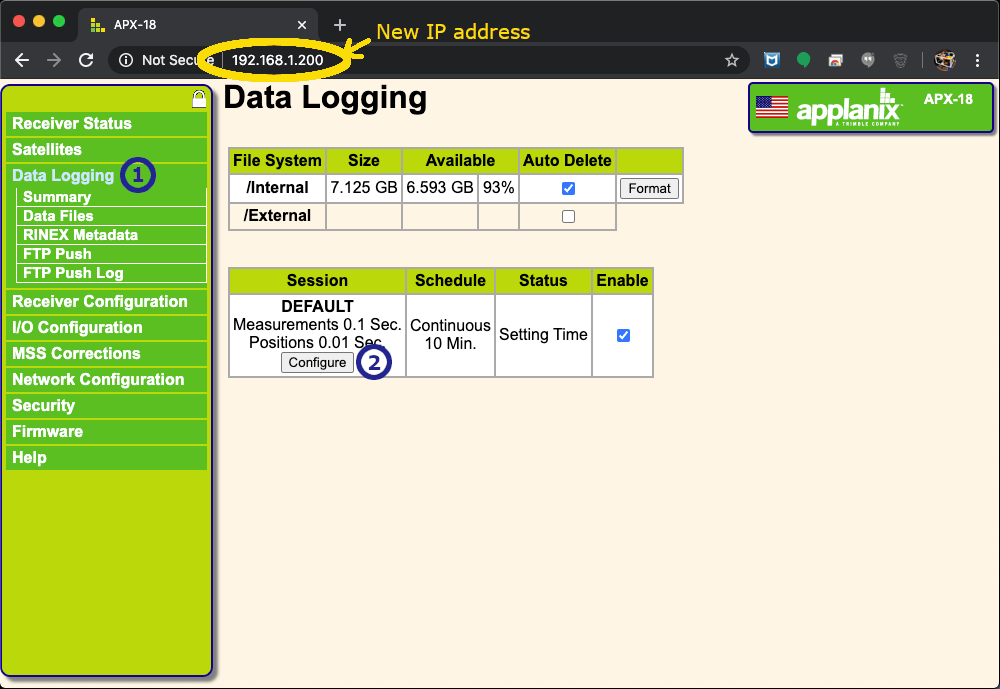

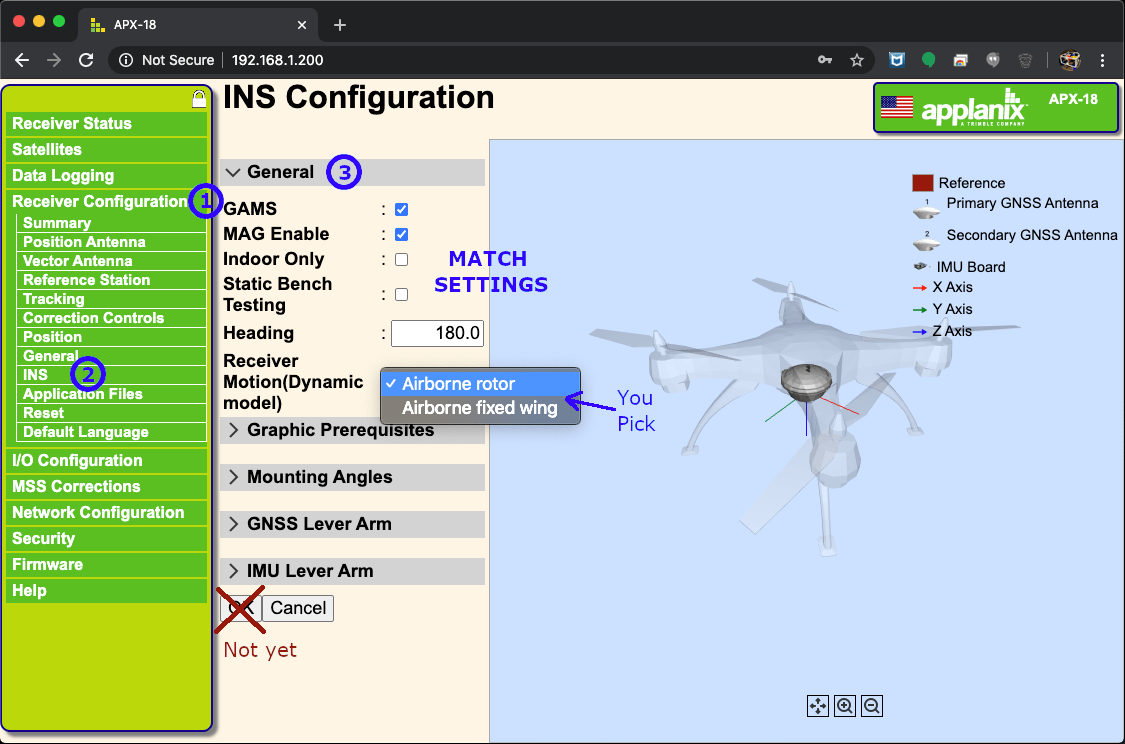

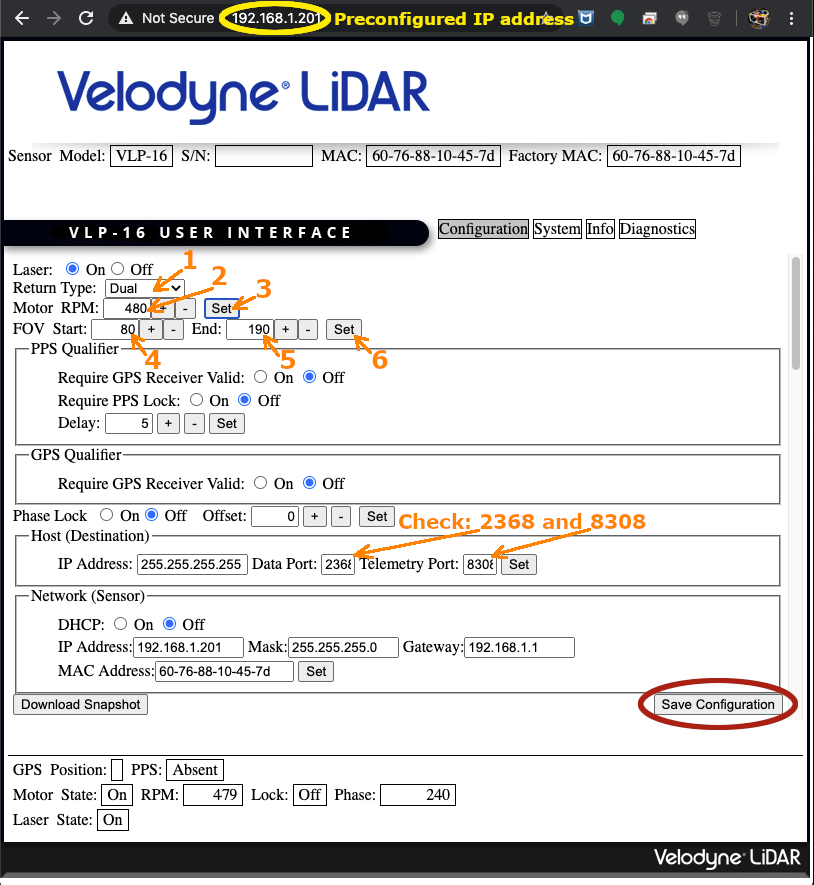

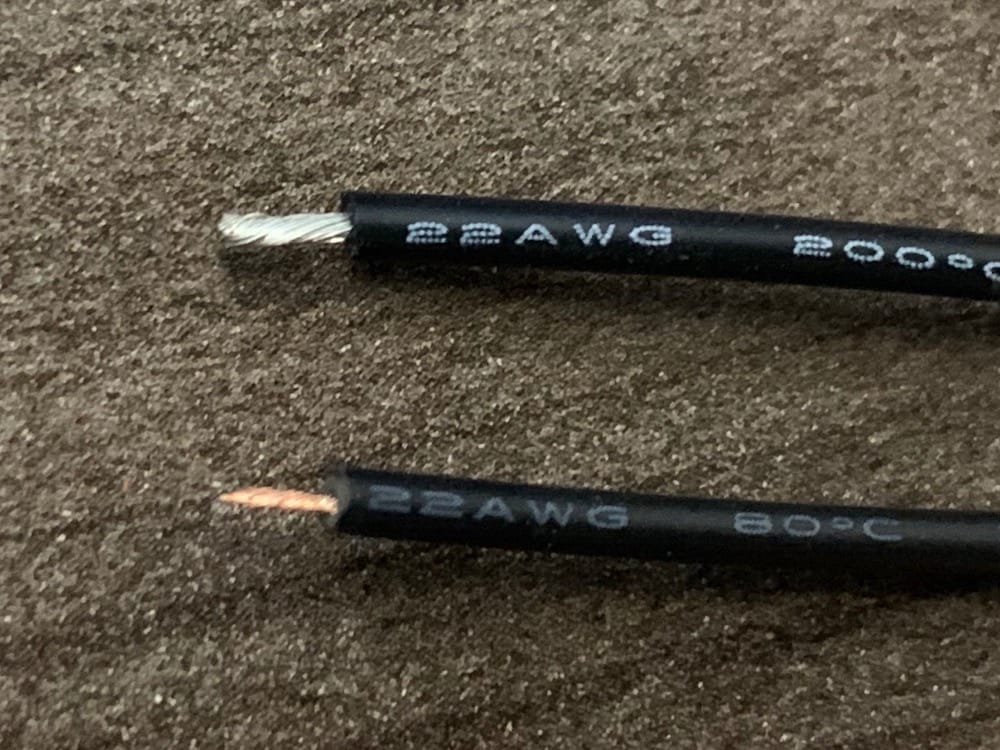

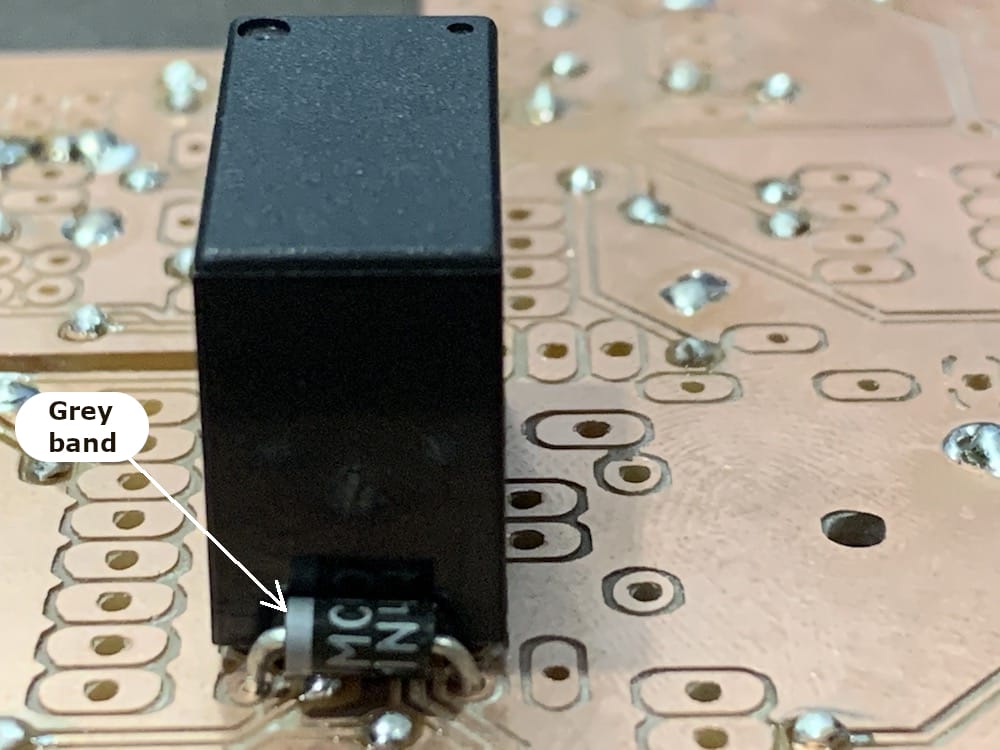

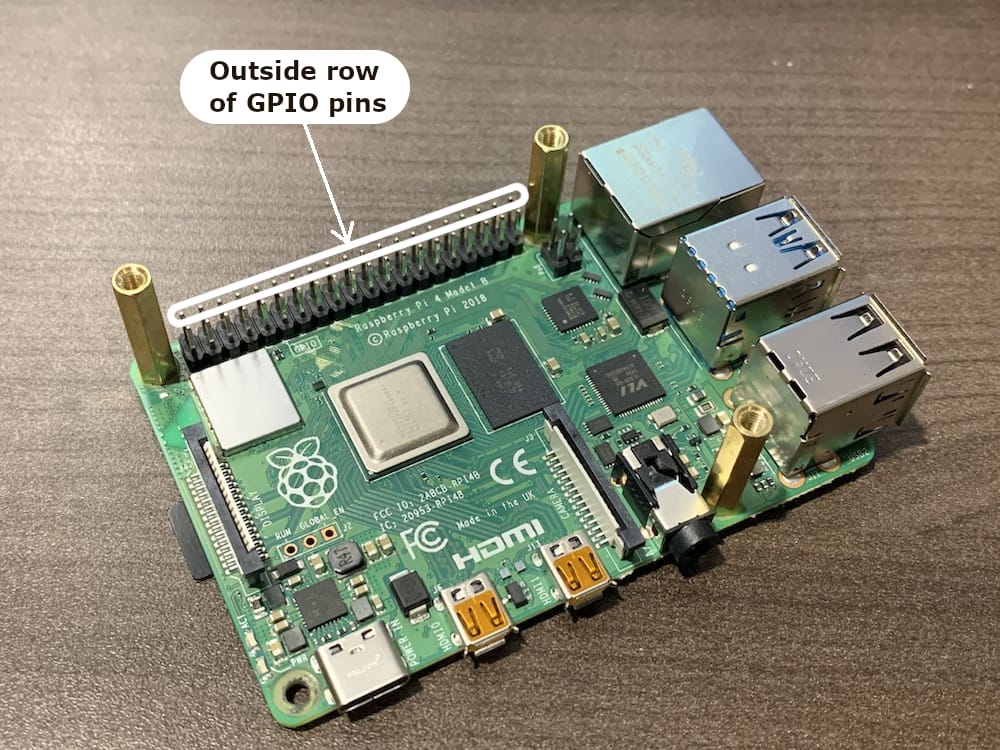

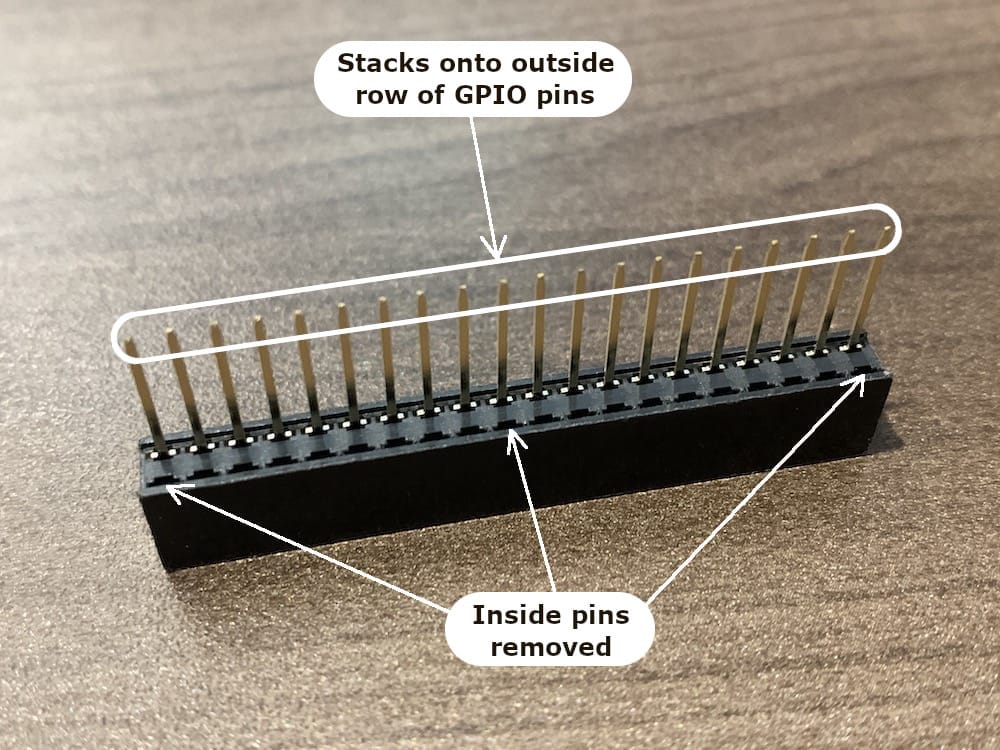

For the OpenMMS sensor, the OUT-1 voltage needs to be configured to be 12V. Optionally, the UBEC Duo’s low voltage alarm values can also be configured, which can come in very handy if powering the OpenMMS sensor using a small battery. The voltage alarm can also be turned off is desired; by default, the alarm is on.